Machining technique of silver/copper double composite strip material

A composite strip, processing technology, applied in the direction of contacts, electrical components, electrical switches, etc., can solve the problems of continuous processing, large-scale production, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

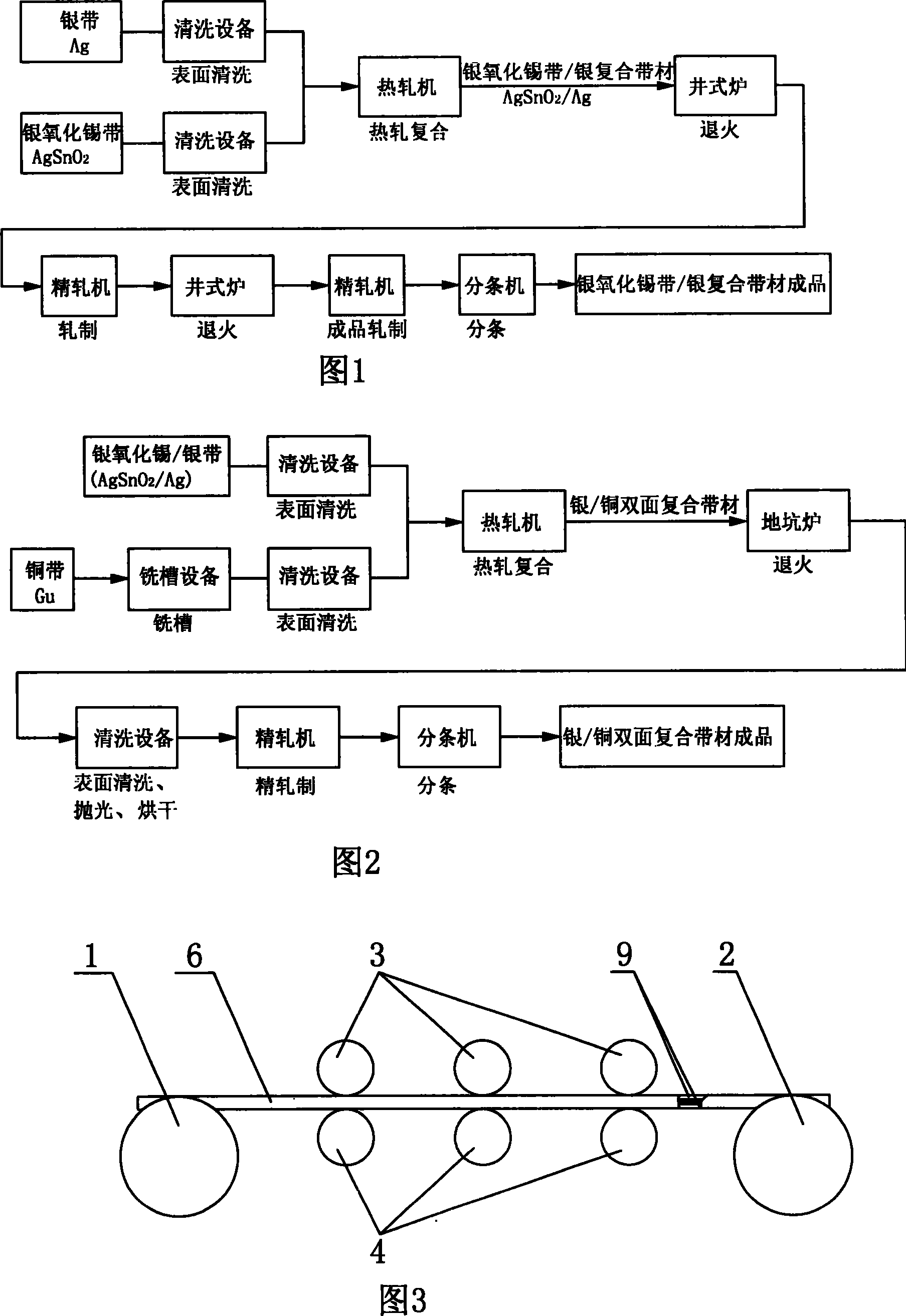

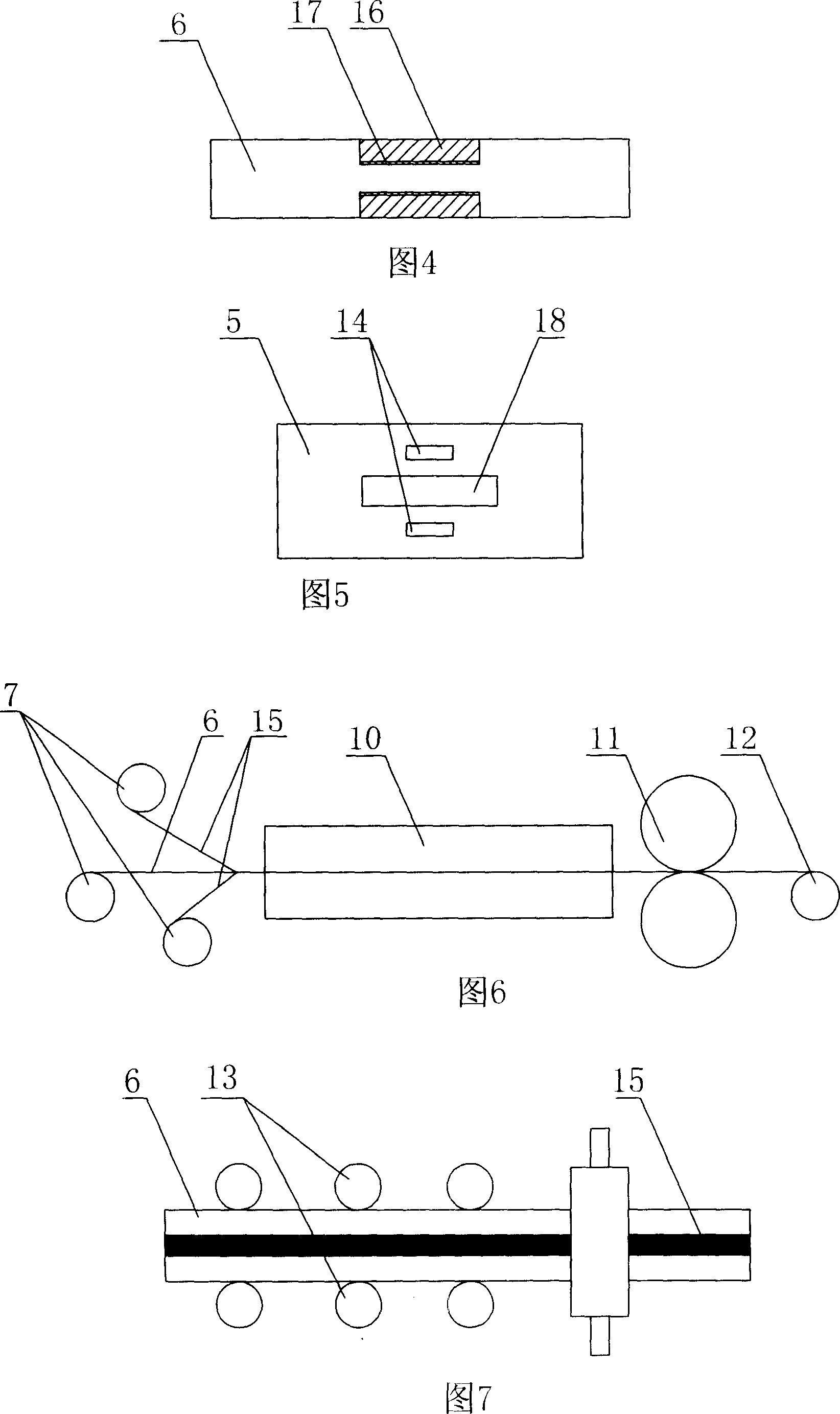

[0026] In order to further prompt the present invention, the following will be specifically described in conjunction with accompanying drawings 1, 2, 3, 4, 5, 6, and 7.

[0027] The copper strip 6 of the present invention is a copper or copper alloy strip, and there is a thinner silver strip 17 transition layer between the silver tin oxide strip 16 and the copper strip 6 on the produced silver / copper double-sided composite strip , and its processing technology is as follows:

[0028] A, carry out surface cleaning to silver band 17 and silver tin oxide band 16 bands respectively, remove oil stain, oxide compound on its surface, then silver band 17 and silver tin oxide band 16 are sent into hot-rolling mill hot-rolled and compounded together again One piece of silver tin oxide / silver composite strip 15, the heating temperature of hot rolling composite is 300-800°C, the strip running speed is 1.0-5.0m / min, the rolling force is 10-120 tons, 10 in the heating zone has protection T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com