Application of activating mono-persulfate based on copper ferrite nano-powder

A technology of persulfate and copper ferrite, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor reuse effect, high cost of activator, and secondary pollution. and other problems, to achieve the effect of good magnetic separation effect, easy recovery and regeneration, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for activating monopersulfate to degrade persistent organic pollution based on nano-copper ferrite is completed in the following steps: 1. The preparation method of nano-copper ferrite:

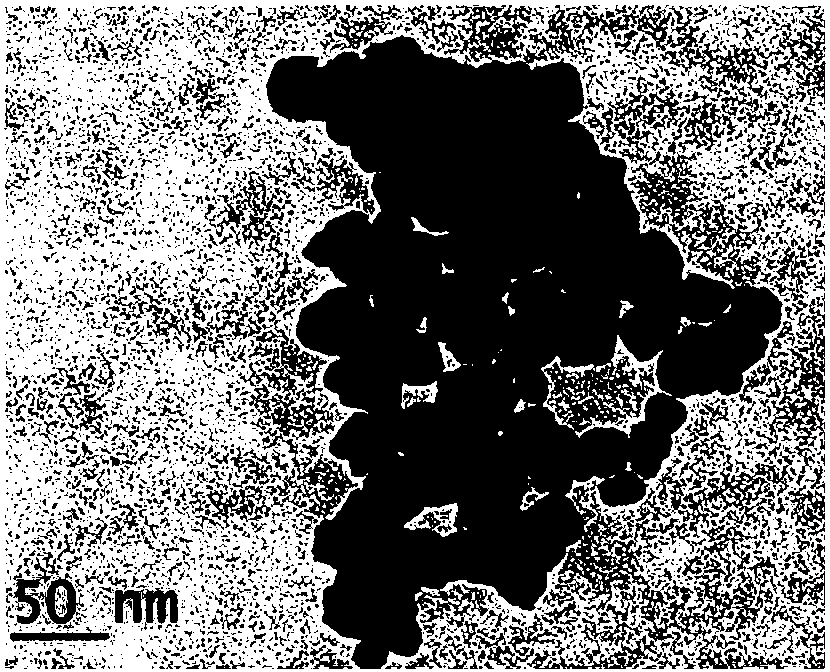

[0031] Weigh 6.04 grams of Cu(NO 3 ) 2 ·3H 2 O and 20.2 g Fe(NO 3 ) 3 9H 2 Dissolve O together in 100mL deionized water, Cu(NO 3 ) 2 ·3H 2 O and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 1:2, stir evenly, then add 75mL4.0mol / L sodium hydroxide solution dropwise, stir evenly, reflux and stir for 2h under the condition of 90℃ water bath; cool to room temperature and centrifuge to obtain solid precipitate, use deionized Wash with water for several times until the pH value is constant, then vacuum-dry at 70°C to obtain a dark brown solid, transfer the solid to a crucible, place it in a muffle furnace and bake it at 600°C for 2 hours, the heating rate of the muffle furnace is 1-1.2°C / min; cool the roasted dark brown solid to room temperature, grind the solid thoroughly an...

Embodiment 2

[0058] The difference between the present embodiment and embodiment 1 is that the amount of sodium peroxymonosulfate added in step 3 is different. Other steps are identical with embodiment 1.

