Door-in-door on tail part of carriage

A door-in-door and carriage technology, which is applied in the door-in-door field, can solve the problems of inability to complete the up and down movement of the hoarding, small lift arms, inconvenient loading and unloading, etc., so as to improve work efficiency and facilitate loading. And the effect of unloading and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

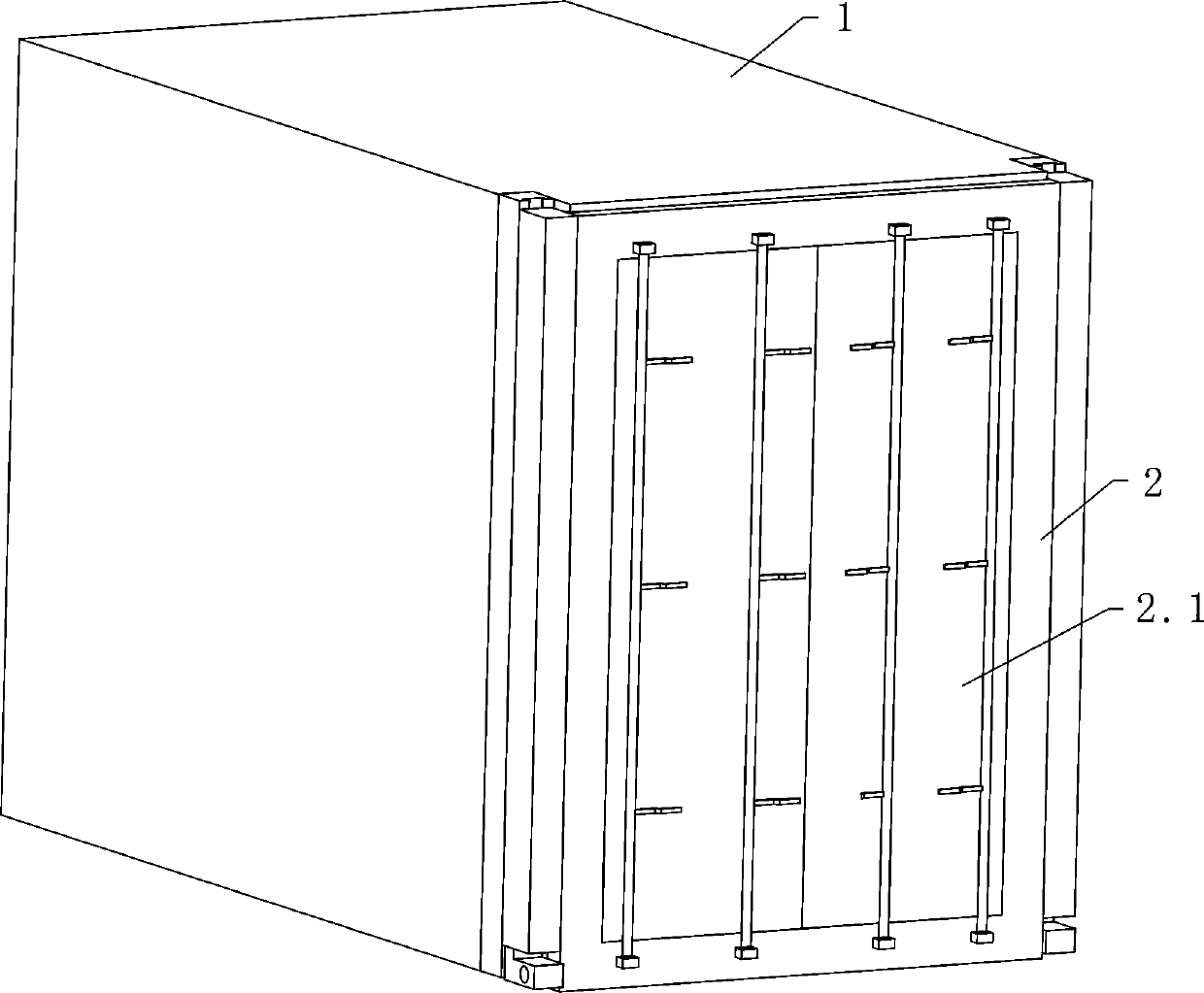

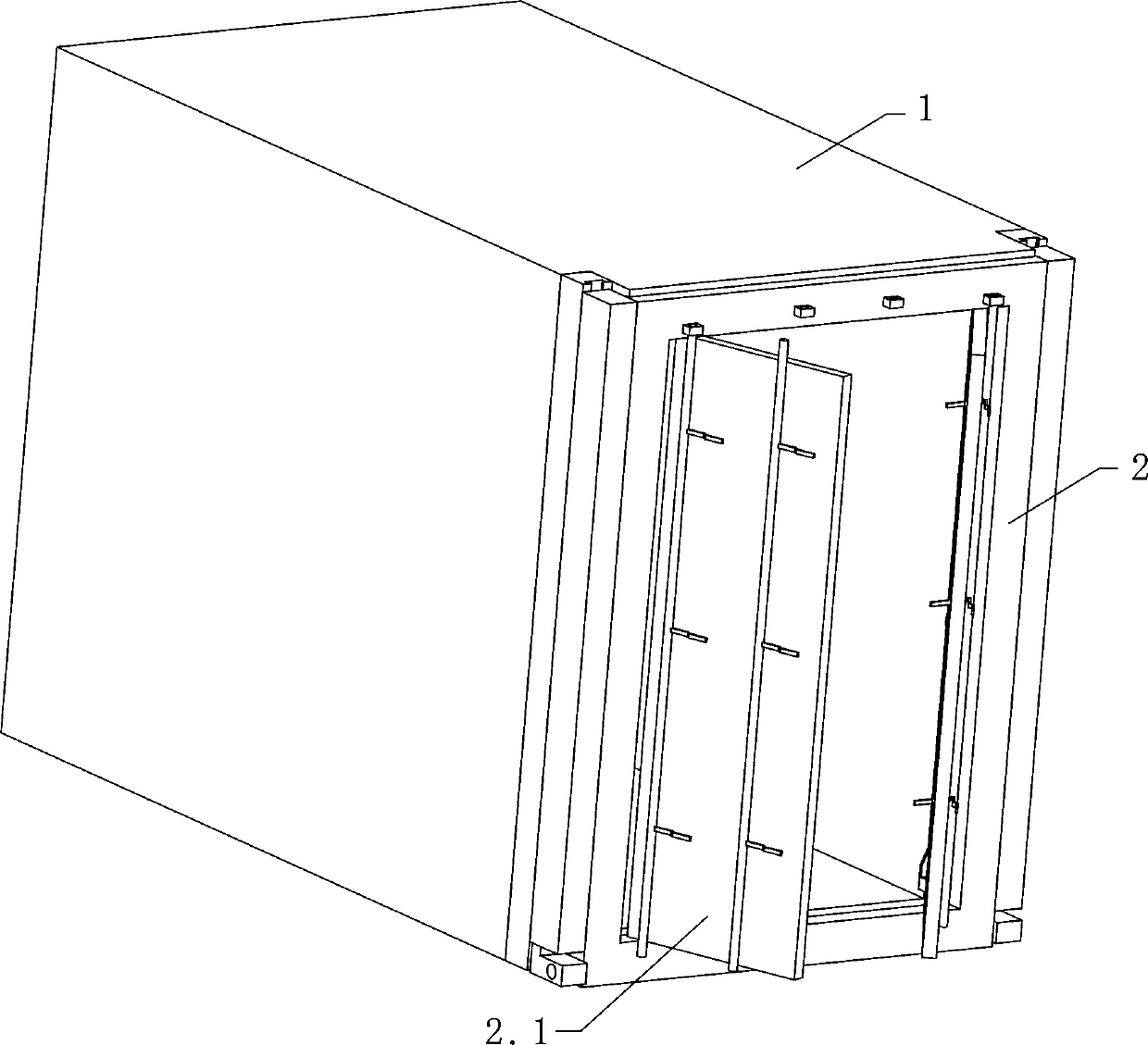

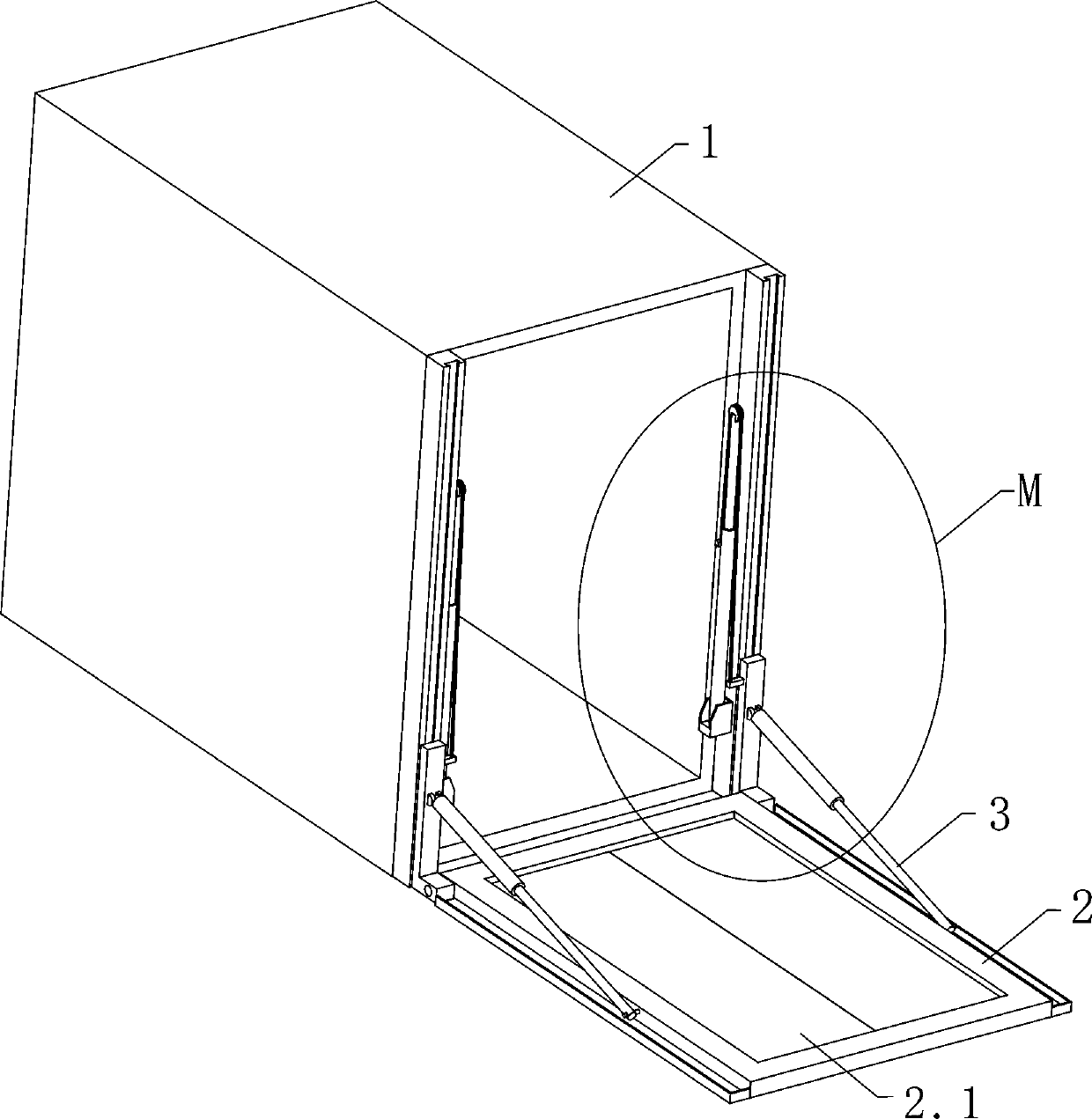

[0033] like Figure 1-Figure 7 As shown, a door-in-door at the rear of a compartment includes a door panel 2, which is installed on the door frame 8 at the rear of the compartment 1 through a slider 4, the slider is connected to the door panel through a pin shaft, and the door panel can take the rotating shaft as the axis To turn over, a vertical power device that drives the slider to move up and down on the door frame is fixedly installed on the inside of the door frame, and a turning power device that drives the door panel to turn over is provided at the front end of the slider.

