LED chip package support and production method thereof

A technology of LED chips and packaging brackets, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as the easy break point of the connecting wire 301, the inability to realize the anti-vulcanization performance of SMD LED, and the influence of light extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the drawings and specific embodiments.

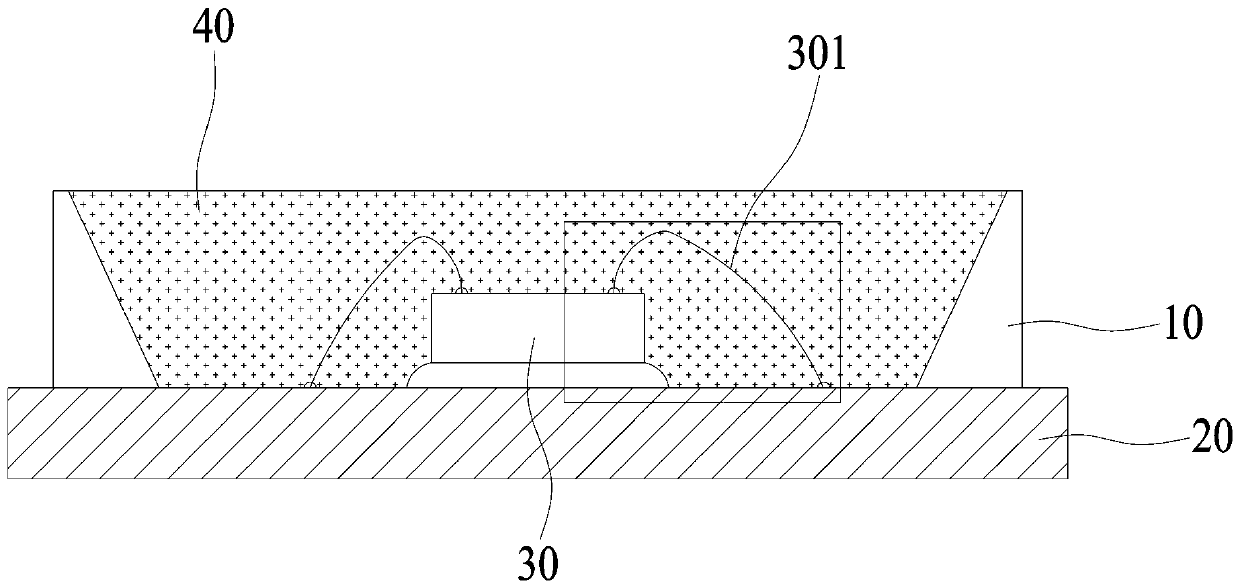

[0032] See Figure 4 and Figure 5 As mentioned, an LED chip packaging support disclosed in the present invention includes a base 1, a reflective cup 2, an LED chip 3, a first silica gel layer 4, and a second silica gel layer 5.

