Full-automatic multi-specification sauce bag filling equipment and production process

A filling equipment and multi-standard technology, which is applied in the field of automatic multi-standard sauce bag filling equipment and production technology, can solve the problems of poor practicability and single storage space, and achieve the effect of convenient feeding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

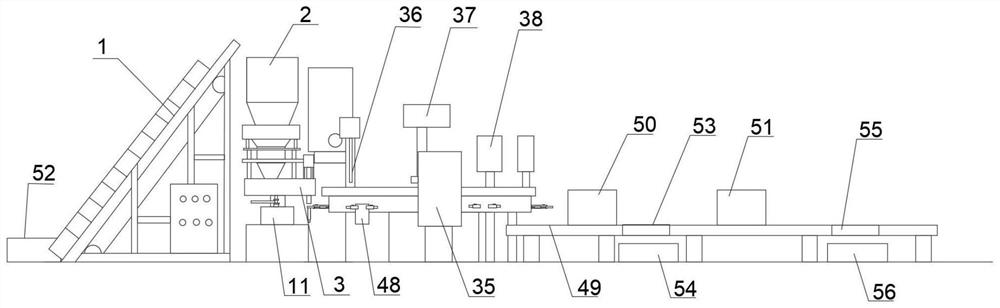

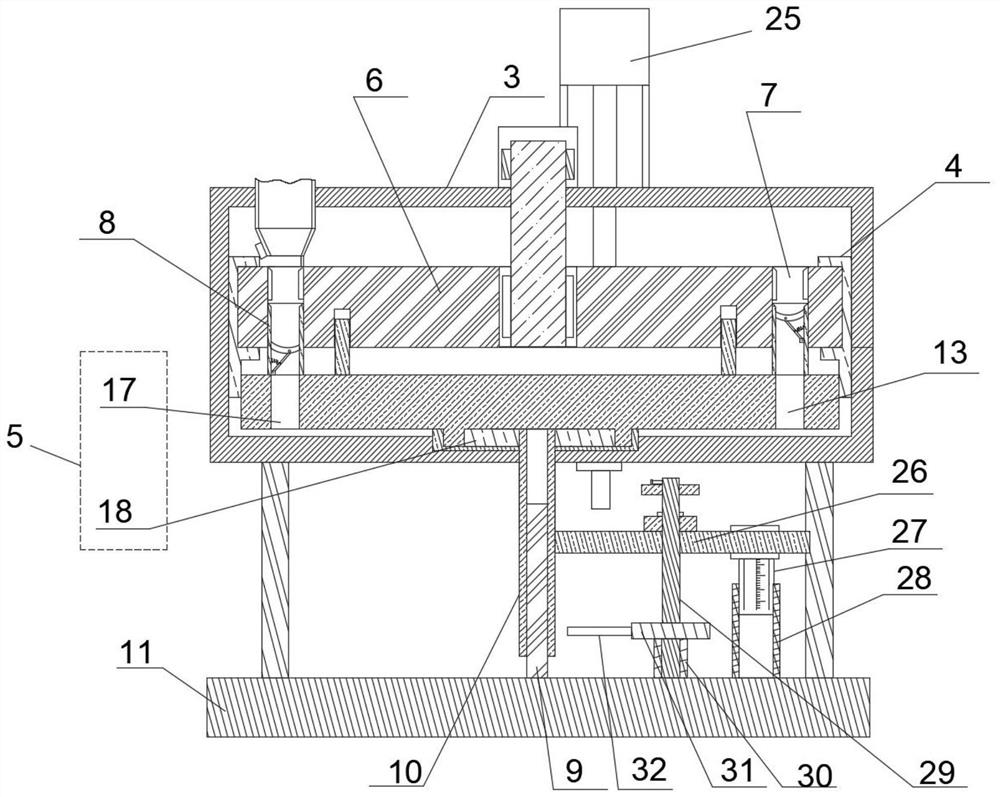

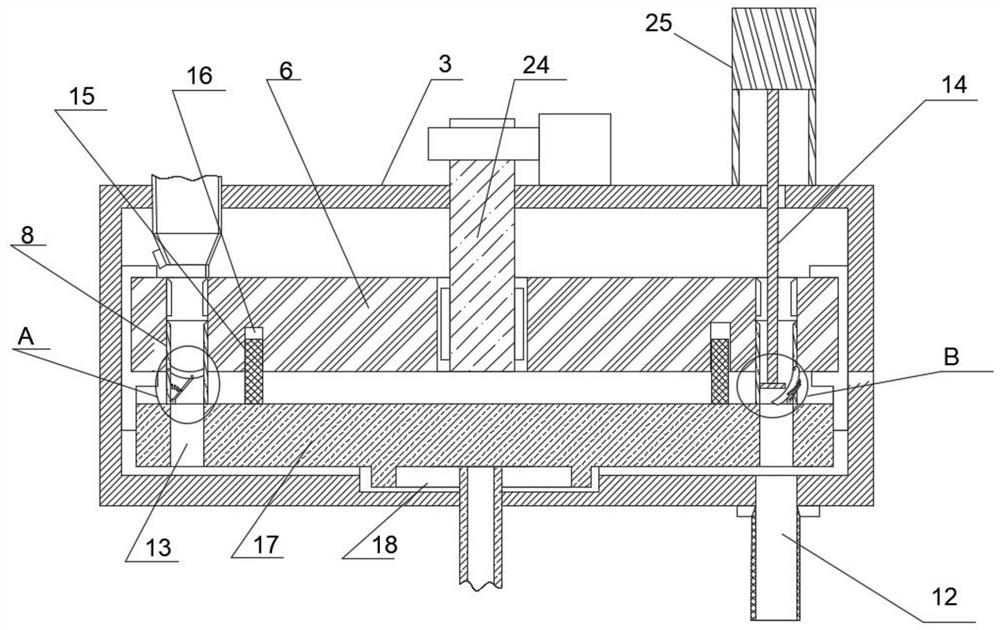

[0061] Such as Figure 1 to Figure 7 As shown, it is an embodiment of the present invention, a fully automatic multi-standard sauce bag filling equipment, including a feeding unit, a quantitative unit, a filling unit and a detection unit, and the feeding unit includes an inclined conveyor frame 1 and The multi-layer storage tower 2 and the inclined conveying frame 1 are suitable for conveying and unloading solid raw materials to the multi-layer storage tower 2. A quantitative unit is installed under the multi-layer storage tower 2. The quantitative unit includes an upper box shell 3 and an upper box shell 3 There is a feeding port on the top, and the multi-layer storage tower 2 is connected with the feeding port. The upper mounting plate 4 and the lower lifting plate 5 are installed in the upper box shell 3. The upper mounting plate 4 is located on the upper side of the lower lifting plate 5, and the upper mounting plate The plate 4 is fixedly connected with the upper box shel...

Embodiment 2

[0073] Such as Figure 8 to Figure 10 As shown, it is another embodiment of the present invention. On the basis of Example 1, in order to reduce the action of the jaws, and then reduce mistakes, the filling unit includes an installation disc 33 with a drive mechanism. The drive mechanism is to realize the installation The disc 33 can be rotated at regular intervals with a fixed angle. For example, when there are 4 sets of clamping components, it can be designed as a sheave mechanism. The clamping components are installed at equal intervals on the mounting disc 33, and the clamping components include two groups of symmetrical clamps. The holder 34, the mounting disc 33 are respectively equipped with a bag taking port 35, a solid discharge port 12, a liquid filling port 36, a lower pressing rod 37 and two sets of heat sealing ports 38;

[0074] Holder 34 comprises fixed plate 39, movable plate 40 and cylinder 41, and fixed plate 39 is fixedly connected with installation disc 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com