Bismuth oxyiodide/porous titanium dioxide composite photocatalyst and its preparation method and application

A technology of porous titanium dioxide and bismuth oxyiodide, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high recombination rate of photogenerated electrons and holes, low utilization efficiency of visible light and sunlight , the inability of efficient catalyst application, etc., to achieve the effect of broadening the spectral response range, realizing photocatalytic activity, and good visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

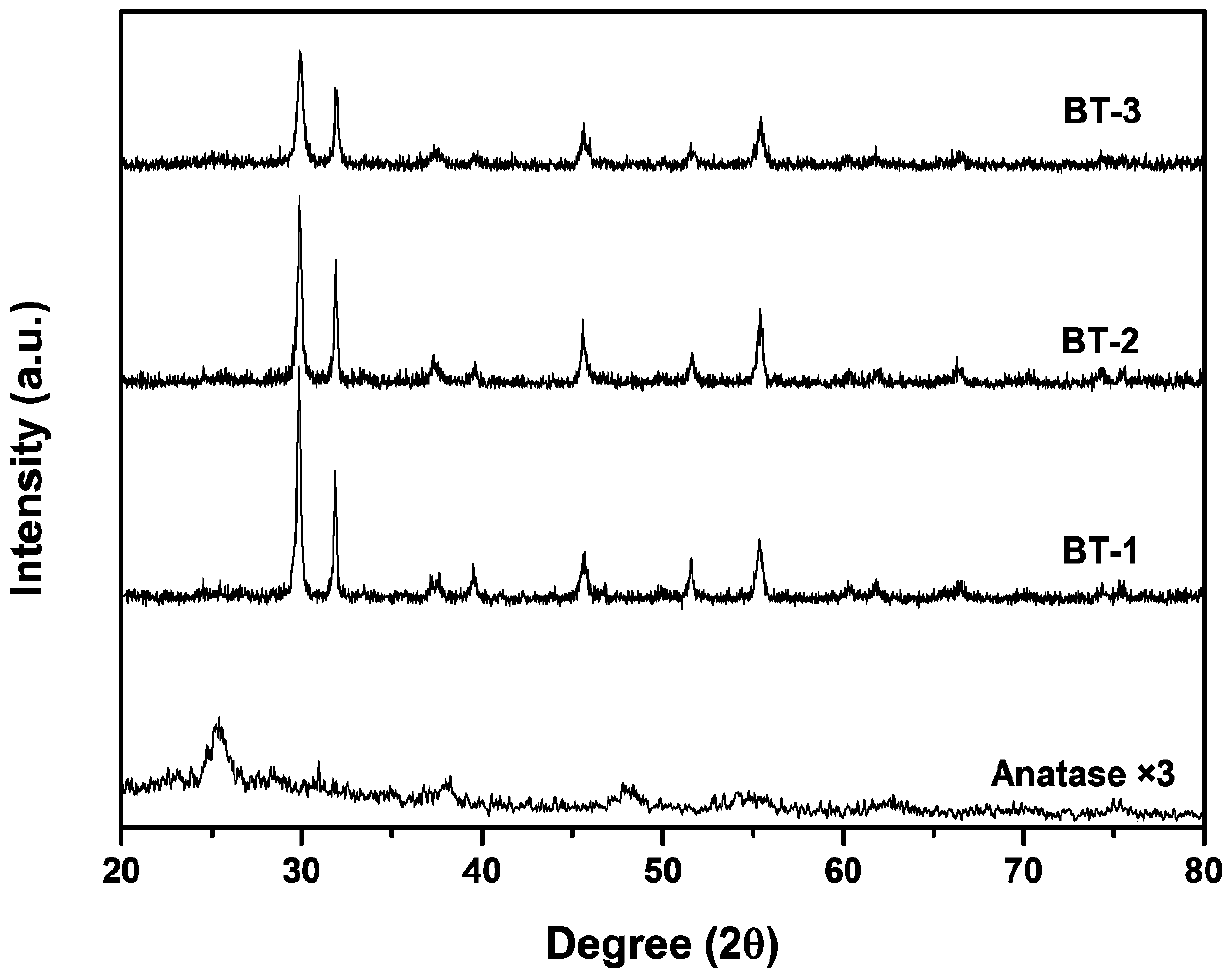

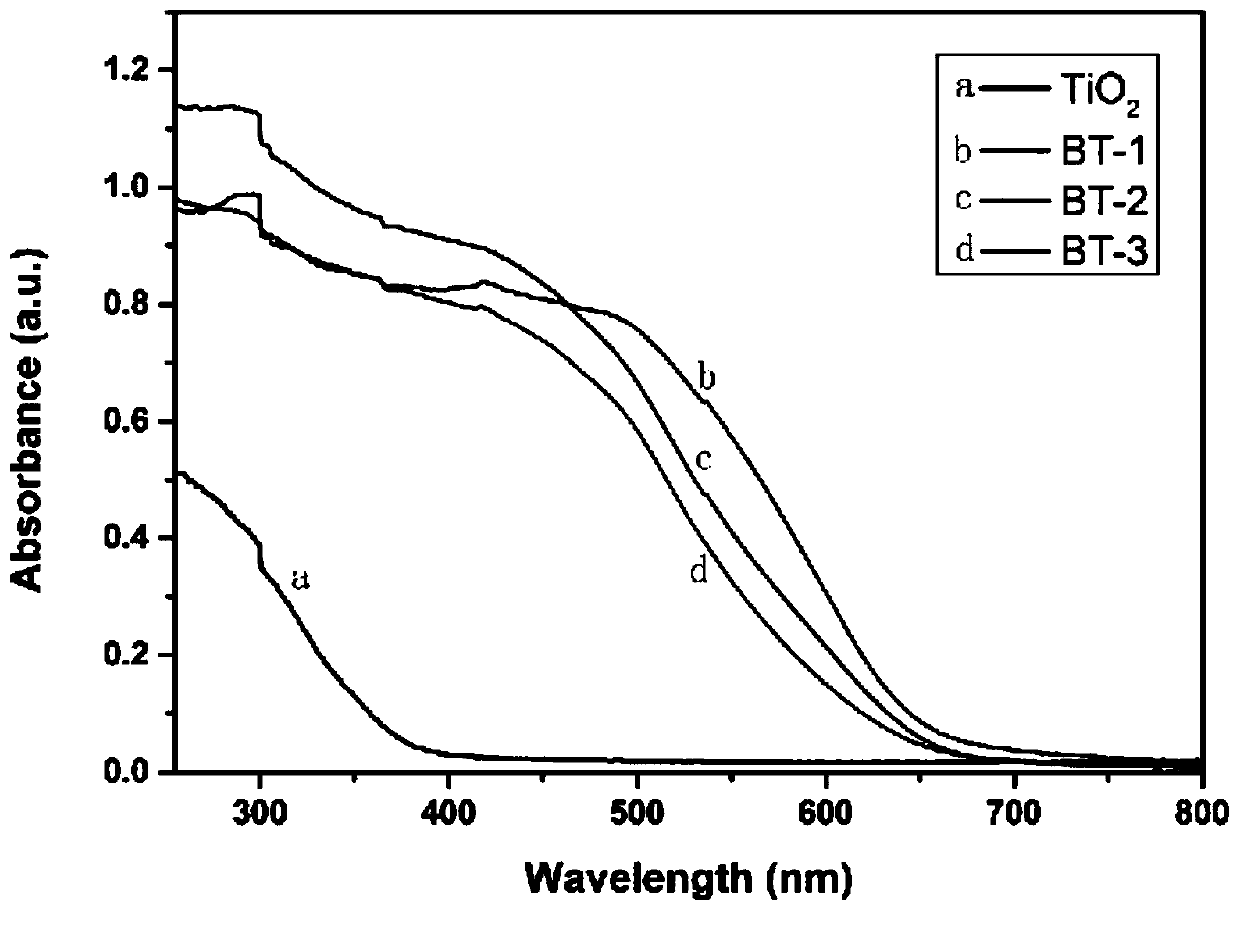

[0024] Example 1 Bismuth oxyiodide / porous titanium dioxide composite photocatalyst (BT-1)

[0025] The preparation method is as follows:

