Machining technique of silver/copper/iron composite strip material

A technology of composite strip material and processing technology, applied in the direction of contacts, electrical components, electric switches, etc., can solve the problems of incapable of large-scale production, backward production technology, high production cost, etc., to save silver, increase welding performance, and enhance bonding The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

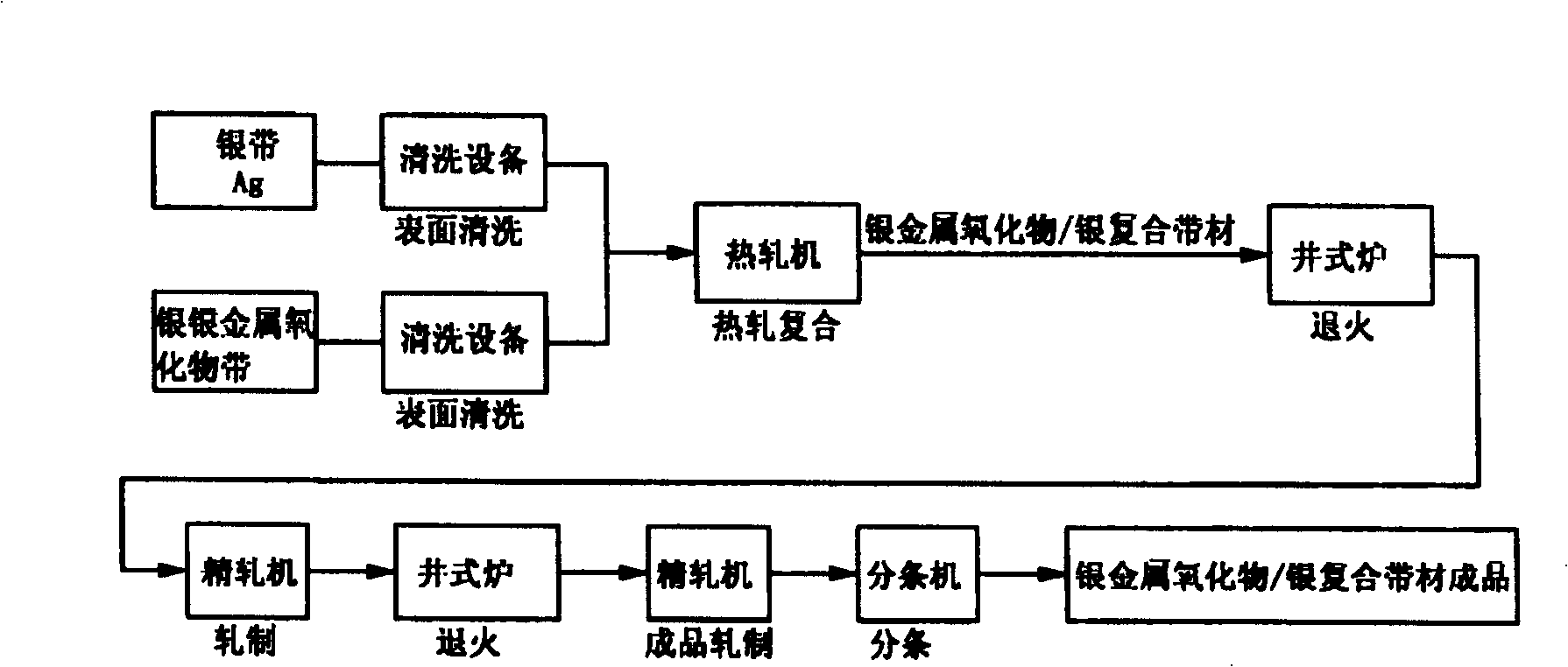

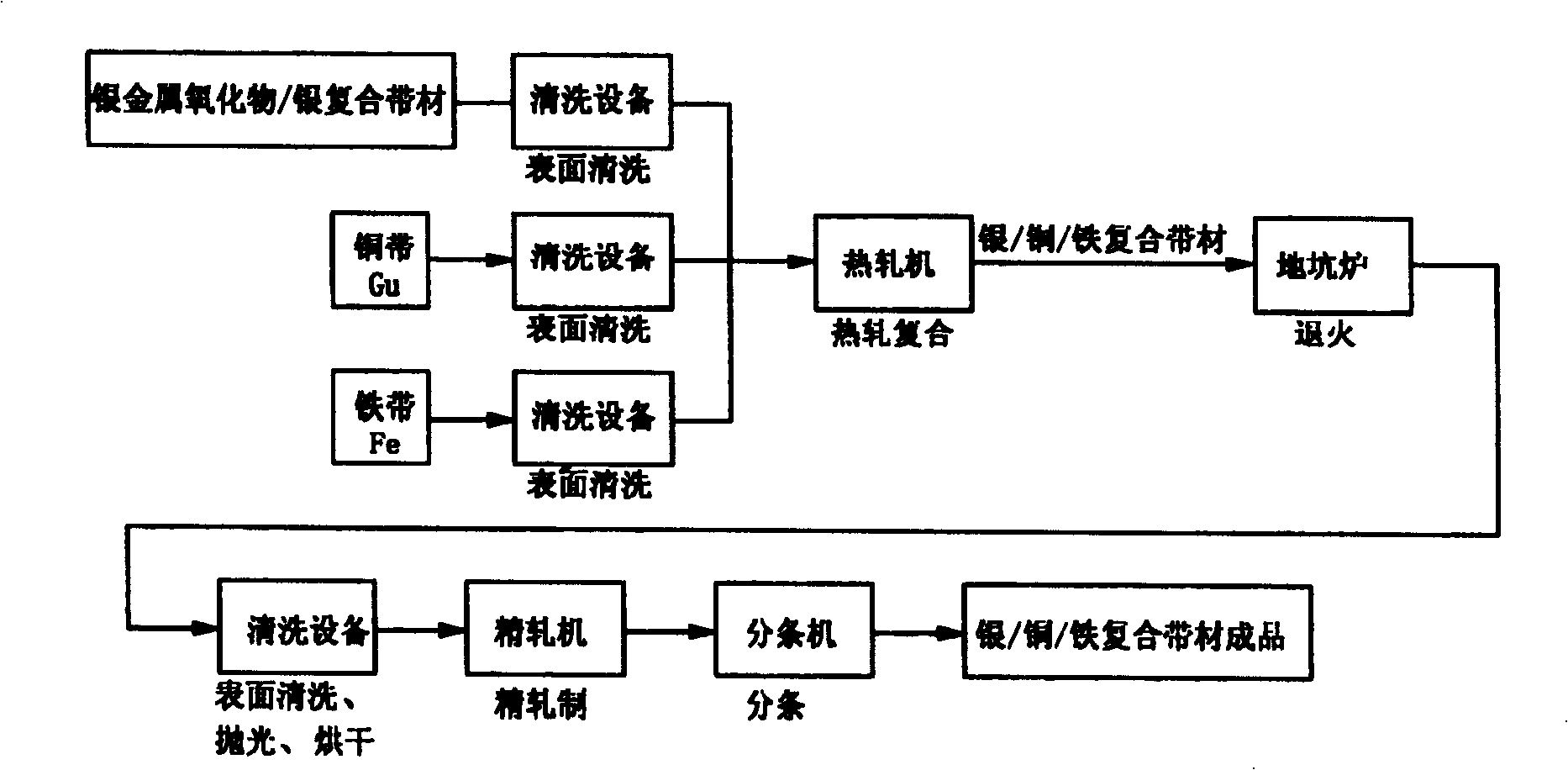

[0016] To further remind the present invention, the following is attached figure 1 , 2 , 3, 4, and 5 are explained in detail.

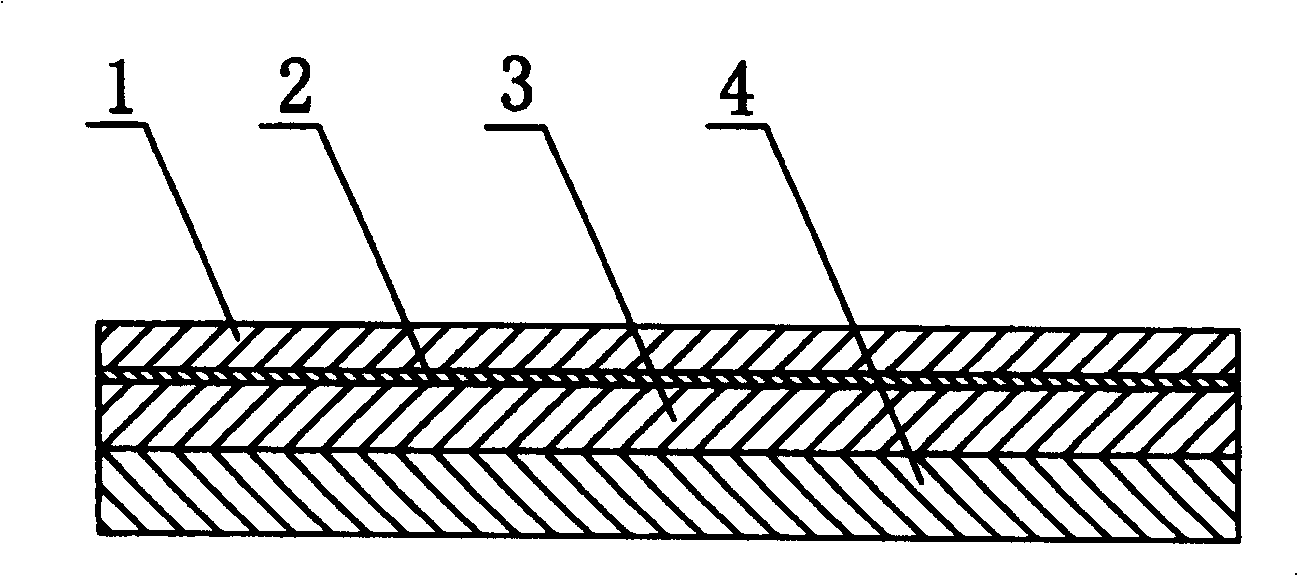

[0017] The silver / copper / iron composite strip produced by the present invention actually has a four-layer structure. From top to bottom, the first layer is silver metal oxide tape 1, and the second layer is a thinner pure silver tape 2 transition layer. , The third layer is copper strip 3, and the fourth layer is iron strip 4. Wherein, the silver metal oxide tape 1 is a tape made of silver metal oxide, and the silver metal oxide includes silver tin oxide indium AgSno2 ino3, silver tin oxide AgSnO2, silver cadmium oxide AgCdO, etc. The copper strip 3 is copper or copper alloy strip, and the process is as follows:

[0018] A. First, clean the surfaces of the silver strip 2 and the silver metal oxide strip 1 to remove the oil and oxides on the surface, and then send the silver strip 2 and the silver metal oxide strip 1 to the hot rolling mill for hot rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com