BOPET film for metal compounding and preparation method thereof

A metal composite and film technology, applied in the field of plastic film manufacturing, can solve the problems of lack of in-depth research on BOPET film, immature products and application markets, etc., to improve can-making efficiency, good composite fastness, and wide application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

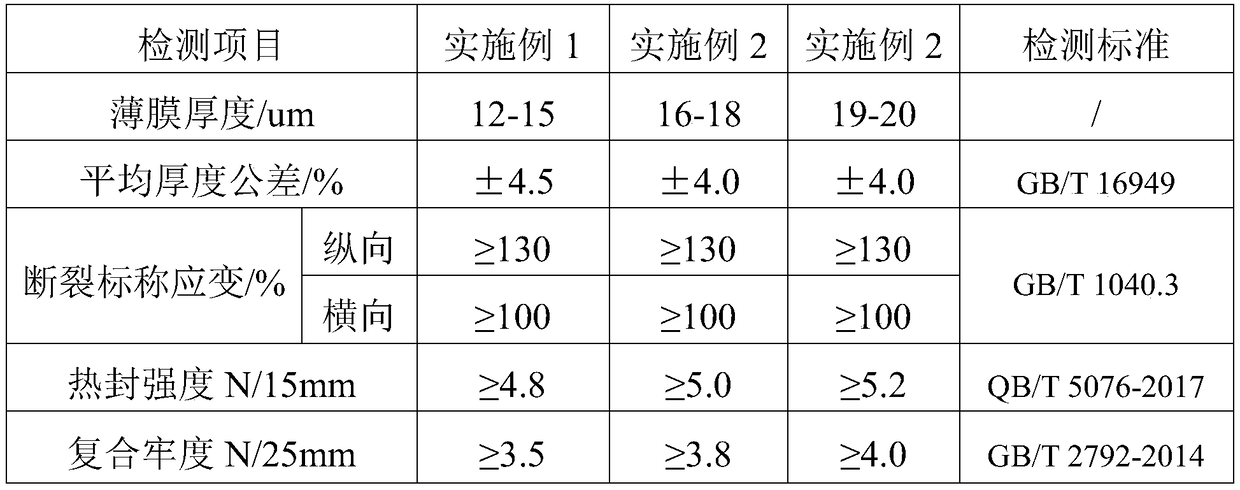

Examples

Embodiment 1

[0022] A BOPET film for metal composites, consisting of an upper surface layer, a core layer and a lower surface layer, the core layer is composed of the following components: 60% PET polyester chips, 20% PBT polyester chips and 20% neopentyl glycol (NPG) copolymerized modified PET polyester chips; the upper surface layer is an anti-adhesive layer, which is composed of 40% bottle-grade PET polyester chips and 60% PET polyester anti-adhesive masterbatch; the lower surface layer is a functional layer, composed of 100% Methyl methacrylate (MMA) graft copolymerized modified PETG heat-sealed chips (PETG heat-sealed chips are PETG polyester chips with heat-sealed properties).

[0023] Among them, the thickness of the upper surface layer accounts for 10%-12.5% of the total thickness of the film, the thickness of the lower surface layer accounts for 16.7%-21%, and the thickness of the core layer accounts for 66.5%-73.3%.

[0024] The preparation method of above-mentioned a kind of m...

Embodiment 2

[0034] A BOPET film for metal composite, consisting of an upper surface layer, a core layer and a lower surface layer, the core layer is composed of the following components: 70% PET polyester chips, 15% PBT polyester chips and 15% neopentyl glycol (NPG) copolymerized modified PET polyester chips; the upper surface layer is an anti-adhesive layer, which is composed of 50% bottle-grade PET polyester chips and 50% PET polyester anti-adhesive masterbatch; the lower surface layer is a functional layer, composed of 100% Methyl methacrylate (MMA) graft copolymerization modified PETG heat-sealed chip composition.

[0035] Among them, the thickness of the upper surface layer accounts for 8.3%-9.4% of the total thickness of the film, the thickness of the lower surface layer accounts for 13.9%-15.6%, and the thickness of the core layer accounts for 75%-77.8%.

[0036] The preparation method of above-mentioned a kind of metal composite BOPET thin film, comprises the following steps:

[...

Embodiment 3

[0046]A BOPET film for metal composites, consisting of an upper surface layer, a core layer and a lower surface layer, the core layer is composed of the following components: 80% PET polyester chips, 10% PBT polyester chips and 10% neopentyl glycol (NPG) copolymerized modified PET polyester chips; the upper surface layer is an anti-adhesive layer, composed of 60% bottle-grade PET polyester chips and 40% PET polyester anti-adhesive masterbatch; the lower surface layer is a functional layer, composed of 100% Methyl methacrylate (MMA) graft copolymerization modified PETG heat-sealed chip composition.

[0047] Among them, the thickness of the upper surface layer accounts for 7.5%-7.9% of the total thickness of the film, the thickness of the lower surface layer accounts for 12.5%-13.2%, and the thickness of the core layer accounts for 78.9%-80%.

[0048] The preparation method of above-mentioned a kind of metal composite BOPET thin film, comprises the following steps:

[0049] 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com