Patents

Literature

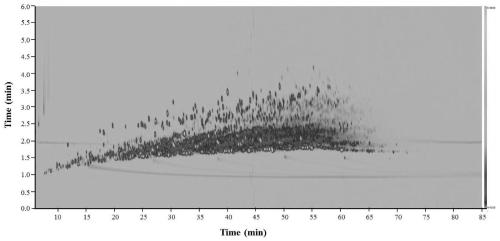

35results about How to "Reduce vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

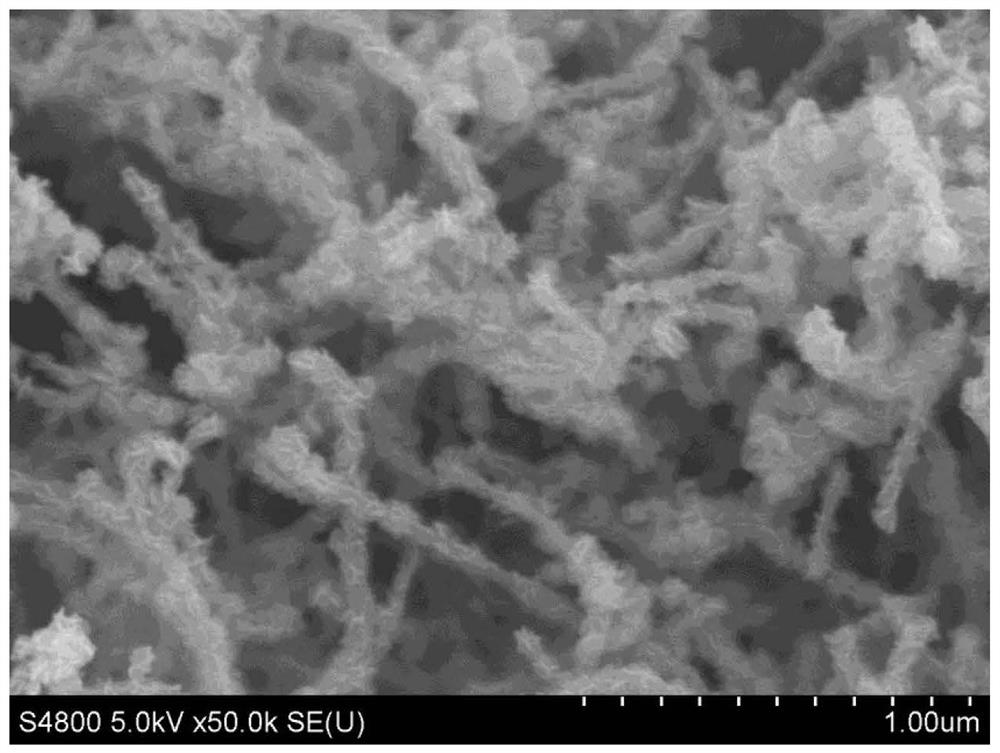

Conductive ink of ultra-low haze silver nanowire film and preparation method and application thereof

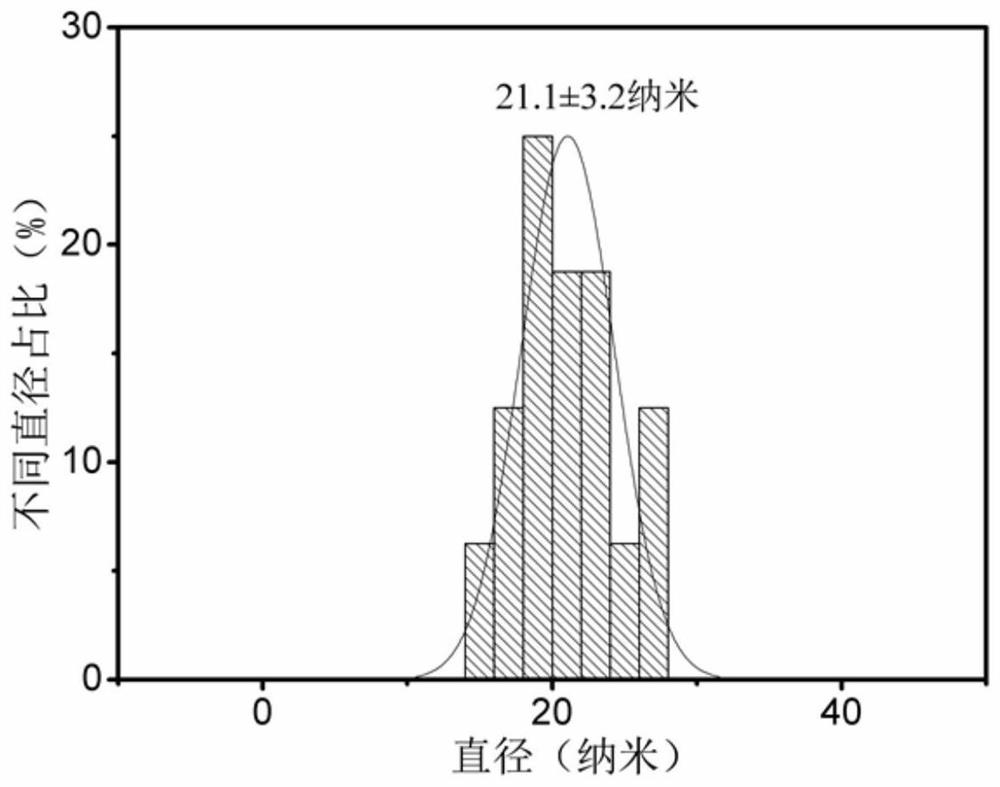

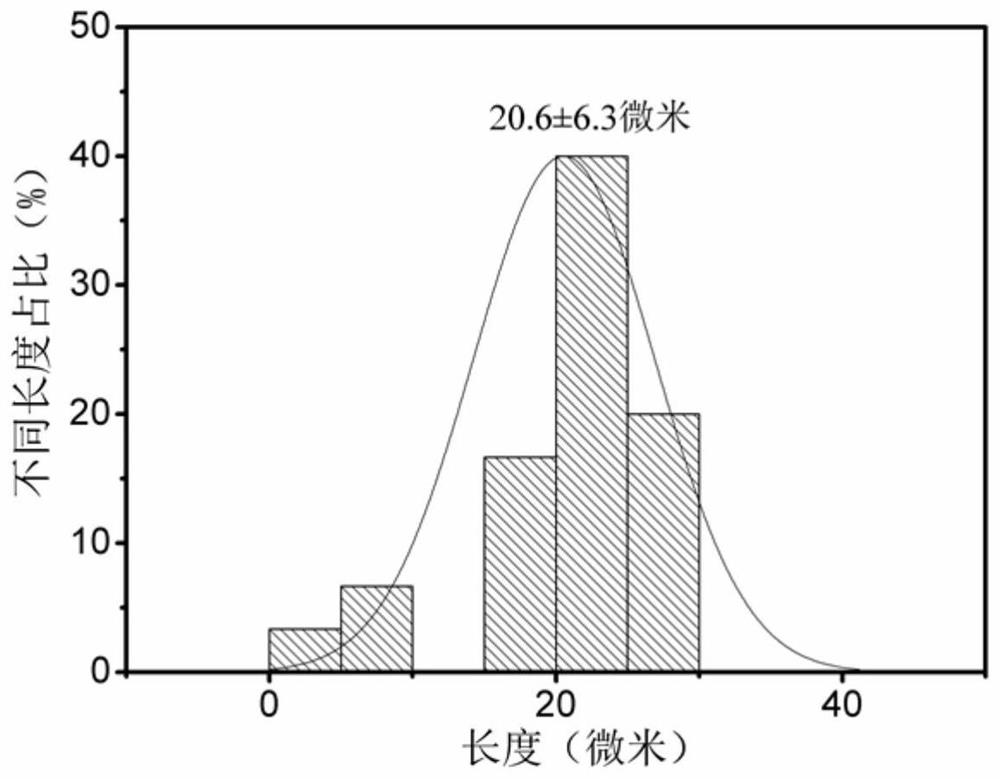

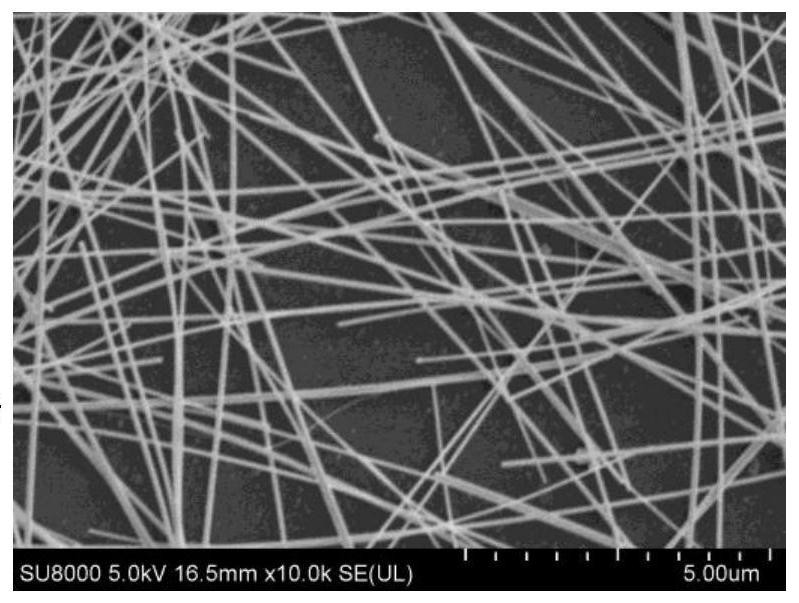

ActiveCN110128883ADimensions required to attenuate scatteringGuaranteed CompatibilityInksPerformance indexSilver nanowires

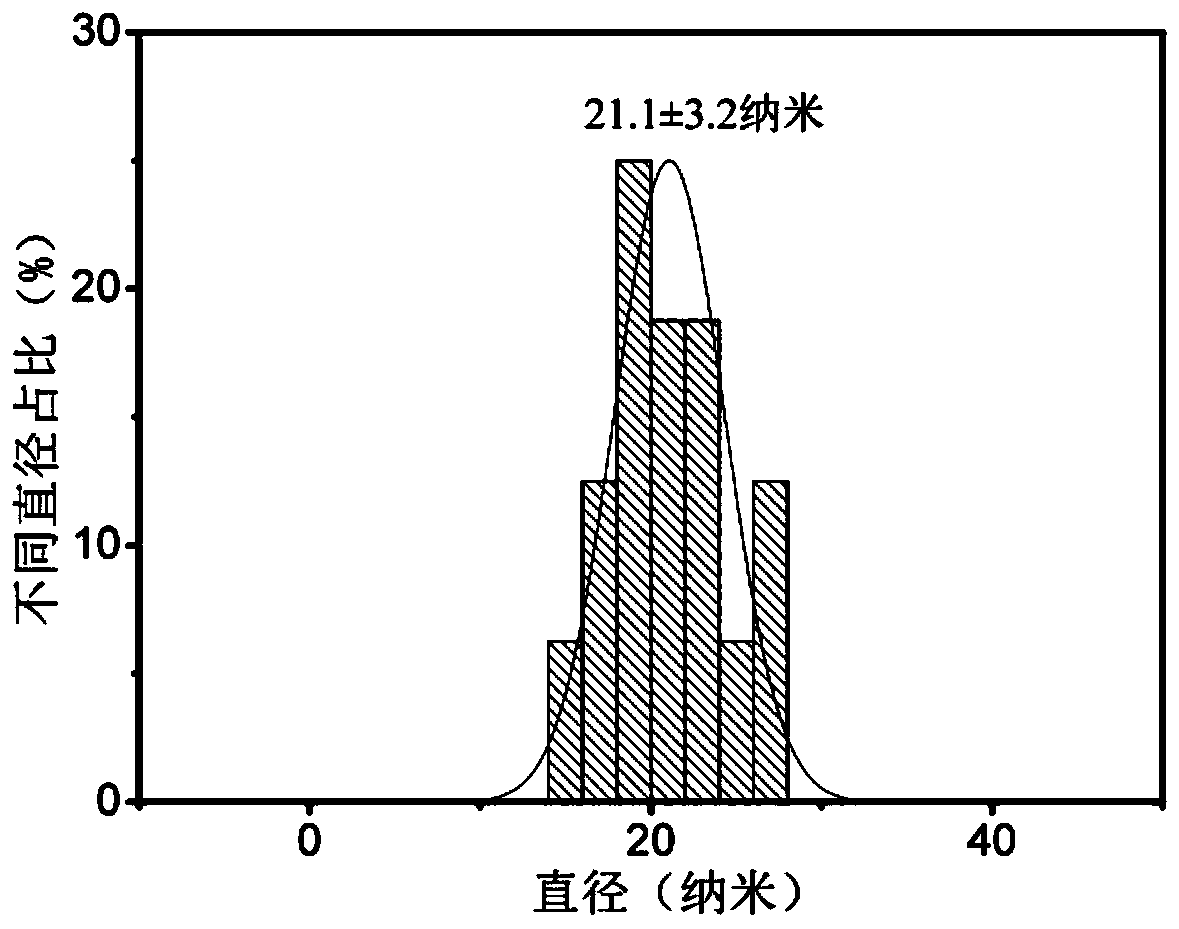

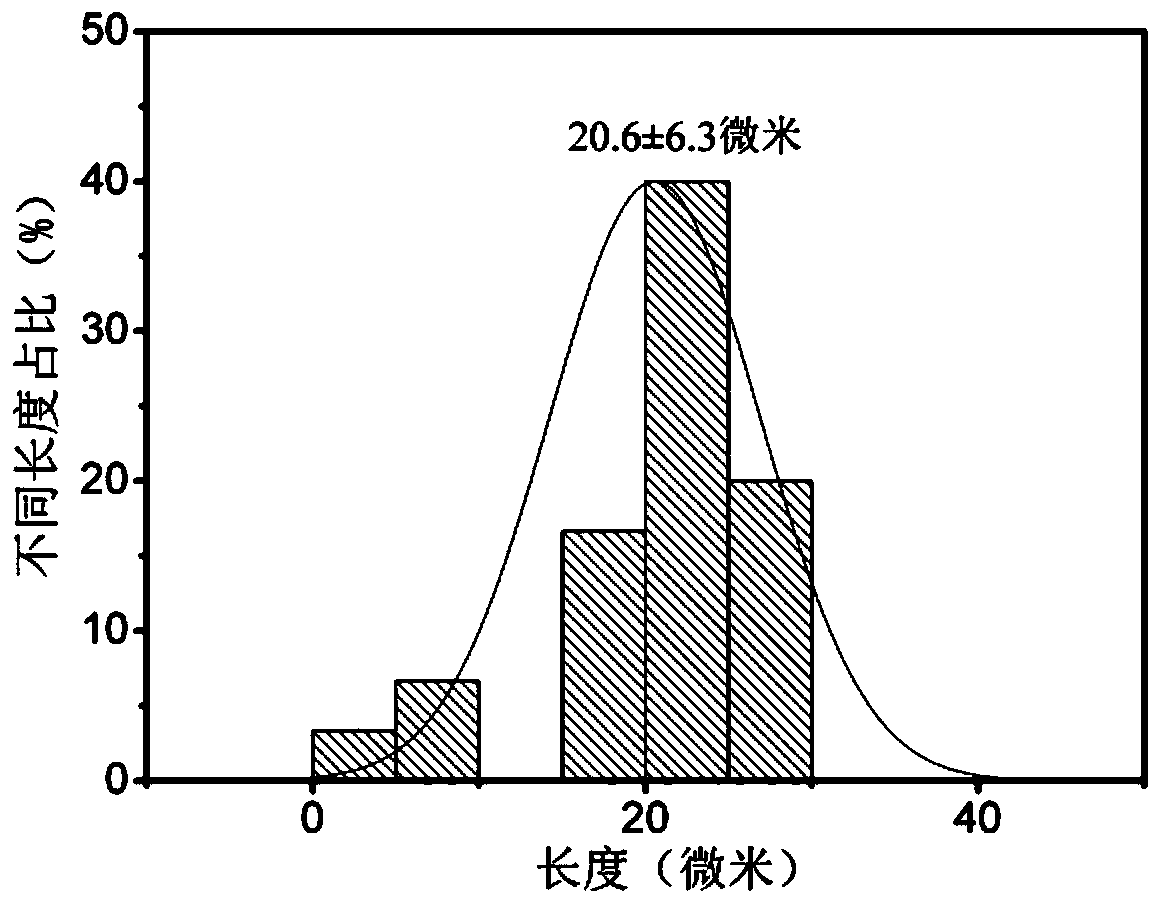

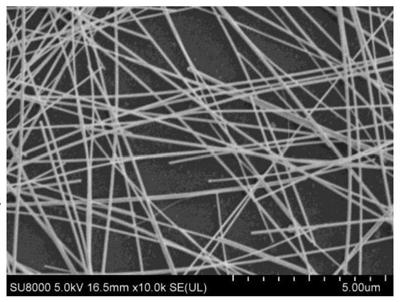

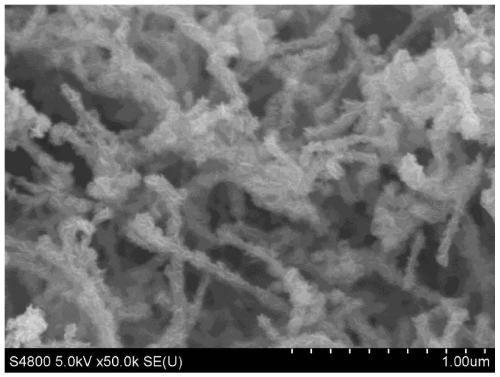

The invention discloses a conductive ink of ultra-low haze silver nanowire film and a preparation method and an application thereof. The conductive ink is used to produce an ultra-low haze silver nanowire film. The silver nanowires obtained in the preparation method have a diameter of 20 nm and an length-diameter ratio of 1000. The optical ink produced by the conductive ink has an optical transmittance of more than 95% and a haze of less than 0.5%. The conductive ink in the present invention is formed in one time to achieve the photoelectric performance index of the film required for the high-definition screen. Silica sol is added to the conductive ink to tightly fix the silver nanowires on the substrate and form an aging protective layer on the surface thereof. The film has a surface hardness of 3H and is scratch resistant. The film has excellent environmental stability and anti-aging effect. The preparation method of conductive ink is environmentally friendly, non-polluting, and doesnot require expensive equipment such as high temperature and vacuum, and is easy to operate, and is advantageous for large-scale and low-cost promotion.

Owner:NANJING SILVERNANO NEW MATERIALS TECH CO LTD

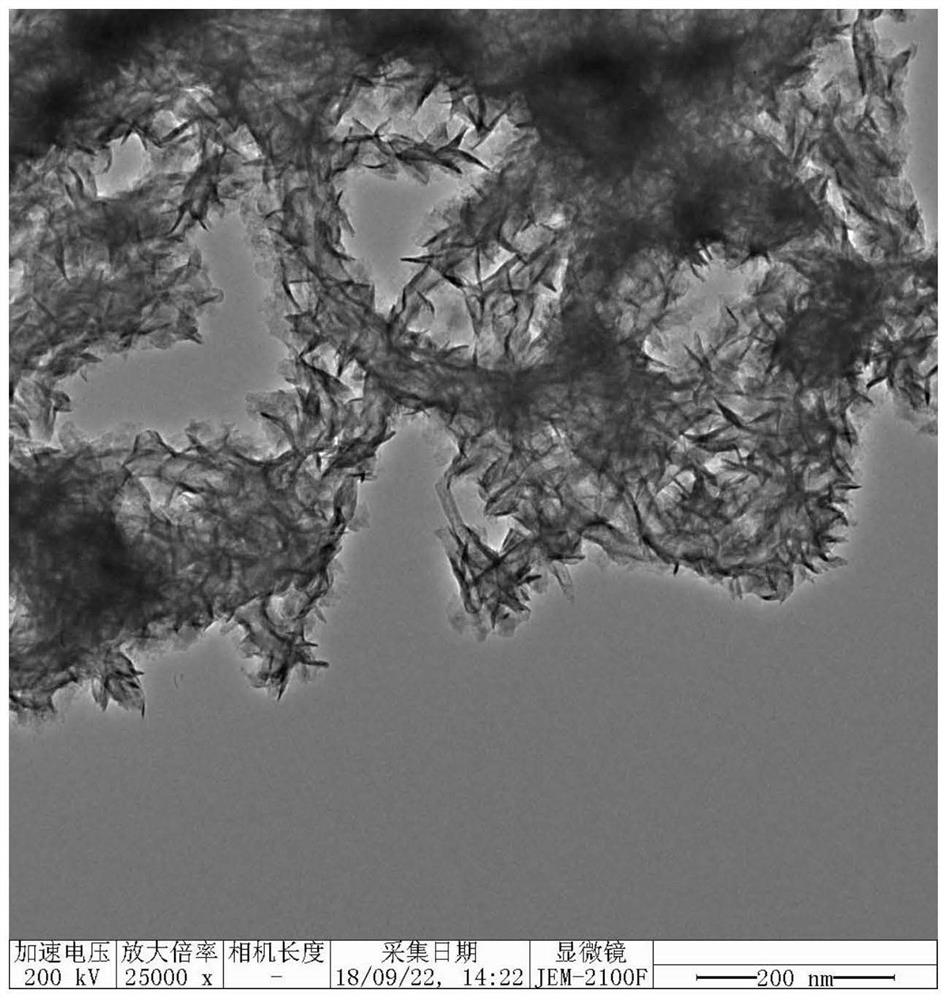

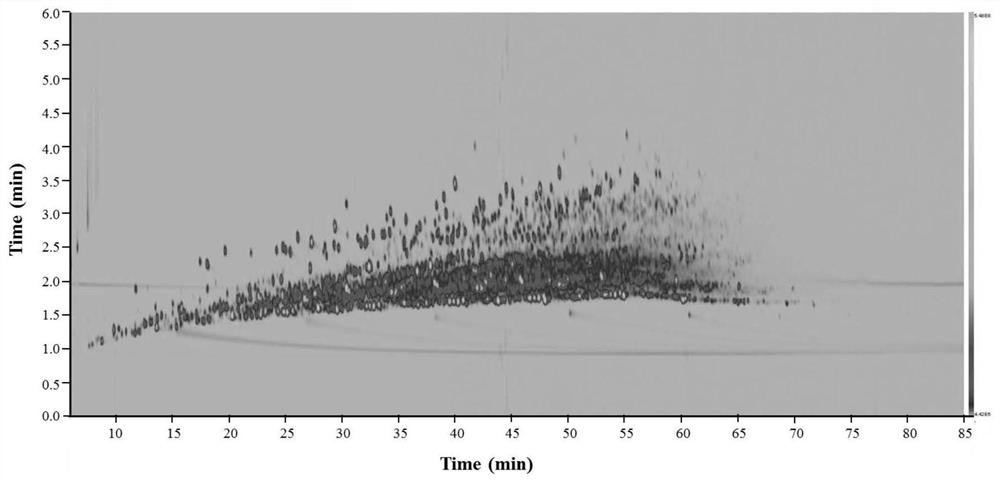

Non-precious metal supported catalyst, preparation method and use thereof

ActiveCN109985641AReduce usageEfficient use ofPhysical/chemical process catalystsHydrocarbon oils treatmentHydrodesulfurizationActive component

