Novel packaging machine and using method thereof

A new type of packaging and packaging film technology, applied in the field of machinery and mechanical parts, can solve the problems of high packaging cost and labor cost, low packaging efficiency, etc., and achieve the effect of enhancing the number of heat sealing, preventing bumps, and ensuring the effect of heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

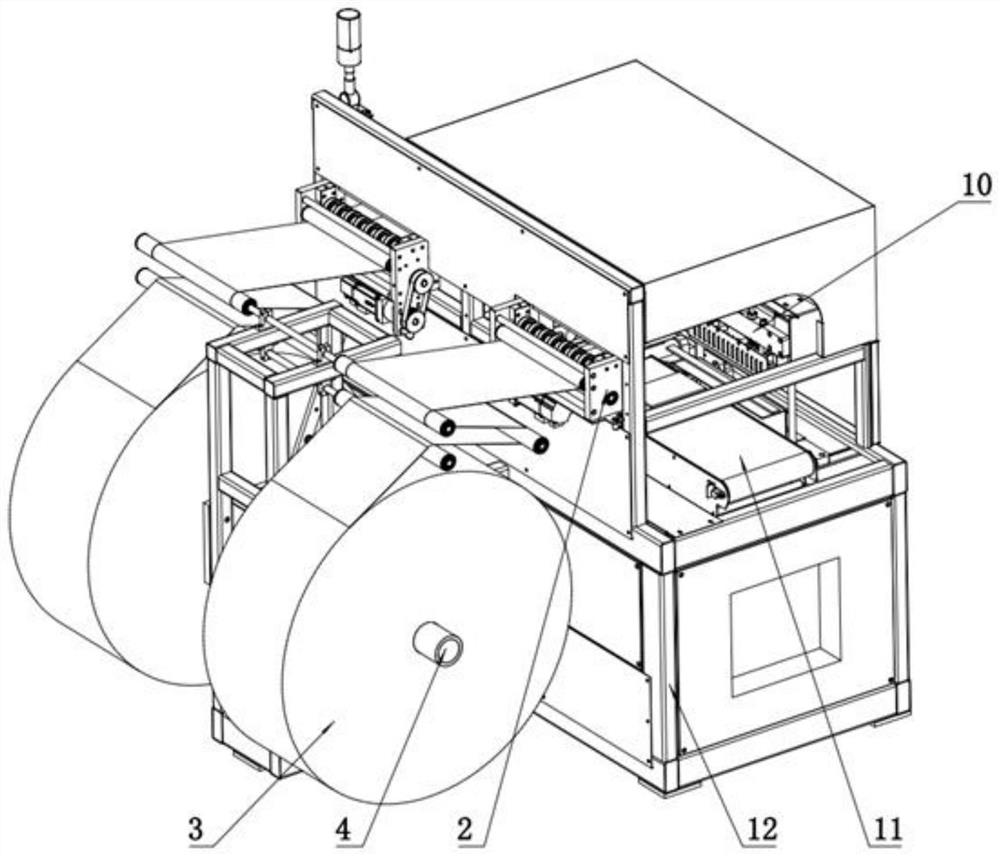

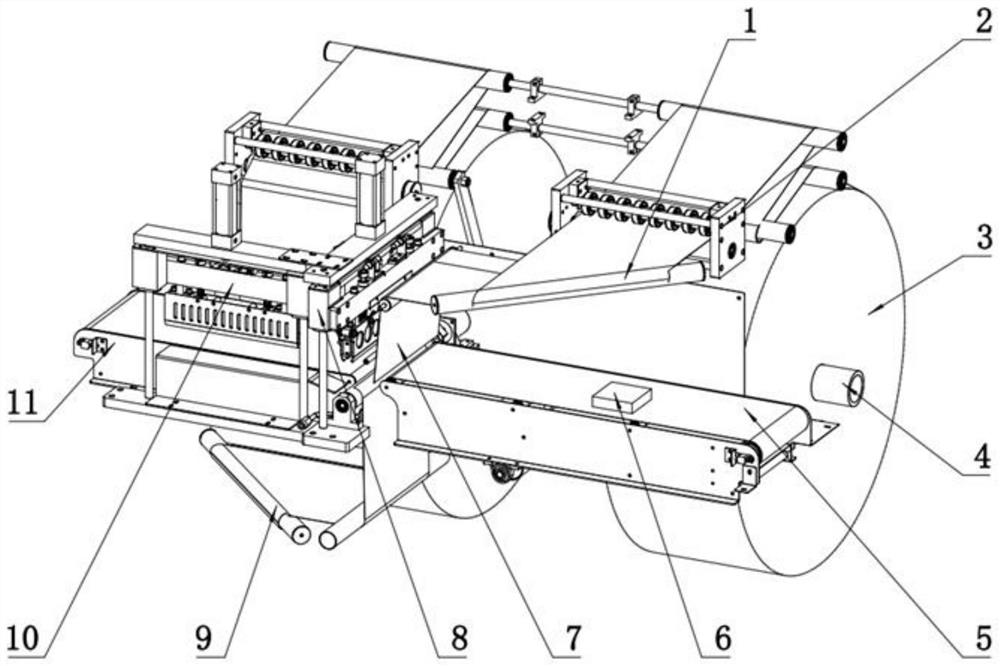

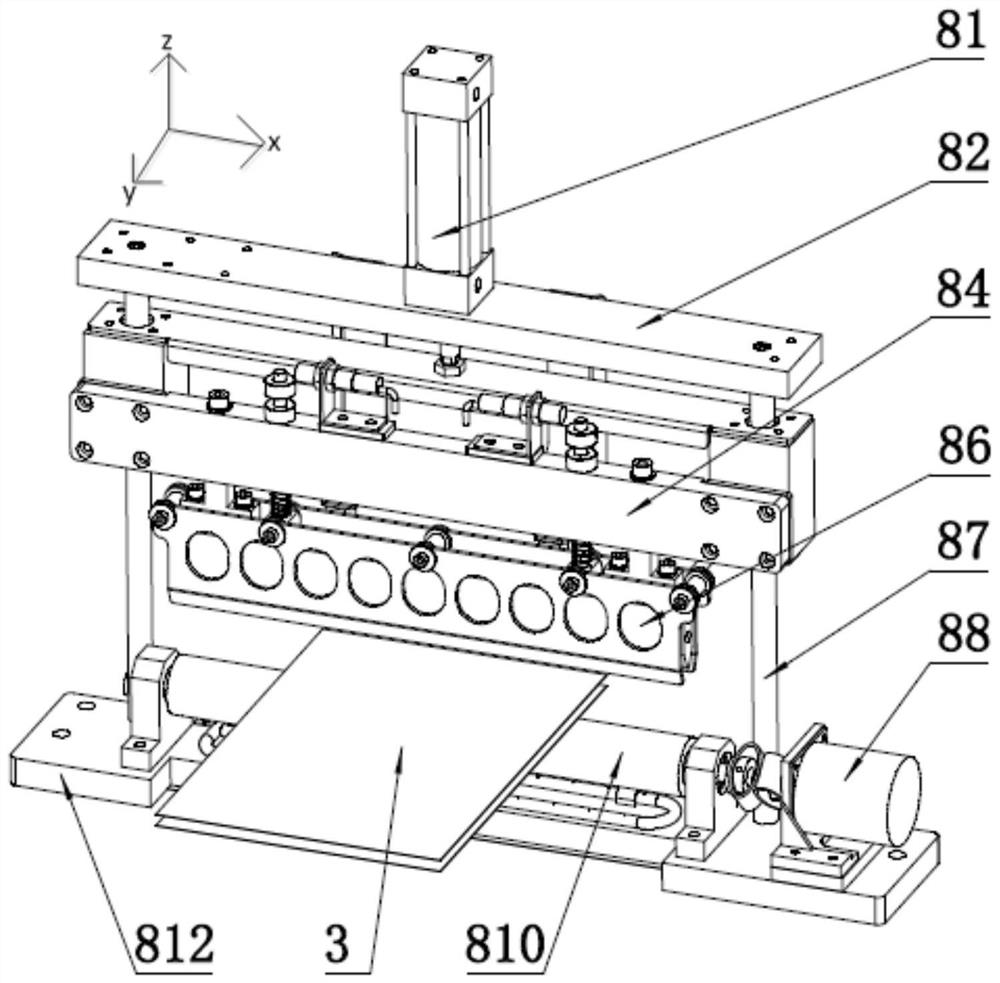

[0039] Refer to attached Figure 1-7 , the present invention is a novel packaging machine and its use method. The novel packaging machine includes a conveying device for conveying products 6, an upper film and a lower film positioned above the conveying device, and a heat-sealing cutting device 8 arranged on the conveying device, and also includes The upper film is conveyed to the first film releasing device above the product 6, and the lower film is conveyed to the second film releasing device between the product 6 and the conveying device.

[0040] The conveying device comprises a first conveyor belt 5 and a second conveyor belt 11 that convey the product 6 in sequence, the first conveyor belt 5 and the second conveyor belt 11 are all located on the frame 12 and there is a gap between the first conveyor belt 5 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com