Method for fabricating plastic lining steel tee joint pipe fitting

A technology for a tee pipe fitting and a manufacturing method, which is applied in the directions of pipes/pipe joints/pipe fittings, pipes, applications, etc., can solve the problems that hinder the reliable use of plastic-lined steel tee pipe fittings, the complex structure of processing equipment and tooling molds, and the lining of plastic layers. Problems such as failure to achieve effective bonding with the inner wall of the steel base pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

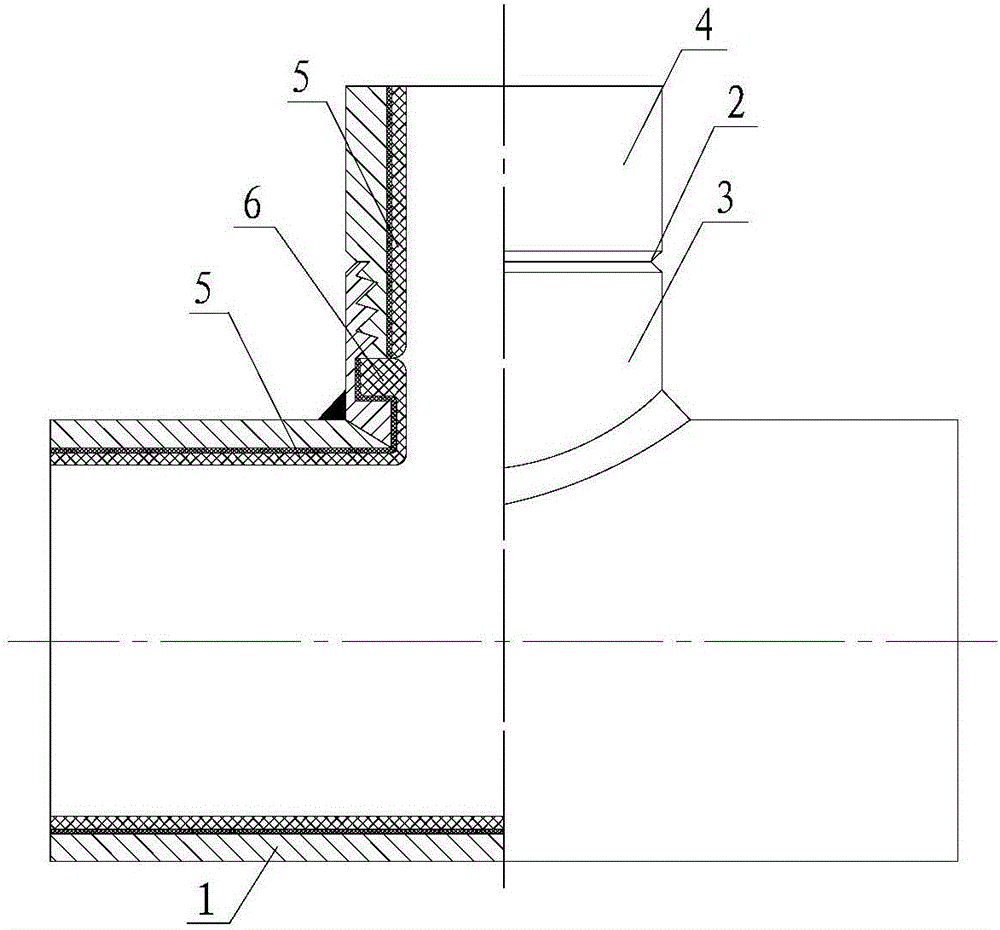

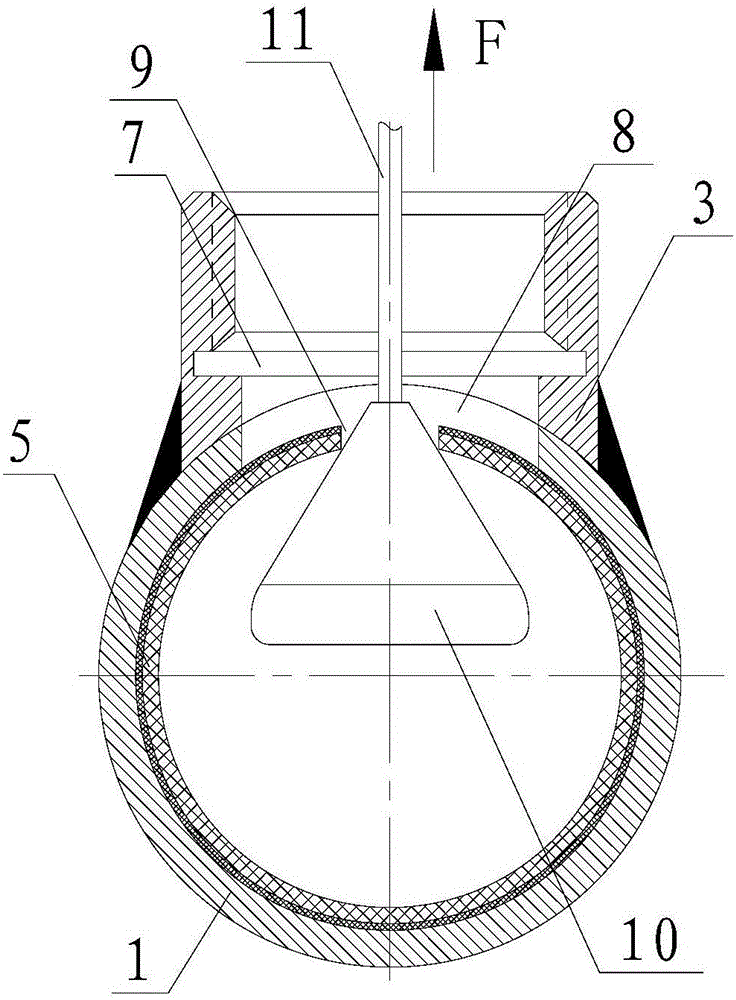

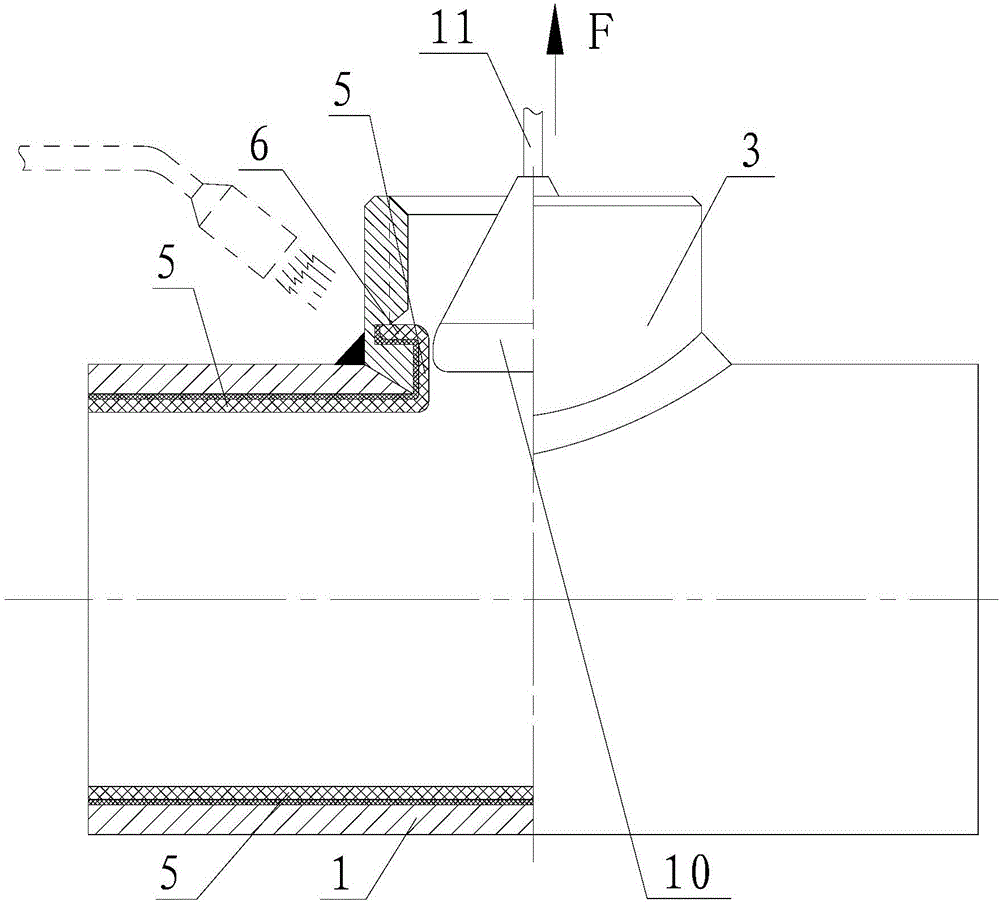

[0015] Such as figure 1 , figure 2 as well as image 3 Shown is a manufacturing method for plastic-lined steel tee pipe fittings that is suitable for various calibers and can ensure the heat-sealing effect of the plastic-lined layer as much as possible, and the plastic-lined steel tee pipe fittings produced by this manufacturing method. . The plastic-lined steel tee pipe fitting includes a straight pipe 1 and a branch pipe 2 connected to the straight pipe 1, and the branch pipe 2 includes a base 3 and a branch pipe extension fixed at the end of the base 3 4. The plastic-lined layer 5 inside the base 3 and the plastic-lined layer 5 inside the straight pipe 1 are integrally formed. The manufacturing method includes the following steps: first prepare the base 3 and the extension 4 of the branch pipe 2; then weld the base 3 to the branch pipe interface 8 of the straight pipe 1; then make the straight pipe 1 and the base The seat 3 is integrally formed with hot-melt lining pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com