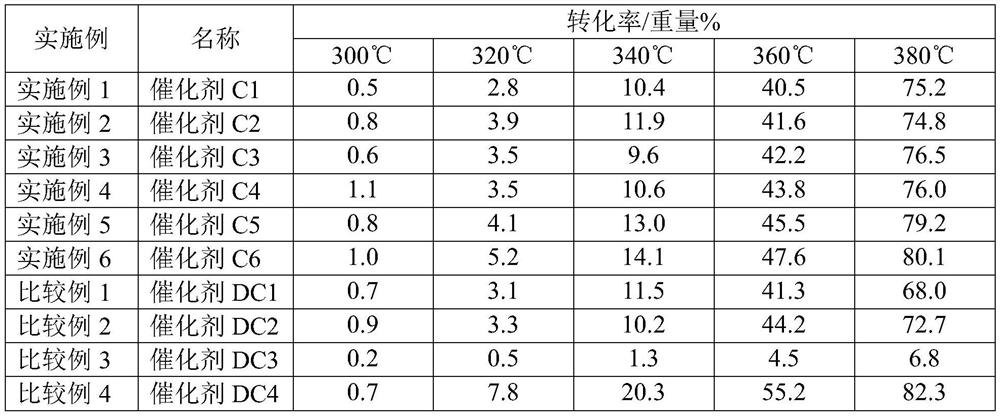

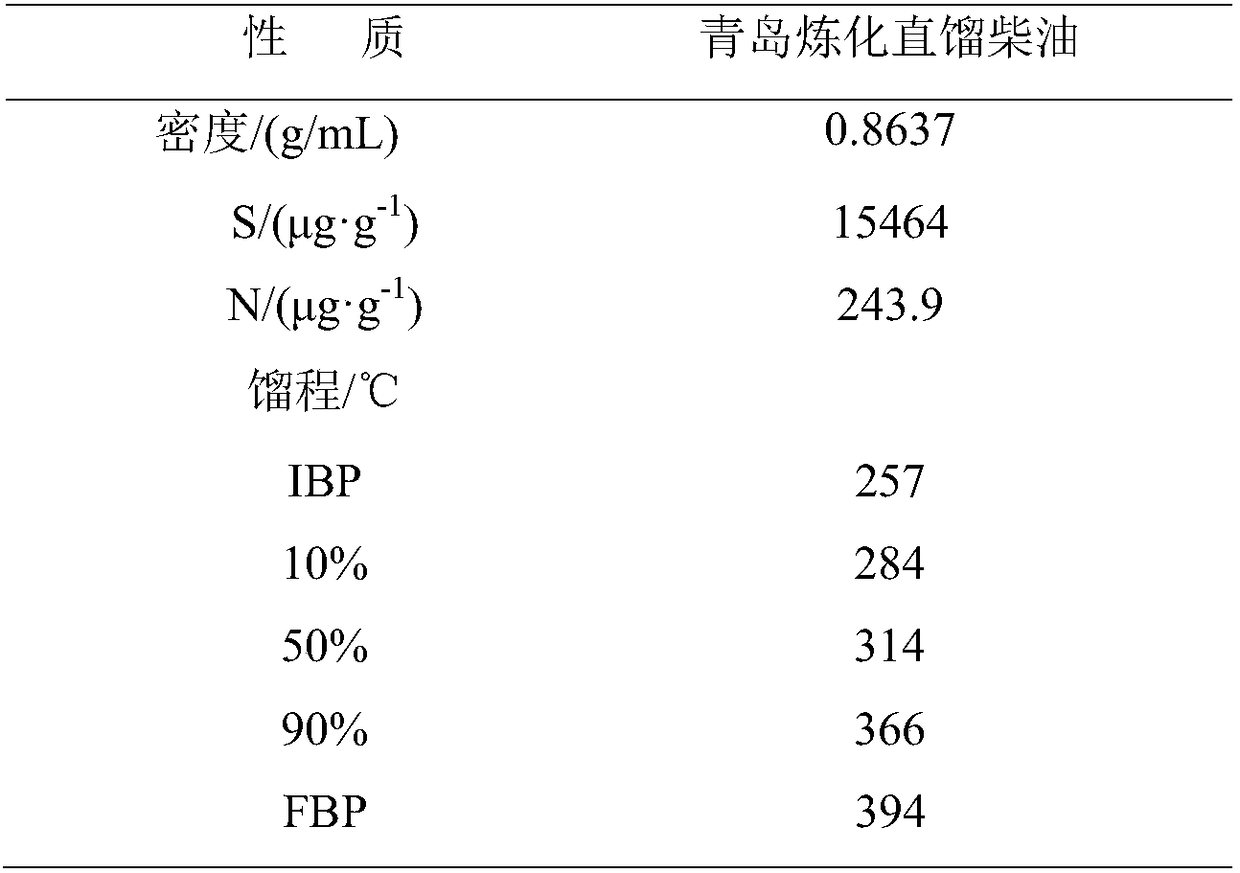

The present invention discloses a non-precious metal sulfide type supported catalyst. In the catalyst, at least one of molybdenum or tungsten, and at least one of cobalt or nickel are supported on a carrier in a wholly or partially sulfide state; the carrier comprises a carbon material; the mass of at least one of molybdenum or tungsten is 10 to 50% of the total mass of the catalyst, the mass of at least one of cobalt or nickel is 1 to 20% of the total mass of the catalyst, and the mass of the carrier is 1 to 20% of the total mass of the catalyst. The invention also discloses a preparation method and use of the catalyst. Compared with the prior art, the catalyst of the invention has high active component content, more active sites and exposed sites, and active components are uniformly dispersed on the carbon material, and when the catalyst is used for preparing high-heat-stability fuel, the catalyst has high hydrodesulfurization activity and aromatic saturation activity.

Owner:TIANJIN UNIV

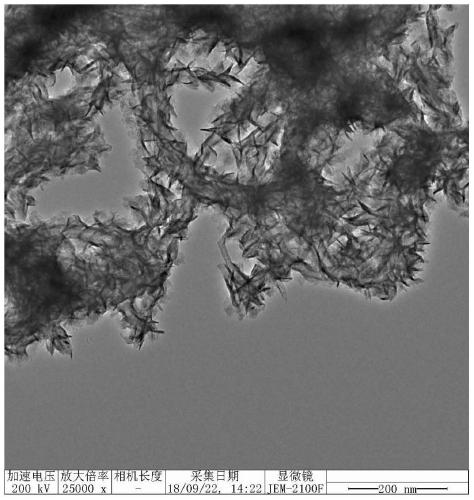

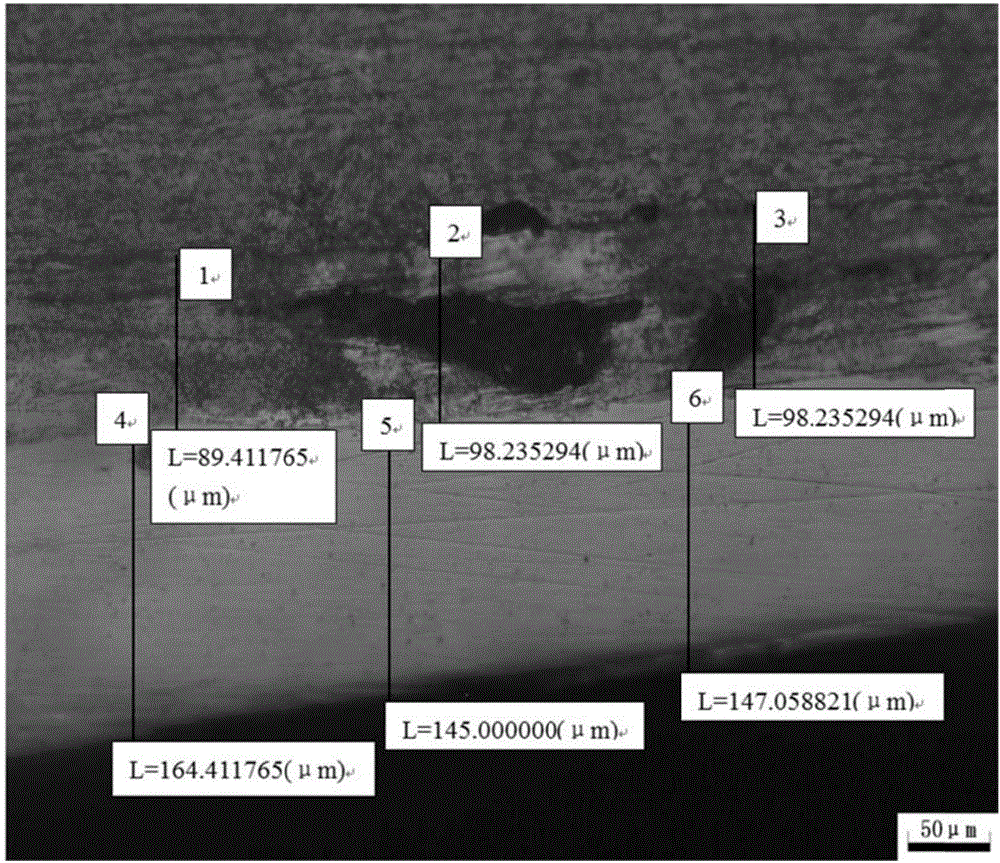

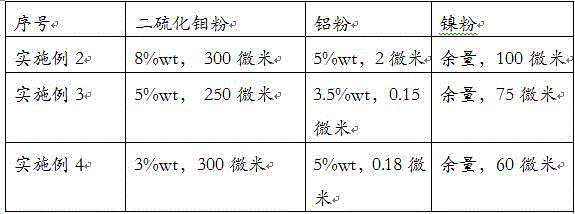

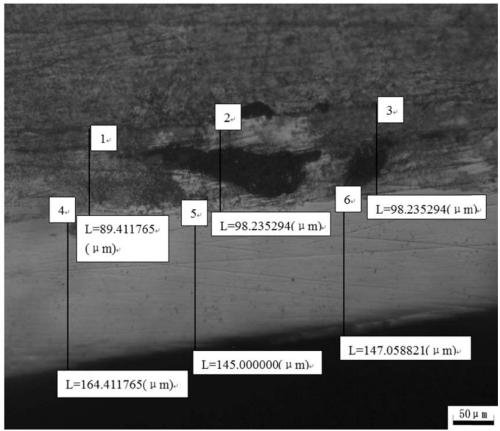

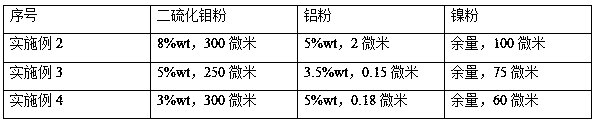

Nickel-based molybdenum disulfide powder for laser cladding and preparing method and application method of nickel-based molybdenum disulfide powder

ActiveCN106435580AGrain refinementReduce vulcanizationTransportation and packagingMetal-working apparatusPhysical chemistryAluminium powder

The invention discloses nickel-based molybdenum disulfide powder for laser cladding and a preparing method and an application method of the nickel-based molybdenum disulfide powder. The nickel-based molybdenum disulfide powder comprises, 3%wt-8%wt of molybdenum disulfide powder with the granularity being 0.1-2 microns, 2%wt-5%wt of aluminum powder with the granularity being 200-300 microns, and the balance nickel powder with the granularity being 50-100 microns. In the laser cladding process of the nickel-based molybdenum disulfide powder, heat decomposition of the molybdenum disulfide is effectively controlled, then the vulcanization action on an obtained cladding layer through decomposition of the molybdenum disulfide is reduced, and the anti-oxidization performance of the cladding layer is improved.

Owner:FUZHOU UNIV

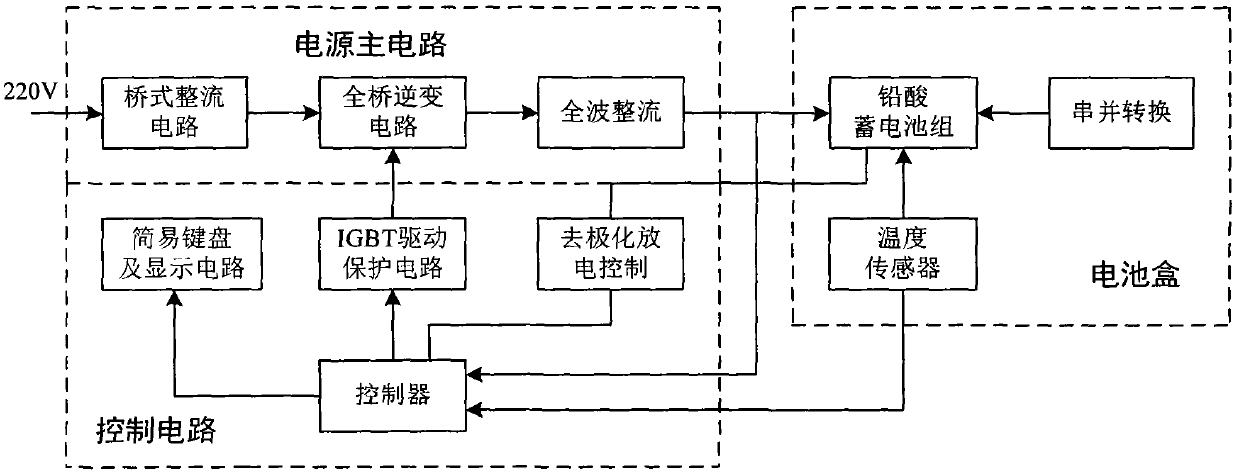

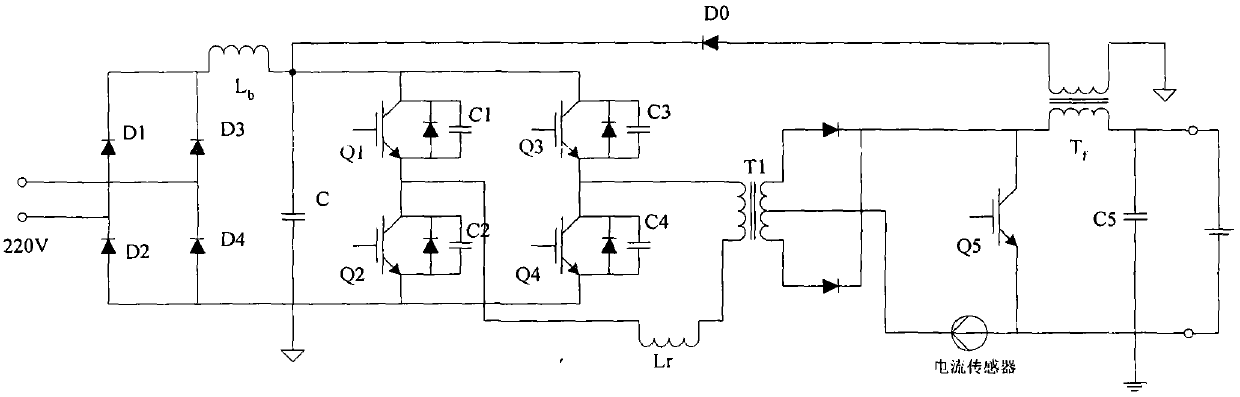

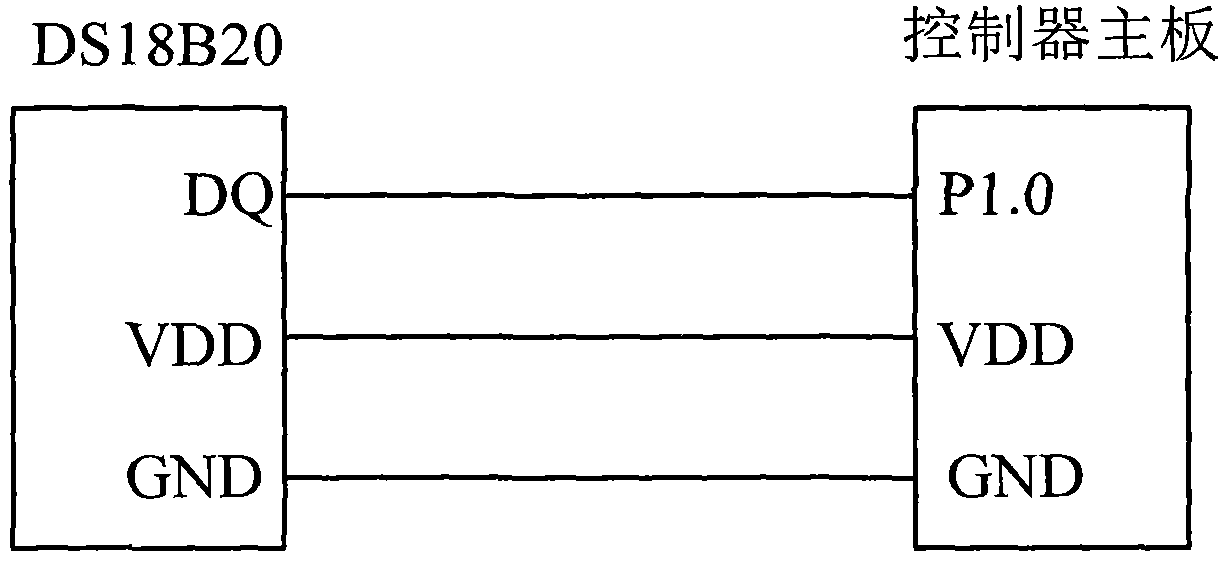

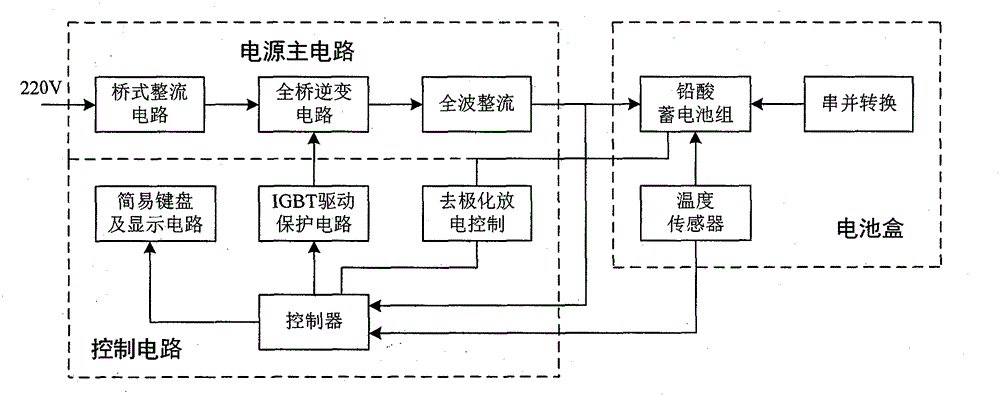

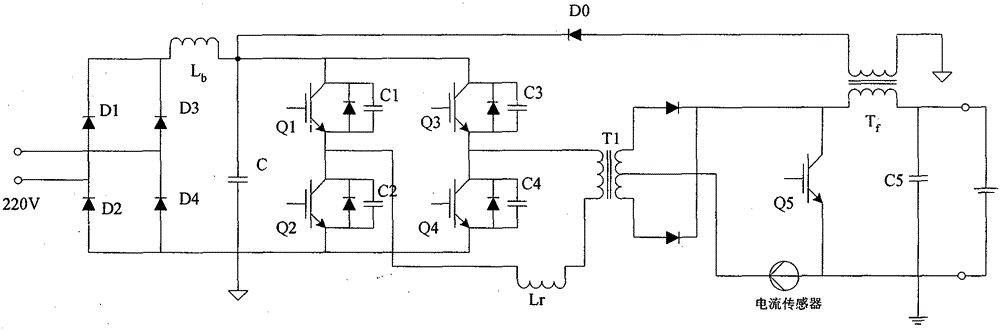

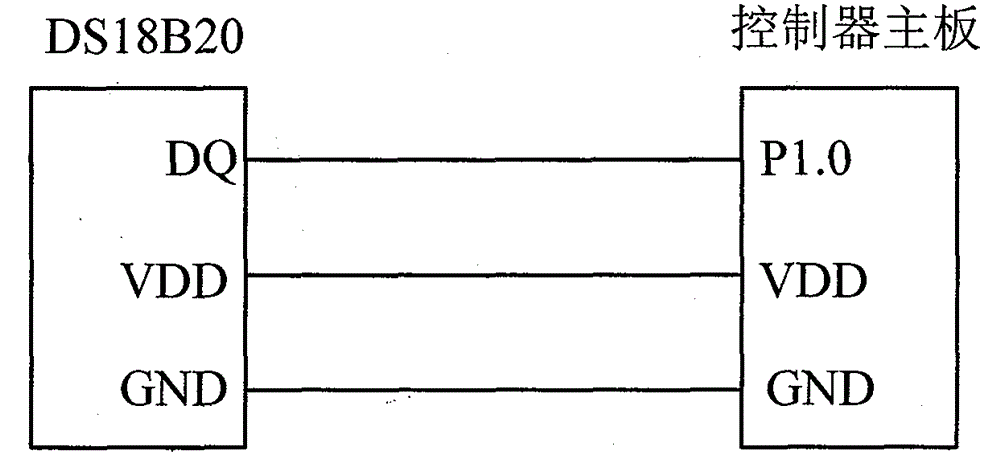

Serial-parallel conversion and intelligent charging system for lead-acid storage battery pack

InactiveCN103812196AReduce vulcanizationIncrease acceptance rateBatteries circuit arrangementsElectric powerMicrocontrollerFull wave

The invention discloses a serial-parallel conversion and intelligent charging system for a lead-acid storage battery pack. An intelligent segmental pulse charging technology is provided, the reverse instantaneous discharge function of a storage battery is added, the vulcanization phenomenon of a battery is reduced, the receiving rate of the battery is increased, the charging speed is increased, and the service life of the battery is prolonged. The system consists of a power supply main circuit, a control circuit, a simple keyboard and display circuit, an energy feedback circuit, a battery pack serial-parallel conversion circuit and a temperature measuring circuit, wherein the power supply main circuit consists of a full-bridge inverter circuit consisting of a full-bridge rectifying circuit and an IGBT (Insulated Gate Bipolar Translator), and a full-wave rectifying circuit; a C8051F020 singlechip is taken as the core of the control circuit; the simple keyboard and display circuit can be used for selectively charging on a peak valley; a transformer is taken as the feedback channel of the energy feedback circuit; discharge energy is stored in a filter capacitor. The battery pack serial-parallel conversion circuit consists of a three-pole double-throw switch and a diode, and a series battery pack adapter is used for charging a parallel battery, thereby solving the problem that all batteries cannot be charged due to damage to a single battery in the battery pack. The system is suitable for intelligent charging of electric bicycles in industrial production and civil use.

