Serial-parallel conversion and intelligent charging system for lead-acid storage battery pack

A lead-acid battery and intelligent charging technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as insufficient charging, accelerated precipitation, and ineffective conversion of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

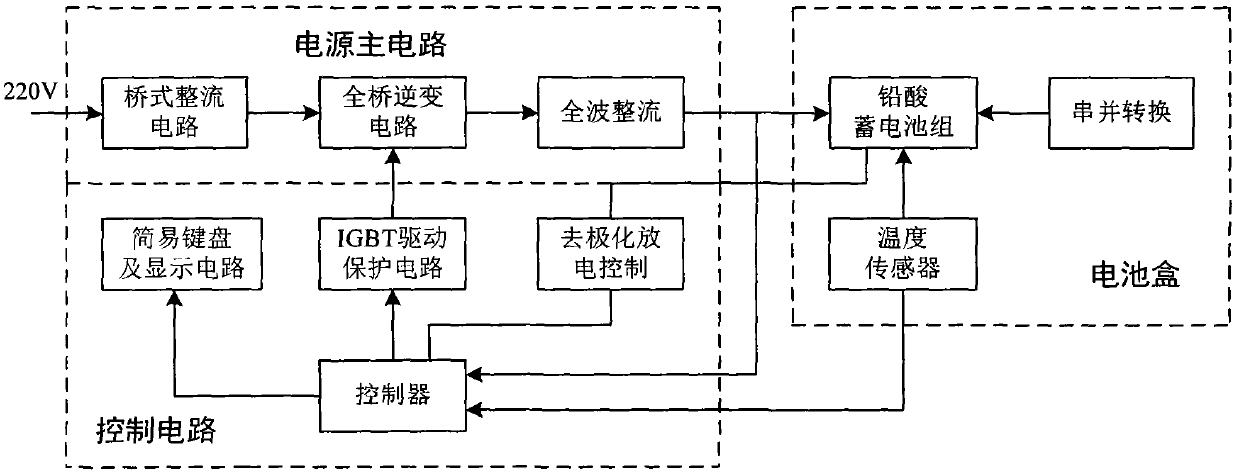

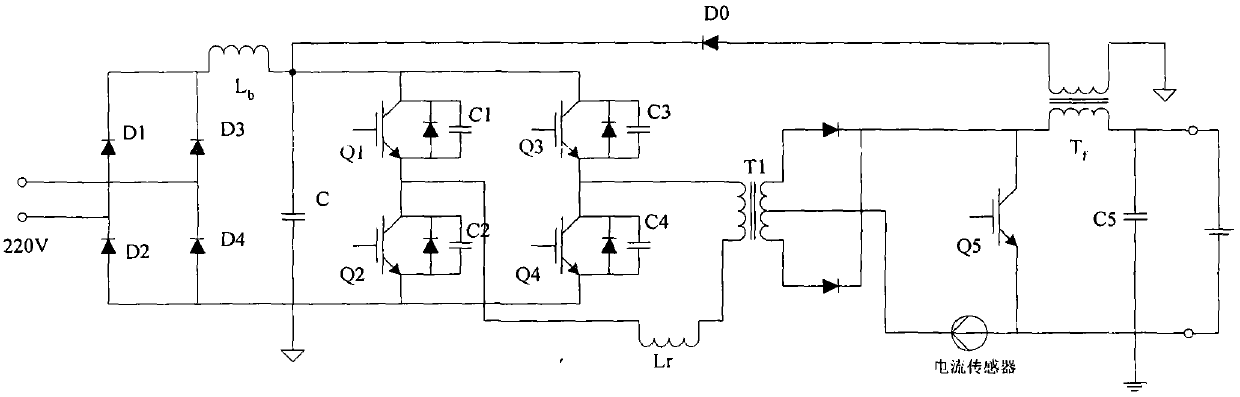

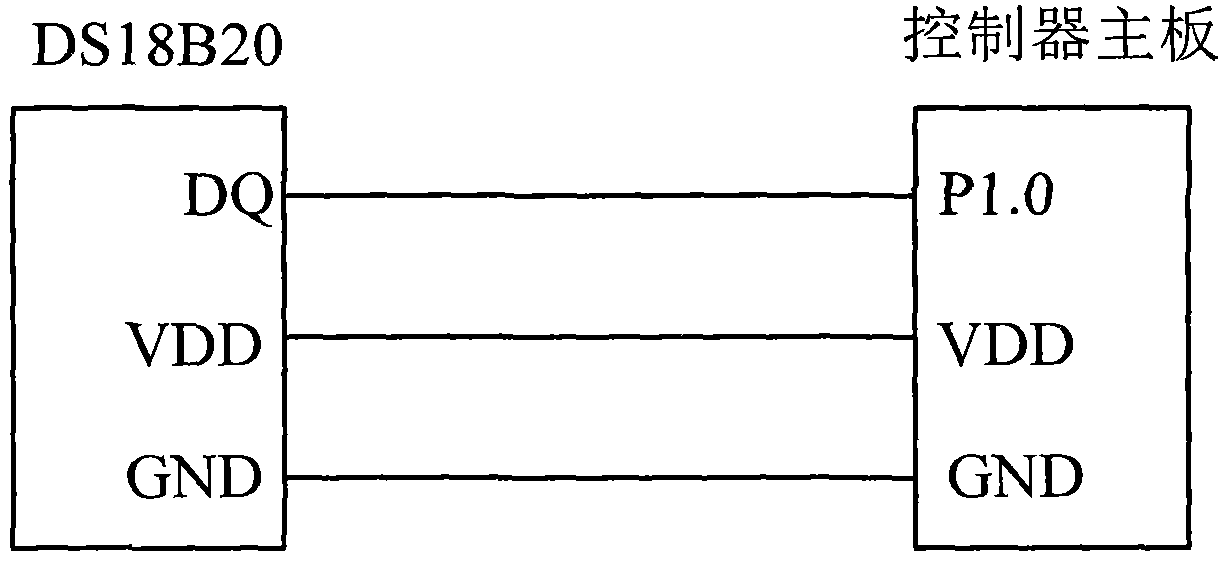

[0016] Depend on figure 1 The system block diagram shows that the intelligent charging system is composed of the main power circuit, control circuit, simple keyboard and display circuit, energy feedback circuit, battery series-to-parallel conversion circuit and temperature measurement circuit. The main circuit of the power supply is composed of a full-bridge rectifier circuit, a full-bridge inverter circuit composed of IGBTs and a full-wave rectifier circuit. The control circuit is based on a C8051F020 single-chip microcomputer. The energy feedback circuit uses a transformer as a feedback channel to store the discharge energy in the filter capacitance. The series-to-parallel conversion circuit of the battery pack is composed of a three-pole double-throw switch and a diode, and the series battery pack is transferred to a parallel battery for charging, which avoids the problem that a single battery in the battery pack is damaged and all the batteries cannot be charged.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com