High-toughness stamping-resistant polyester resin for compounding aluminum-plastic film of lithium battery

A technology of polyester resin and aluminum-plastic film, applied in the direction of adhesives, etc., can solve the problems of compressed profit margins and high prices of imported resins, and achieve good composite fastness and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

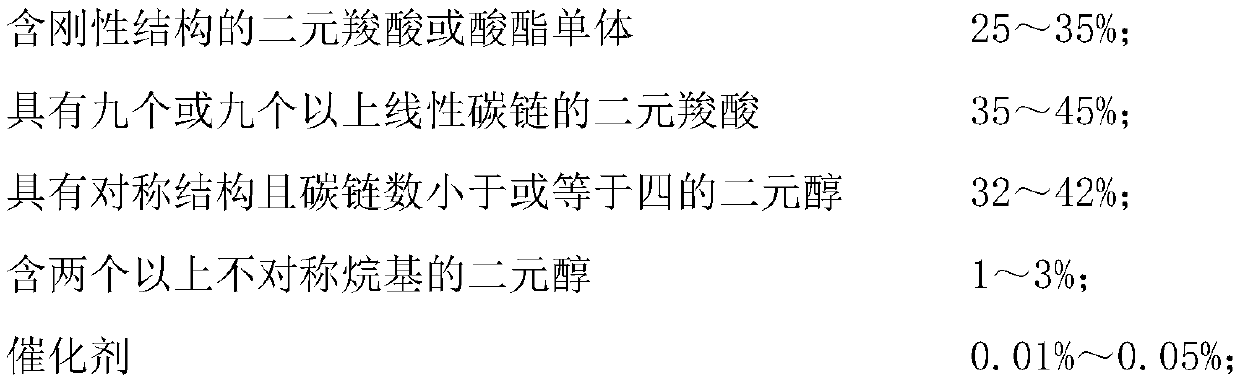

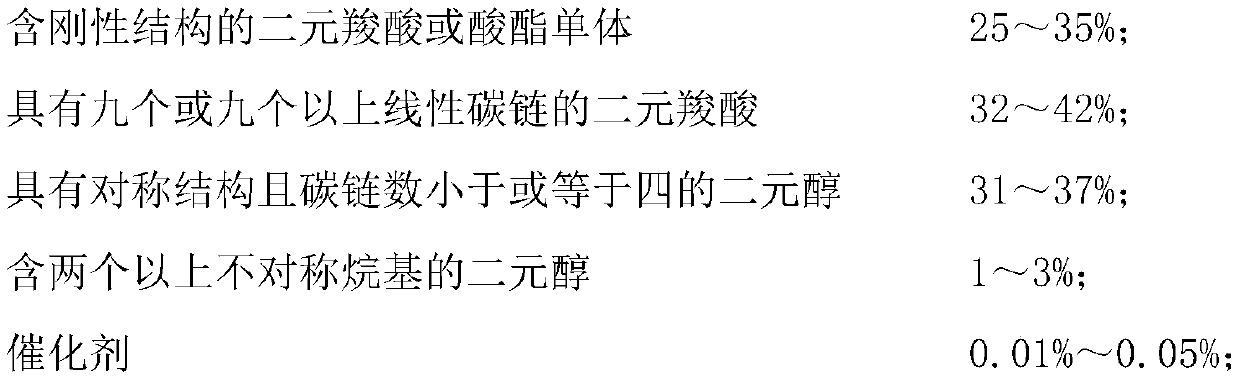

Method used

Image

Examples

Embodiment 1

[0034] This embodiment relates to a high-toughness stamping-resistant polyester resin for lithium battery aluminum-plastic film compounding. The raw materials of the polyester resin include the following components in weight percentage: 16.44% terephthalic acid, isophthalic acid 13.15%, sebacic acid 36.17%, ethylene glycol 32.89%, 2,2,4-trimethyl-1,3-pentanediol 1.32% and dihydroxybutyltin chloride 0.03%.

[0035] Concrete synthesis comprises the following process steps:

[0036] (1) Put 25kg terephthalic acid, 20kg isophthalic acid, 55kg sebacic acid, 50kg ethylene glycol, 2Kg 2,2,4-trimethyl-1,3-pentanediol into the reaction kettle Stir and heat at 130°C. After the material is melted, add 45g of dihydroxybutyl tin chloride, and gradually raise the temperature to 250°C for reaction. When it is measured that the lactonization rate in the kettle is >94%, start vacuuming at a constant temperature of 240°C, and gradually increase the vacuum until the hydroxyl value of the mater...

Embodiment 2

[0069] This embodiment relates to a high-toughness stamping-resistant polyester resin for lithium battery aluminum-plastic film compounding. The raw materials of the polyester resin include the following components in weight percentage: dimethyl terephthalate 13%, m- Phthalic acid 12%, azelaic acid 42%, 1,4-butanediol 31%, 2-methyl-2,4-pentanediol 1.99% and monobutyltin triisooctoate 0.01%.

[0070] Concrete synthesis comprises the following process steps:

[0071] (1) 19.5kg dimethyl terephthalate, 18kg isophthalic acid, 63kg azelaic acid, 46.5kg 1,4-butanediol, 2.99Kg 2-methyl-2,4-pentanediol, Throw it into a reaction kettle and heat it with stirring at a temperature of 120°C. After the material was dissolved, 15 g of tin monobutyl triisooctoate was added, and the temperature was gradually raised to 240° C. for reaction. When it is measured that the lactonization rate in the kettle is >94%, start vacuuming at a constant temperature of 240°C, and gradually increase the vacu...

Embodiment 3

[0076] This embodiment relates to a high-toughness stamping-resistant polyester resin for lithium battery aluminum-plastic film compounding. The raw materials of the polyester resin include the following components in weight percentage: dimethyl terephthalate 35%, nonyl Diacid 32%, Ethylene Glycol 31.95%, 2-Butyl-2-Ethyl-1,3-Propanediol 1%, and Zinc Oxalate 0.05%.

[0077] Concrete synthesis comprises the following process steps:

[0078] (1) Put 52.5kg dimethyl terephthalate, 48kg azelaic acid, 47.93kg ethylene glycol, 1.5Kg 2-butyl-2-ethyl-1,3-propanediol into the reaction kettle at 140°C Stir and heat at temperature. After the material was dissolved, 75g of zinc oxalate was added, and the temperature was gradually raised to 260°C for reaction. When it is measured that the lactonization rate in the kettle is >94%, start vacuuming at a constant temperature of 240°C, and gradually increase the vacuum until the hydroxyl value of the material in the kettle is 46±4mgKOH / g.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com