Owner:YANCHENG INST OF TECH

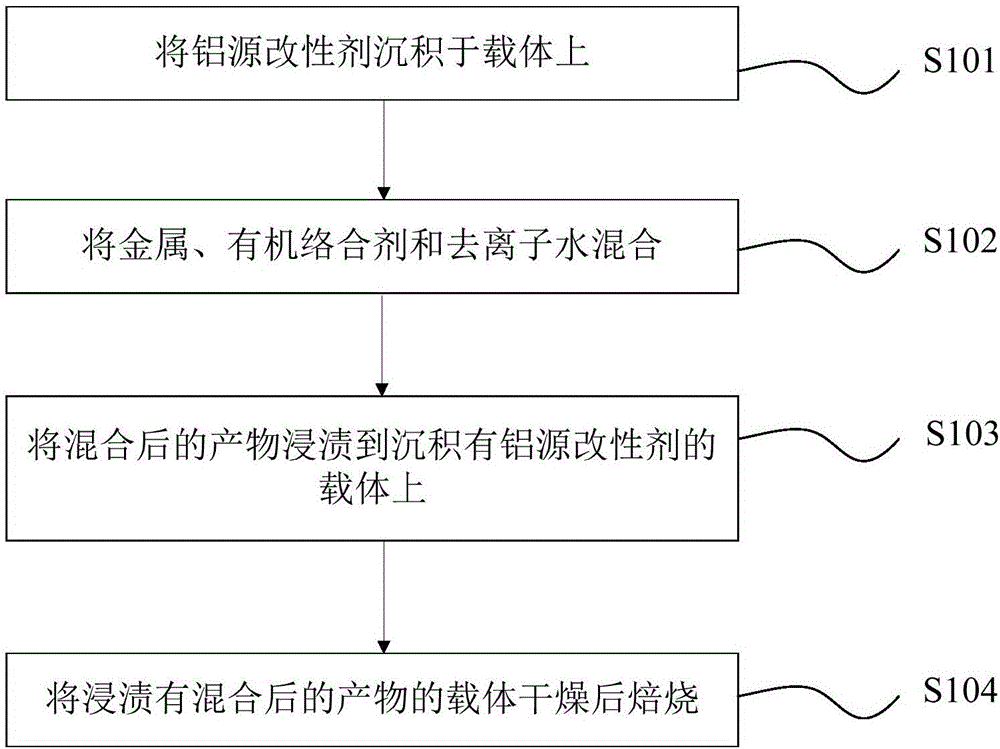

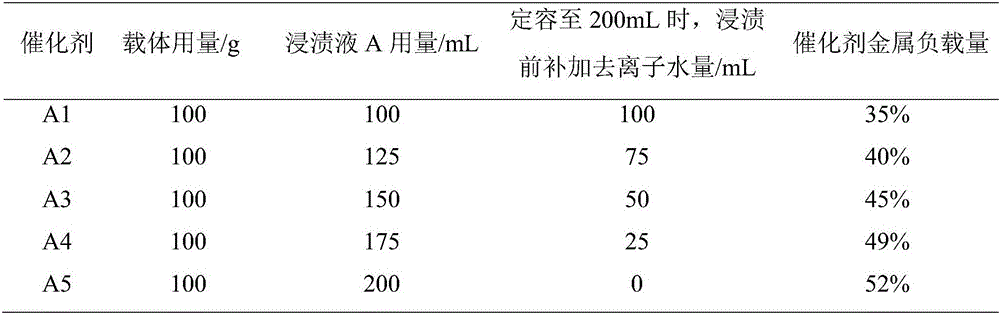

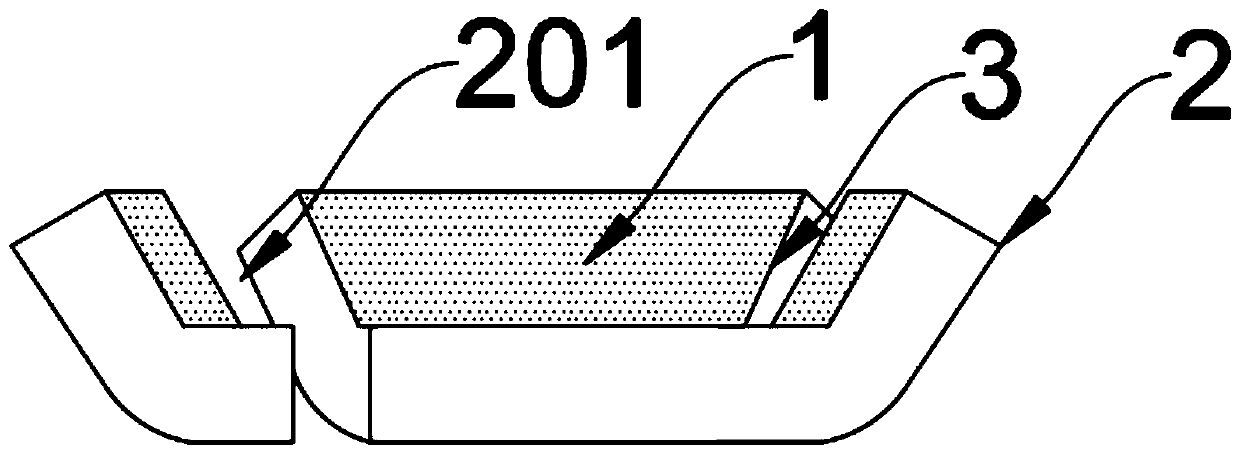

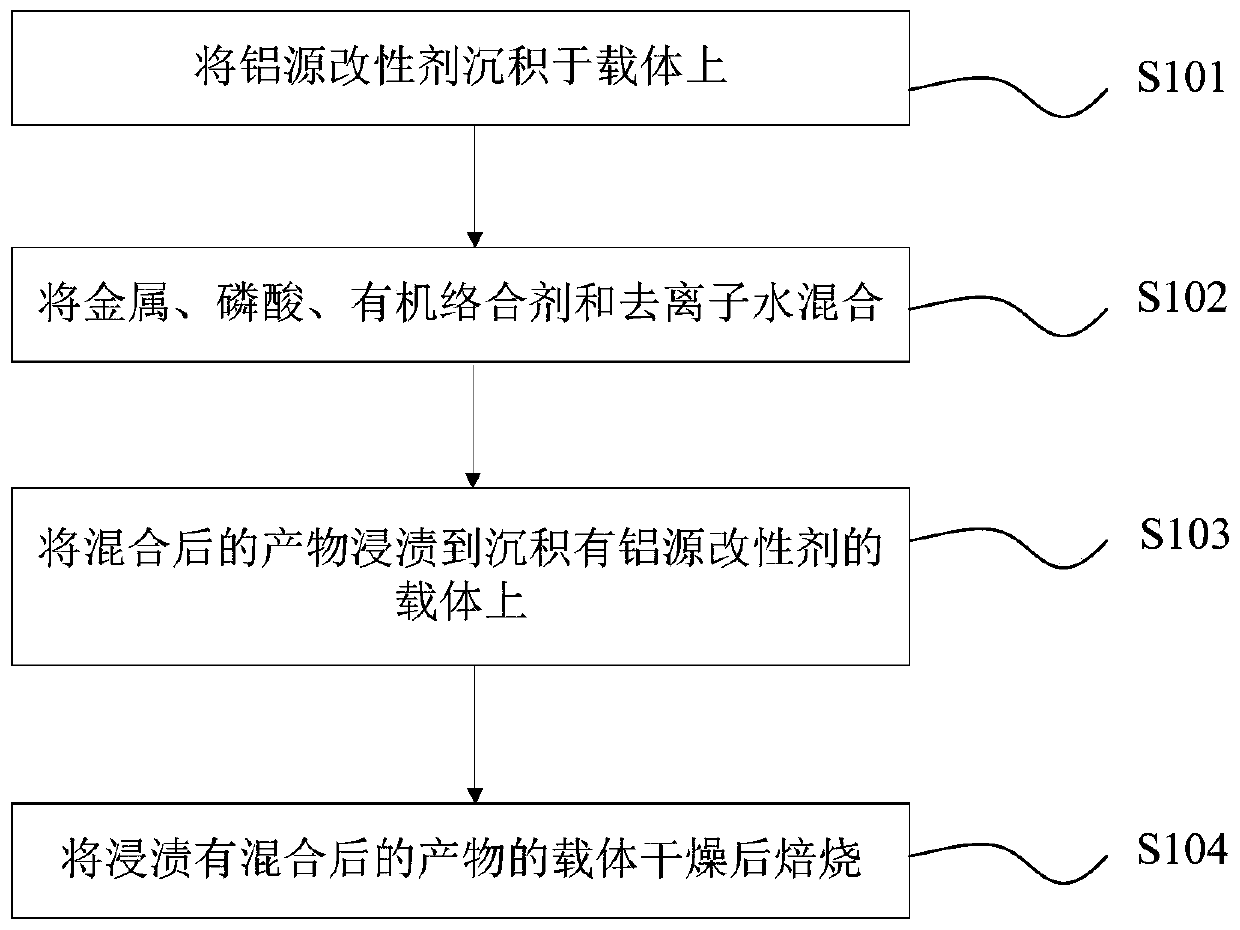

Method for preparing superhigh metal load capacity hydrogenation catalyst

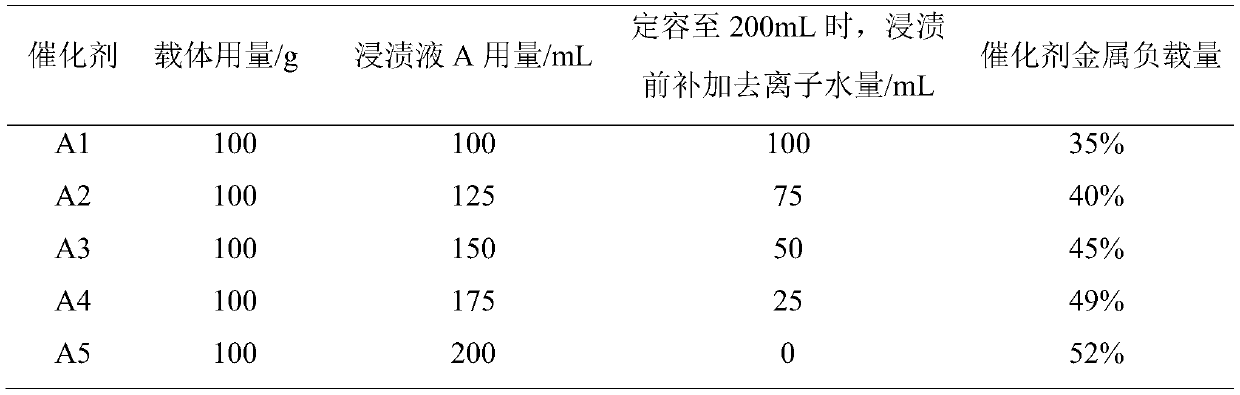

ActiveCN106475110AHigh activitySimple preparation processCatalyst carriersHeterogenous catalyst chemical elementsChlorideAluminium isopropoxide

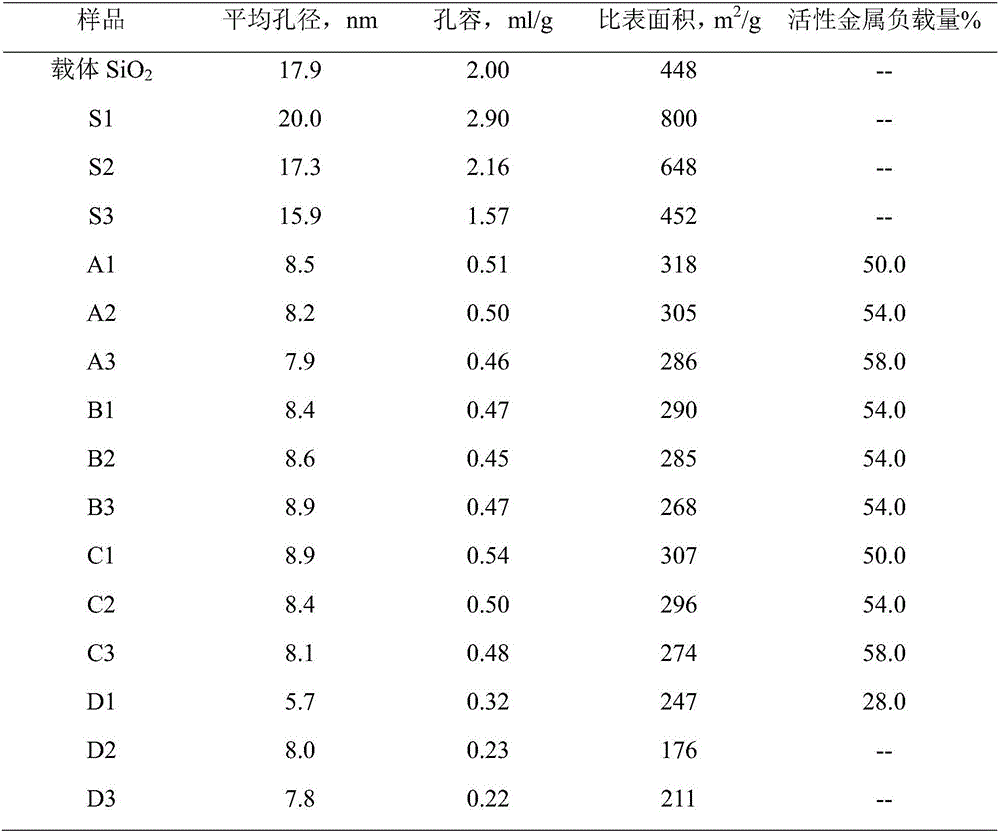

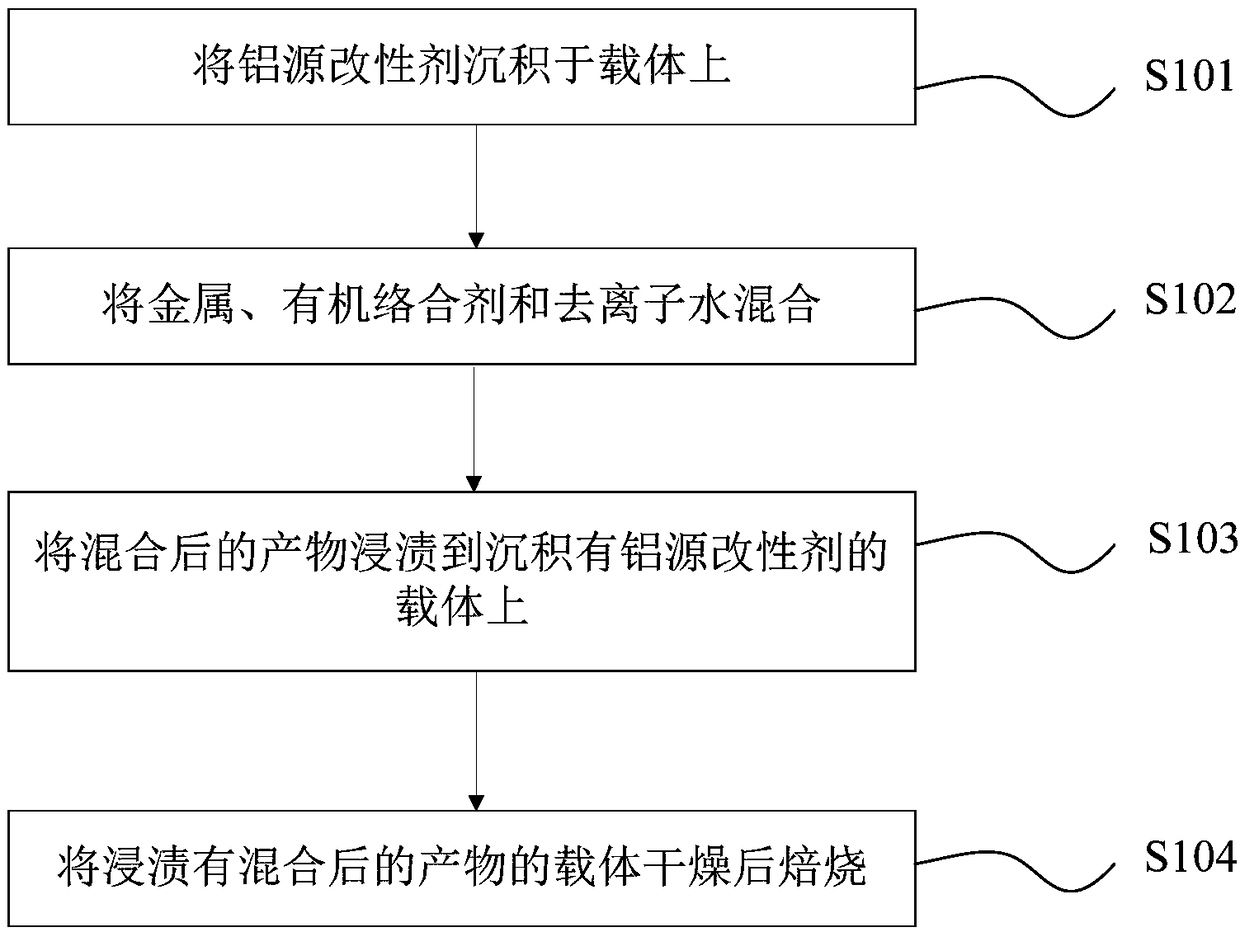

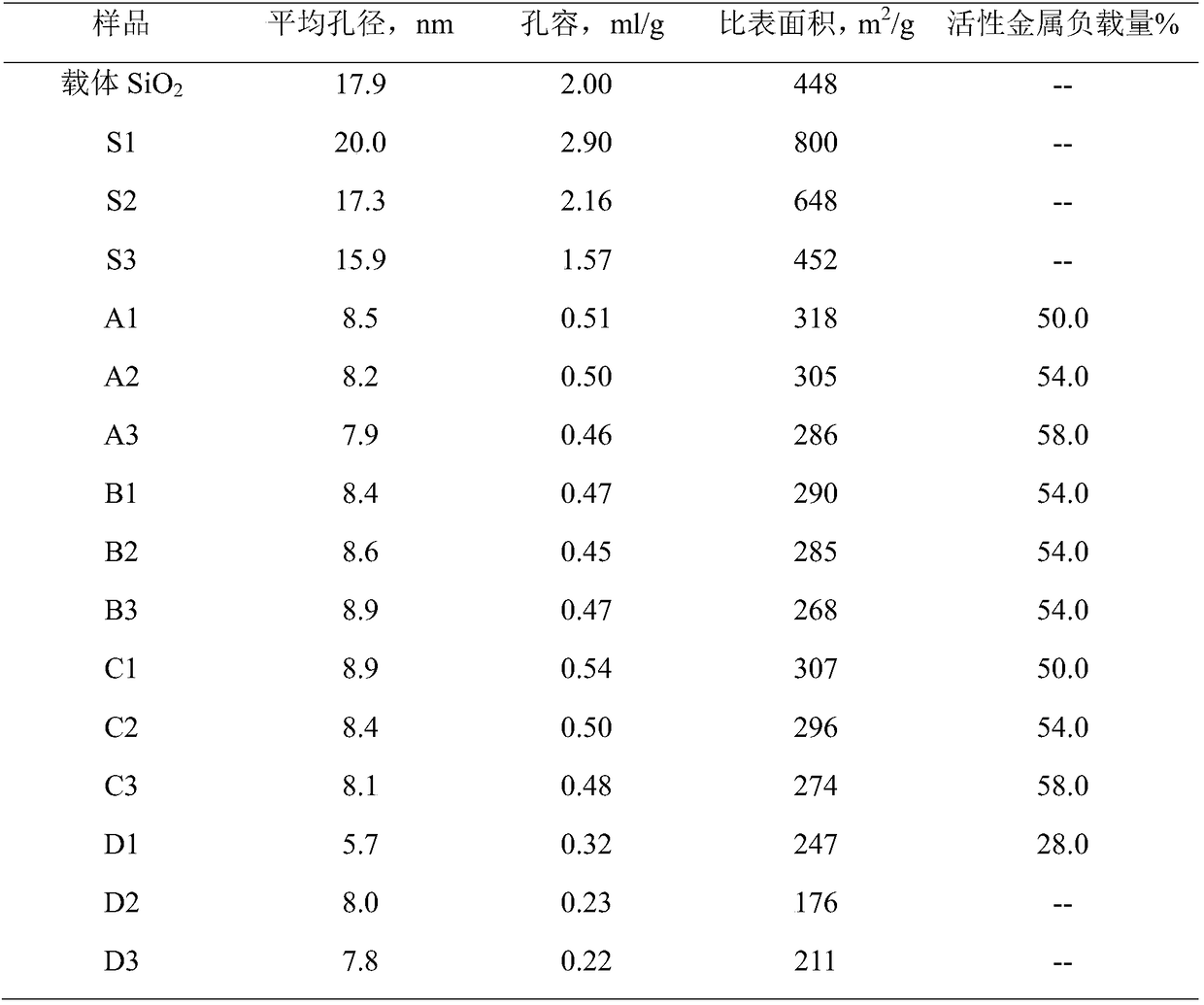

The invention relates to a method for preparing a superhigh metal load capacity hydrogenation catalyst. The method comprises the following steps: depositing an aluminum source modifier on a carrier; metal, an organic complexing agent and deionized water are mixed; the mixed product is dipped on a carrier deposited with the aluminum source modifier; the carrier dipped with the mixed product is dried and roasted; wherein, the main metal components are Mo and W of VIB family, the auxiliary agent components are Co and / or Ni of VIII family; the aluminum source modifier is one or combination of aluminum isopropoxide, aluminum chloride and aluminum nitrate; the pore volume of the carrier deposited with the aluminum source modifier is 1.5-3.0 ml / g, the specific surface area is 400-800 m<2> / g, and the aperture proportion of the aperture with 15-20 nm is greater than 50%. According to the preparation method of the invention, catalyst activity is obviously increased by increasing the metal load capacity, the catalyst has a good pore structure and a large specific surface area; preparation flow of the catalyst is simplified, and the preparation cost of the hydrogenation catalyst with high metal content is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of high-metal-content hydrogenation catalyst

ActiveCN106423183ALarge specific surface areaHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationCarrying capacityPhosphoric acid

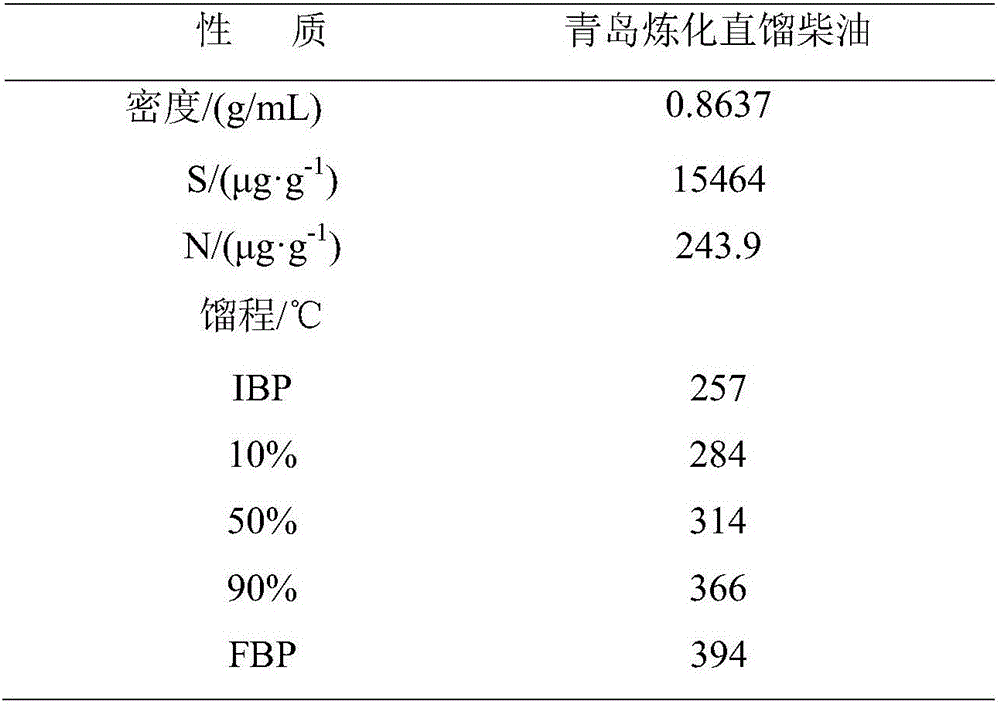

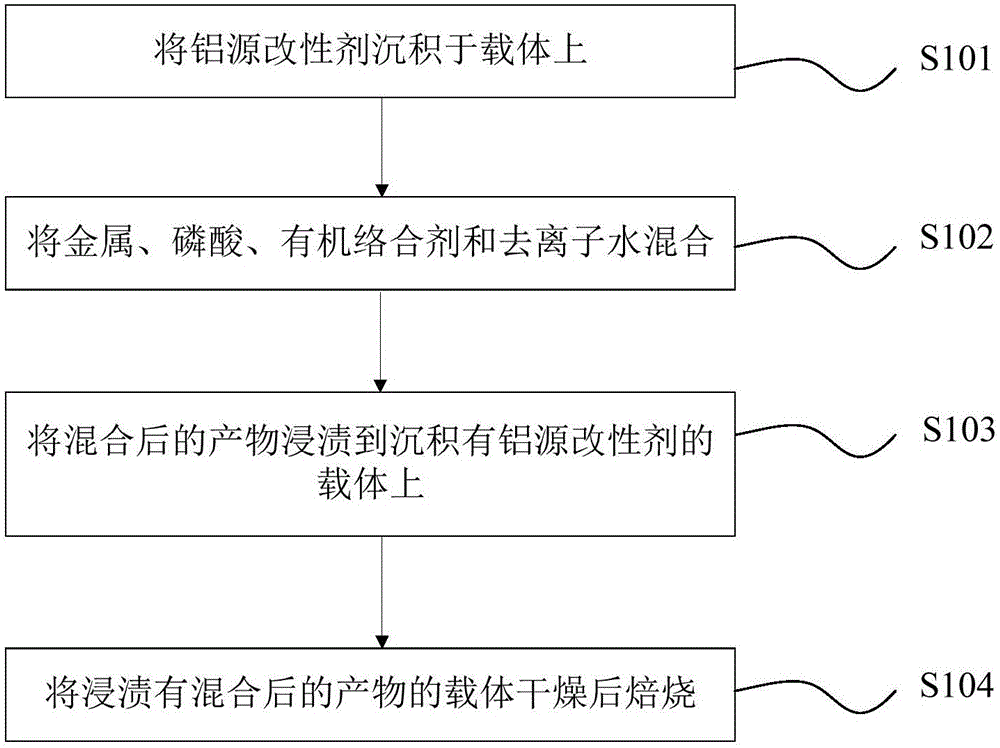

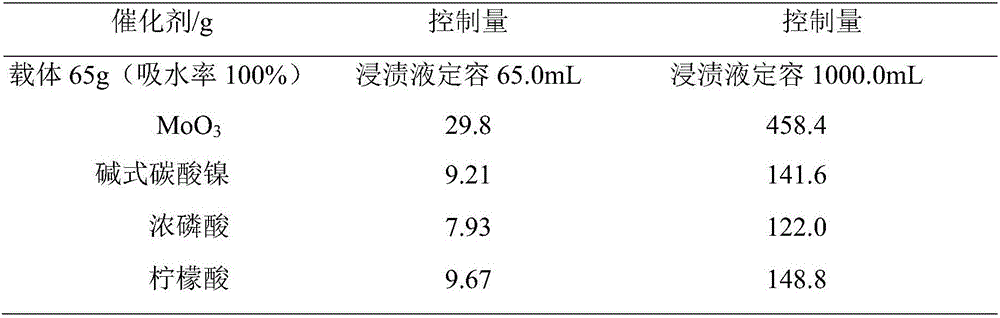

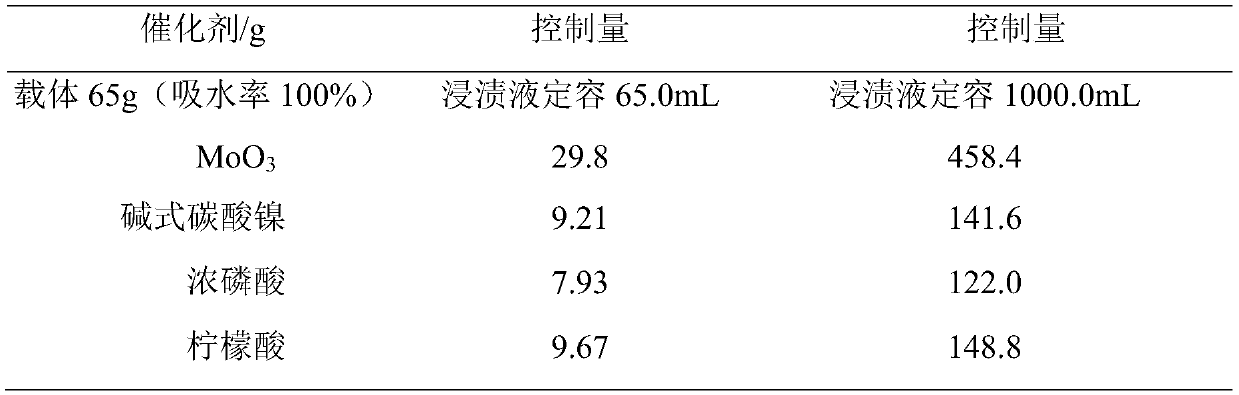

The invention relates to a preparation method of a high-metal-content hydrogenation catalyst, comprising the steps of depositing an aluminum source modifier to a carrier; mixing a metal, phosphoric acid, an organic complexing agent and deionized water; impregnating the mixture to the carrier on which the aluminum source modifier is deposited; drying and calcining the carrier on which the mixture is impregnated; wherein the metal is made from a main component, Mo in VIB, and an aid component, Ni in VIII, the aluminum source modifier is one, or a composition of any, of aluminum isopropoxide, aluminum chloride and aluminum nitrate, the carrier on which the aluminum source modifier is deposited is 1.3-2.3 ml / g in pore volume and 400-700 m<2> / g in specific surface area, and pores 14-18 nm in diameter accounts for greater than 50%. The preparation method of the high-metal-content hydrogenation catalyst provided herein has significantly improved activity and good pore structure and large specific surface area since metal carrying capacity is increased; the preparation process of the catalyst is simplified, and the preparation cost of high-metal-content hydrogenation catalyst is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ventilation-cooling method for high-geothermal deeply-buried diversion tunnel construction

