A kind of manufacturing equipment and manufacturing method of composite silver belt

A composite belt and silver belt technology, applied in the silver field, can solve the problems of increasing work efficiency and achieve the effects of increasing work efficiency, high bonding strength, and long strip length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

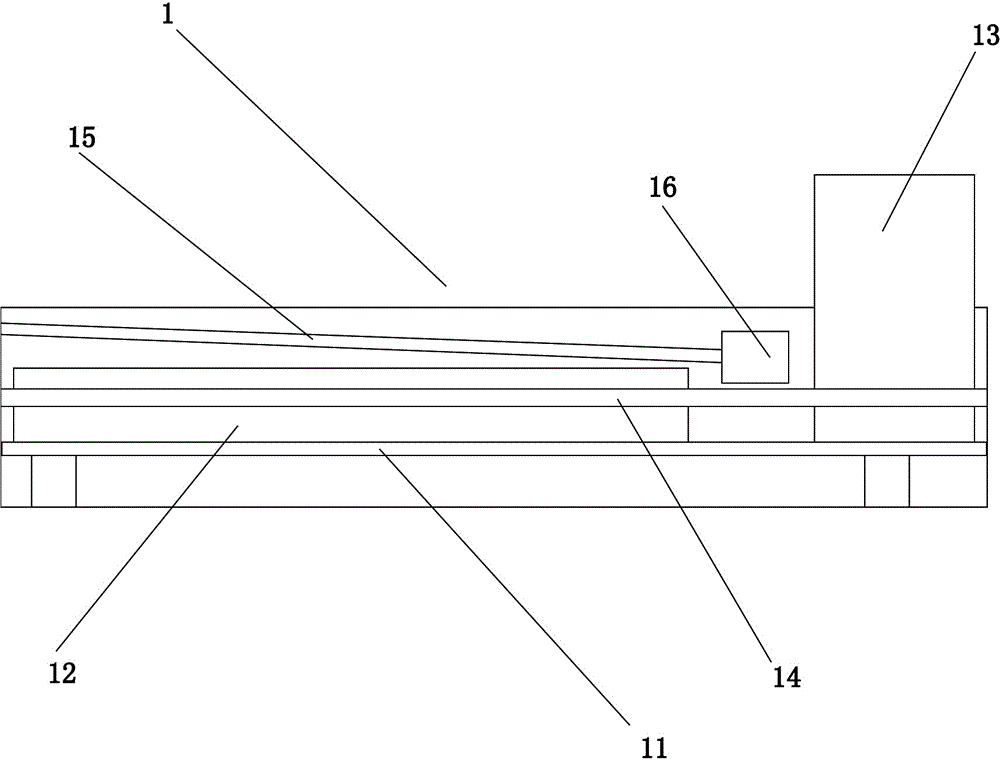

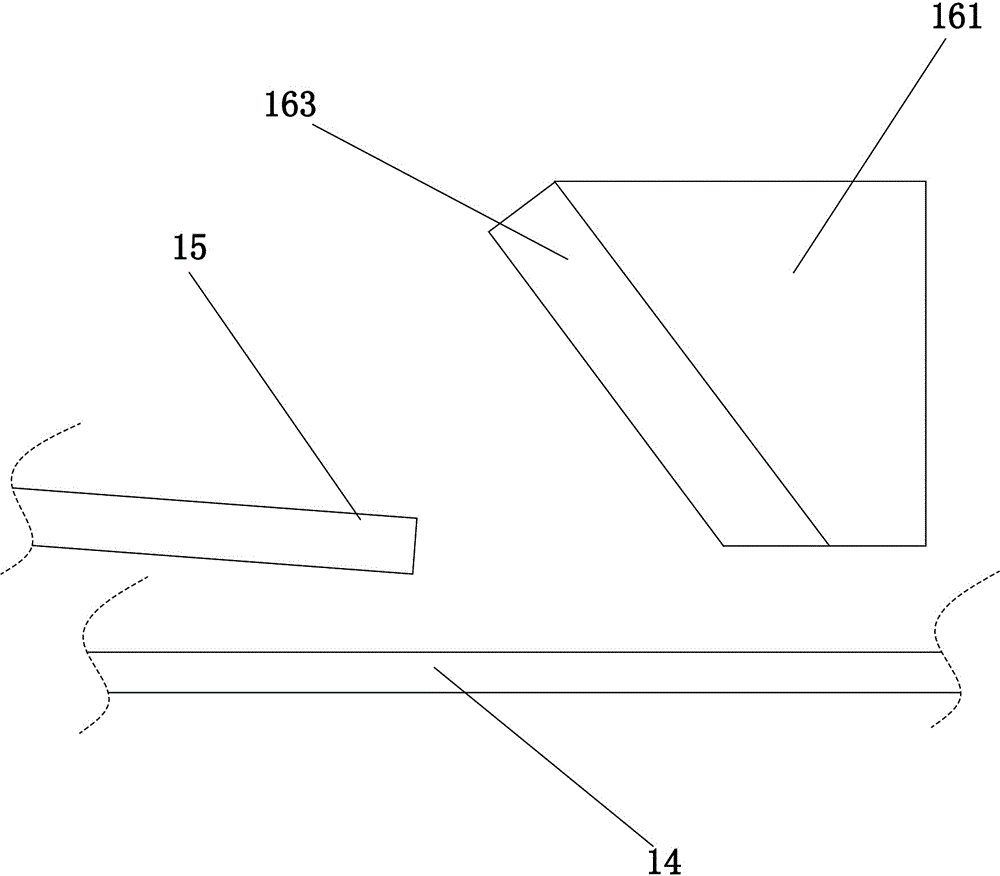

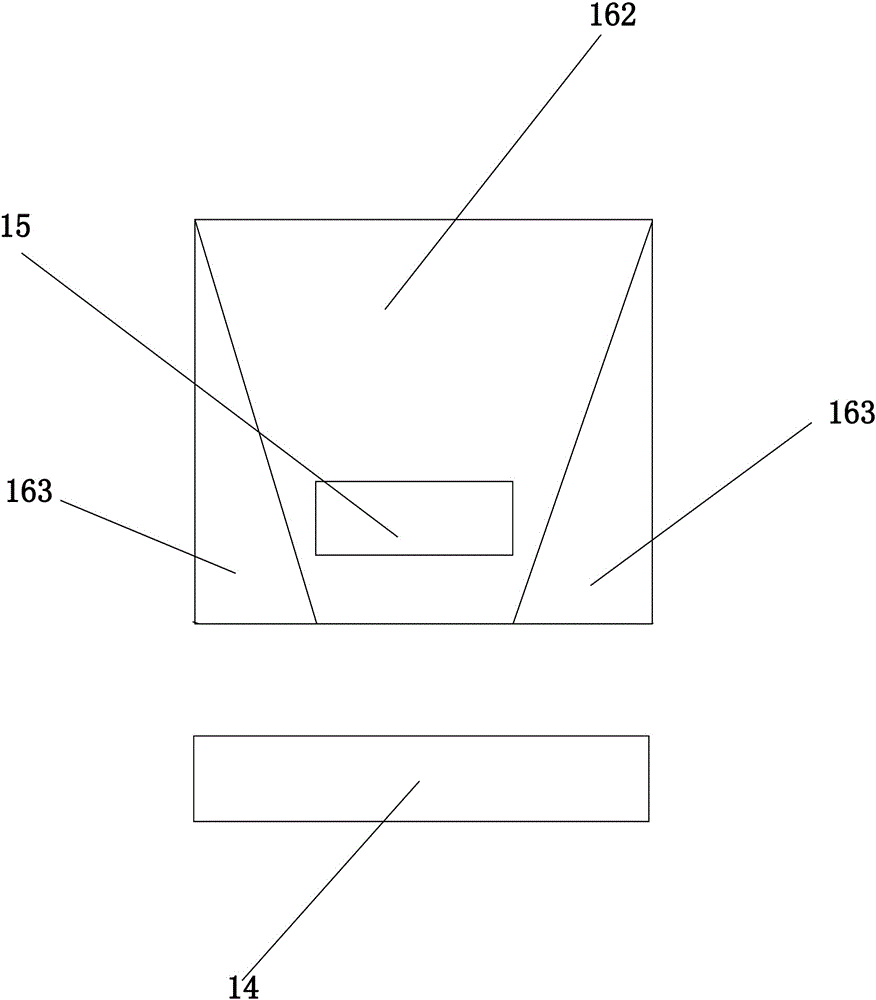

[0020] Example 1: Step A, clean the surface of the copper strip and the silver metal oxide strip to remove the oil and impurities on the surface, and then open the groove matching the silver metal oxide strip on the copper strip, and the groove on the copper strip The width is equal to the width of the silver metal oxide band, and the depth of the groove is 150% of the height of the silver metal oxide band. Finally, the copper strip and the metal oxide strip are polished. Step B: Put the copper strip on the conveying device 14 in the hot compound rolling mill 1, and heat it in a heating furnace at a heating temperature of 550°C and a belt running speed of 1.5m / min. The heating furnace is provided with a protective device Protective atmosphere, the protective atmosphere is pure nitrogen or pure hydrogen, the protective atmosphere flow is 2m 3 / h; Then the silver metal oxide strip is fed into the groove on the copper strip through the unloading device 16 on the B conveying device...

Embodiment 2

[0021] Example 2: Step A, clean the surface of the copper strip and the silver metal oxide strip to remove the oil and impurities on the surface, and then open the groove matching the silver metal oxide strip on the copper strip, and the groove on the copper strip The width is