Preparation method of low-temperature non-aqueous sol-gel of high-activity carbon-chlorine codoped titanium dioxide visible light catalyst

A titanium dioxide, co-doping technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of low synthesis temperature, easy operation, and small industrial amplification factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

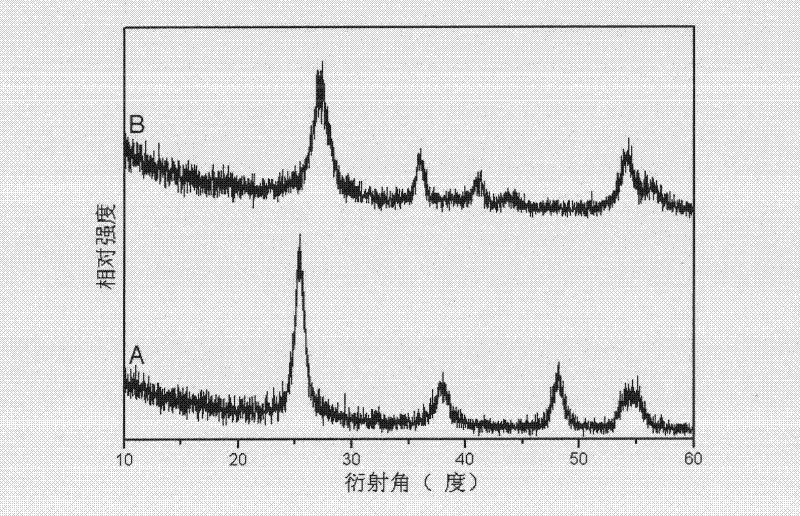

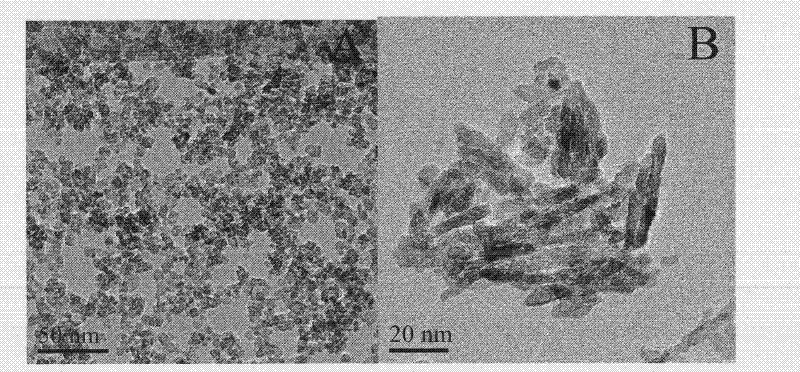

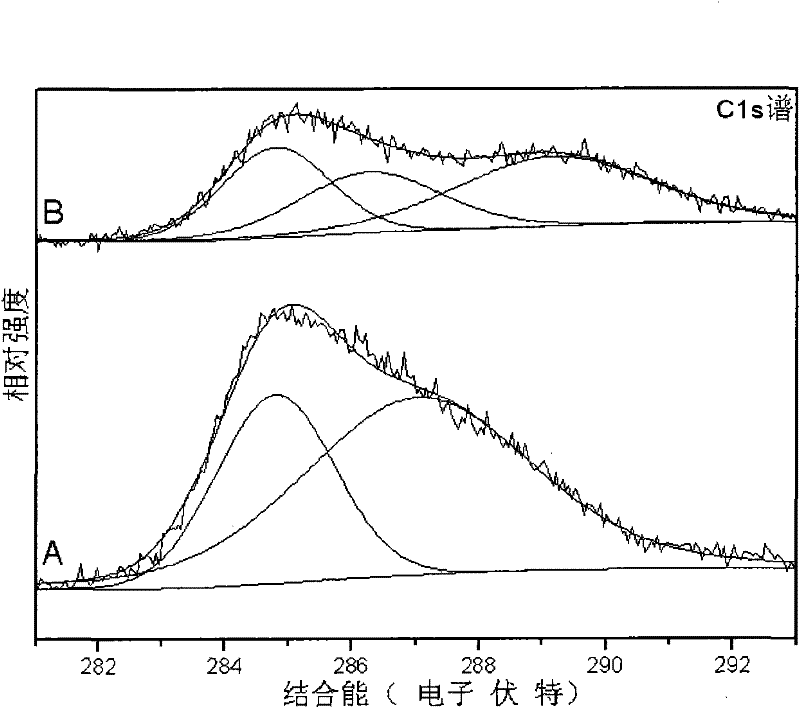

[0030] Carbon and chlorine co-doped anatase titanium dioxide preparation, the preparation steps are:

[0031] Step 1: Add isopropyl titanate to a mixed solvent of ethanol and monochloromethane, the volume of the mixed solvent is 15 milliliters, the volume ratio of ethanol to monochloromethane is 5:1, and the amount of isopropyl titanate is 0.01 mole / liter;

[0032] Step 2: subjecting the mixed solution to solvent heat treatment at a temperature of 120° C. for 12 hours;

[0033] Step 3: After step 2 is completed, filter and rinse the filtered solid product with distilled water and ethanol four times respectively, and vacuum dry the product at 100° C. for 6 hours to obtain carbon and chlorine co-doped anatase titanium dioxide.

Embodiment 2

[0035] Carbon and chlorine co-doped anatase titanium dioxide preparation, the preparation steps are:

[0036] Step 1: add titanium tetrachloride in the mixed solvent of ethanol and monochloromethane, the volume of its mixed solvent is 15 milliliters, and the volume ratio of ethanol and monochloromethane is 4: 1, and the amount of titanium tetrachloride is 0.01 mol / Lift;

[0037] Step 2: subjecting the mixed solution to solvent heat treatment at a temperature of 100°C for 18 hours;

[0038] Step 3: After step 2 is completed, filter and rinse the filtered solid product three times with distilled water and ethanol respectively, and dry the product in vacuum at 100°C for 6 hours to obtain carbon and chlorine co-doped anatase titanium dioxide.

Embodiment 3

[0040] Carbon and chlorine co-doped anatase titanium dioxide preparation, the preparation steps are:

[0041]Step 1: Add tetrabutyl titanate to a mixed solvent of ethanol and monochloromethane, the volume of the mixed solvent is 15 milliliters, the volume ratio of ethanol to monochloromethane is 5:2, and the amount of tetrabutyl titanate is 0.01 mole / liter;

[0042] Step 2: subjecting the mixed solution to solvent heat treatment at a temperature of 100°C for 18 hours;

[0043] Step 3: After step 2 is completed, filter and rinse the filtered solid product three times with distilled water and ethanol respectively, and dry the product in vacuum at 100°C for 6 hours to obtain carbon and chlorine co-doped anatase titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com