InactiveCN104314056AReduce heat crampsIncrease profitWater-power plantsHydro energy generationLubricationEmulsion explosive

The invention provides a ventilation-cooling method for high-geothermal deeply-buried diversion tunnel construction. The ventilation-cooling method comprises the following steps: I, carrying out health management of people; II, ventilation-cooling; III, cooling blast holes; IV, making ice to cool; and V, cooling measurement equipment. According to the ventilation-cooling method, a ventilation technology and a low-temperature cold water technology are integrated so as to construct in high temperature environment, so that the heatstroke symptoms of constructors in high temperature environment are reduced; the wearing of mechanical parts caused by engine oil temperature increase, viscosity drop and lubrication effect reduction of a construction machine is prevented; pipe burst, oil leakage of a joint and solenoid valve coil burning caused by high temperature are prevented; the accelerated aging of a sealing member is prevented; the emulsion explosive failure in high temperature environment is also prevented and the phenomena of nonel softening and misfire are avoided; the normal use of monitoring equipment in high temperature environment is guaranteed.

Owner:HEBEI UNIV OF ENG

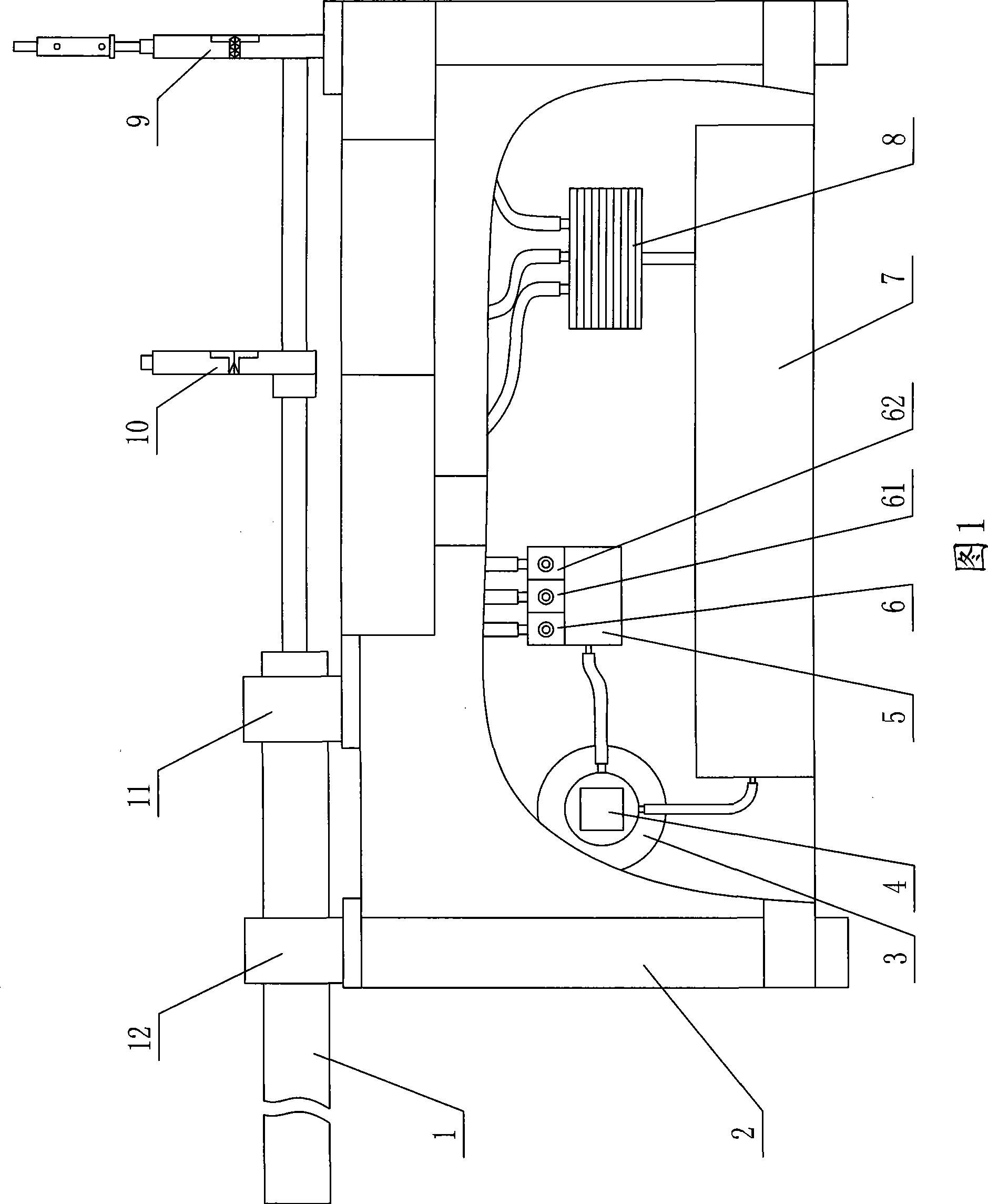

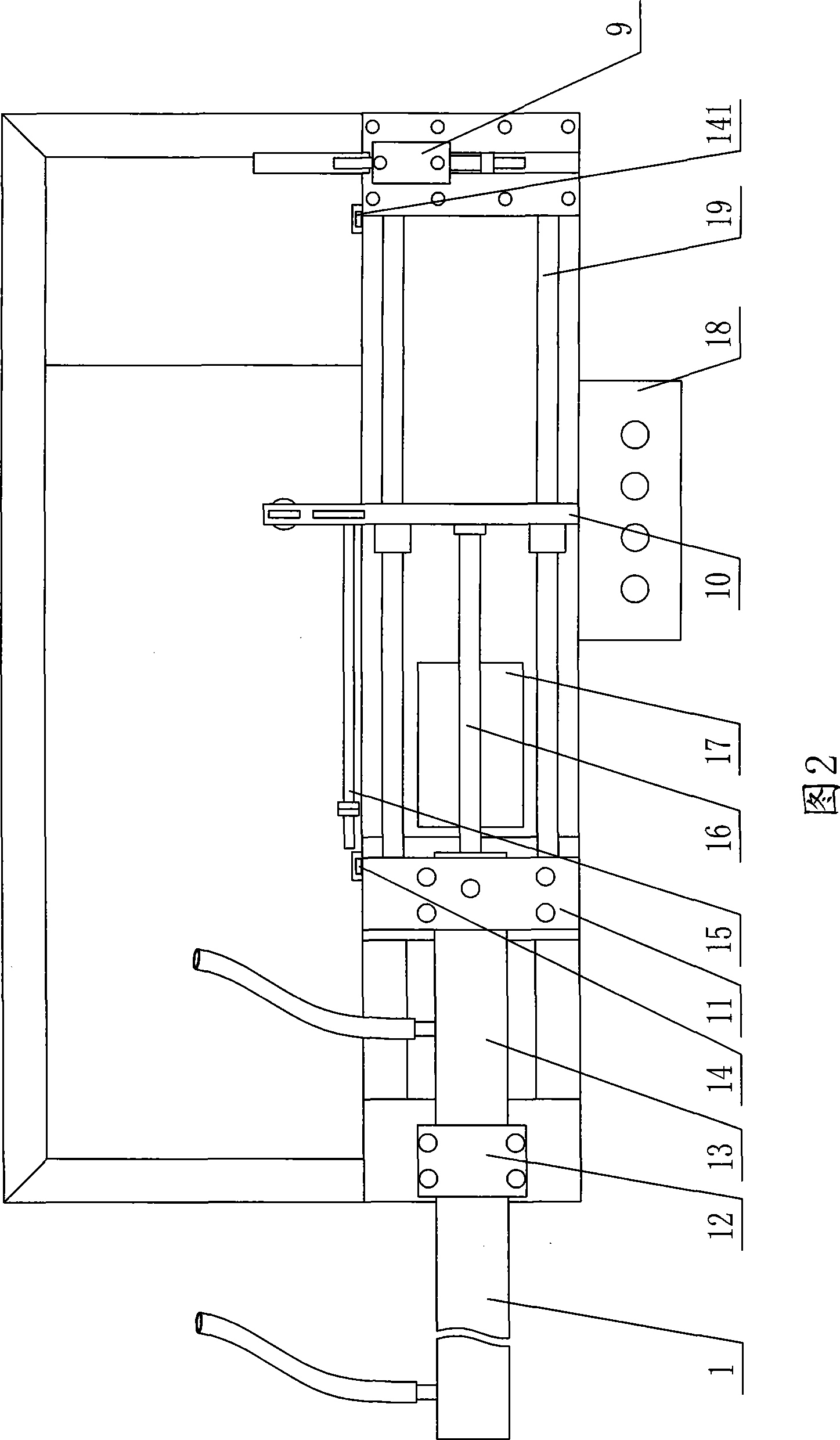

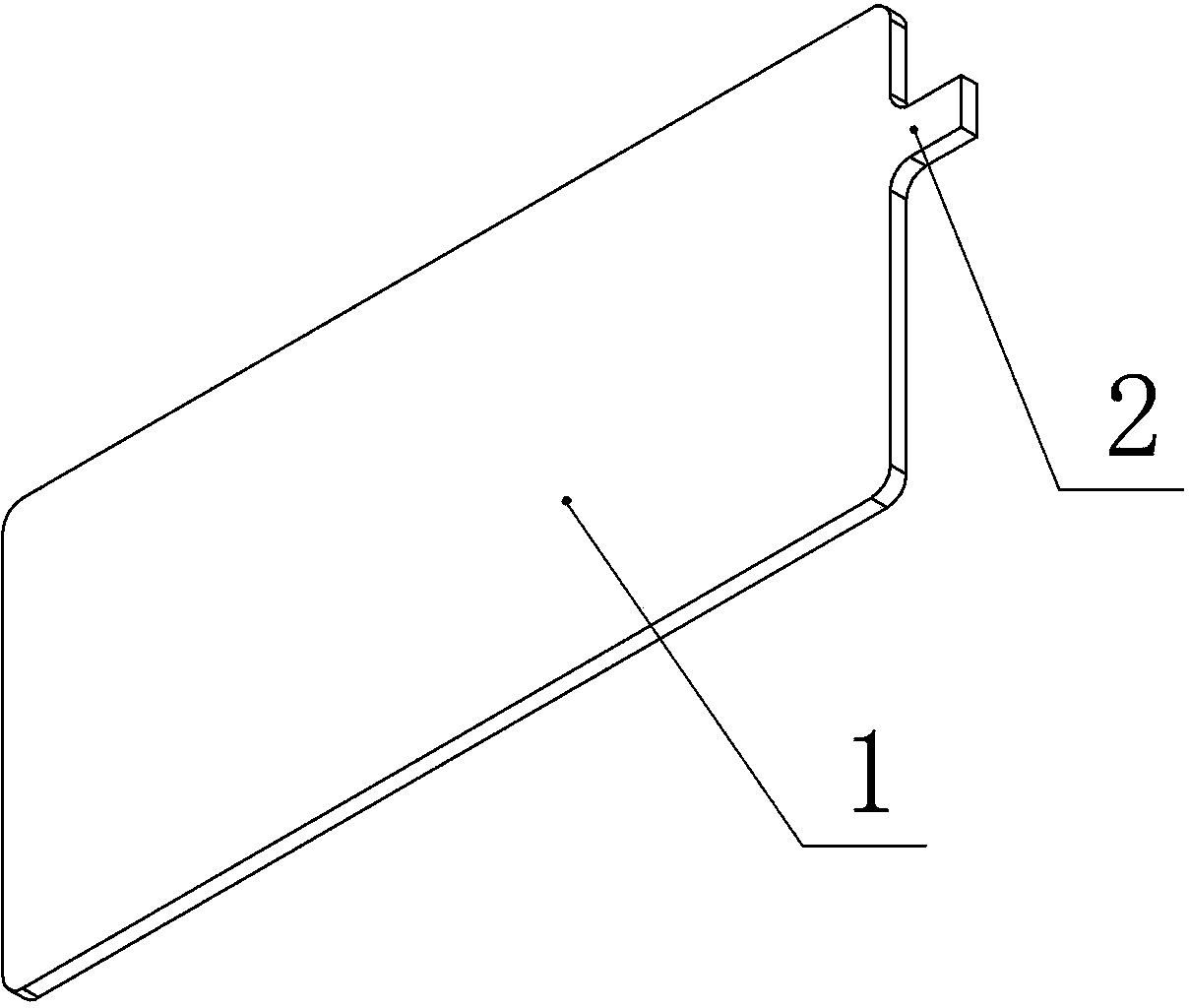

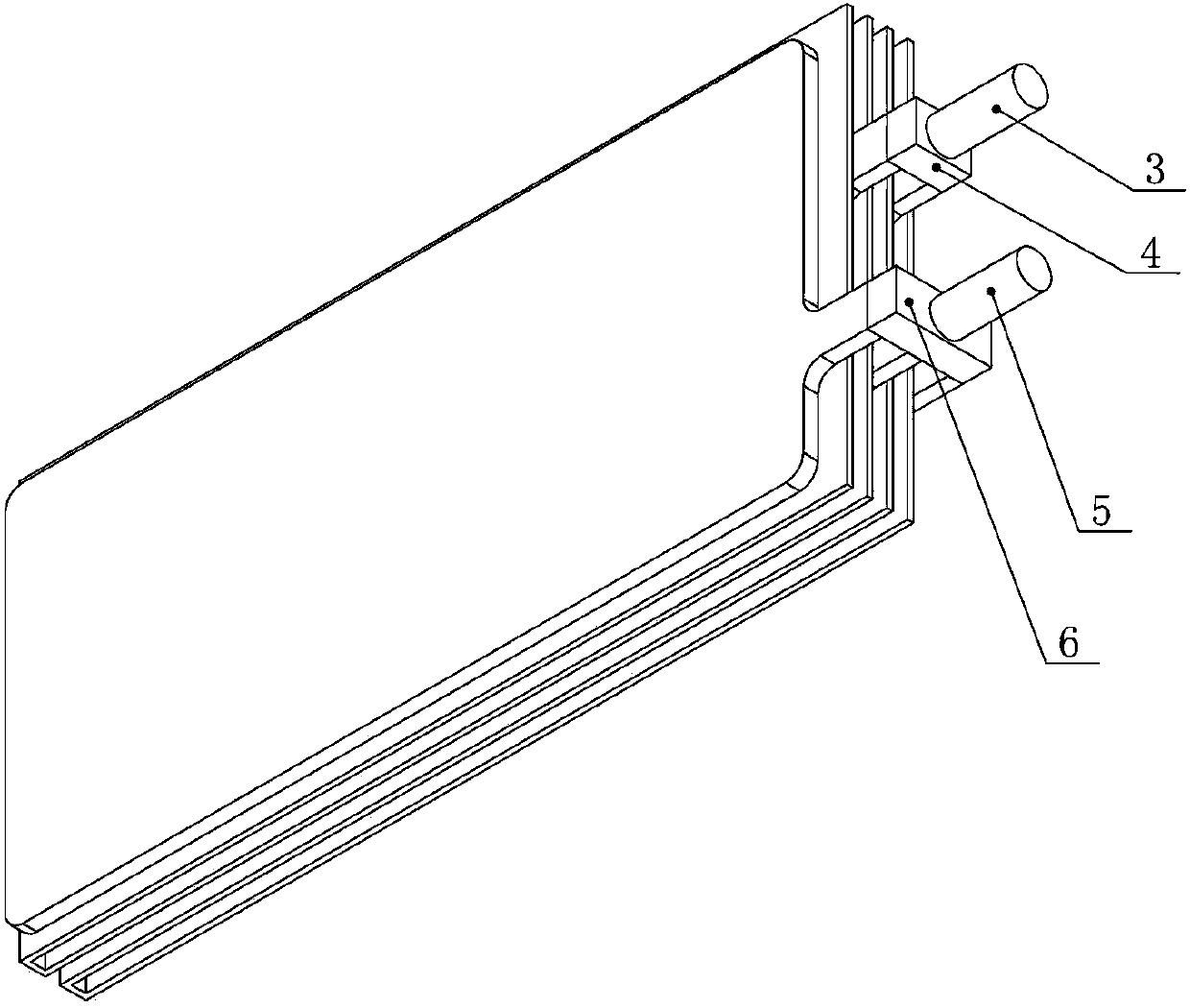

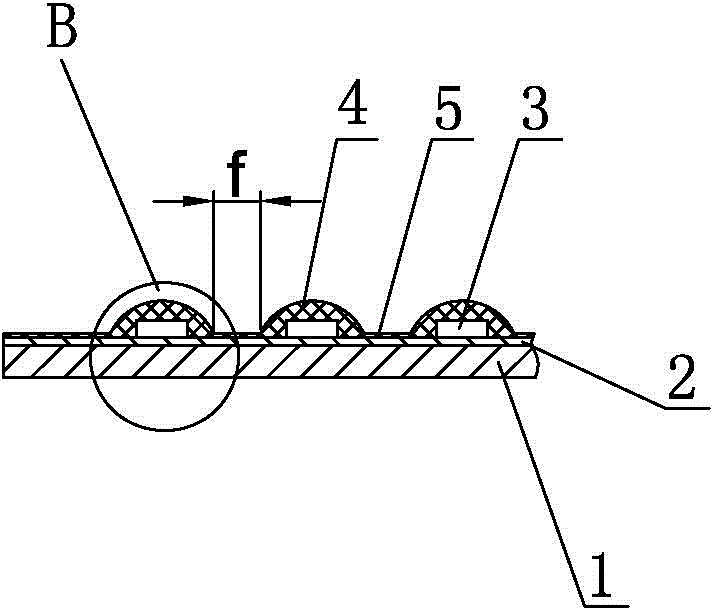

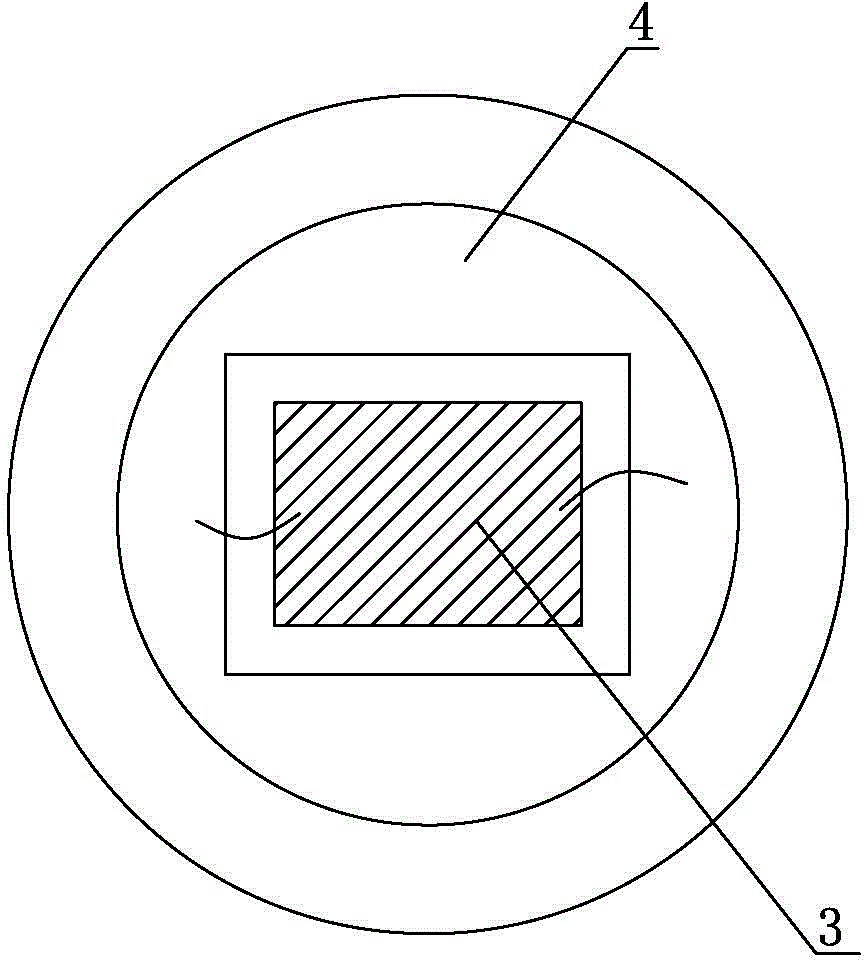

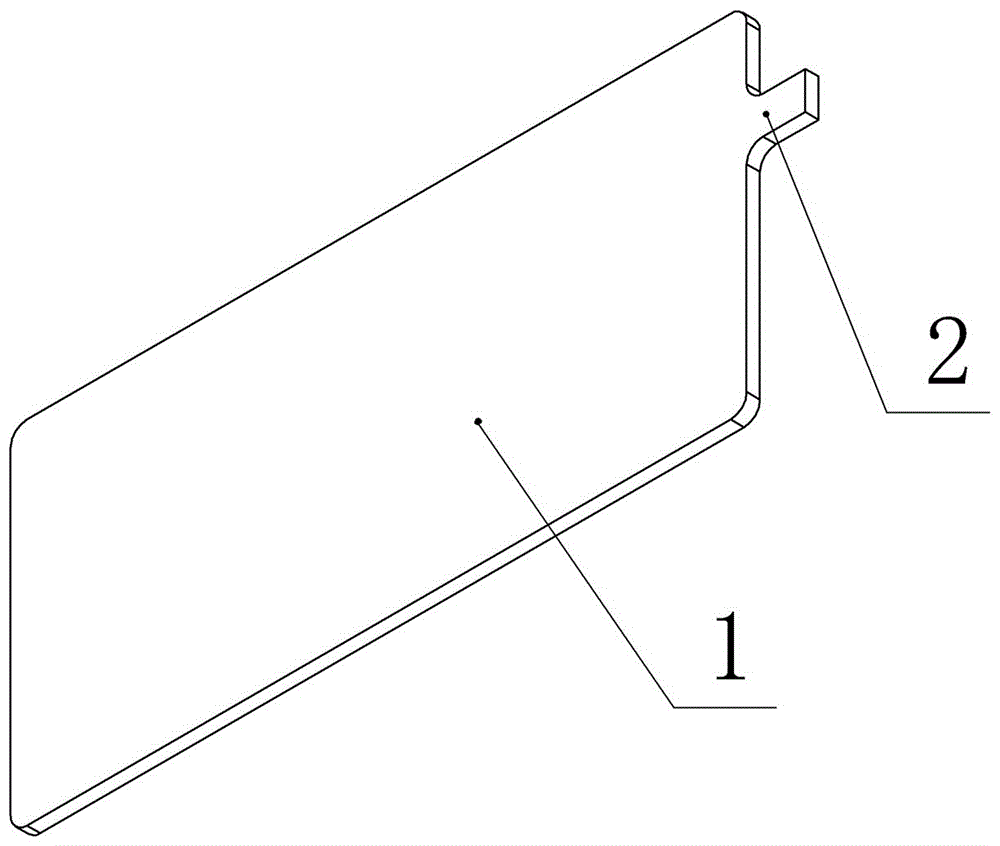

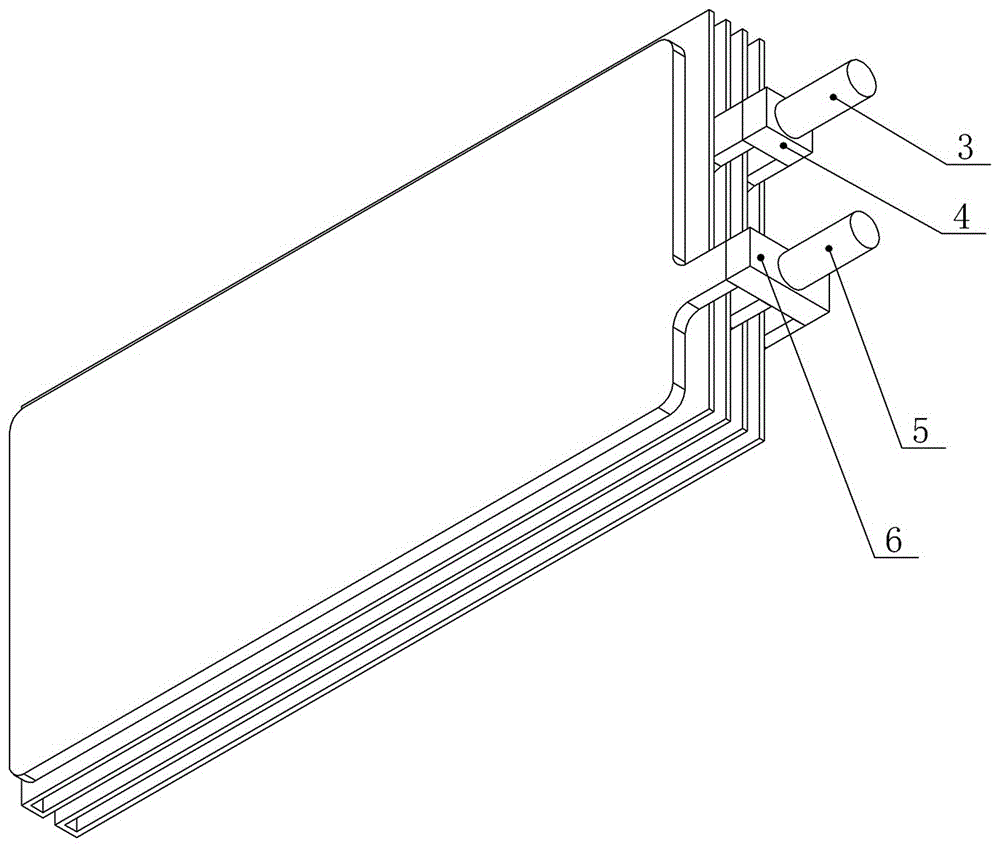

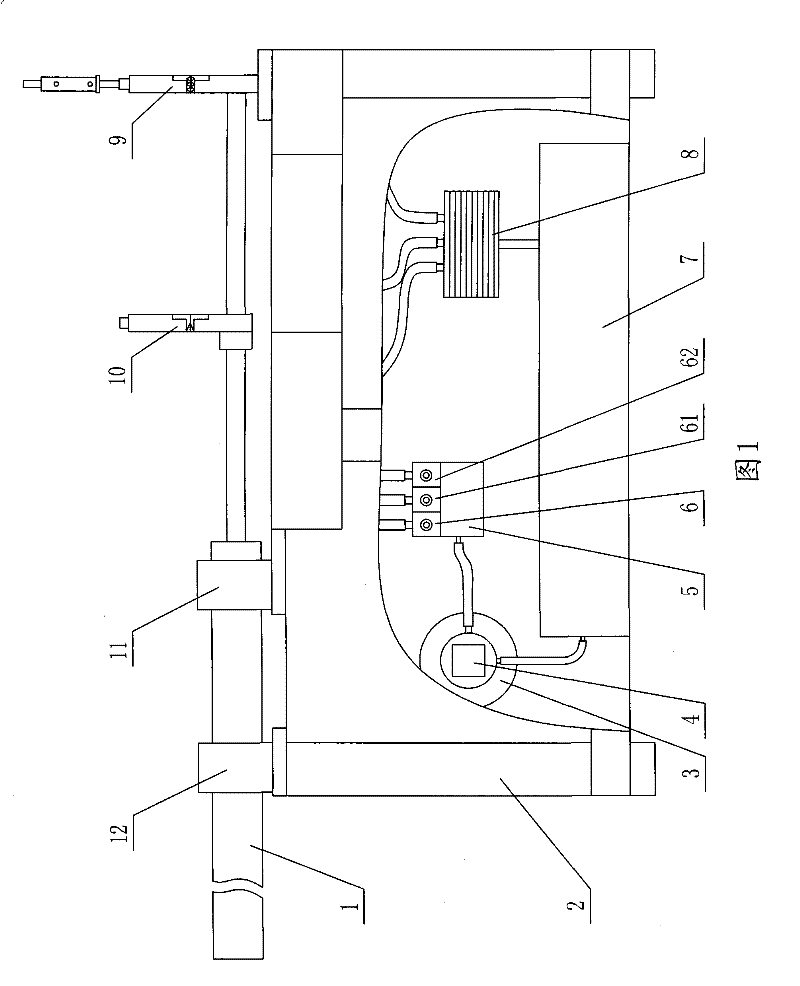

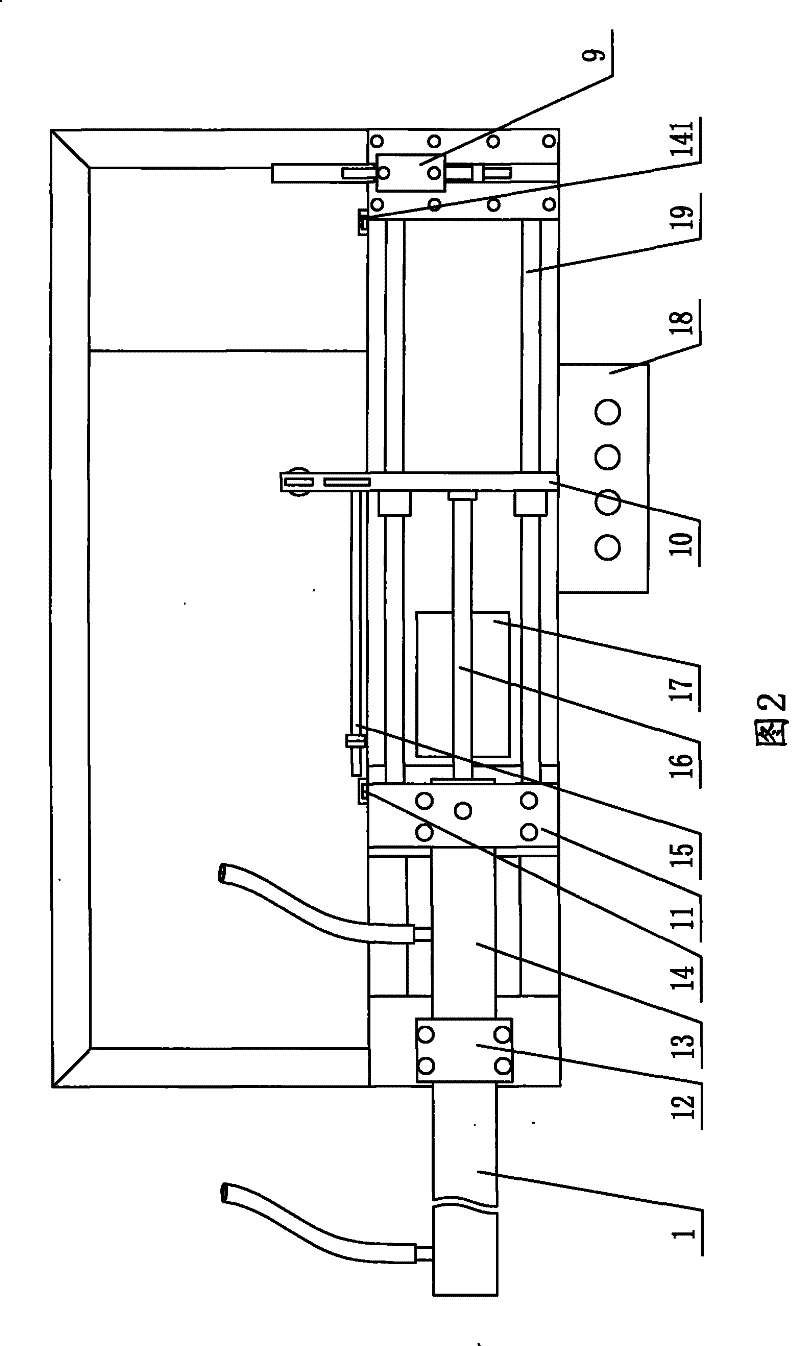

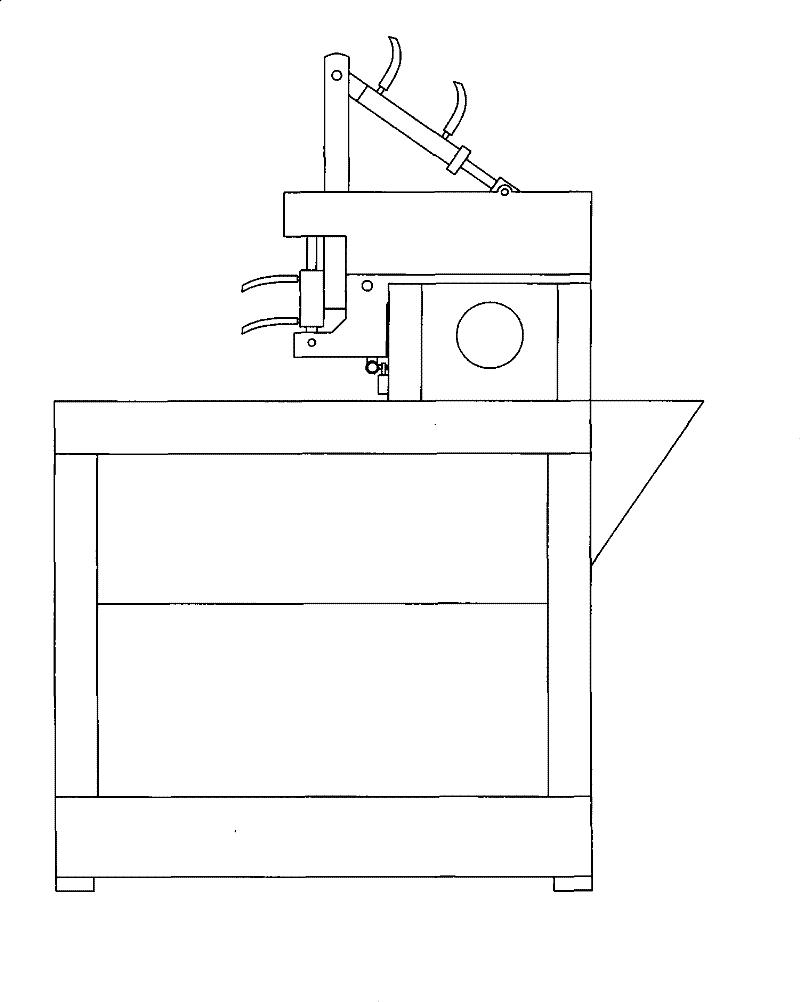

Spreading machine

The invention relates to a spreading machine, which comprises a machine body, a motor, a driving device, and an actuating mechanism, wherein the driving device is arranged in the machine body; the actuating mechanism arranged on the machine body comprises a glue pulling mechanism, a doubling mechanism, and a spreading mechanism; and the spreading mechanism is arranged between the doubling mechanism and the glue pulling mechanism or the doubling mechanism is arranged between the spreading mechanism and the glue pulling mechanism, the glue pulling mechanism is fixedly connected with the doubling mechanism through two guiding shafts, the spreading mechanism is sleeved on the two guiding shafts through two linear bearings, and a piston rod in a hydraulic actuating mechanism of the glue pulling mechanism is connected with a lower fixed clip knife bracket of the spreading mechanism. The spreading machine changes the prior manual glue-scaling method, and has the advantages of fast spreading speed, high efficiency, high recycling rate, fully-automatic operation, and labor conservation.

Owner:尹家旺

Preparation method and application of passivated sulfurized hydrocracking catalyst

PendingCN113509954ACracking activity inhibitionReduce wasteMolecular sieve catalystsCatalyst activation/preparationPtru catalystMetallurgy

