Automatic high-efficiency L-type packaging machine

A packaging machine, L-shaped technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve problems such as unreasonable structural design, lower production efficiency, production interruption, etc., achieve simple and easy working principle, improve production efficiency, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

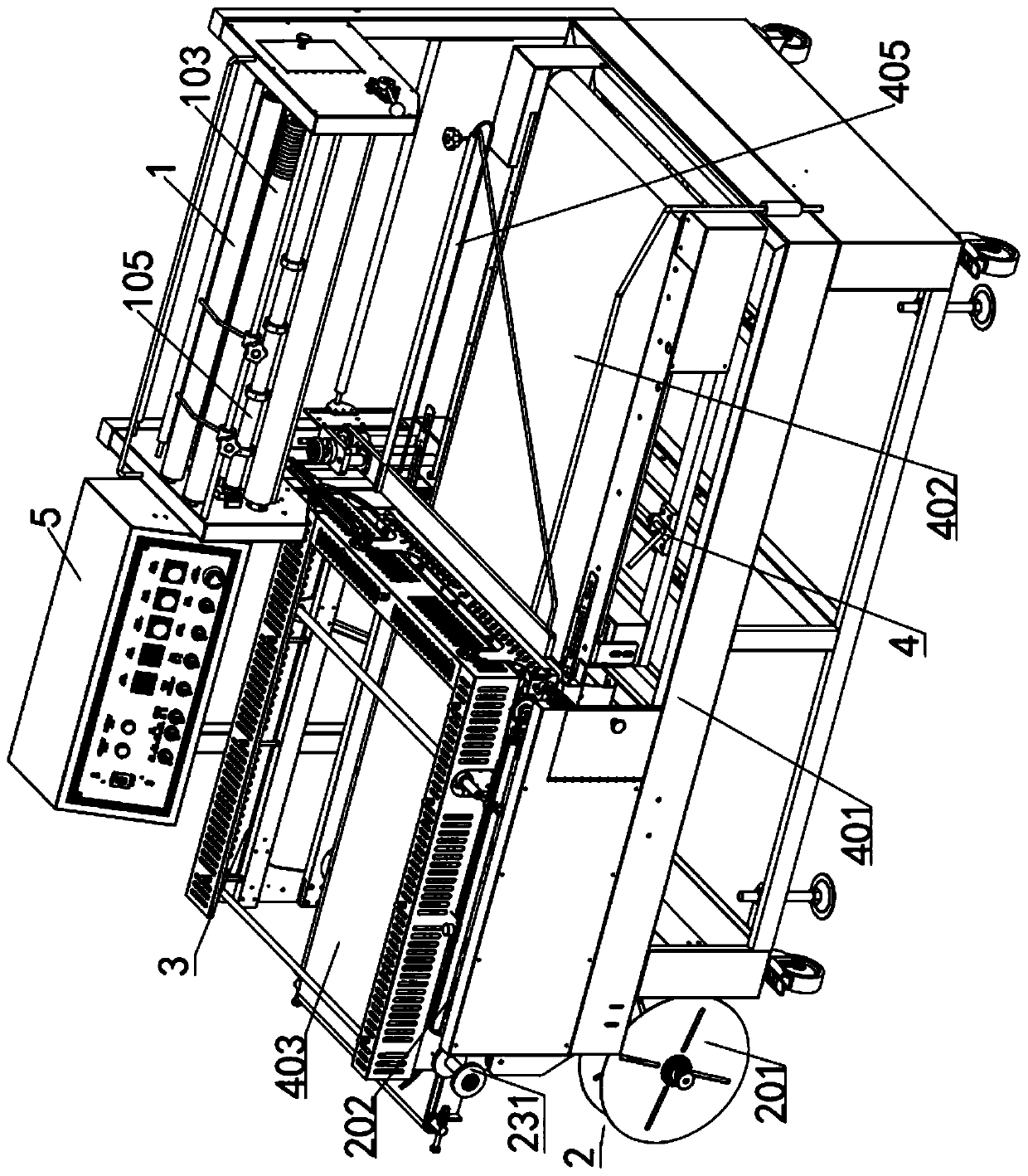

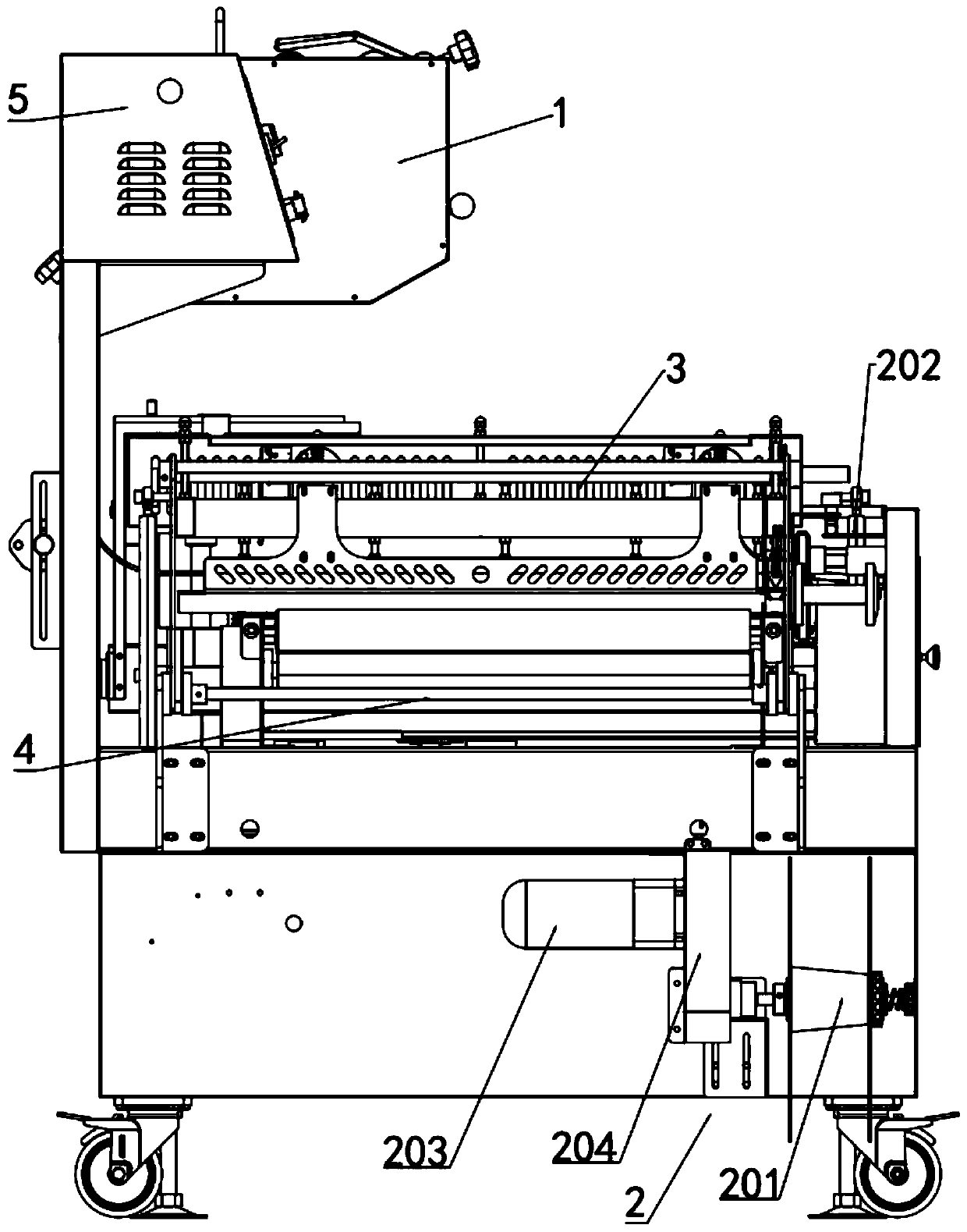

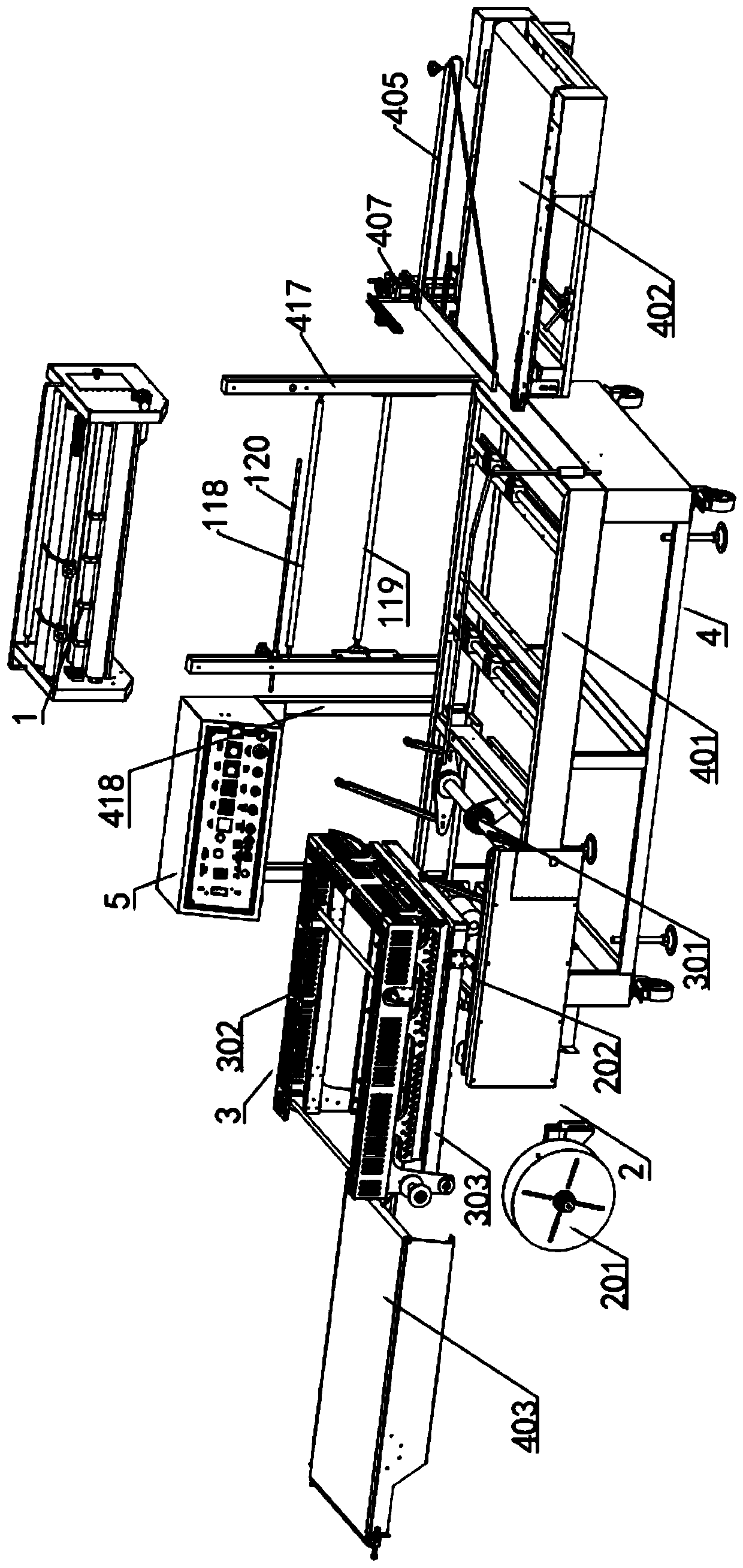

[0047] Such as Figure 1-3 The automatic and efficient L-shaped packaging machine shown includes a film assembly device 1, a residual material automatic receiving device 2, an upper and lower cutter device 3, an automatic conveying device 4, and a control panel 5. The film assembly device 1, automatic The conveying device 4, the upper and lower cutter device 3 and the residual material automatic receiving device 2 are arranged in sequence according to the production process. The control panel 5 is provided with an adjustment knob, which can set the working parameters of the L-shaped packaging machine.

[0048] Specifically, in the above structure, such as Figure 4-10 The shown film assembly device 1 includes a film left frame 101, a film right frame 102, a film roller one 103, a film roller two 104, a needle roller set 105, a needle passive roller 106, and a film feeding power Roller 107, film-feeding driven roller 108, aluminum alloy roller 109, film-setting motor 110, film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com