Plastic bag heat sealing machine

A technology of plastic bags and heat sealing machines, which is applied in packaging sealing/fastening, transportation packaging, packaging, etc., can solve the problems of weakened elastic properties of pressure springs, easy damage and broken roots of pressure springs, and improve processing efficiency and guarantee The effect of heat sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

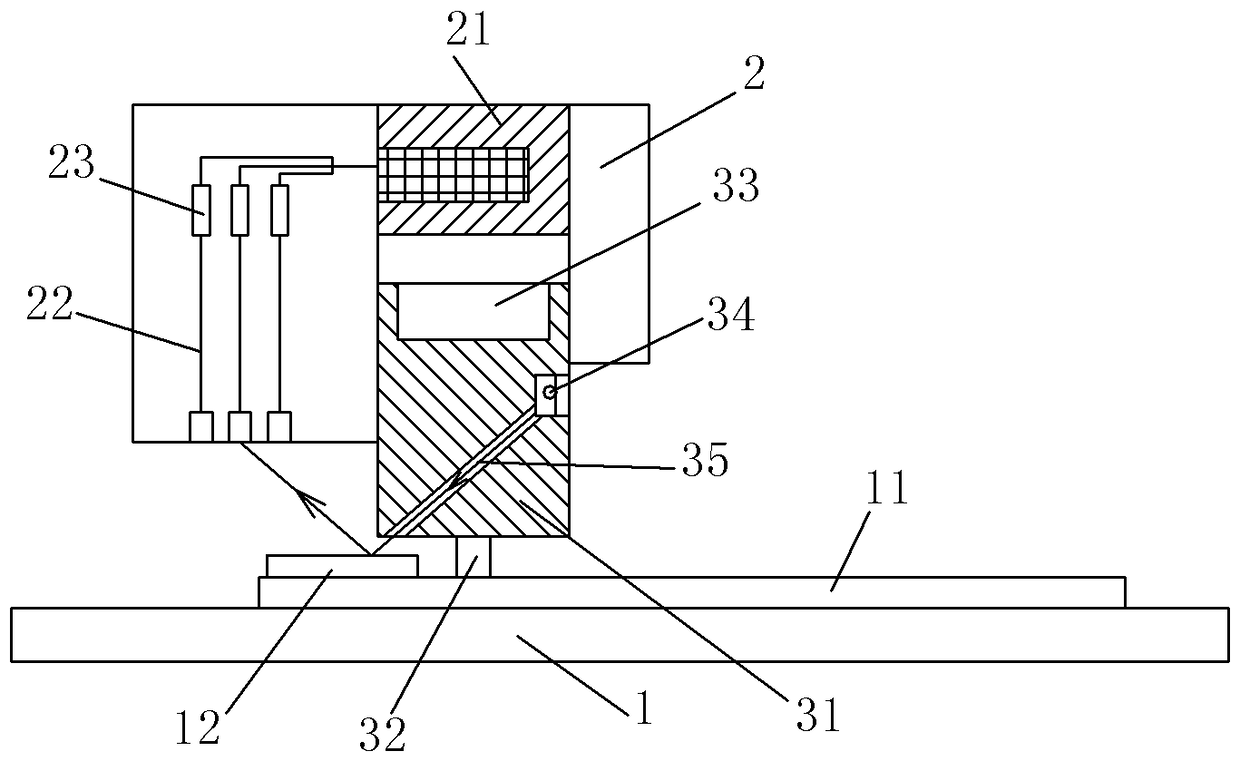

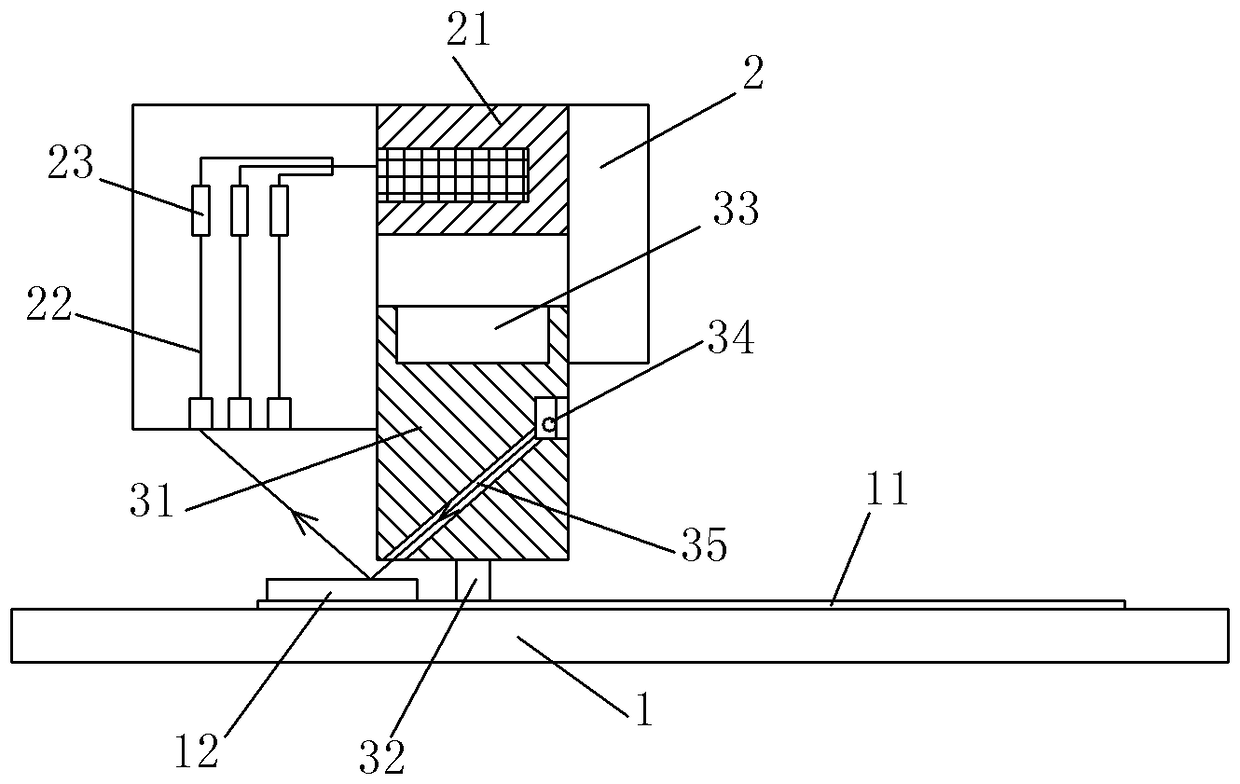

[0020] The reference signs in the accompanying drawings include: base 1, plastic bag 11, lens 12, heat sealing seat 2, electromagnetic block 21, photoelectric switch 22, resistor 23, cutter body 31, cutter head 32, permanent magnet 33, light source 34, The light hole 35.

[0021] The embodiment is basically as attached figure 1 And attached figure 2 Shown: plastic bag heat-sealing machine, comprises base 1, and base 1 top is used for placing the plastic bag 11 to be heat-sealed, and also placed lens 12 on the left side of plastic bag 11 heat-sealing position, and lens 12 can be on the one hand plastic The bag 11 generates a certain pressure to prevent the plastic bag 11 from moving during the heat sealing process, and the lens 12 is also used for light reflection.

[0022] The upper side of the plastic bag 11 is provided with a heat-sealing seat 2, and a through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com