The invention relates to a preparation method of a passivated sulfurized hydrocracking catalyst and the hydrocracking catalyst obtained by the method. The method comprises the following steps of: dipping an oxidized hydrocracking catalyst by adopting a solution containing a nitrogen-containing compound and organic alcohol, then drying the oxidized hydrocracking catalyst, and carrying out sulfuration treatment on the dried oxidized hydrocracking catalyst to obtain the passivated sulfurated hydrocracking catalyst. According to the method, the passivation process can be completed while the hydrocracking catalyst is sulfurized, the sulfuration and passivation effects of the catalyst are good, the reaction activity of the catalyst is high, the catalyst does not need to be sulfurized or activated when a hydrocracking device is started, oil can be directly fed for starting, the starting steps are simplified, and the starting time of the hydrocracking device is shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

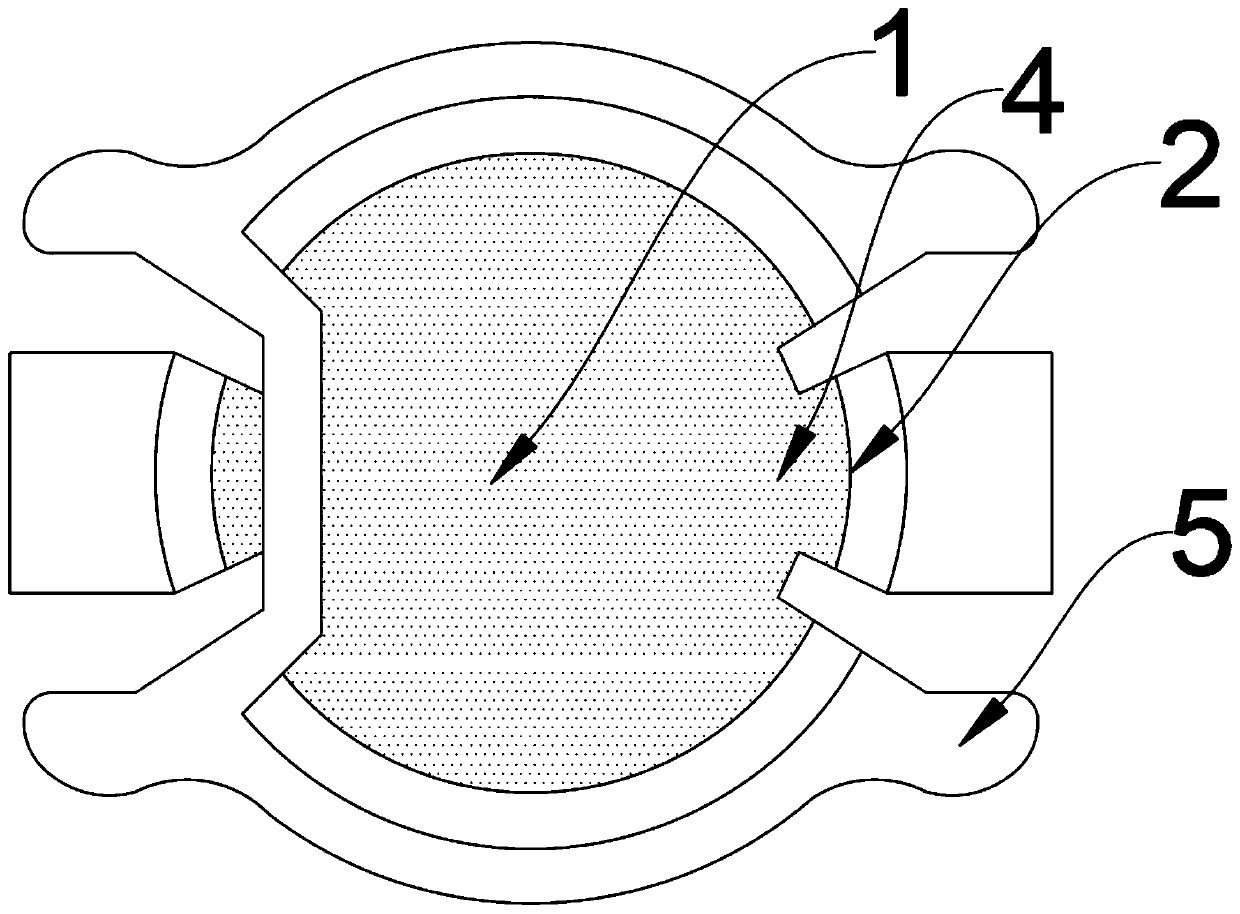

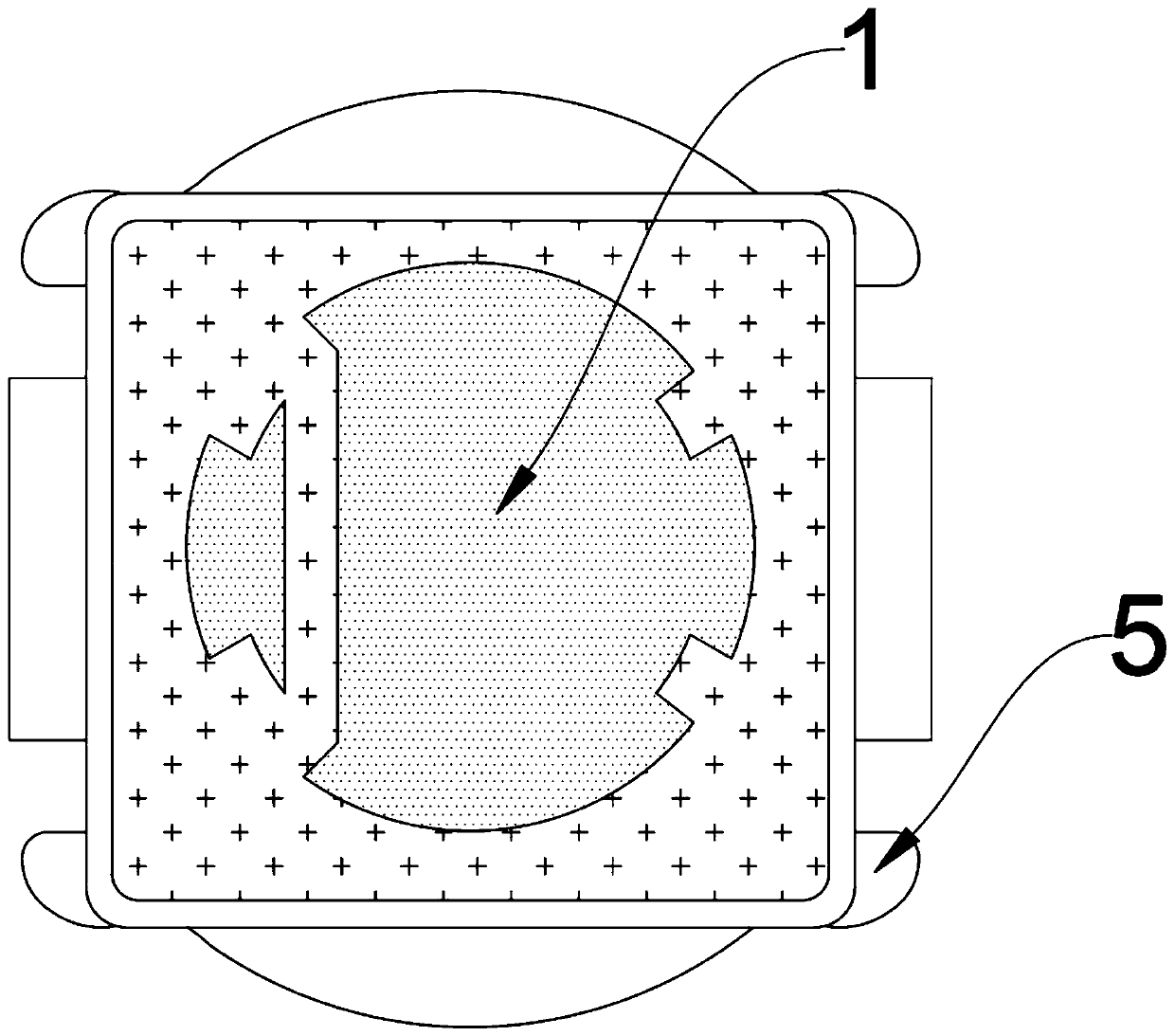

Four-pole-ear pole plate, four-pole-ear pole group and four-pole-ear storage battery

ActiveCN103633280AReduce softeningReduce vulcanizationFinal product manufactureSmall-sized cells cases/jacketsBattery chargePower flow

The invention discloses a four-pole-ear pole plate, a four-pole-ear pole group and a four-pole-ear storage battery. The four-pole-ear pole plate comprises a plate body and pole ears, wherein four pole ears are fixed on the peripheral side walls of the plate body; the distances among the pole ears along the edge of the plate body are equal. The four-pole-ear pole group is composed of multiple layers of positive pole plates and negative pole plates in an alternative arrangement and lamination mode, wherein baffles are arranged between the positive pole plates and the negative pole plates; bus bars form four groups of positive and negative bus bars which are distributed at the periphery of the pole group; a group of positive and negative bus bars are distributed on each side wall of the pole group. The four-pole-ear storage battery comprises a sealed battery outer shell and electrolyte, wherein eight terminal holes are formed on the peripheral side walls of the outer shell; positive and negative terminals are respectively led from the terminal holes so as to form four groups of positive and negative terminals; each side wall of the peripheral walls of the outer shell is respectively provided with a group of positive and negative terminals. According to the invention, the battery charging and discharging cycle life is prolonged; the battery is prevented from expanding because of water loss; the using safety and high-current discharge performance are improved.

Owner:HENAN CHAOWEI POWER SUPPLY

Preparation method of anti-sulfur chip LED (Light Emitting Diode) packaging adhesive

ActiveCN105567155AImprove air tightnessReduce vulcanizationNon-macromolecular adhesive additivesVulcanizationSulfur

The invention provides a preparation method of anti-sulfur chip LED (Light Emitting Diode) packaging adhesive. The preparation method at least comprises the steps of adding white carbon powder and silazane into initial phenyl vinyl silicone resin to perform stirring and hyperthermic treatment. The LED packaging adhesive prepared by the preparation method of the anti-sulfur chip LED packaging adhesive has a certain function of adsorbing and removing oxidizing substances, and the gas tightness of the packaging adhesive can be effectively improved, andthus a function of delaying vulcanization can be well realized.

