Medical orthopedic implantation bundling strap

A strapping and orthopedic technology, which is applied in the field of medical orthopedic implant strapping, can solve the problems of difficult shaping, split sternum, and open sternum, and achieve the effect of not easy to loosen or fall off, not easy to slip, and tightly meshed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

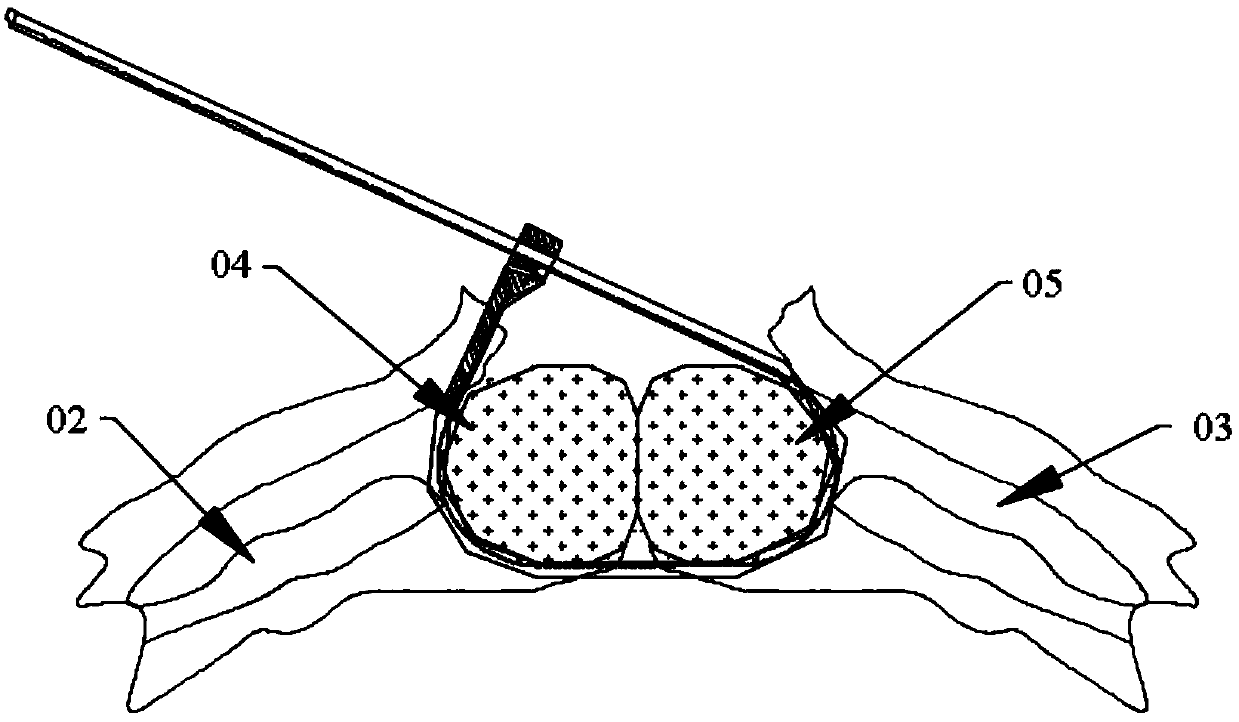

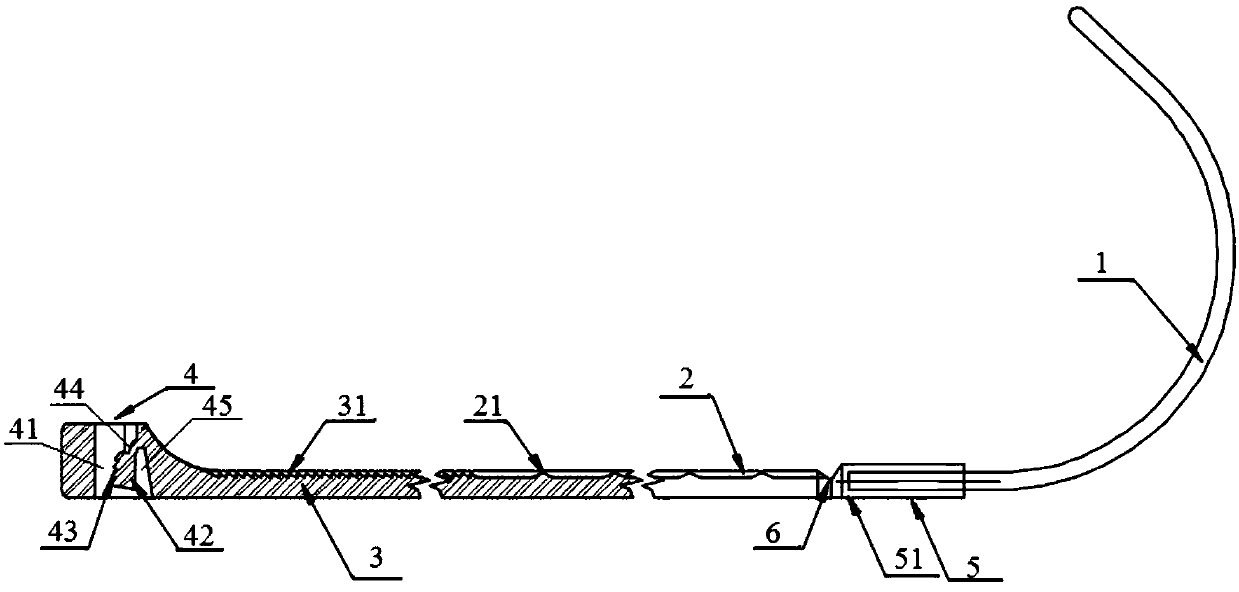

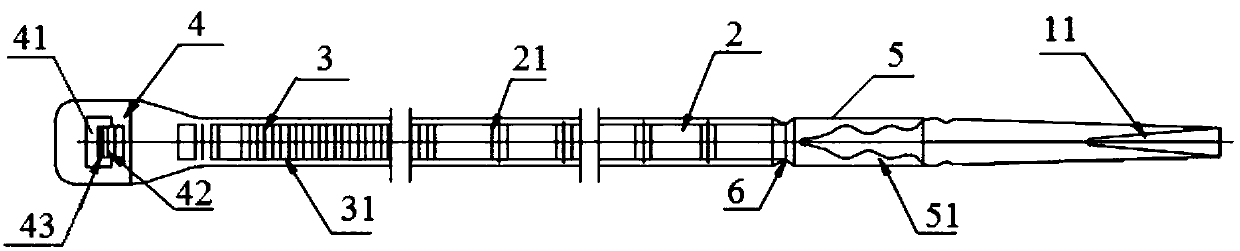

[0039] Such as Figure 1 to Figure 7 As shown, the medical orthopedic implant strap of this embodiment also includes an injection molding coating section 5, the injection molding coating section 5 includes an injection molding coating layer 51, and one end of the injection molding coating layer 51 is connected to the piercing section 2, and the piercing section 1 faces the piercing section 2. One end of the leading section 2 is covered in the injection molding coating layer 51 .

[0040]A cutting groove 6 is provided between the injection molding coating section 5 and the threading section 2 . It can be used to mark the cut-off position of the metal puncture segment, which is convenient for cutting off the puncture head at a suitable position after the puncture is completed, avoiding the damage of the puncture head to human tissues during further operations, and improving the efficiency of the operation.

[0041] refer to figure 1 The reed 42 includes a reed body and an L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com