Benzimidazolone H3G/TiO2 compound photo-catalyst with visible light response function and preparation method thereof

A benzimidazolone yellow and catalyst technology, which is applied in the field of photocatalytic material preparation, can solve the problems of sensitized catalyst stability and repeated use performance limitations, and achieves good visible light catalytic activity, high chemical and physical stability, and high production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Composite Photocatalyst Benzimidazolone Yellow H3G / TiO 2 The common hydrothermal method is used for the preparation: in a glass container, add N,N-dimethylformamide 35g, benzimidazolone yellow H3G 0.8g, TiO 2 4g, Span 80 0.05g, stirred at room temperature for 30min. This mixture was added into a closed autoclave with a polytetrafluoroethylene liner, and loaded by adsorption at 195°C for 4h. After the reaction was completed, it was cooled to room temperature and centrifuged to obtain a light yellow solid, which was washed with ethanol and water respectively, and dried by filtration. The obtained light yellow solid was placed in a vacuum drying oven and dried at 100°C for 0.5h to obtain benzimidazolone yellow H3G / TiO 2 Composite photocatalytic materials. Abbreviated as BYH3G / TiO 2 .

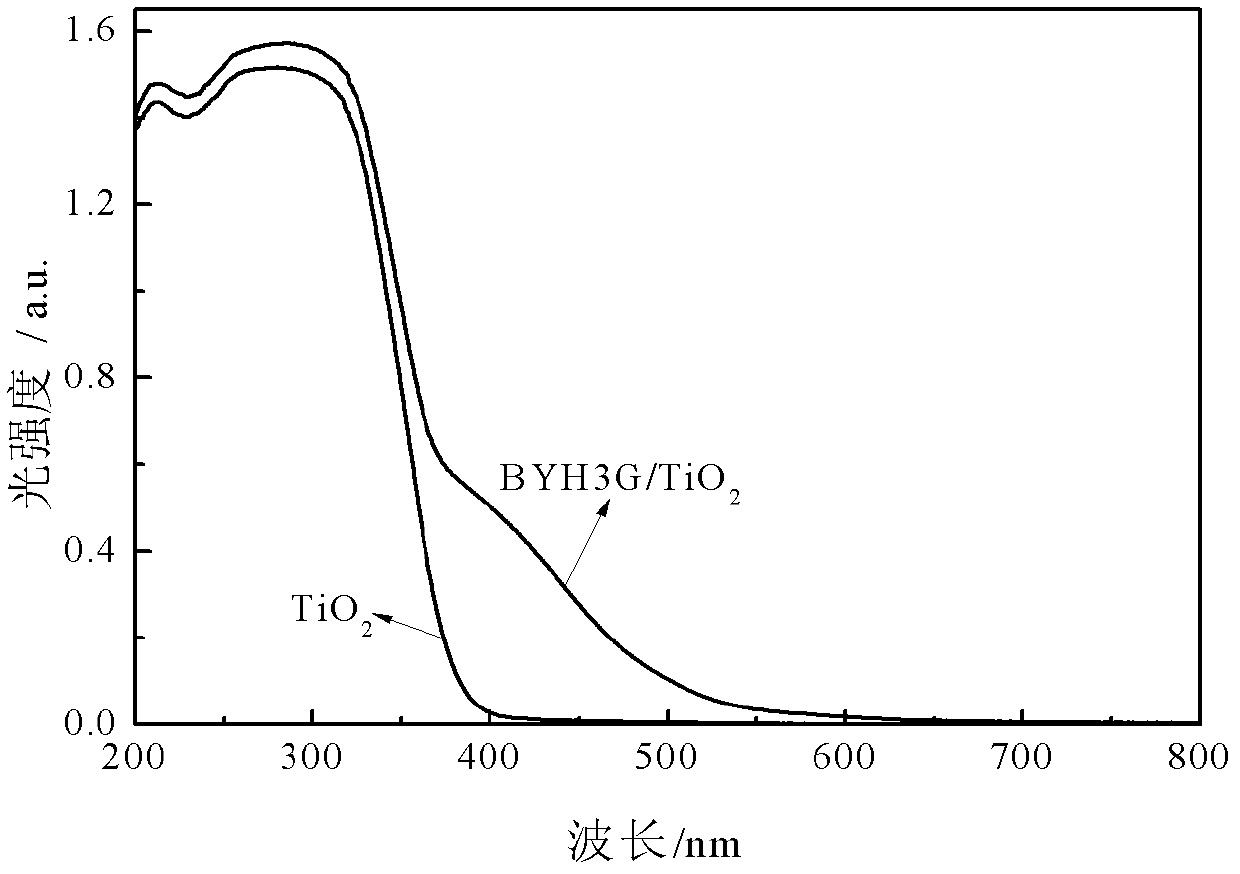

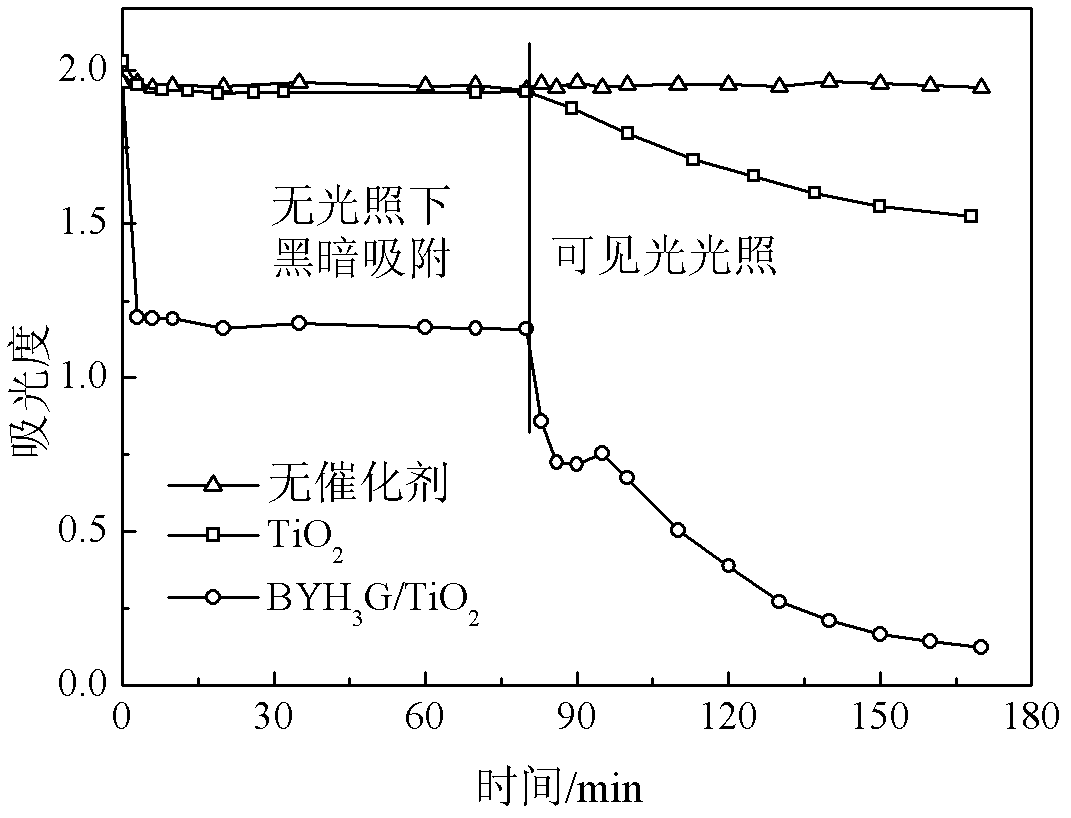

[0029] figure 1 It is the composite photocatalytic material BYH3G / TiO of the present invention 2 with pure TiO 2 The UV-Vis diffuse reflectance spectrum comparison chart, the result...

Embodiment 2

[0033] Benzimidazolone Yellow H3G / TiO 2 Preparation: In a glass container, add N,N-dimethylformamide 24g, benzimidazolone yellow H3G 0.2g, TiO 2 4g, Span 80 0.08g, stirred at room temperature for 30min. This mixture was added into a closed autoclave with a polytetrafluoroethylene liner, and loaded by adsorption at 180°C for 6h. After the reaction was completed, it was cooled to room temperature and centrifuged to obtain a light yellow solid, which was washed with ethanol and water respectively, and dried by filtration. The obtained light yellow solid was placed in a vacuum drying oven and dried at 100°C for 0.5h to obtain benzimidazolone yellow H3G / TiO 2 Composite photocatalytic materials.