Owner:GUANGDONG JIEGUO NEW MATERIAL CO LTD

Preparation method of ultra-high metal loading hydrogenation catalyst

ActiveCN106475110BHigh activitySimple preparation processCatalyst carriersHeterogenous catalyst chemical elementsChlorideAluminium isopropoxide

The invention relates to a method for preparing an ultra-high metal loading hydrogenation catalyst, which includes the following steps: depositing an aluminum source modifier on a carrier; mixing metal, organic complexing agent and deionized water; and impregnating the mixed product. onto a carrier deposited with an aluminum source modifier; the carrier impregnated with the mixed product is dried and then roasted; where the main metal components are Mo and W from group VIB, and the auxiliary components are Co and / or from group VIII. or Ni; the aluminum source modifier is one or more combinations of aluminum isopropoxide, aluminum chloride and aluminum nitrate; the pore volume of the carrier on which the aluminum source modifier is deposited is 1.5 to 3.0ml / g , the specific surface area is 400~800m2 / g, and the proportion of 15~20nm pore diameter is greater than 50%. The preparation method of an ultra-high metal loading hydrogenation catalyst provided by the present invention not only significantly improves the catalyst activity by increasing the metal loading, but also makes the catalyst have a better pore structure and a larger specific surface area; and simplifies the preparation process of the catalyst. , reducing the preparation cost of hydrogenation catalysts with high metal content.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

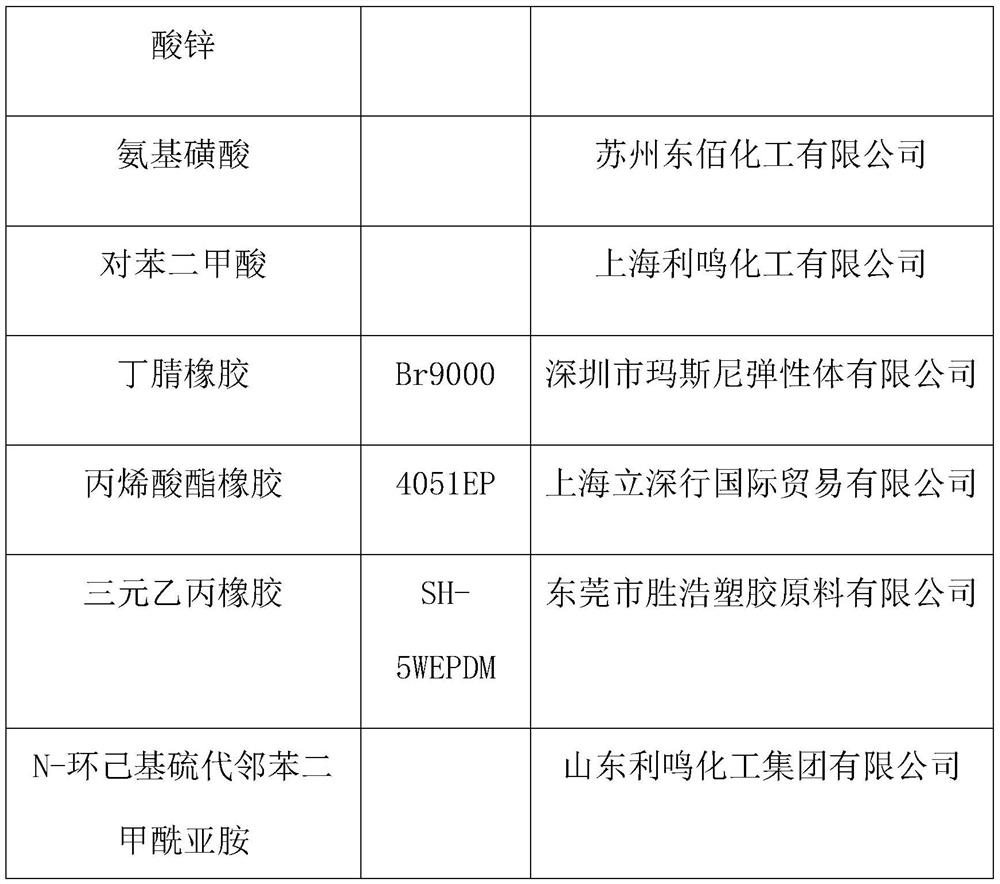

Rubber anti-yellowing accelerator, preparation method thereof and rubber product

The invention relates to the field of rubber production, and particularly discloses a rubber anti-yellowing accelerant, a preparation method thereof and a rubber product. The rubber anti-yellowing accelerant comprises rubber, white carbon black, a scorch retarder, long-chain primary alkyl zinc dithiophosphate, sulfamic acid and terephthalic acid. The preparation method comprises the following steps: firstly, adding the rubber into an internal mixing chamber of an internal mixer for plastifying and stirring, then adding the remaining raw material components into the internal mixing chamber for mixing with the rubber, and discharging to obtain the rubber yellowing-resistant accelerant. The rubber yellowing-resistant accelerant is applied to rubber products. The rubber yellowing-resistant accelerant has the effects of improving the anti-yellowing performance of the rubber product and prolonging the service life of the rubber product.

Owner:佛山市丰正科技有限公司

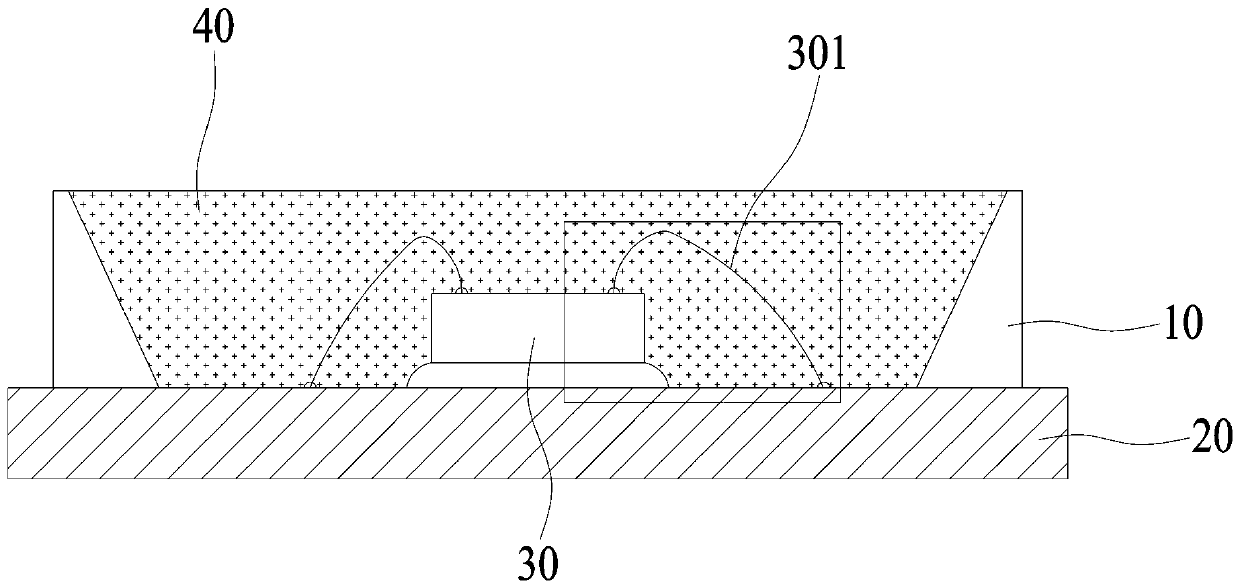

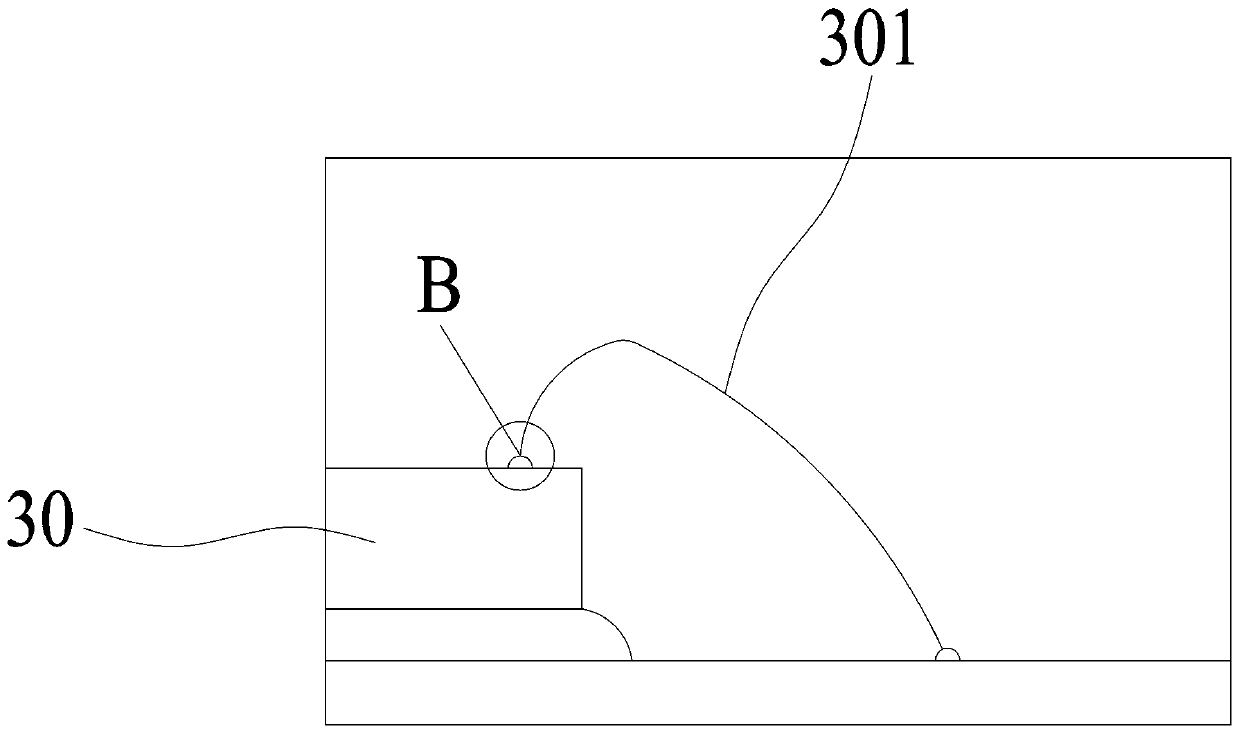

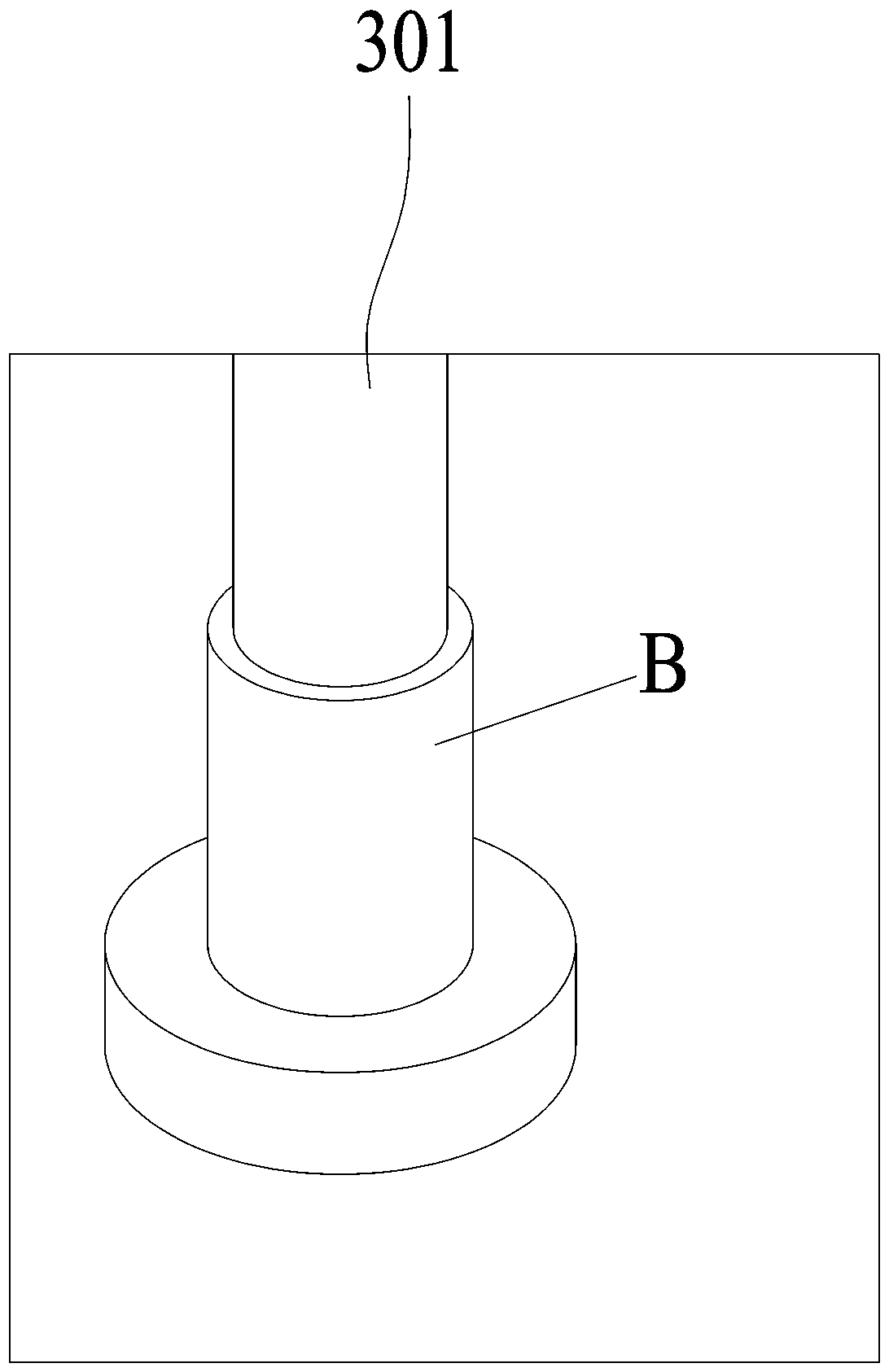

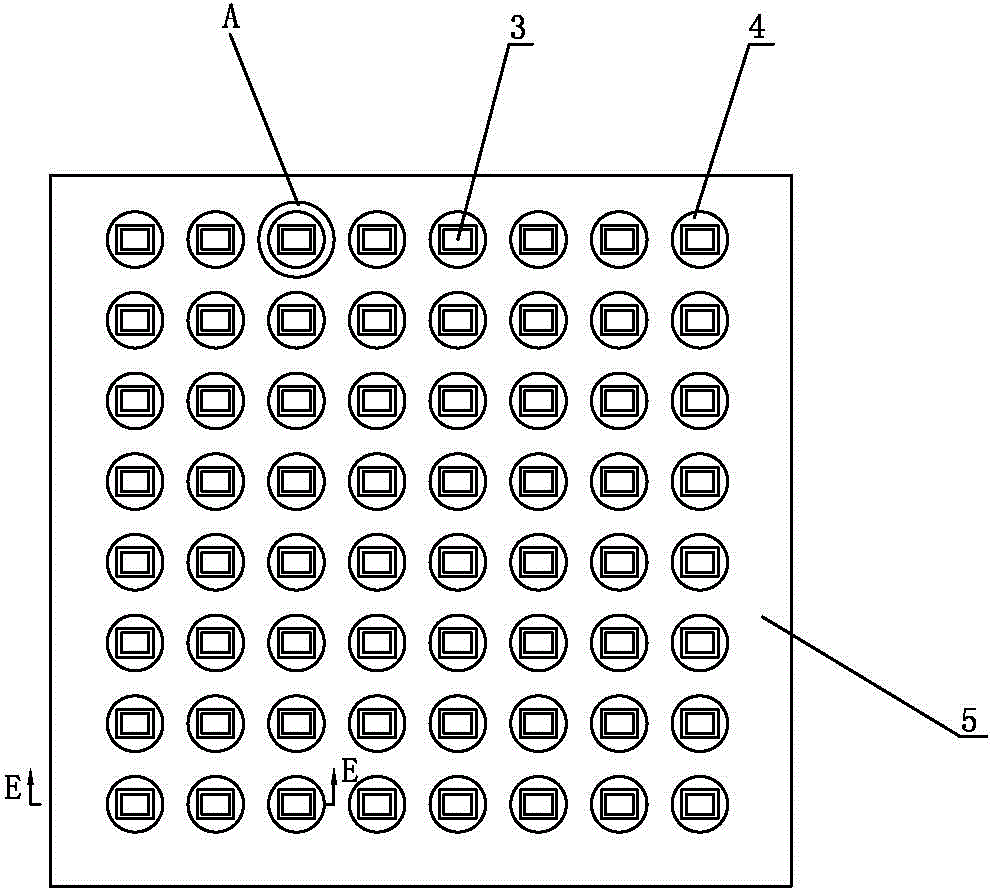

LED chip package support and production method thereof

PendingCN109888077AHigh Shore hardnessSmall Shore hardnessSemiconductor devicesVulcanizationSurface mounting

The invention discloses an LED chip package support. The LED chip package support comprises a base, a reflection cup, an LED chip, a first silica gel layer and a second silica gel layer, wherein the reflection cup is arranged on the base, a lower surface of the LED chip is surface-mounted onto the base and is arranged at the bottom of the reflection cup, a positive electrode and a negative electrode of the LED chip are connected with a pin by a connection wire, the first silica gel layer is arranged at the bottom of the reflection cup, the second silica gel layer is arranged on the first silica gel layer, the second silica gel layer covers an upper surface of the LED chip, the shore hardness of the first silica gel layer is larger than the shore hardness of the second silica gel layer, andfluorescent powder is mixed in the second silica gel layer. The invention also discloses a production method of the LED chip package support. By the LED chip package support, the vulcanization-prevention performance of an SMD LED is improved, the cold and hot impact resistant performance of the SMD LED is also improved, and meanwhile, the production cost is reduced.

Owner:福建省信达光电科技有限公司

One-piece high-power LED integrated light source with more than two convex mirrors and its manufacturing process

ActiveCN102916006BIncrease connection areaImprove connection strengthPlanar light sourcesPoint-like light sourceEngineeringLight-emitting diode

The invention discloses an integrated high-power LED (Light Emitting Diode) light source with more than two convex mirrors and a manufacturing process thereof, wherein the integrated LED light source comprises a substrate and more than two LED chips or more than two sets of LED chip modules; the LED chips or the LED chip modules are installed on the substrate; independent convex mirrors are formed on the LED chips or the LED chip modules by being quantitatively pressed through an automatic high-temperature high-pressure die; and a film bonded to the substrate is formed between the adjacent convex mirrors in the quantitative pressing and forming processes by adopting the automatic high-temperature high-pressure die. The manufacturing process mainly comprises the steps of quantitatively pressing and forming the convex mirrors by adopting the automatic high-temperature high-pressure die, and forming a silicone film between every two convex mirrors. According to the invention, the cost of the manufacturing process is low; the technological process is simple; the light condensation effect of the manufactured integrated high-power LED light source is good; consistency of light colours is good; air vulcanization on the integrated high-power LED light source is effectively reduced; and the service life of the integrated LED light source is greatly increased.

Owner:GUAGNZHOU TIANXIN PHOTOELECTRIC CO LTD

Four-pole ear plate, pole group and four-pole ear battery

ActiveCN103633280BReduce softeningReduce vulcanizationFinal product manufactureSmall-sized cells cases/jacketsPower flowBattery charge

The invention discloses a four-pole tab plate, an pole group and a four-pole tab battery. The four-pole tab plate includes a plate body and tabs. Four tabs are fixed on the side walls around the plate body. The distances between the edges of the body are equal; the four-pole ear pole group is composed of positive and negative plates alternately arranged and stacked in multiple layers. There are separators between the positive and negative plates, and the bus bars form four sets of positive and negative bus bars distributed around the pole group. A set of positive and negative busbars is distributed on each side wall of the pole group; a four-pole battery includes a sealed battery case and electrolyte, and eight terminal holes are opened on the side walls around the case. The negative terminals are led out from the terminal holes respectively to form four sets of positive and negative terminals, and one set of positive and negative terminals is respectively arranged on each side wall of the battery case. The invention prolongs the charge-discharge cycle life of the battery, prevents the battery from dehydrating and swelling, and improves the use safety and high-current discharge performance.