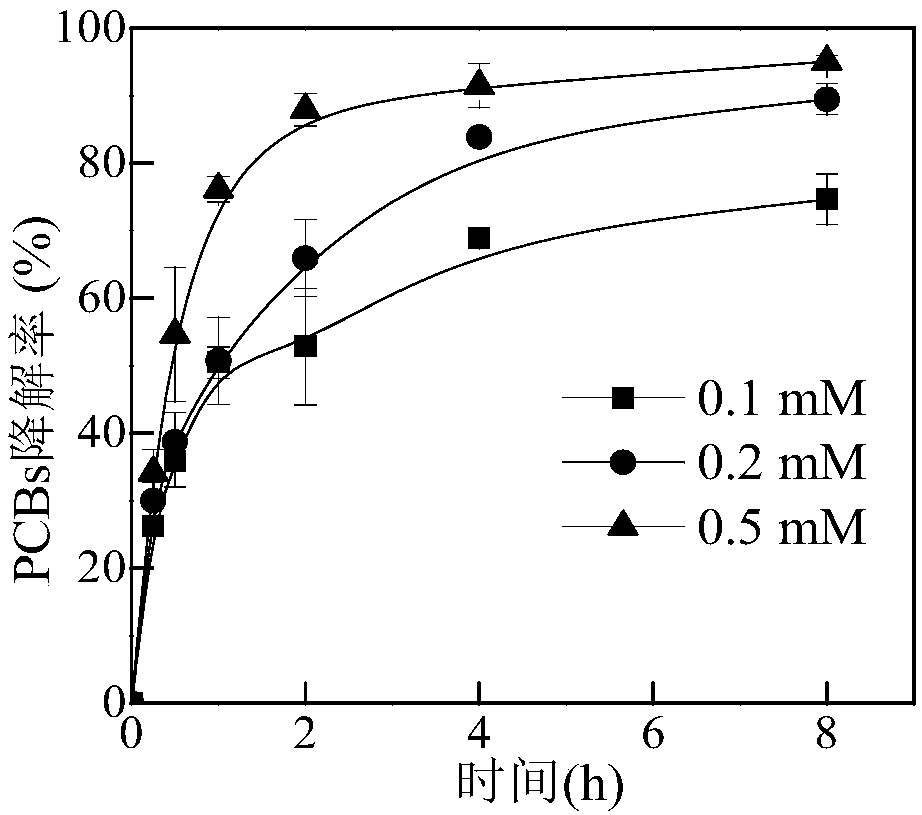

[0059] Specifically, in the heterogeneous activation reaction using nano-copper ferrite to activate monopersulfate, a glass bottle with a polytetrafluoroethylene stopper is used as the reaction vessel, the reaction solution is 20 mL, and the initial concentration of nano-copper ferrite is 0.1 g / L, the concentration of PCBs is 0.5mg / L, and the content of sodium peroxymonosulfate is 0.1-0.5mmol / L. The reaction bottle is placed in a vibrating bed with a rotation speed of 150rpm and a temperature of 25°C. The processing time is 8h, and the processing results are shown in figure 2 . With the increase of the amount of sodium persulfate, the degradation rate of PCBs also increases, increasing the amount of oxidant can effectively increase the degradation rate of PCBs, such as when the amoun...

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is that the amount of the activator nano-copper ferrite in step 2 is different. Other steps are identical with embodiment 1.

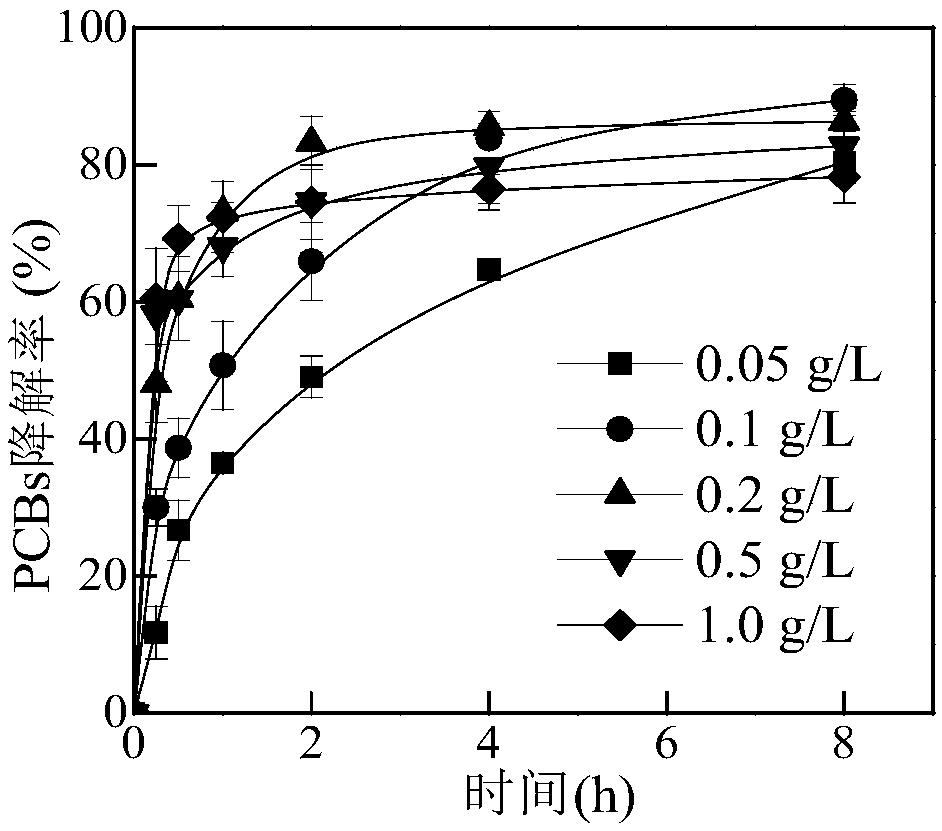

[0062] Specifically, in the heterogeneous activation reaction using nano-copper ferrite to activate monopersulfate, a glass bottle with a polytetrafluoroethylene stopper is used as the reaction vessel, the reaction solution is 20 mL, and the initial concentration of sodium peroxymonosulfate is 0.2mmol / L, the concentration of PCBs is 0.5mg / L, and the content of nano-copper ferrite is 0.05-1.0g / L. The reaction bottle is placed in a vibrating bed with a rotation speed of 150rpm and a temperature of 25°C. The processing time is 8h, and the processing results are shown in image 3 . With the increase of the amount of activator nano-copper ferrite, the degradation rate of PCBs showed a trend of increasing and then decreasing. When the concentration of nano-copper ferrite increased from 0.05g / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com