Printed non-woven fabric and processing method and device thereof

The technology of a processing device and processing method is applied in the decoration of textiles, non-woven fabrics, textiles and papermaking, etc. It can solve the problems of increasing the production cost of printed non-woven fabrics, the pattern of printing layers is easy to fade, and the price of environmentally friendly inks is high. Stereoscopic visual effect, saving material cost and equipment cost, and shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

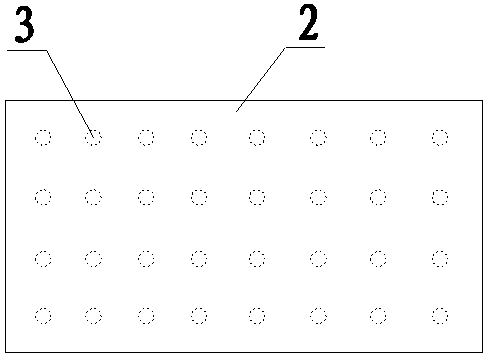

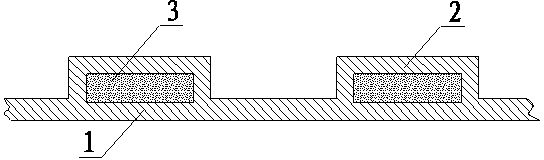

[0017] Embodiment 1: with reference to attached figure 1 , 2 . A printed non-woven fabric, comprising two layers of intertwined and fixed bottom fiber web layer 1 and upper fiber web layer 2, and a plurality of patterned sheets 3 arranged and fixed in the two fiber web layers at intervals; the pattern Adhesives may also be provided at the joints between the surface of the sheet 3 and the two fiber mesh layers.

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, take the processing of the above-mentioned nonwoven fabric as an example. A kind of processing method of printing non-woven fabric, comprises the following steps:

[0019] ① Forming the bottom fiber mesh layer 1 through a wet forming process;

[0020] ② Cut the continuously rolled sheets purchased after fully stretching and stretching to form a plurality of patterned sheets 3 with certain shapes;

[0021] ③ transporting the sheared pattern sheet 3 to the bottom fiber web layer 1 through the suction mechanism, and arranging them at intervals on the bottom fiber web layer 1;

[0022] ④ Cover the upper fiber web layer 2 formed by the wet forming process on the bottom fiber web layer 1, and the upper fiber web layer 2 wraps the patterned sheet 3 on the bottom fiber web layer 1;

[0023] ⑤Compressing the bottom fiber web layer 1, the upper layer fiber web layer 2 and the patterned sheet 3 between them by using the pressure roller...

Embodiment 3

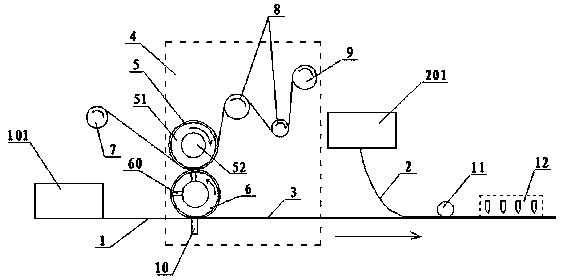

[0026] Embodiment 3: on the basis of embodiment 1, with reference to appended image 3 , 4 . A processing device for printed non-woven fabrics, comprising a molding machine A101, a molding machine B201, a conveying device 4 for a patterned sheet 3, a pressure roller mechanism 11, and a spunlace device 12; the molding machine A101 is installed in front of the molding machine B201 On the process production line; the molding machine A101 and the molding machine B201 respectively form the bottom fiber web layer 1 and the upper fiber web layer 2 through a wet molding process; the conveying device 4 of the pattern sheet 3 is installed on the molding machine A101 and the molding machine On the production line between B201; the press roller mechanism 11 and the spunlace device 12 are successively installed on the rear process production line of the molding machine B201; the conveying device 4 of the patterned sheet 3 includes an unwinding mechanism 9, which is installed and connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com