A high-toughness stamping-resistant polyester resin for lithium battery aluminum-plastic film composite

A technology of polyester resin and aluminum-plastic film, applied in the direction of adhesives, etc., can solve the problems of high imported resin prices and compressed profit margins, and achieve good composite fastness and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

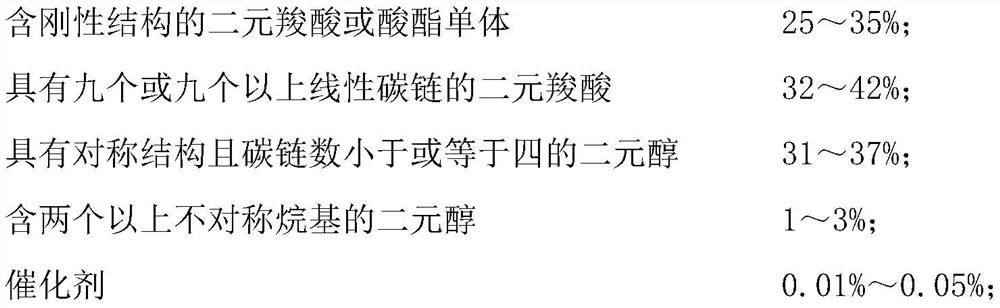

Method used

Image

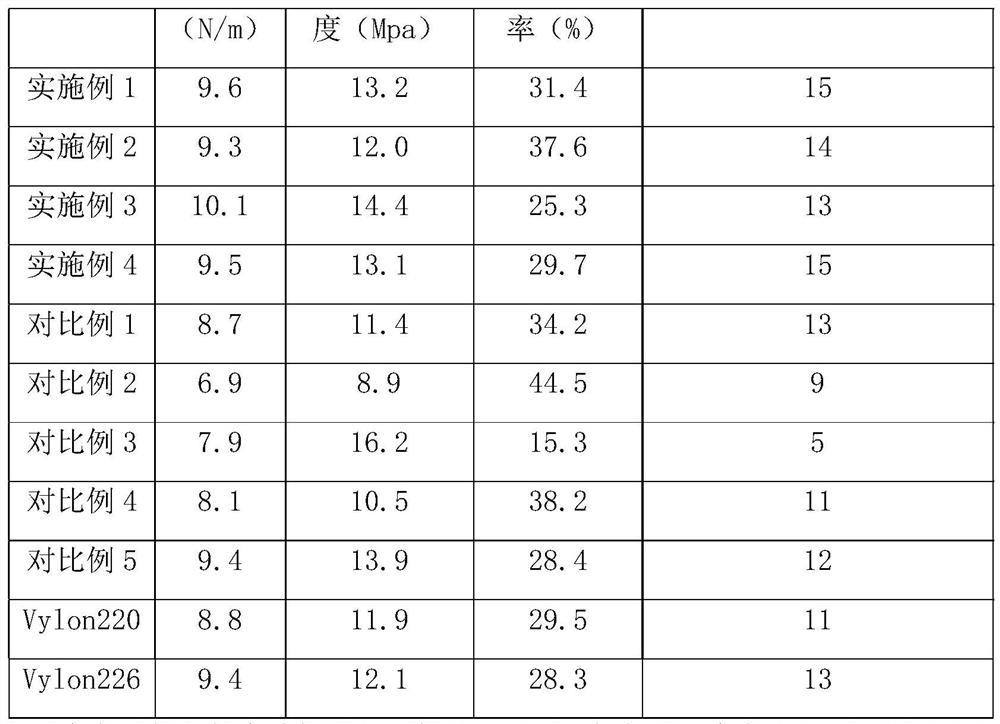

Examples

Embodiment 1

[0034] This embodiment relates to a high-toughness stamping-resistant polyester resin for lithium battery aluminum-plastic film compounding. The raw materials of the polyester resin include the following components in weight percentage: 16.44% terephthalic acid, isophthalic acid 13.15%, sebacic acid 36.17%, ethylene glycol 32.89%, 2,2,4-trimethyl-1,3-pentanediol 1.32% and dihydroxybutyltin chloride 0.03%.

[0035] Concrete synthesis comprises the following process steps:

[0036] (1) Put 25kg terephthalic acid, 20kg isophthalic acid, 55kg sebacic acid, 50kg ethylene glycol, 2Kg 2,2,4-trimethyl-1,3-pentanediol into the reaction kettle Stir and heat at 130°C. After the material is melted, add 45g of dihydroxybutyl tin chloride, and gradually raise the temperature to 250°C for reaction. When it is measured that the lactonization rate in the kettle is >94%, start vacuuming at a constant temperature of 240°C, and gradually increase the vacuum until the hydroxyl value of the mater...

Embodiment 2

[0069] This embodiment relates to a high-toughness stamping-resistant polyester resin for lithium battery aluminum-plastic film compounding. The raw materials of the polyester resin include the following components in weight percentage: dimethyl terephthalate 13%, m- Phthalic acid 12%, azelaic acid 42%, 1,4-butanediol 31%, 2-methyl-2,4-pentanediol 1.99% and monobutyltin triisooctoate 0.01%.

[0070] Concrete synthesis comprises the following process steps:

[0071] (1) 19.5kg dimethyl terephthalate, 18kg isophthalic acid, 63kg azelaic acid, 46.5kg 1,4-butanediol, 2.99Kg 2-methyl-2,4-pentanediol, Throw it into a reaction kettle and heat it with stirring at a temperature of 120°C. After the material was dissolved, 15 g of tin monobutyl triisooctoate was added, and the temperature was gradually raised to 240° C. for reaction. When it is measured that the lactonization rate in the kettle is >94%, start vacuuming at a constant temperature of 240°C, and gradually increase the vacu...

Embodiment 3

[0076] This embodiment relates to a high-toughness stamping-resistant polyester resin for lithium battery aluminum-plastic film compounding. The raw materials of the polyester resin include the following components in weight percentage: dimethyl terephthalate 35%, nonyl Diacid 32%, Ethylene Glycol 31.95%, 2-Butyl-2-Ethyl-1,3-Propanediol 1%, and Zinc Oxalate 0.05%.

[0077] Concrete synthesis comprises the following process steps:

[0078] (1) Put 52.5kg dimethyl terephthalate, 48kg azelaic acid, 47.93kg ethylene glycol, 1.5Kg 2-butyl-2-ethyl-1,3-propanediol into the reaction kettle at 140°C Stir and heat at temperature. After the material was dissolved, 75g of zinc oxalate was added, and the temperature was gradually raised to 260°C for reaction. When it is measured that the lactonization rate in the kettle is >94%, start vacuuming at a constant temperature of 240°C, and gradually increase the vacuum until the hydroxyl value of the material in the kettle is 46±4mgKOH / g.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com