Owner:HENAN CHAOWEI POWER SUPPLY

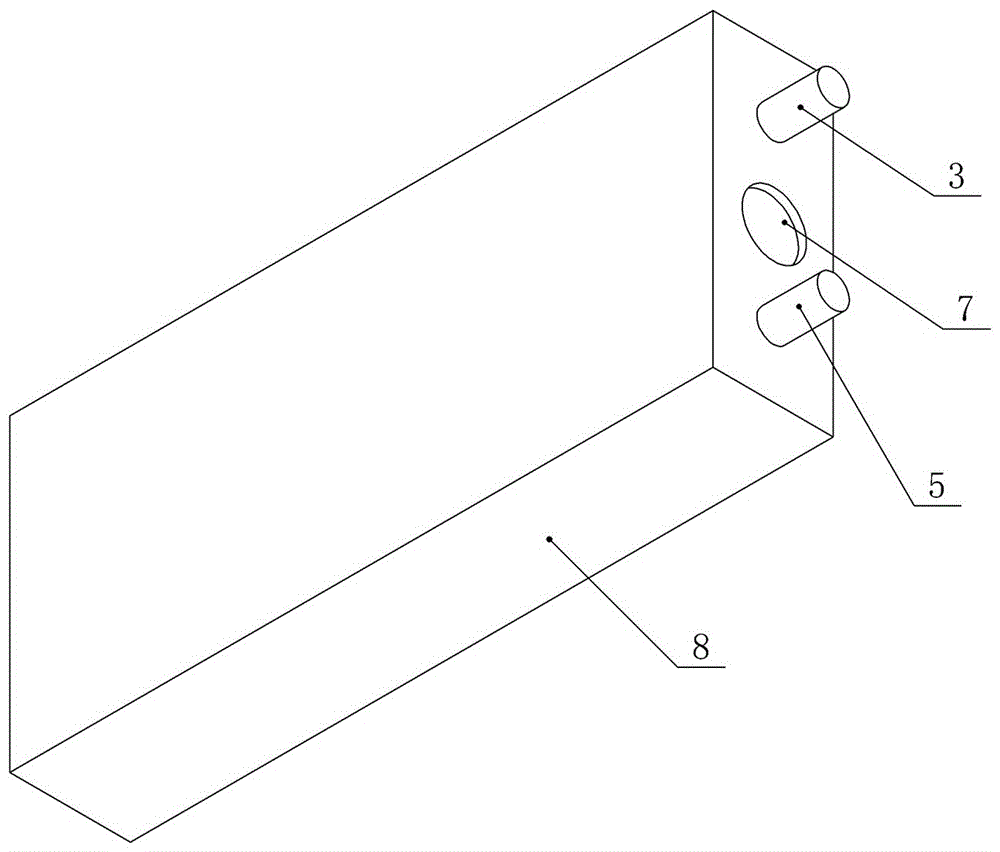

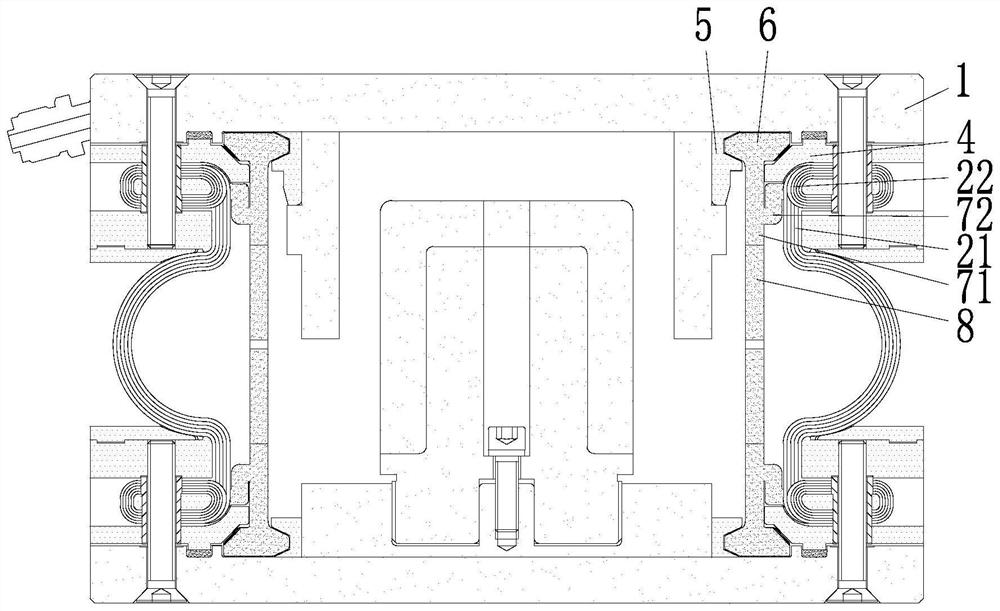

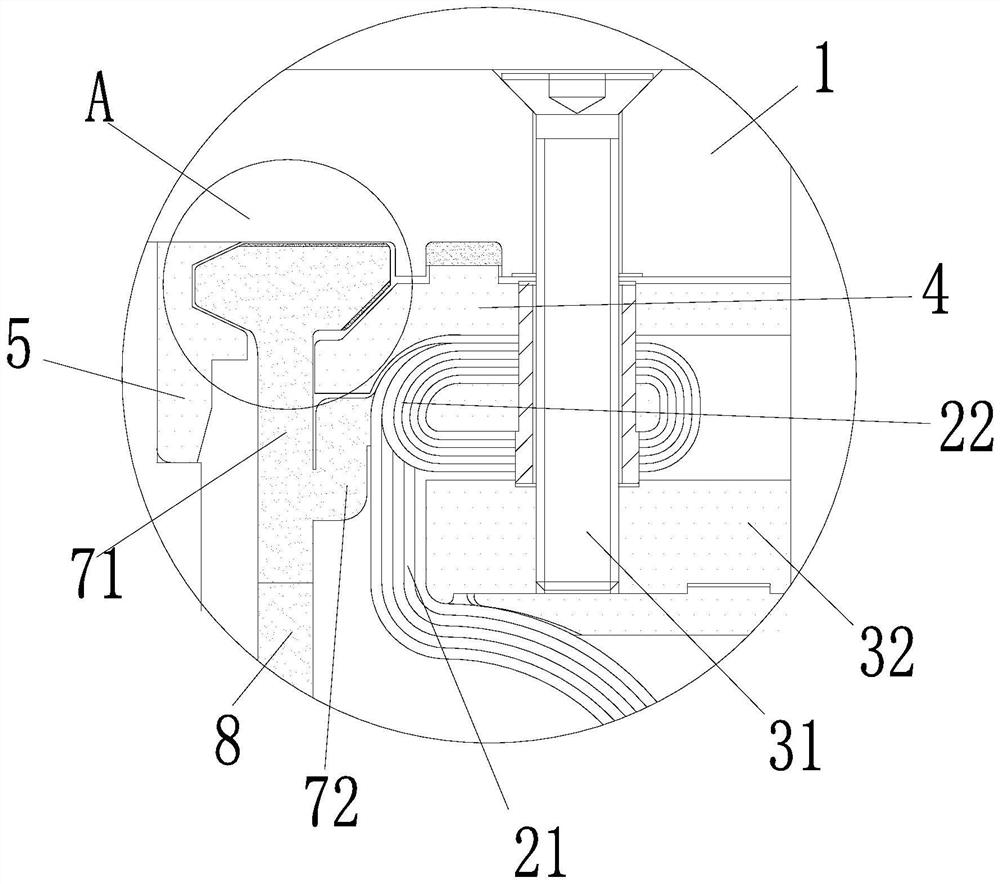

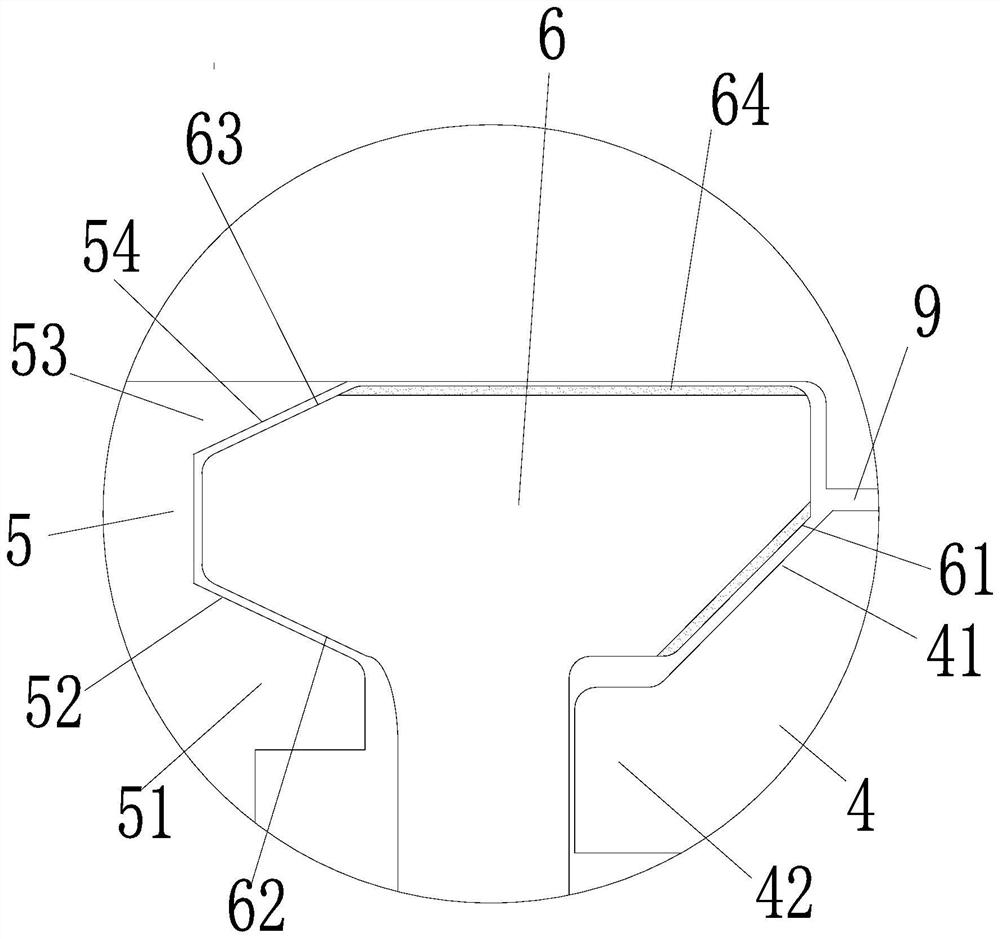

Novel air bag vibration isolator

PendingCN114810901AImprove sealingSolve the problem of air leakageSpringsGas based dampersEngineeringStructural engineering

The invention relates to a vibration isolator, in particular to a novel air bag vibration isolator. Comprising an outer bag body, cover plates fixed to the two ends of the outer bag body and clamping parts used for connecting the outer bag body and the cover plates, the outer bag body comprises a main bag body and a connecting bag body arranged on the outer side of the end of the main bag body, and a first extrusion ring is arranged between the corresponding connecting bag body and the cover plate; the inner wall of the cover plate is provided with an abutting ring, a filling ring is arranged between the abutting ring and the corresponding first extrusion ring, the side, close to the corresponding cover plate, of the first extrusion ring is provided with a first sliding face, and a sealing belt ring is further arranged between the filling ring and the main bag body. The air leakage problem of the first gap can be effectively solved through the sealing belt ring, the air leakage problem of the second gap can be effectively solved through arrangement of the first sliding face and extrusion of the filling ring and the abutting ring, the vulcanization process between the first extrusion ring and the connecting bag body can be reduced, and the preparation technology is simplified.

Owner:NAVAL UNIV OF ENG PLA

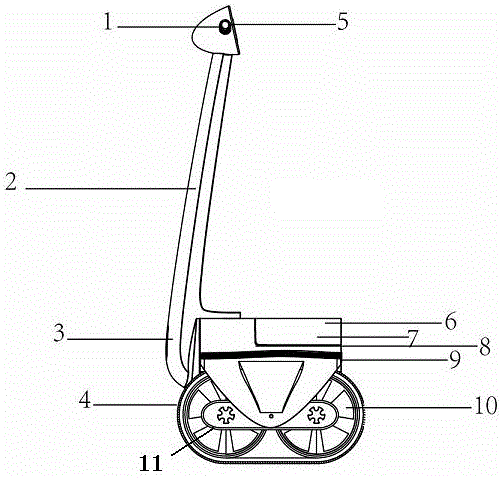

Multifunctional snowmobile

InactiveCN105946994AReduce vulcanizationAchieve energy saving and emission reductionCycle control systemsEndless track vehiclesJoystickSlide plate

The invention discloses a multifunctional snowmobile. The multifunctional snowmobile comprises a rotary handle, a joystick, a nocturnal light, a crawler belt, a display screen, a solar charging panel, a controller, a signal lamp, a charge port, motors and a baffle. The crawler belt is used for replacing a sliding plate and car wheels, and meanwhile operation in environments such as snowfields, deserts and flat ground is achieved, so that the car achieves multiple purposes.

Owner:NANCHANG UNIV

A kind of non-precious metal supported catalyst, its preparation method and application

ActiveCN109985641BReduce usageEfficient use ofPhysical/chemical process catalystsHydrocarbon oils treatmentPtru catalystPhysical chemistry

The invention discloses a non-precious metal vulcanized supported catalyst, which is at least one of molybdenum or tungsten, at least one of cobalt or nickel supported on a carrier in a fully or partially vulcanized state; the carrier includes carbon materials; wherein The mass of at least one of molybdenum or tungsten is 10-50% of the total mass of the catalyst, the mass of at least one of cobalt or nickel is 1-20% of the total mass of the catalyst, and the mass of the carrier is 1-20% of the total mass of the catalyst . The invention also discloses the preparation method and application of the catalyst. Compared with the prior art, the catalyst of the present invention has high content of active components, many active site exposure sites, and the active components are evenly dispersed on the carbon material, which is used to prepare fuels with high thermal stability and has high hydrodesulfurization and Aromatic saturation activity.

Owner:TIANJIN UNIV

Preparation method of anti-vulcanization patch LED encapsulation glue

ActiveCN105567155BReduce oxidationImprove air tightnessNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention provides a preparation method of anti-sulfur chip LED (Light Emitting Diode) packaging adhesive. The preparation method at least comprises the steps of adding white carbon powder and silazane into initial phenyl vinyl silicone resin to perform stirring and hyperthermic treatment. The LED packaging adhesive prepared by the preparation method of the anti-sulfur chip LED packaging adhesive has a certain function of adsorbing and removing oxidizing substances, and the gas tightness of the packaging adhesive can be effectively improved, andthus a function of delaying vulcanization can be well realized.

Owner:GUANGDONG JIEGUO NEW MATERIAL CO LTD

High-efficiency three-dimensional lamp cup type LED support

PendingCN110880545AExtend the time of normal brightnessExtended service lifeSemiconductor devicesPlastic materialsPhysical chemistry

The invention discloses a high-efficiency three-dimensional lamp cup type LED support, and relates to the LED support related field. In order to solve the problems that in the prior art, after a PCT and an EMC are packaged and are powered on to heat, a plastic material has light failure due to thermal yellowing, and the light attenuation occurs due to the vulcanization of a silver-plated layer inthe air, and because that the physical property of a metal material is more stable than that of the plastic material, an anti-vulcanization film layer (namely Miro material) is plated on a metal silver-plated reflecting surface, and with the design of a lamp cup, the light condensation effect is effectively formed, the light effect is better reflected, the application of the LED bracket with higher power and high brightness is facilitated, and an energy-saving effect is achieved. The lamp cup is formed in the middle of a metal support, the metal support comprises a left half structure and a right half structure, and an empty groove is formed between the left half structure and the right half structure; the metal silver-plated reflecting surface is arranged on the inner surface of the lampcup, and the inner surface of the metal silver-plated reflecting surface is plated with the anti-vulcanization film layer (namely Miro material).

Owner:普利仕科技(苏州工业园区)有限公司

Preparation method of hydrogenation catalyst with high metal content

ActiveCN106423183BReduce manufacturing costHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationCarrying capacityPhosphoric acid

The invention relates to a preparation method of a high-metal-content hydrogenation catalyst, comprising the steps of depositing an aluminum source modifier to a carrier; mixing a metal, phosphoric acid, an organic complexing agent and deionized water; impregnating the mixture to the carrier on which the aluminum source modifier is deposited; drying and calcining the carrier on which the mixture is impregnated; wherein the metal is made from a main component, Mo in VIB, and an aid component, Ni in VIII, the aluminum source modifier is one, or a composition of any, of aluminum isopropoxide, aluminum chloride and aluminum nitrate, the carrier on which the aluminum source modifier is deposited is 1.3-2.3 ml / g in pore volume and 400-700 m<2> / g in specific surface area, and pores 14-18 nm in diameter accounts for greater than 50%. The preparation method of the high-metal-content hydrogenation catalyst provided herein has significantly improved activity and good pore structure and large specific surface area since metal carrying capacity is increased; the preparation process of the catalyst is simplified, and the preparation cost of high-metal-content hydrogenation catalyst is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

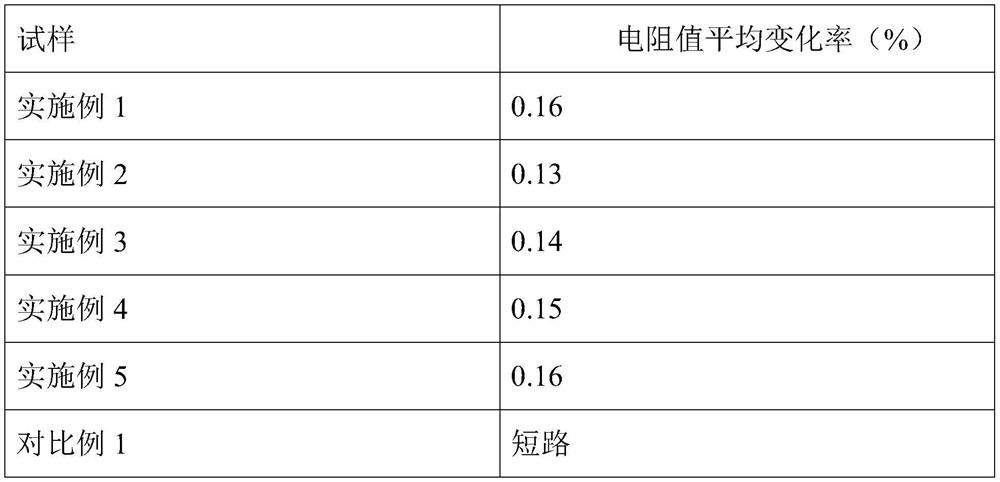

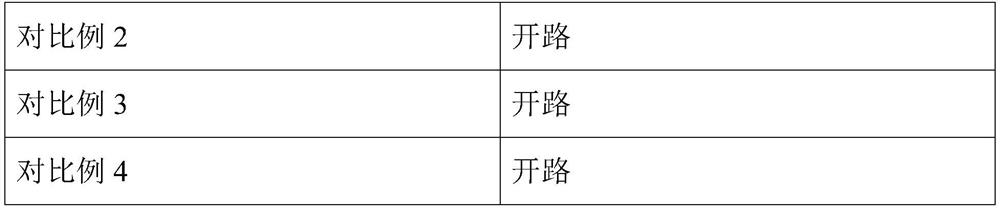

Method for preparing anti-vulcanization thick film chip resistor

PendingCN113972045AInhibit migrationAvoid short circuitResistive material coatingColloidal silicaSlurry

The invention discloses a method for preparing an anti-vulcanization thick-film chip resistor and belongs to the field of thick-film chip resistors. The method specifically comprises the following steps that: an insulating plate is coated with a layer of conformal coating in advance to prepare a substrate; the substrate is coated with anti-vulcanization conductive slurry and resistance slurry through a mask; sintering is performed to form an electrode layer and a resistance layer on the substrate; and a protective coating is further applied between the electrode layer and the resistance layer, and drying is performed to form a coating layer to prepare a chip resistor, wherein the protective coating is prepared from the following raw materials in parts by mass: 40 to 89 parts of potting silica gel, 5 to 20 parts of modified heat-conducting filler and 1 to 20 parts of flame retardant, wherein the modified heat-conducting filler is composed of a small-particle-size heat-conducting filler and a large-particle-size heat-conducting filler. According to the method of the invention, a layer of conformal coating is coated on the insulating plate in advance, so that silver migration under the action of high temperature, high humidity and electric field force can be prevented, and short circuit between lines is avoided.

Owner:江西昶龙科技有限公司

Spreading machine

The invention relates to a spreading machine, which comprises a machine body, a motor, a driving device, and an actuating mechanism, wherein the driving device is arranged in the machine body; the actuating mechanism arranged on the machine body comprises a glue pulling mechanism, a doubling mechanism, and a spreading mechanism; and the spreading mechanism is arranged between the doubling mechanism and the glue pulling mechanism or the doubling mechanism is arranged between the spreading mechanism and the glue pulling mechanism, the glue pulling mechanism is fixedly connected with the doubling mechanism through two guiding shafts, the spreading mechanism is sleeved on the two guiding shafts through two linear bearings, and a piston rod in a hydraulic actuating mechanism of the glue pulling mechanism is connected with a lower fixed clip knife bracket of the spreading mechanism. The spreading machine changes the prior manual glue-scaling method, and has the advantages of fast spreading speed, high efficiency, high recycling rate, fully-automatic operation, and labor conservation.

