Continuous pulp shaping machine and working method thereof

A shaping machine and pulp technology, applied in textiles and papermaking, etc., can solve the problems of inability to eliminate the striae of the pulp net, high cost, and reduced work efficiency, and achieve simple and easy working principle, high degree of automation, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

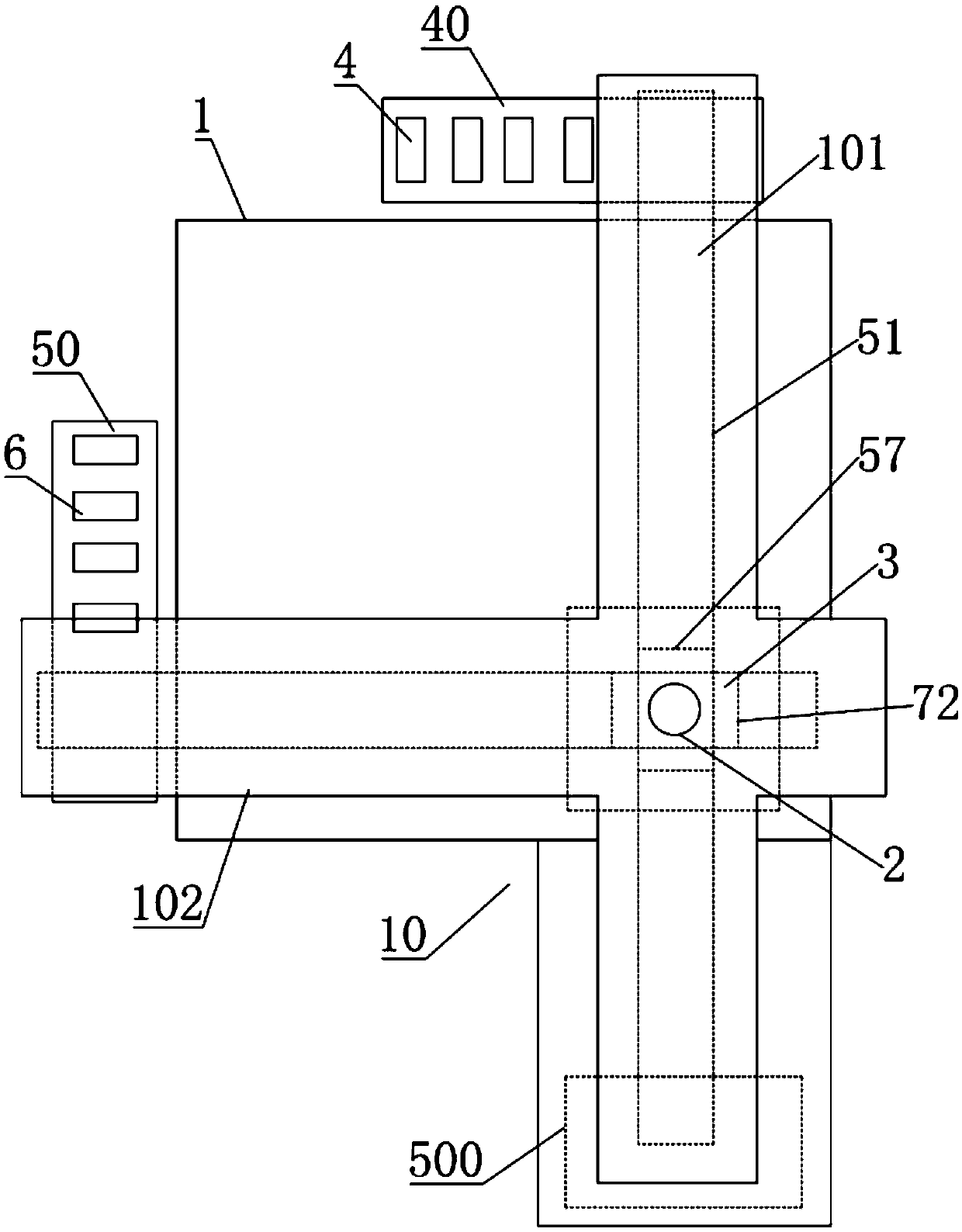

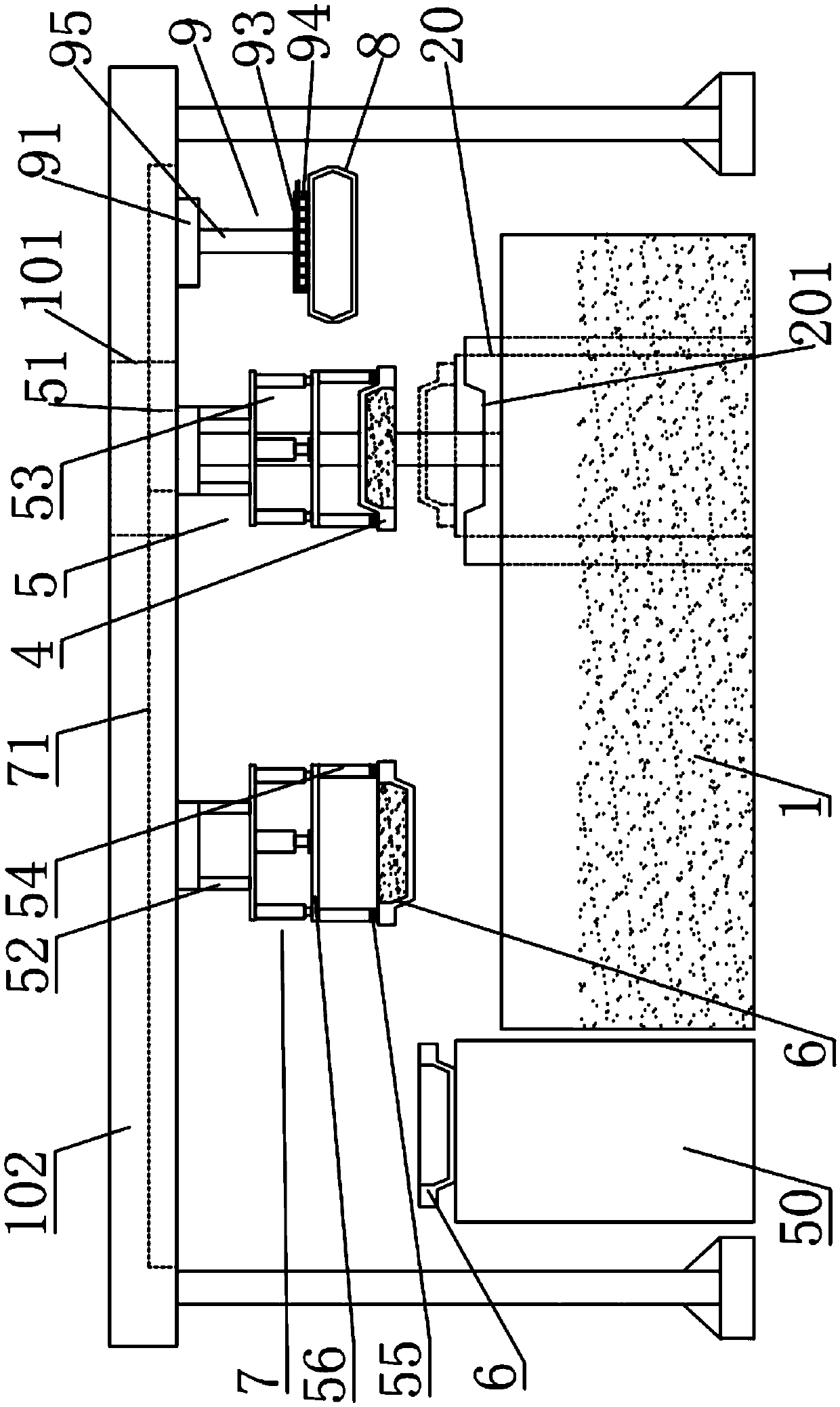

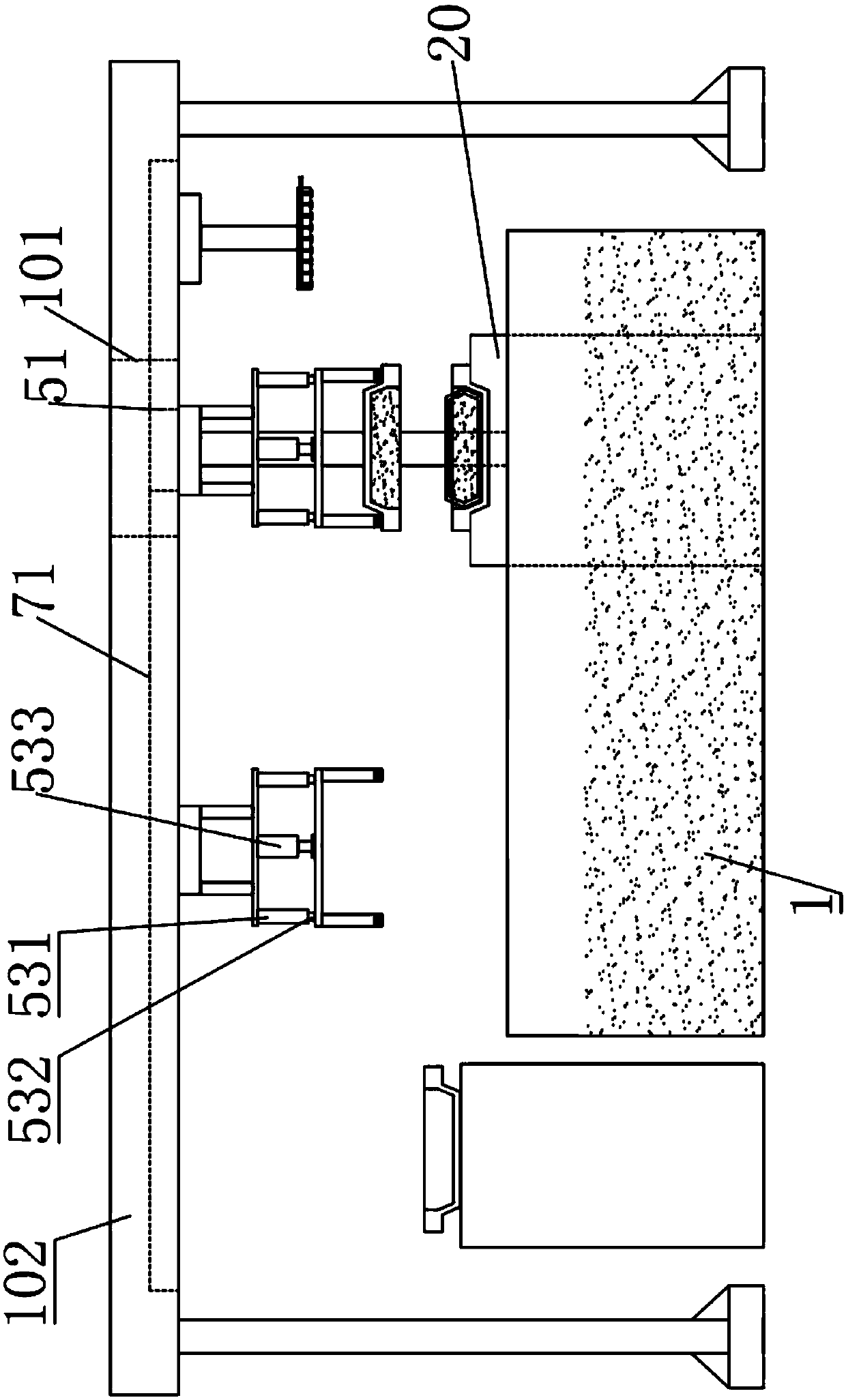

[0038] like Figure 1-9 The shown continuous pulp shaping machine includes a heat-press shaping machine table 500, a lower die base 501, a heat-pressing assembly 502, a transfer manipulator 503 and a pulp molding machine 200. The lower die base 501 and the transfer manipulator 503 are both. Set on the hot-pressing machine table 500, the transfer manipulator 503 can transport the product forming upper mold and the product forming lower mold on the pulp molding machine 200 to the lower mold base 501 and the hot-pressing assembly 502, respectively. The hot-pressing assembly 502 and the lower die base 501 hot-extrude the molded product; wherein, the hot-pressing assembly 502 includes a first sliding block 504, a third cylinder 505 and an adsorption plate 506, and the hot-pressing machine table 500 is provided with an electric heating module 507, and the electric heating module 507 is located under the lower die base 501, the first sliding block 504 is arranged on the sliding rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com