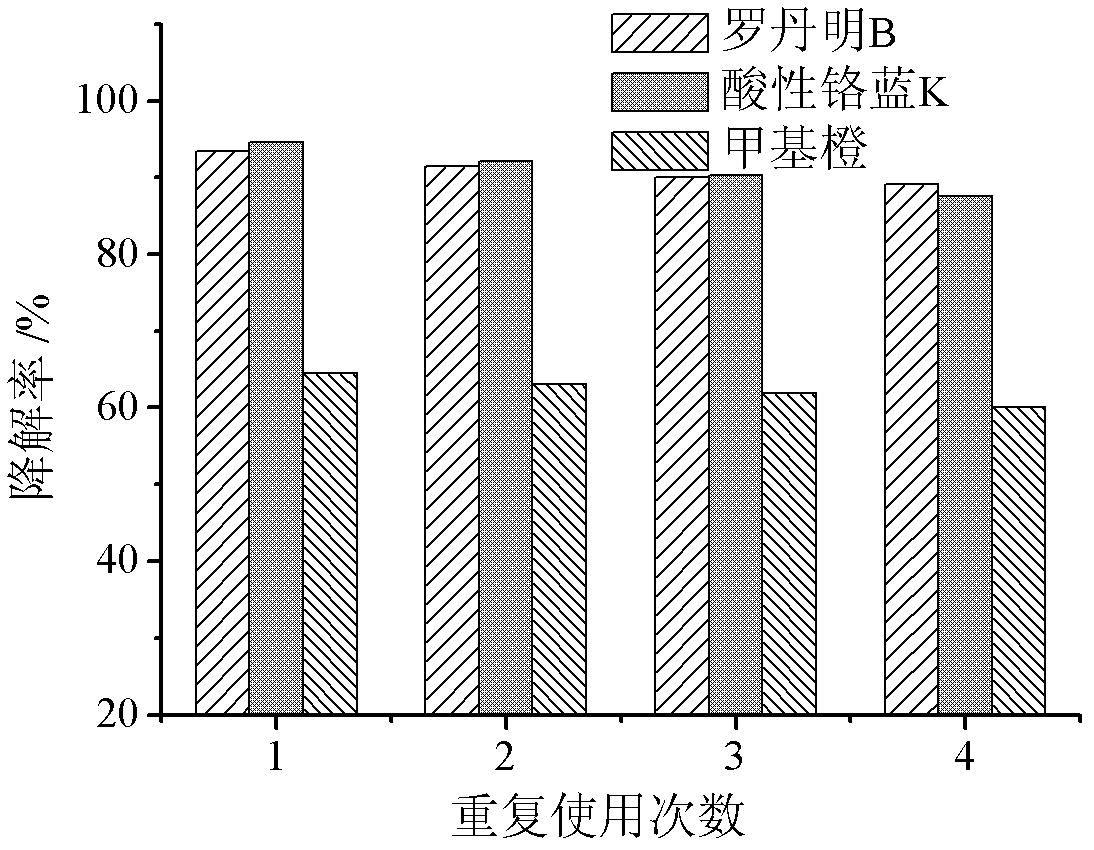

[0034] The photocatalyst is used for visible light catalytic degradation dye rhodamine B, visible light catalytic degradation conditions: irradiate with visible light (150W iodine tungsten lamp light source, 420nm filter to filter out ultraviolet light), rhodamine B aqueous solution 10...

Embodiment 3

[0036] Benzimidazolone Yellow H3G / TiO 2 Preparation: In a glass container, add N,N-dimethylformamide 48g, benzimidazolone yellow H3G 0.5g, TiO 2 4g, Span 80 0.012g, stirred at room temperature for 30min. This mixture was added into a closed autoclave with a polytetrafluoroethylene liner, and loaded by adsorption at 210°C for 2h. After the reaction was completed, it was cooled to room temperature, centrifuged and filtered to obtain a light yellow solid, which was washed with ethanol and water respectively, and dried by filtration. The obtained light yellow solid was placed in a vacuum drying oven and dried at 100°C for 0.5h to obtain benzimidazolone yellow H3G / TiO 2 Composite photocatalytic materials.

[0037] The photocatalyst is used for visible light catalytic degradation dye rhodamine B, visible light catalytic degradation conditions: irradiate with visible light (150W iodine tungsten lamp light source, 420nm filter to filter out ultraviolet light), rhodamine B aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com