equal to the width of the silver metal oxide band, and the depth of the groove is 125% of the height of the silver metal oxide band. Finally, the copper strip and the metal oxide strip are polished. Step B: Put the copper strip on the conveying device 14 in the hot compound rolling mill 1, and heat it in a heating furnace. The heating temperature is 720°C, the belt travel speed is 3.0m / min, and the heating furnace is provided with a protective function. Protective atmosphere, protective atmosphere is pure nitrogen or pure hydrogen, protective atmosphere flow rate is 12m 3 / h; Then the silver metal oxide strip is fed into the groove on the copper strip through the unloading device 16 on the B conveying dev...

Embodiment 3

[0022] Embodiment 3: Step A, clean the surface of copper strip and silver metal oxide strip to remove the oil and impurities on the surface, and then open the groove matching the silver metal oxide strip on the copper strip, and the groove on the copper strip The width is equal to the width of the silver metal oxide band, and the depth of the groove is 125% of the height of the silver metal oxide band. Finally, the copper strip and the metal oxide strip are polished. Step B: Put the copper strip on the conveying device 14 in the hot compound rolling mill 1, and heat it in a heating furnace at a heating temperature of 600°C and a belt running speed of 2.0m / min. The heating furnace is provided with a protective function Protective atmosphere, protective atmosphere is pure nitrogen or pure hydrogen, protective atmosphere flow rate is 6.5m 3 / h; Then the silver metal oxide strip is fed into the groove on the copper strip through the unloading device 16 on the B conveying device 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com