Biodegradable high-barrier paper-plastic packaging composite film and preparation method thereof

A biodegradable, high-barrier technology, applied in the field of packaging materials, can solve problems such as the need to control the degradation rate, increase the cost of raw materials, lack of elasticity and flexibility, etc., achieve good printing performance and appearance, control production and processing costs, and good composite fastness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

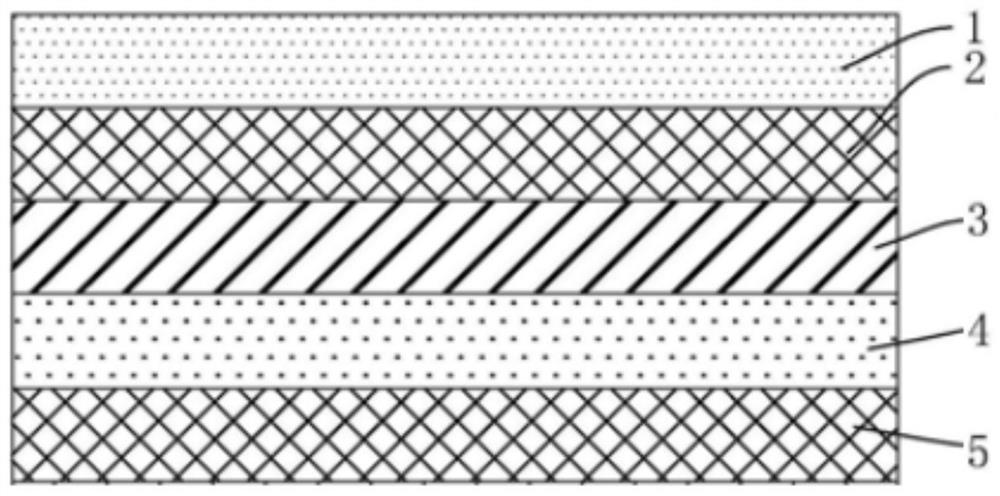

[0049] The preparation method of the biodegradable high-barrier paper-plastic packaging composite film provided by the present invention comprises the following steps:

[0050] 1) Use gravure printing technology to print degradable water-based ink on the surface of kraft paper;

[0051] 2) In parts by weight, add 55 parts of PLA particles and 1 part of bifunctional compatibilizer KT20 into the casting machine, mix for 20 minutes and then raise the temperature to 175°C to make the PLA particles reach a molten state, then cool down to 140°C, add 18 1 part of PBAT and 10 parts of PPC were mixed for 2 hours and then extruded through a flat die to form a film at a film forming temperature of 50°C to obtain PLA layer 5;

[0052] 3) Vacuum-deposit a layer of aluminum foil on the PLA layer 5 to form the aluminum-coated layer 4;

[0053] 4) Bond the kraft paper to the aluminized layer 4 with a solvent-free polyurethane adhesive. The specific steps are: at room temperature, roll-coat c...

Embodiment 2

[0055] The preparation method of the biodegradable high-barrier paper-plastic packaging composite film provided by the present invention comprises the following steps:

[0056] 1) Use gravure printing technology to print degradable water-based ink on the surface of wood pulp paper;

[0057] 2) In parts by weight, add 58 parts of PLA particles and 2 parts of compatibilizer EsunBio5004K into the casting machine, mix for 30 minutes and then heat up to 170°C to make the PLA particles reach a molten state, then cool down to 150°C and add 20 parts of PBAT and 8 parts of PPC, mixed for 1.5 h, extruded through a flat sheet die to form a film, and the film forming temperature was 40 ° C to obtain PLA layer 5;

[0058] 3) Vacuum-deposit a layer of aluminum foil on the PLA layer 5 to form the aluminum-coated layer 4;

[0059] 4) Bond the wood pulp paper and the aluminum layer 4 with a solvent-free polyurethane adhesive. The specific steps are: mix components A and B of the solvent-free ...

Embodiment 3

[0061] The preparation method of the biodegradable high-barrier paper-plastic packaging composite film provided by the present invention comprises the following steps:

[0062] 1) Use gravure printing technology to print degradable water-based ink on the surface of glassine paper;

[0063] 2) In parts by weight, add 60 parts of PLA particles and 0.5 parts of BASF epoxy chain extender ADR 4468 into the casting machine, mix for 25 minutes and then heat up to 180°C to make the PLA particles reach a molten state, then cool down to 160°C , add 15 parts of PBAT and 5 parts of PPC, mix for 1 hour and extrude through a flat sheet die to form a film at a film forming temperature of 60°C to obtain PLA layer 5;

[0064] 3) Vacuum-deposit a layer of aluminum foil on the PLA layer 5 to form the aluminum-coated layer 4;

[0065] 4) Bond the glassine paper to the aluminum layer 4 with a solvent-free polyurethane adhesive. The specific steps are: roll or spray the one-component solvent-free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com