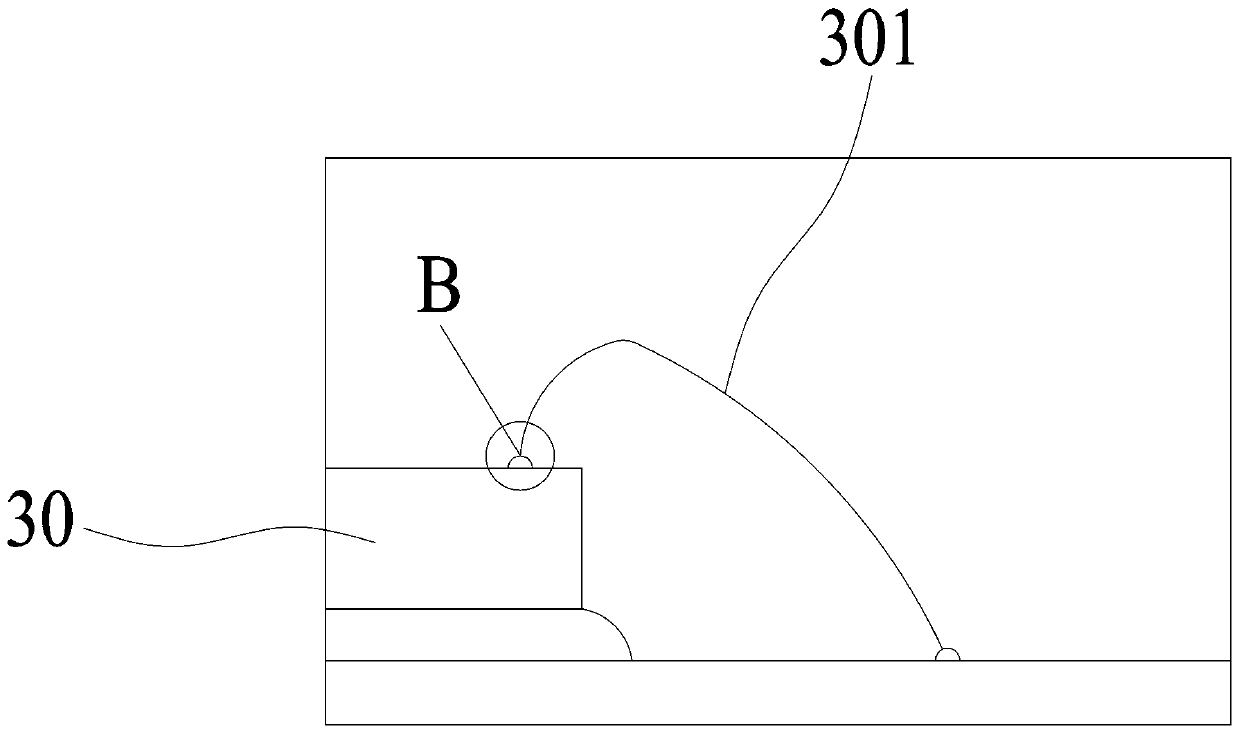

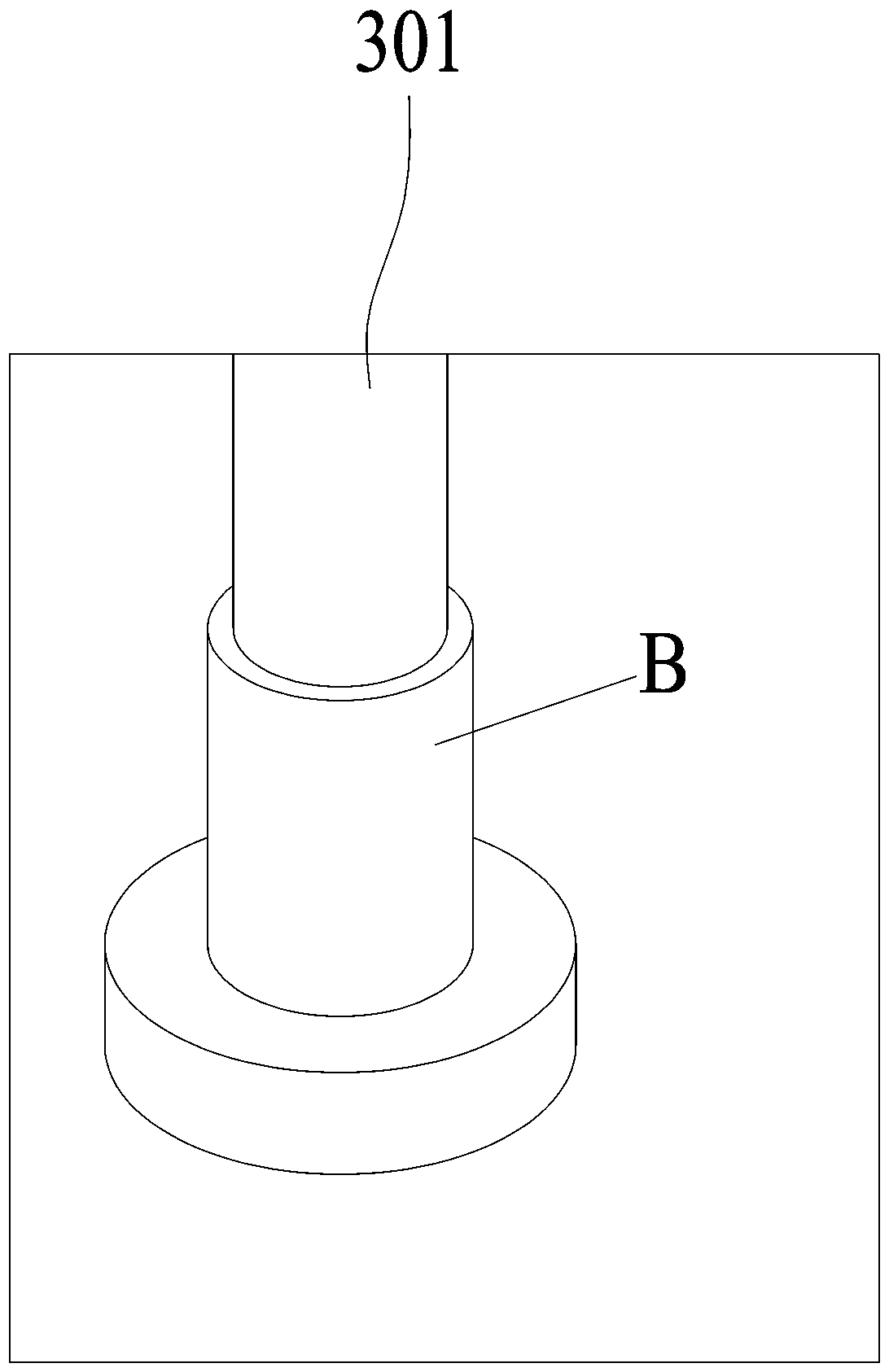

[0033] The reflector cup 2 is arranged on the base 1, the lower surface of the LED chip 3 is mounted on the base 1 and located at the bottom of the reflector cup 2, and the positive and negative poles of the LED chip 3 are respectively connected to the pins by connecting wires 6. This is a conventional structure. I will not repeat them here. The side where the LED chip 3 is attached to the base 1 is the lower surface, and the other side opposite to the lower surface is the upper surface, that is, the side closer to the base 1 is the lower surface, and the side farther from the base 1 is the upper surface .

[0034] The bottom of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com