Compression molding method of antenna housing and pre-compaction mold

A technology for molding and forming molds, which is used in household appliances, other household appliances, household components, etc., can solve the problems of cracking, mechanical strength drop, protrusions and other problems at the clamping seam, so as to achieve a tight fit and improve interlayer adhesion. combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

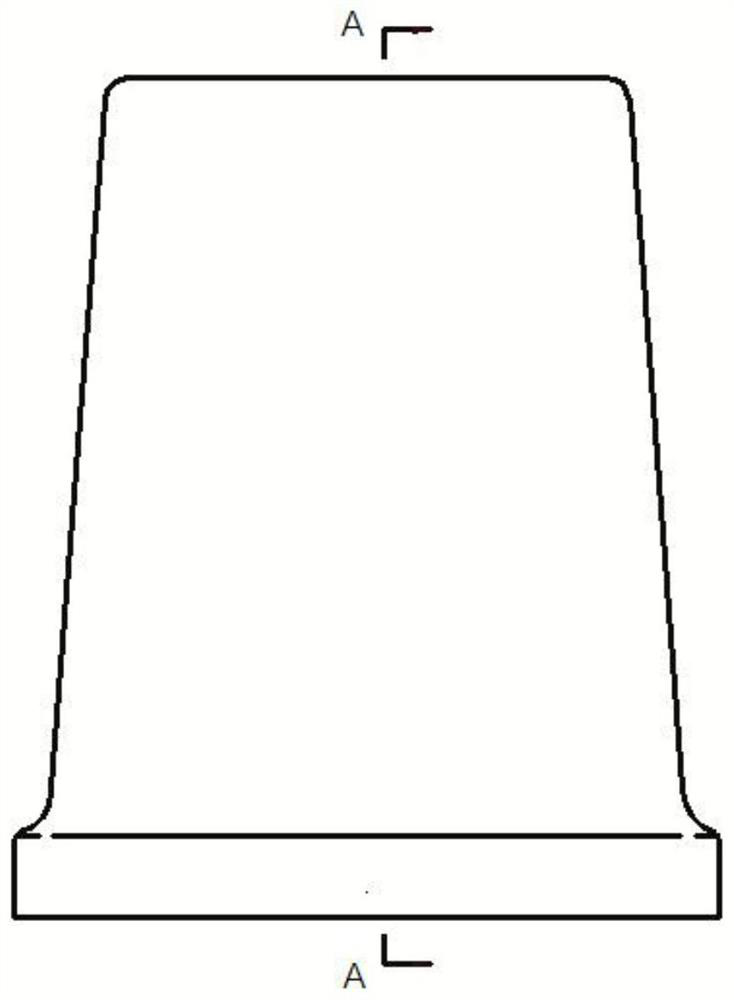

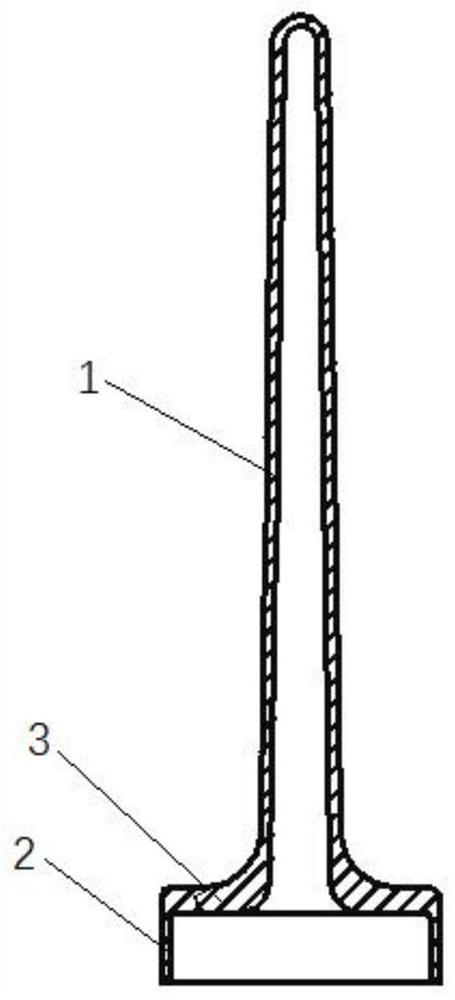

[0038] An embodiment of the present invention, such as Figure 1 to Figure 2 As shown, a compression molding method of a radome is disclosed. Specific steps include:

[0039] Step 1: Analyze the structure of the part and determine the parts that are prone to problems when the part is molded:

[0040] The part that is prone to problems during compression molding is the part with a large local thickness of the part. When laying up prepregs, lay them up as a whole first. After several layers, stop laying up parts with smaller thickness, and continue laying up parts with larger thickness. Because the thickness of each layer of prepreg is the same, the part with a larger local thickness will have more prepreg layers than other parts when the prepreg is laid, and the number of layers will make the volume of the part larger. After the stacking is completed, the size of this part is larger than the cavity size of the forming mold, causing the fibers in the thicker part to be squeez...

Embodiment 2

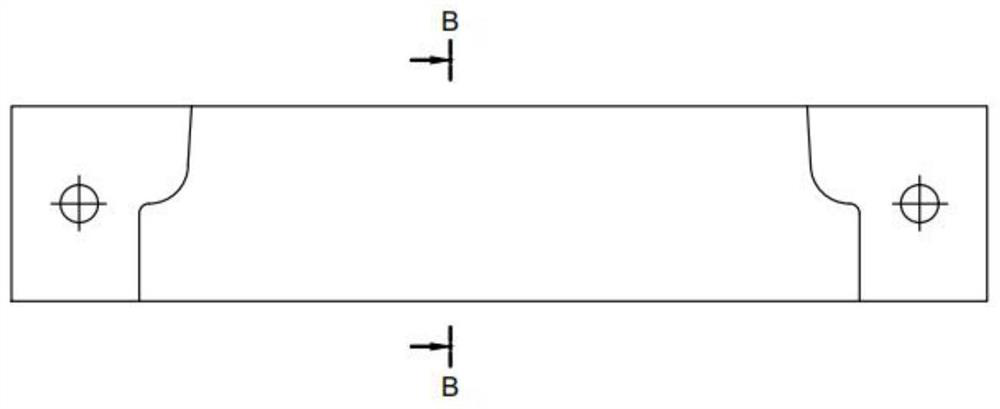

[0054] Such as image 3 , Figure 4 As shown, the embodiment of the present invention provides the pre-compacting molds in Embodiment 1, and each set of pre-compacting molds includes two counter-molds on the left and right. In this embodiment, the radome has a left-right symmetrical structure, so the left-right mold structure is symmetrical. According to the shape of the radome, the pre-compaction mold can be designed, and it can also be designed as a top-down mold or an asymmetric mold.

[0055] This embodiment includes two groups of pre-compacting molds. According to the shape of the radome, the pre-compacting mold is a cuboid with a groove. The shape of the groove corresponds to the shape of the radome. The pre-compacting mold is the female mold of the forming mold. a part of. The pre-compaction mold can also be designed into other shapes, and the overall should meet the requirements of regularity, simplicity, and convenient design and processing. The height of the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com