A kind of degradable wet wipes production process and wet wipes, packaging film for the wet wipes

A production process and packaging film technology, applied in the production process of degradable wet wipes and wet wipes, used in the packaging film field of the wet wipes, can solve the problems of non-recyclable and non-degradable polyester fibers, etc., to improve mechanical properties, Ensure the effect of heat sealing performance and barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

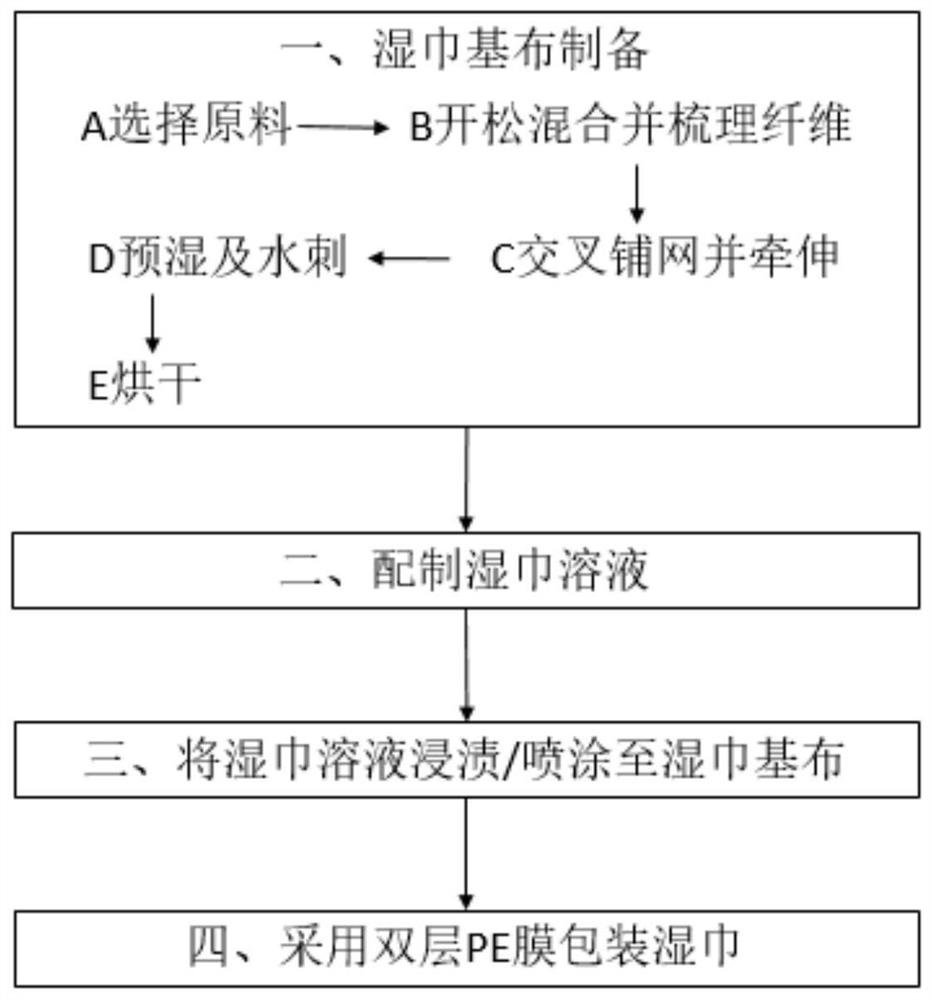

[0031] [A production process of degradable wet wipes]

[0032] The production process includes:

[0033] The first part prepares the base cloth for wet wipes, which specifically includes the following steps:

[0034] A selects raw materials, B opens, mixes and combs fibers, C cross-laps and draws, D is pre-wetted and spunlaced, and E is dried; among them,

[0035] The selected raw materials in the step A are: screening wood pulp wt 50%, 8-10mm polylactic acid staple fiber wt 15% with a fineness of 1.5 dtex, and 8-10mm lyocell staple fiber wt 15 with a fineness of 2.0 dtex % and 9mm fineness of 1.67 dtex viscose staple fiber wt20% as the raw material of non-woven fabric;

[0036] The step B of opening, mixing and carding the fibers is as follows: polylactic acid staple fibers, lyocell staple fibers and viscose staple fibers are respectively opened by separate rough opening and fine opening equipment, and carded by a carding machine, Among them, the cylinder of the carding ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com