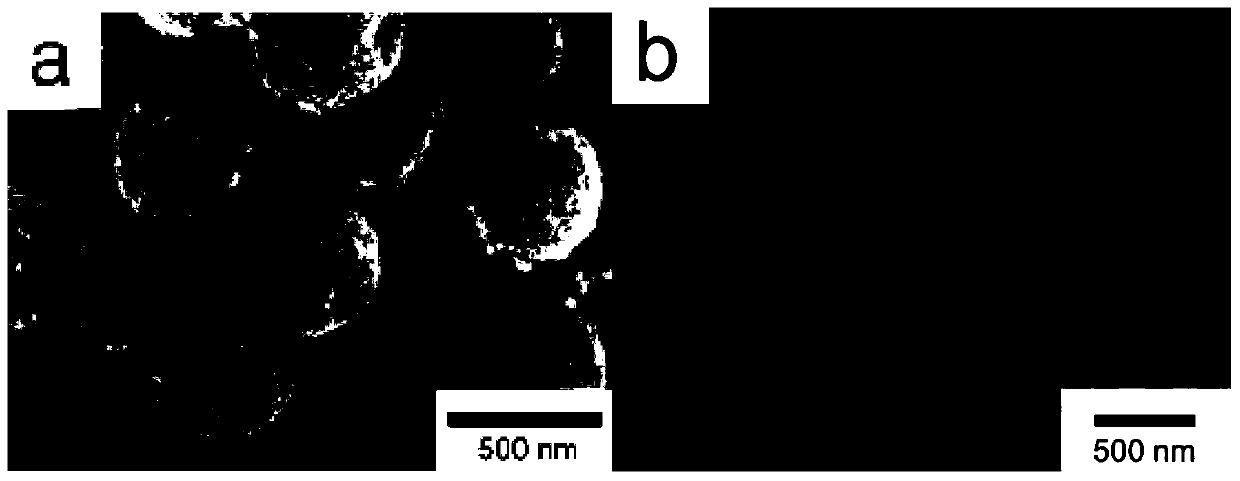

[0026] 1) Add 1 mL of tetrabutyl titanate into 25 mL of ethylene glycol under vigorous stirring, and supply nitrogen gas to the system for about 10 minutes while stirring; after continuous stirring for 24 hours, pour the mixture into 100 mL of acetone containing 1 mL of ultrapure water In the medium, stir for 10 minutes, after that, let it stand and age for about 16 hours; collect the product after aging, wash and dry; take 1g of the dried sample, disperse it in 80mL ultrapure water, and transfer it to 100mL lined with polytetrafluoroethylene In a stainless steel autoclave, react at 180°C for 10 hours; after naturally cooling to room temperature, filter, wash, and dry, the obtained dry white powder is porous titanium dioxide microspheres.

[0027] 2) Disperse 0.970g (0.002mol) of bismuth nitrate pentahydrate in 20mL of ethylene glycol, the...

Embodiment 2

[0028] Example 2 Bismuth oxyiodide / porous titanium dioxide composite photocatalyst (BT-2)

[0029] The preparation method is as follows:

[0030] 1) method is the same as embodiment 1.

[0031] 2) Disperse 0.485g (0.001mol) of bismuth nitrate pentahydrate in 20mL of ethylene glycol, then add 0.166g (0.001mol) of potassium iodide to the system, and stir at room temperature; then add 0.160g (0.002mol) of porous titanium dioxide microspheres , and then add 20mL ultrapure water, stir at room temperature for 2h, collect the obtained product, wash and dry to obtain bismuth oxyiodide / porous titanium dioxide composite photocatalyst, which is named BT-2. The molar ratio of bismuth oxyiodide in the component is 33%.

Embodiment 3

[0032] Example 3 Bismuth oxyiodide / porous titanium dioxide composite photocatalyst (BT-3)

[0033] The preparation method is as follows:

[0034] 1) method is the same as embodiment 1.

[0035] 2) Disperse 0.323g (0.00067mol) of bismuth nitrate pentahydrate in 20mL of ethylene glycol, then add 0.111g (0.00067mol) of potassium iodide to the system, and stir at room temperature; then add 0.160g (0.002mol) of porous titanium dioxide microspheres , and then add 20mL ultrapure water, stir at room temperature for 2h, collect the obtained product, wash and dry to obtain bismuth oxyiodide / porous titanium dioxide composite photocatalyst, which is named BT-3. The molar ratio of bismuth oxyiodide in the component is 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com