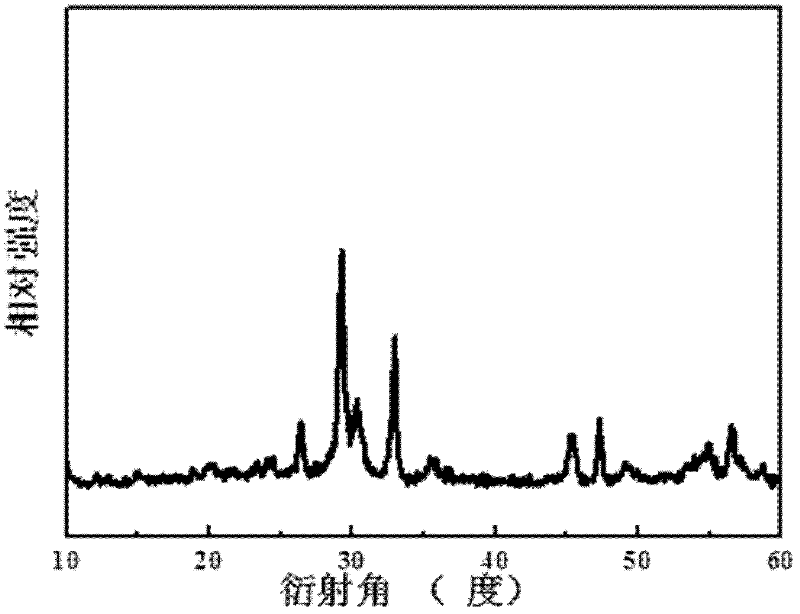

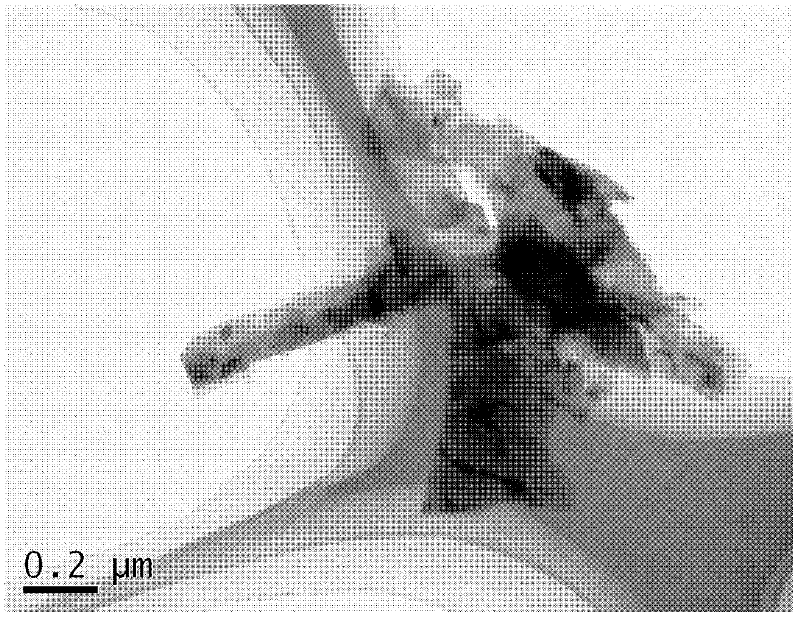

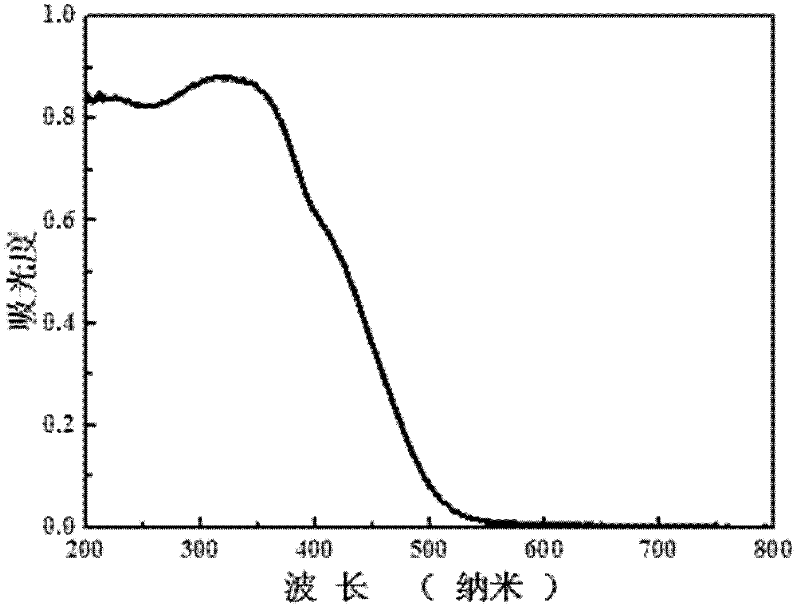

Visible light photocatalyst Bi12O17Cl2 and preparation method thereof

A bi12o17cl2, 2.bi12o17cl2 technology, applied in the field of visible light photocatalyst Bi12O17Cl2 and its preparation, can solve problems such as insufficient toxic organic pollutants, and achieve the effects of small industrial amplification factor, good visible light catalytic activity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Bi 12 o 17 Cl 2 Visible light catalyst preparation, the preparation steps are as follows:

[0026] Step 1: Add bismuth nitrate pentahydrate and potassium chloride into a 25 ml reaction kettle, add 15 ml distilled water to form a mixed solution, wherein the amount of bismuth nitrate pentahydrate is 0.05-0.1 mol / liter, and the amount of potassium chloride 0.05-0.1 mol / liter, the molar ratio of bismuth nitrate pentahydrate and potassium chloride is equal to 1;

[0027] Step 2: Stir the mixed solution in step 1 at room temperature for 10 minutes, then adjust the pH value of the solution to 12.5 to 13 with 1 mol / L sodium hydroxide solution, stir for 10 minutes, and then carry out hydrothermal treatment to the mixed solution at a temperature of 160 ~180℃, constant temperature for 12~24 hours;

[0028] Step 3: After step 2 is completed, filter and rinse the solid product obtained by filtration with distilled water and ethanol three times respectively, and then dry the prod...

Embodiment 2

[0030] Bi 12 o 17 Cl 2 Visible light catalyst preparation, the preparation steps are as follows:

