Special membrane for disposable bioreactor and preparation method thereof

A bioreactor, disposable technology, applied in biochemical equipment and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the obstacles to the development of disposable bioreactors, increase Problems such as the use cost of domestic users and the unfavorable sustainable development of the industry have achieved the effect of improving the gas barrier function, reducing operating costs, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

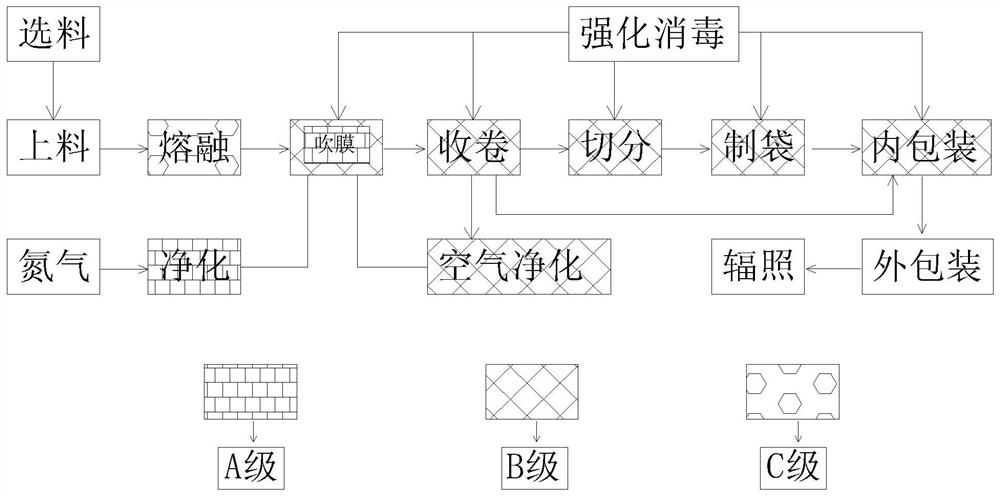

[0026] This embodiment relates to a special membrane for a disposable bioreactor and its preparation.

Embodiment 11

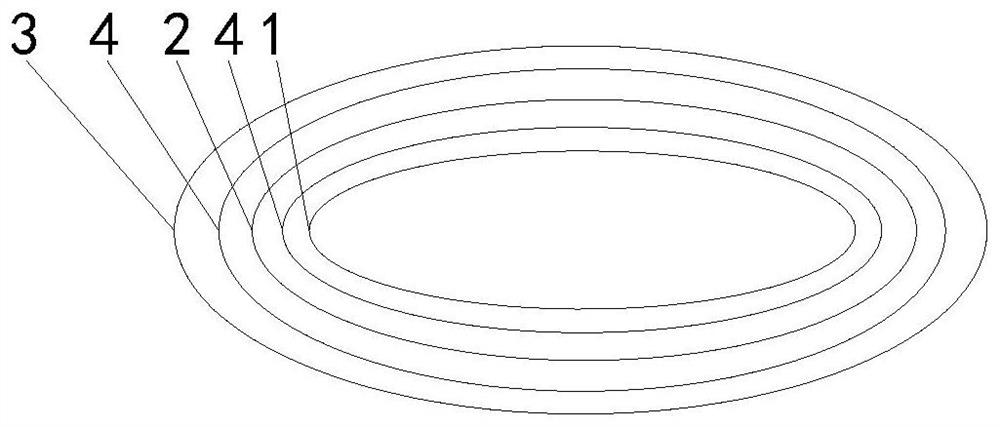

[0028] Disposable bioreactor special membrane, including an ultra-low density polyethylene layer placed in the innermost layer of the membrane body, a low density polyethylene layer placed in the outermost layer, an ethylene / vinyl alcohol copolymer layer in the middle of the membrane body, and An adhesive layer arranged between two adjacent layers;

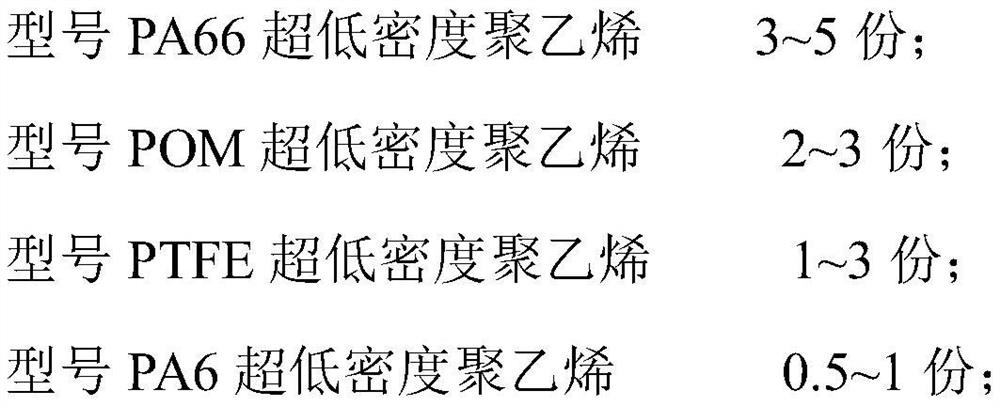

[0029] Among them, the ultra-low-density polyethylene layer, the raw material formula is: 4 parts of ultra-low-density polyethylene of model PA66; 3 parts of ultra-low-density polyethylene of model POM; 1.5 parts of ultra-low-density polyethylene of model PTFE; 0.5 parts of ultra-low-density polyethylene of model PA6 share.

[0030] Among them, the low-density polyethylene layer, the raw material formula is: 4 parts of low-density polyethylene of model 2420D; 1 part of low-density polyethylene of model 2010MA; 1 part of low-density polyethylene of model LD100AC; Density polyethylene 0.5 parts.

[0031] The raw material formula o...

Embodiment 12

[0038] Disposable bioreactor special membrane, including an ultra-low density polyethylene layer placed in the innermost layer of the membrane body, a low density polyethylene layer placed in the outermost layer, an ethylene / vinyl alcohol copolymer layer in the middle of the membrane body, and An adhesive layer arranged between two adjacent layers;

[0039] Among them, the ultra-low-density polyethylene layer, the raw material formula is: 4 parts of ultra-low-density polyethylene of model PA66; 2 parts of ultra-low-density polyethylene of model POM; 2 parts of ultra-low-density polyethylene of model PTFE; 0.5 parts of ultra-low-density polyethylene of model PA6 share.

[0040] Among them, the low-density polyethylene layer, the raw material formula is: 5 parts of model 2420D low-density polyethylene; 2 parts of model 2010MA low-density polyethylene; 1 part of model LD100AC low-density polyethylene; 0.5 parts of model 2426H low-density polyethylene; Density polyethylene 0.5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com