Method for preparing anti-vulcanization thick film chip resistor

A technology of chip resistance and anti-sulfurization, which is applied in the direction of coating resistance materials, etc., can solve the problems of affecting electrode performance and vulcanization, and achieve the effects of reducing the possibility of vulcanization, improving adhesion, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

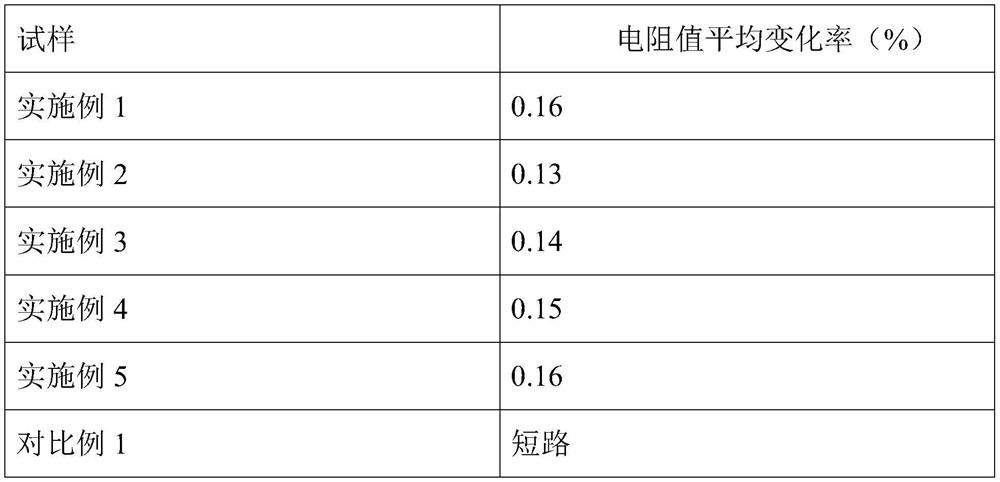

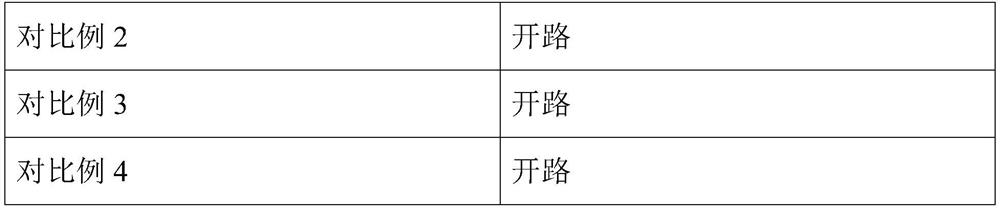

Examples

Embodiment 1

[0025] A method for preparing an anti-sulfurization thick-film chip resistor. A layer of conformal paint is coated on an insulating plate in advance to obtain a substrate, and an anti-sulfurization conductive paste and a resistance paste are coated on the substrate through a mask, and then Sintering forms an electrode layer and a resistance layer on the substrate, continues to coat a protective coating between the electrode layer and the resistance layer, and dries to form a cladding layer to obtain a chip resistor;

[0026] The protective coating includes raw materials in parts by mass: 59 parts of potting silica gel, 7 parts of modified thermal conductive filler and 4 parts of flame retardant;

[0027] The modified thermally conductive filler is composed of a small particle size thermally conductive filler (3-5 μm) and a large particle size thermally conductive filler (14-20 μm), with a mass ratio of 1:7.

[0028] The anti-sulfurization conductive paste contains palladium-si...

Embodiment 2

[0037] A method for preparing an anti-sulfurization thick-film chip resistor. A layer of conformal paint is coated on an insulating plate in advance to obtain a substrate, and an anti-sulfurization conductive paste and a resistance paste are coated on the substrate through a mask, and then Sintering forms an electrode layer and a resistance layer on the substrate, continues to coat a protective coating between the electrode layer and the resistance layer, and dries to form a cladding layer to obtain a chip resistor;

[0038] The protective coating includes raw materials in parts by mass: 69 parts of potting silica gel, 11 parts of modified thermally conductive filler and 9 parts of flame retardant;

[0039] The modified thermally conductive filler is composed of a thermally conductive filler with a small particle size (3-5 μm) and a thermally conductive filler with a large particle size (14-20 μm), with a mass ratio of 1:8.

[0040] The anti-sulfidation conductive paste contai...

Embodiment 3

[0049] A method for preparing an anti-sulfurization thick-film chip resistor. A layer of conformal paint is coated on an insulating plate in advance to obtain a substrate, and an anti-sulfurization conductive paste and a resistance paste are coated on the substrate through a mask, and then Sintering forms an electrode layer and a resistance layer on the substrate, continues to coat a protective coating between the electrode layer and the resistance layer, and dries to form a cladding layer to obtain a chip resistor;

[0050] The protective coating includes raw materials in parts by mass: 68 parts of potting silica gel, 14 parts of modified thermally conductive filler and 11 parts of flame retardant;

[0051] The modified thermally conductive filler is composed of a small particle size thermally conductive filler (3-5 μm) and a large particle size thermally conductive filler (14-20 μm), with a mass ratio of 1:7.

[0052] The anti-sulfurization conductive paste contains palladiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com