[0031] Step 1: Add bismuth nitrate pentahydrate and potassium chloride in a 25 ml reaction kettle, add 15 milliliters of distilled water, and make a mixed solution, wherein the amount of bismuth nitrate pentahydrate is 0.05 mol / liter, and the amount of potassium chloride is 0.05 Mole / liter, the molar ratio of bismuth nitrate pentahydrate and potassium chloride is equal to 1;

[0032] Step 2: Stir the mixed solution in step 1 at room temperature for 10 minutes, then adjust the pH value of the solution to 12.6 with 1 mol / liter of sodium hydroxide, stir for 10 minutes, and then carry out hydrothermal treatment to the mixed solution at a temperature of 160°C. Constant temperature for 12 hours;

[0033]Step 3: After step 2 is completed, filter and rinse the solid product obtained by filtration with distilled water and ethanol several times, and dry the product at 50°C for 8 hours ...

Embodiment 3

[0035] Efficient Bi 12 o 17 Cl 2 Visible light catalyst preparation, the preparation steps are:

[0036] Step 1: Add bismuth nitrate pentahydrate and potassium chloride in a 25 ml reaction kettle, add 15 milliliters of distilled water, and make a mixed solution, wherein the amount of bismuth nitrate pentahydrate is 0.1 mol / liter, and the amount of potassium chloride is 0.1 Mole / liter, the molar ratio of bismuth nitrate pentahydrate and potassium chloride is equal to 1;

[0037] Step 2: Stir the mixed solution in step 1 at room temperature for 10 minutes, then adjust the pH value of the solution to 12.7 with 1 mol / liter of sodium hydroxide, stir for 10 minutes, and then carry out hydrothermal treatment to the mixed solution at a treatment temperature of 160°C. Constant temperature for 24 hours;

[0038] Step 3: After step 2 is completed, filter and rinse the solid product obtained by filtration with distilled water and ethanol three times respectively, and dry the product a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com