[0034] In this embodiment, the door panel 2 is a rectangular frame, and an openable cargo door 2.1 is installed inside through a hinge.

[0035] In this embodiment, the vertical power device includes a jacking cylinder 5 and a pulling wire 7, the telescoping rod at the upper end of the jacking cylinder is equipped with a reversing wheel 6, and the cylinder body of the jacking cylinder is fixedly co...

Embodiment 2

[0045] like Figure 1-Figure 7 As shown, a door-in-door at the rear of a compartment includes a door panel 2, which is installed on the door frame 8 at the rear of the compartment 1 through a slider 4, the slider is connected to the door panel through a pin shaft, and the door panel can take the rotating shaft as the axis To turn over, a vertical power device that drives the slider to move up and down on the door frame is fixedly installed on the inside of the door frame, and a turning power device that drives the door panel to turn over is provided at the front end of the slider.

[0046] In this embodiment, the door panel 2 is a rectangular frame, and an openable cargo door 2.1 is installed inside through a hinge.

[0047] In this embodiment, the vertical power device includes a jacking cylinder 5 and a pulling wire 7, the telescoping rod at the upper end of the jacking cylinder is equipped with a reversing wheel 6, and the cylinder body of the jacking cylinder is fixedly co...

Embodiment 3

[0055] like Figure 8-Figure 9 As shown, the structure of this embodiment is the same as that of Embodiment 1, except that an auxiliary support cylinder 9 is provided behind the door panel. When the door panel is opened and the heavy items are moved up, it is ensured that the items can move up smoothly, and the auxiliary support The cylinder and the jacking cylinder act oppositely. The telescopic rod for lifting drives the door panel to move through the pulling wire, while the telescopic rod of the auxiliary support cylinder extends downward to push the door panel to move;

[0056] At the same time, in this embodiment, a detachable auxiliary plate is installed inside the door panel, and the auxiliary plate 10 can ensure that heavy items are placed on the door panel without the door panel being damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com