Owner:尹家旺

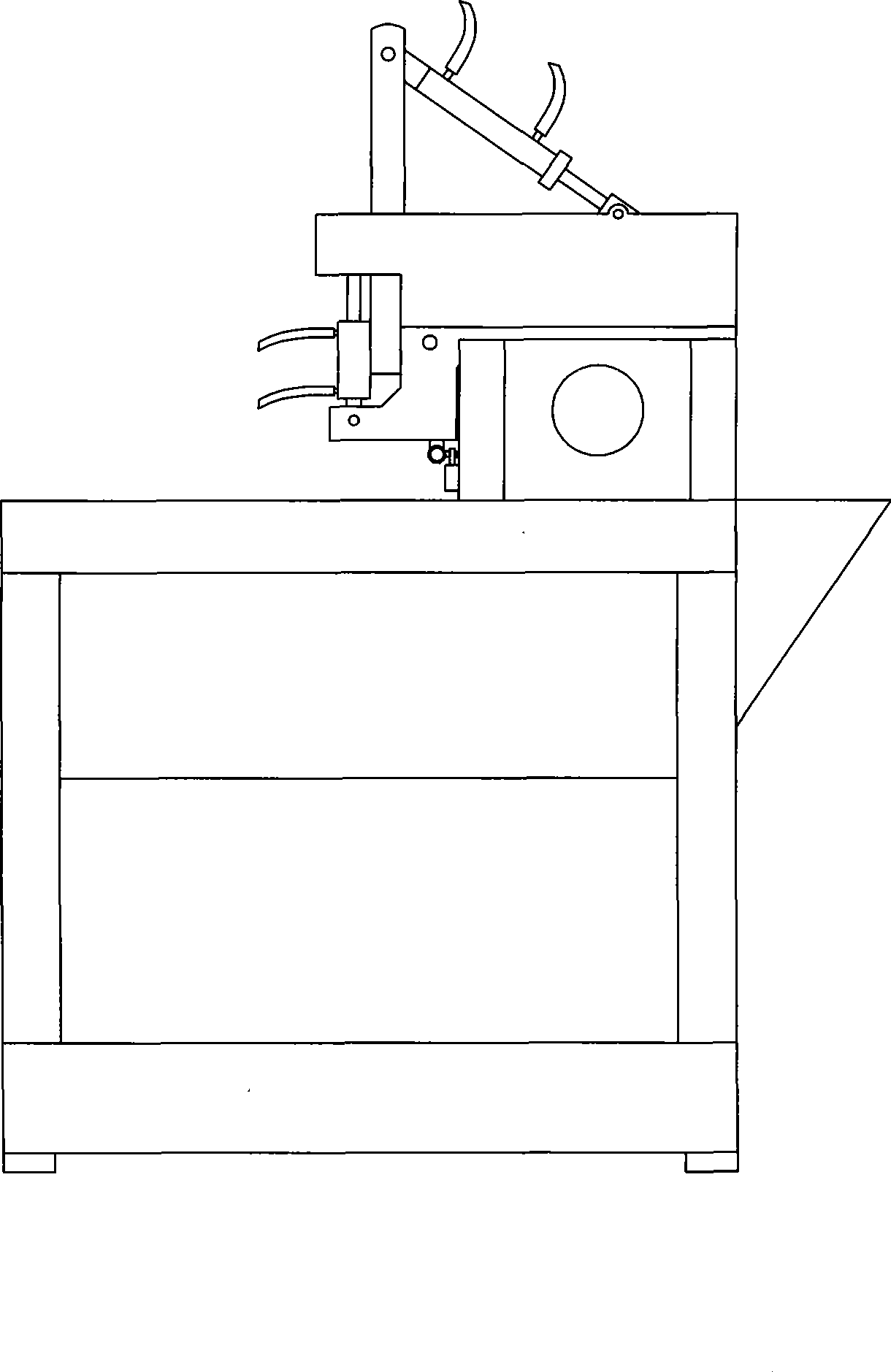

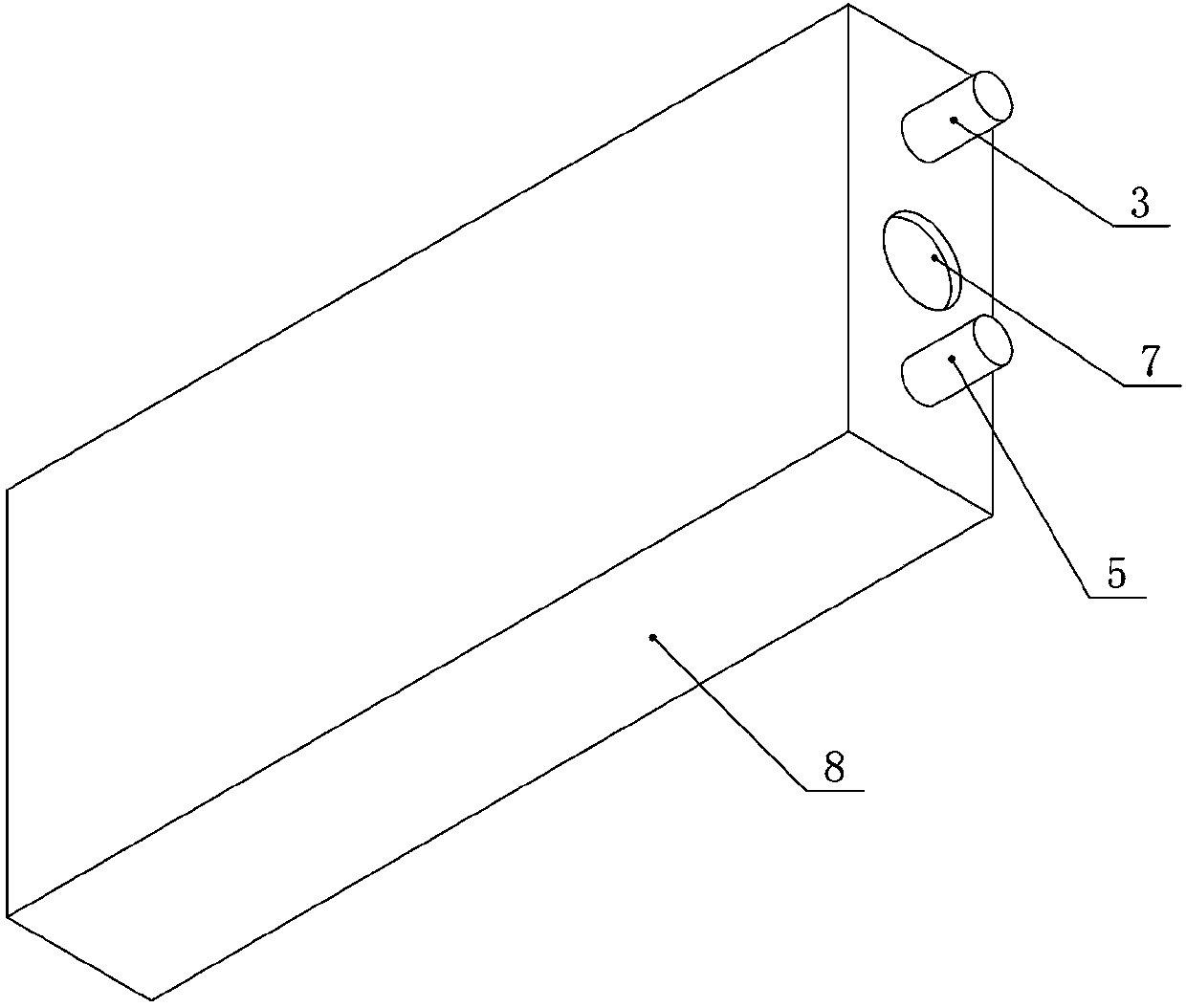

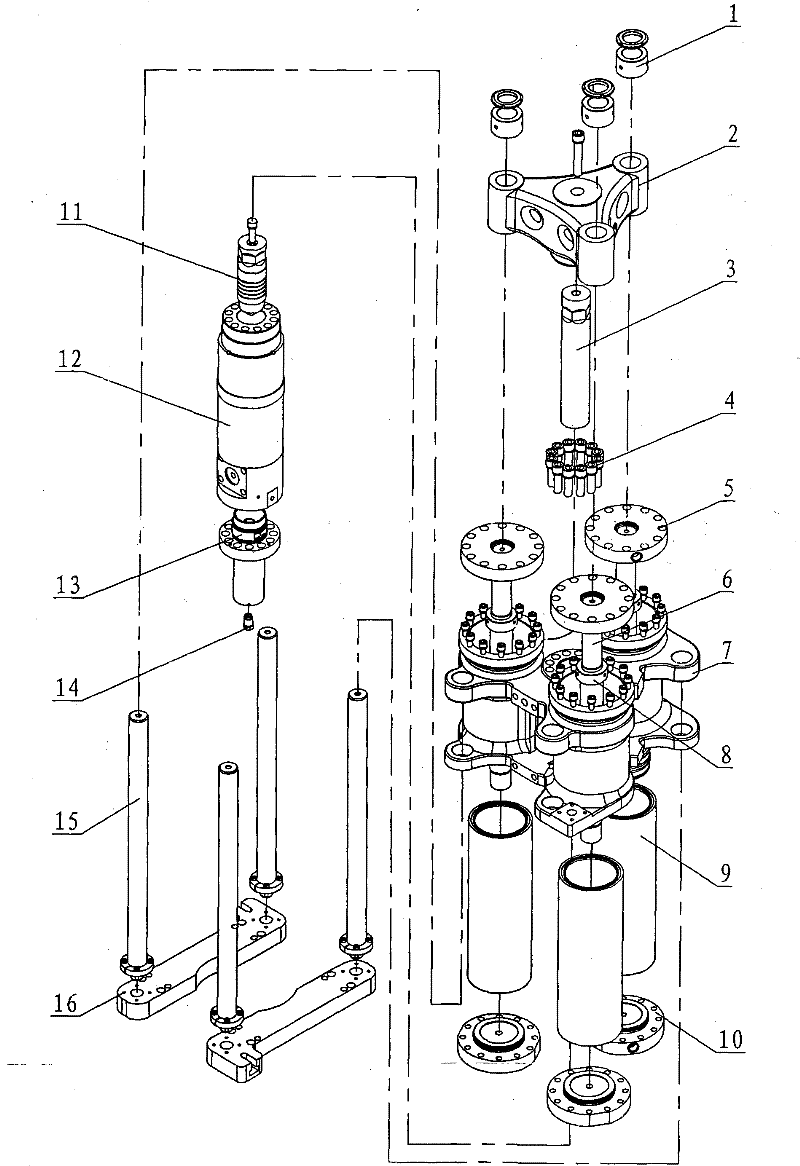

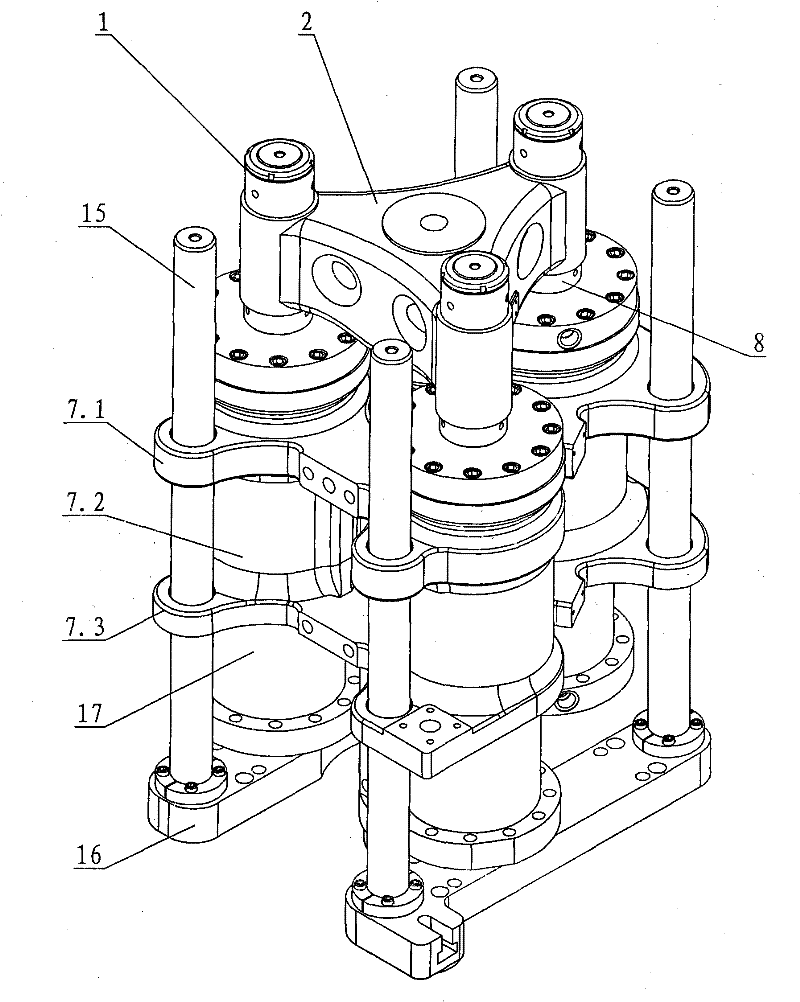

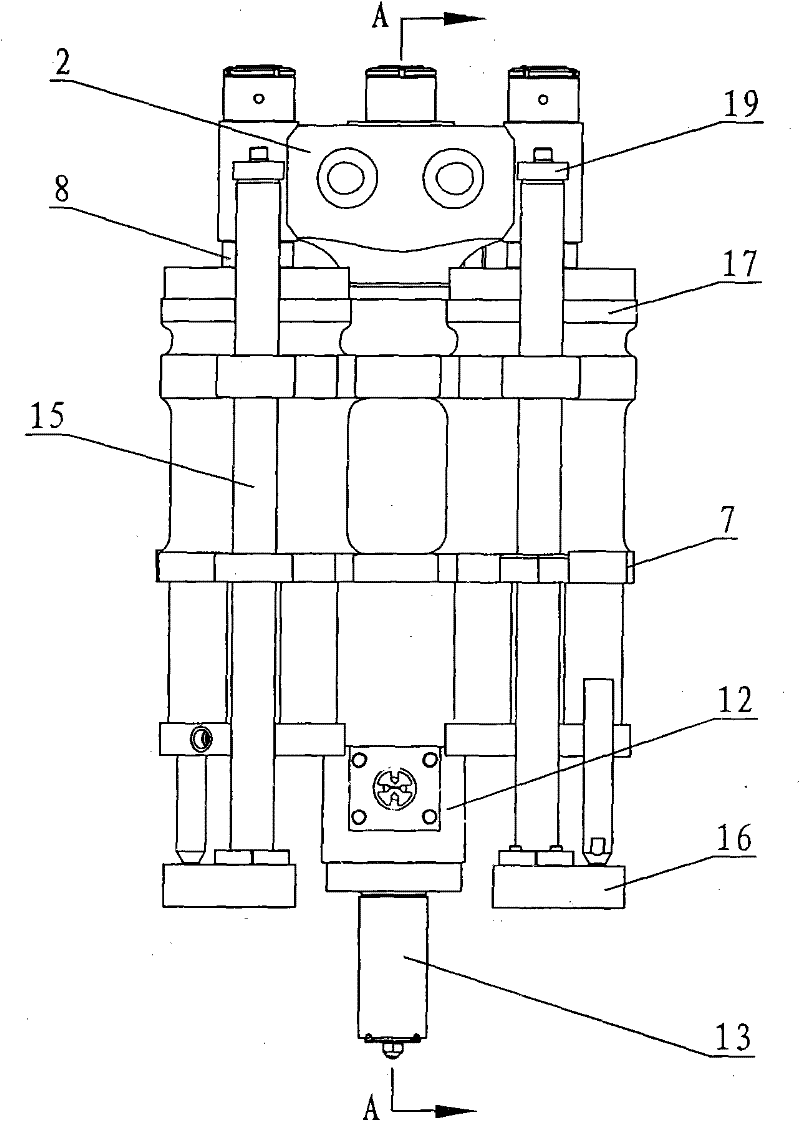

Rubber injection machine balance injection structure

A balanced injection structure for a rubber injection machine, comprising an upright injection barrel connected to a plasticizing part, with an injection plunger head in transmission connection with an injection cylinder, a nozzle body at the lower end, and an injection cylinder with a There are more than two, which are evenly distributed on the side of the injection barrel, and the piston rod of the injection cylinder is connected with the transmission plunger head of the injection cylinder. The injection part of the present invention is placed vertically, but the injection cylinder and the injection barrel are arranged in a plane and parallel, so that the height of the whole machine is reduced; the plasticizing part and the injection part are independent, the temperature control of the plasticizing and injection parts is easy to control, and the nozzle opening is reduced The amount of vulcanization of the rubber material, and the cleaning of the rubber material is convenient; at the same time, there are more than two injection cylinders, which are evenly distributed on the side of the injection barrel, and the piston rod is connected to the injection plunger head of the injection barrel through a beam. When injecting, the piston rod retracts and pulls the crossbeam; the crossbeam pushes the injection plunger head, and the injection plunger head pushes the rubber to be injected through the inner flow channel of the nozzle body.

Owner:广东伊之密精密橡塑装备科技有限公司

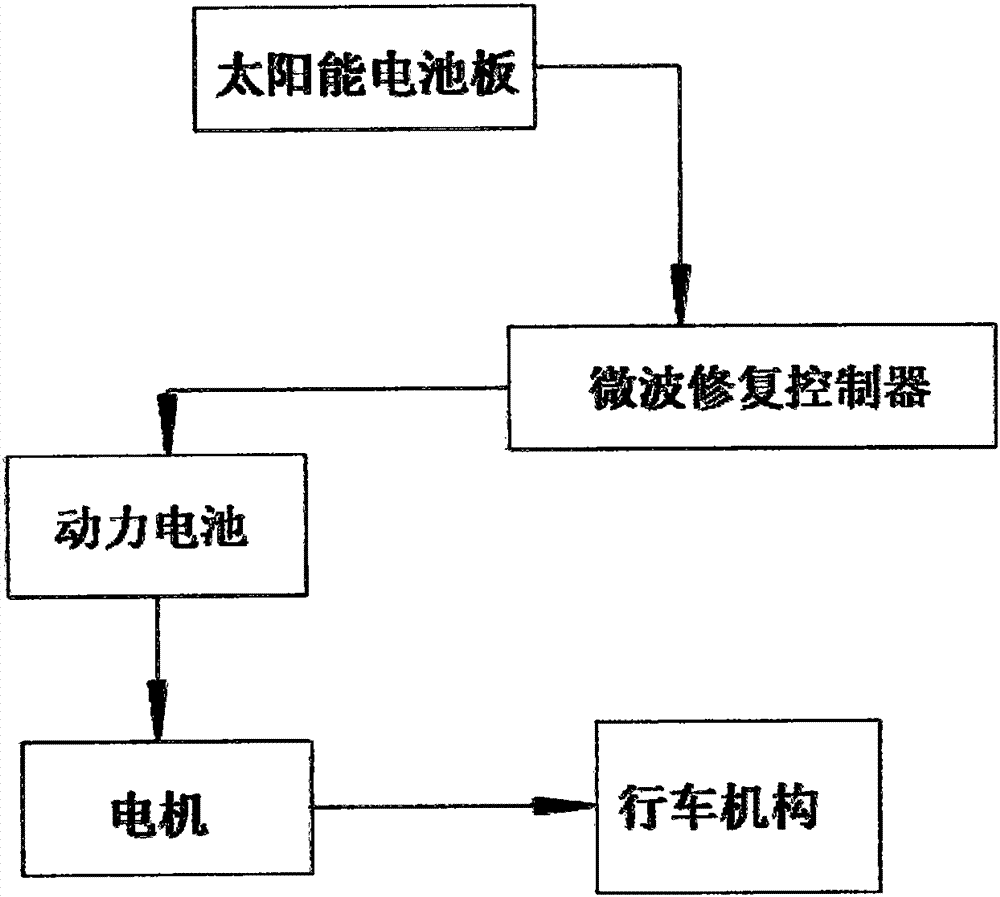

Automatic solar repair system and method for power battery

InactiveCN106856251ATimely supplementReduce the number of flushesBatteries circuit arrangementsSecondary cells charging/dischargingPower batteryBattery charge

The invention relates to an automatic solar repair system and method for a power battery. The system comprises a solar panel arranged on the top of an electric car and a microwave repair controller arranged in the electric car, wherein the output terminal of the solar panel is connected with the input terminal of the microwave repair controller, and the output terminal of the microwave repair controller is connected with the input terminal of the power battery located in the electric car. The method is to use the solar panel for continuous microwave charging of the power battery. According to the invention, the solar panel is used for continuous microwave charging of the power battery to improve the sulfuration phenomenon of the pole plates of the power battery and to prevent ageing of the pole plates caused by over discharge of the power battery. The microwave microcurrent repairing charging of the system and method mainly acts on ageing of the battery, decreases the ageing speed of the battery and enables the service life of the battery to be increased by 30%; meanwhile, the charging frequency of the battery can be decreased, and the consumption of electric energy is reduced; so the system and method are applicable to promotion in the field of electric cars.

Owner:四川天非尼迪新能源科技有限公司

Conductive ink of ultra-low haze silver nanowire film and its preparation method and application

ActiveCN110128883BDimensions required to attenuate scatteringGuaranteed CompatibilityInksOptical transmittanceThin membrane

The invention discloses a conductive ink of an ultra-low haze silver nanowire film and its preparation method and application. The conductive ink prepared by the preparation method is used to manufacture an ultra-low haze silver nanowire film. The preparation method obtained The silver nanowire has a diameter of 20 nanometers and an aspect ratio of 1000; the optical transmittance of the film made of conductive ink is higher than 95%, and the haze is lower than 0.5%. The conductive ink in the present invention reaches the photoelectric performance index of the film required by the high-definition screen in one film formation, and the silica sol added in the conductive ink tightly fixes the silver nanowires on the substrate and forms an aging protective layer on its surface. The surface hardness of the film reaches 3H, which is scratch-resistant, and has excellent environmental stability and anti-aging. The preparation method of the conductive ink is environmentally friendly and pollution-free, does not require expensive equipment such as high temperature and vacuum, is easy to operate, and is conducive to large-scale and low-cost promotion.

Owner:NANJING SILVERNANO NEW MATERIALS TECH CO LTD

Lead-acid battery series-to-parallel conversion and intelligent charging system

InactiveCN103812196BReduce vulcanizationIncrease acceptance rateBatteries circuit arrangementsElectric powerMicrocontrollerVulcanization

The invention discloses a serial-parallel conversion and intelligent charging system for a lead-acid storage battery pack. An intelligent segmental pulse charging technology is provided, the reverse instantaneous discharge function of a storage battery is added, the vulcanization phenomenon of a battery is reduced, the receiving rate of the battery is increased, the charging speed is increased, and the service life of the battery is prolonged. The system consists of a power supply main circuit, a control circuit, a simple keyboard and display circuit, an energy feedback circuit, a battery pack serial-parallel conversion circuit and a temperature measuring circuit, wherein the power supply main circuit consists of a full-bridge inverter circuit consisting of a full-bridge rectifying circuit and an IGBT (Insulated Gate Bipolar Translator), and a full-wave rectifying circuit; a C8051F020 singlechip is taken as the core of the control circuit; the simple keyboard and display circuit can be used for selectively charging on a peak valley; a transformer is taken as the feedback channel of the energy feedback circuit; discharge energy is stored in a filter capacitor. The battery pack serial-parallel conversion circuit consists of a three-pole double-throw switch and a diode, and a series battery pack adapter is used for charging a parallel battery, thereby solving the problem that all batteries cannot be charged due to damage to a single battery in the battery pack. The system is suitable for intelligent charging of electric bicycles in industrial production and civil use.

Owner:YANCHENG INST OF TECH

Nickel-based molybdenum disulfide powder for laser cladding, its preparation method and use method

ActiveCN106435580BGrain refinementReduce vulcanizationTransportation and packagingMetal-working apparatusVulcanizationDecomposition

The invention discloses a nickel-based molybdenum disulfide powder for laser cladding, a preparation method and a use method thereof, comprising the following components: molybdenum disulfide powder: 3-8%wt, particle size 0.1-2 microns; aluminum powder : 2~5%wt, particle size 200~300 microns; the balance is nickel powder, particle size 50~100 microns. The nickel-based molybdenum disulfide powder involved in the invention can effectively control the thermal decomposition of the molybdenum disulfide during the laser cladding process, thereby reducing the vulcanization effect of the decomposition on the obtained cladding layer, and improving the oxidation resistance of the cladding layer.

Owner:FUZHOU UNIV

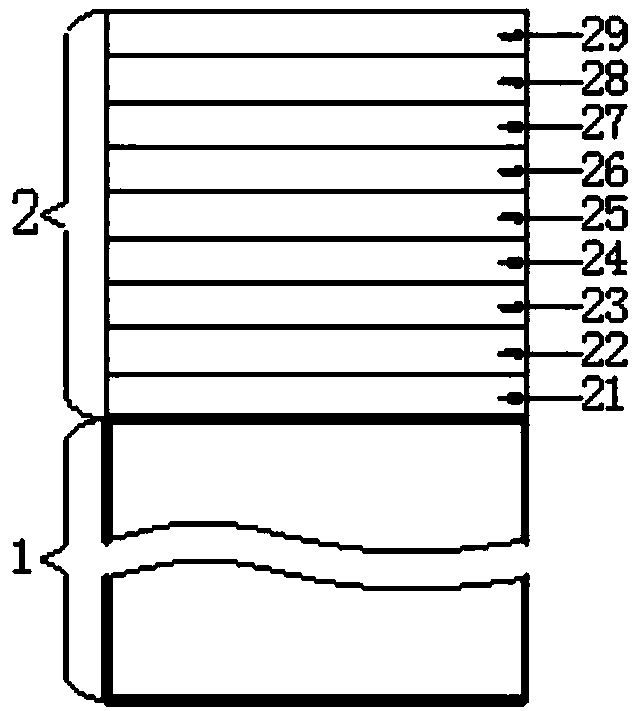

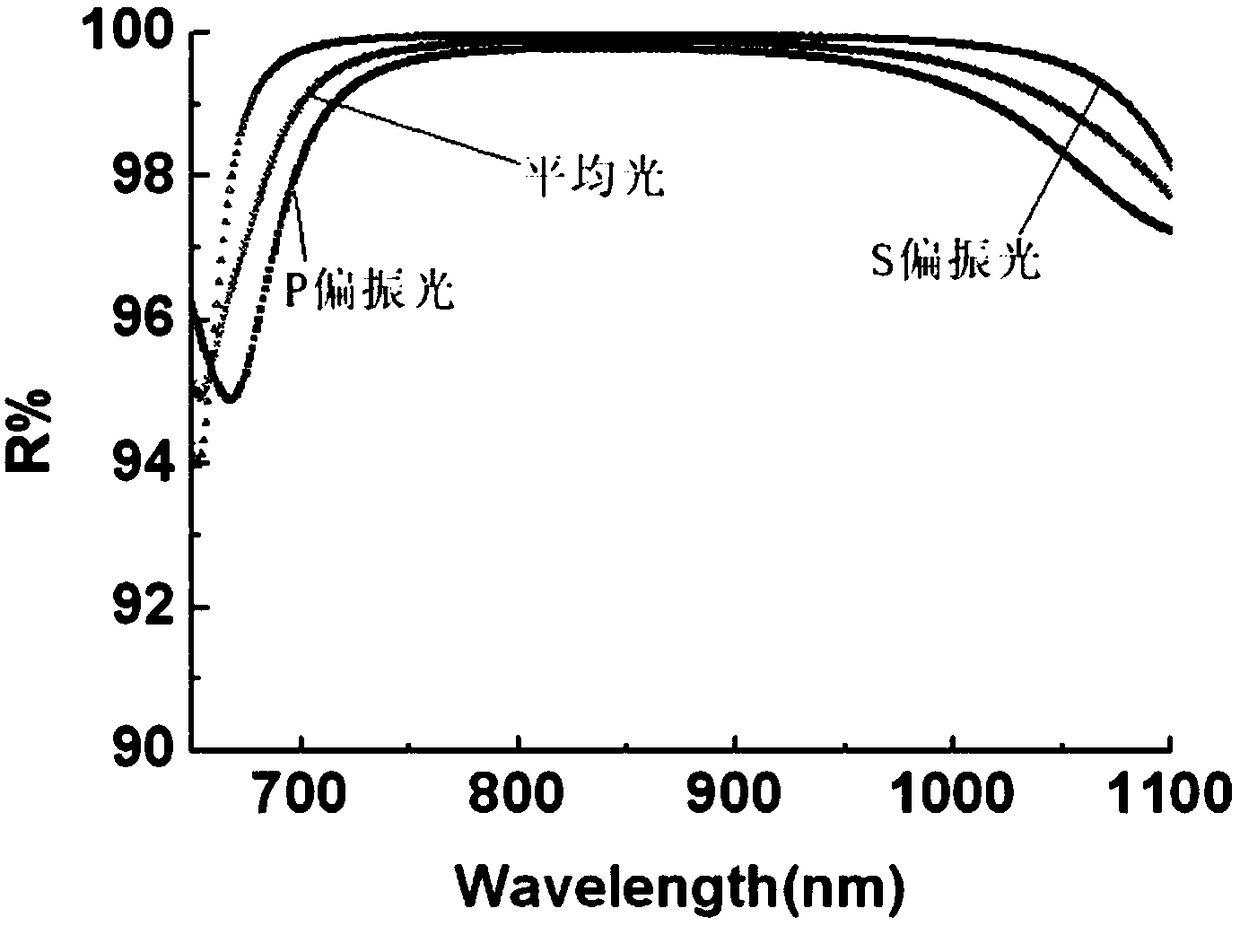

A kind of ultra-high reflectivity optical scanning vibrating mirror and its preparation method

ActiveCN105824119BHigh bandwidthIncrease the angleVacuum evaporation coatingSputtering coatingResonance angleRefractive index

The invention relates to an optical scanning galvanometer of super high reflectivity, which is composed of a glass substrate layer and a highly-reflective film deposited and plated on the glass substrate layer. The highly-reflective film is composed of nine film layers, which are sequentially, according to the distance from the glass substrate layer from small to large, a first Al2O3 film layer, an Ag film layer, a second Al2O3 film layer, a first SiO2 film layer, a first high-refractivity material film layer, a second SiO2 film layer, a second high-refractivity material film layer, a third SiO2 film layer, and a third high-refractivity material film layer. The beneficial effects are as follows: the reflection bandwidth and resonance angle are increased greatly while the number of coating layers is reduced; the reflection bandwidth with the reflectivity higher than 99% is up to 300nm; and the effective resonance angle can be 0-80 degrees.

Owner:SANMING FOCTEK PHOTONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com