Patents

Literature

135results about How to "Reduce charging voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

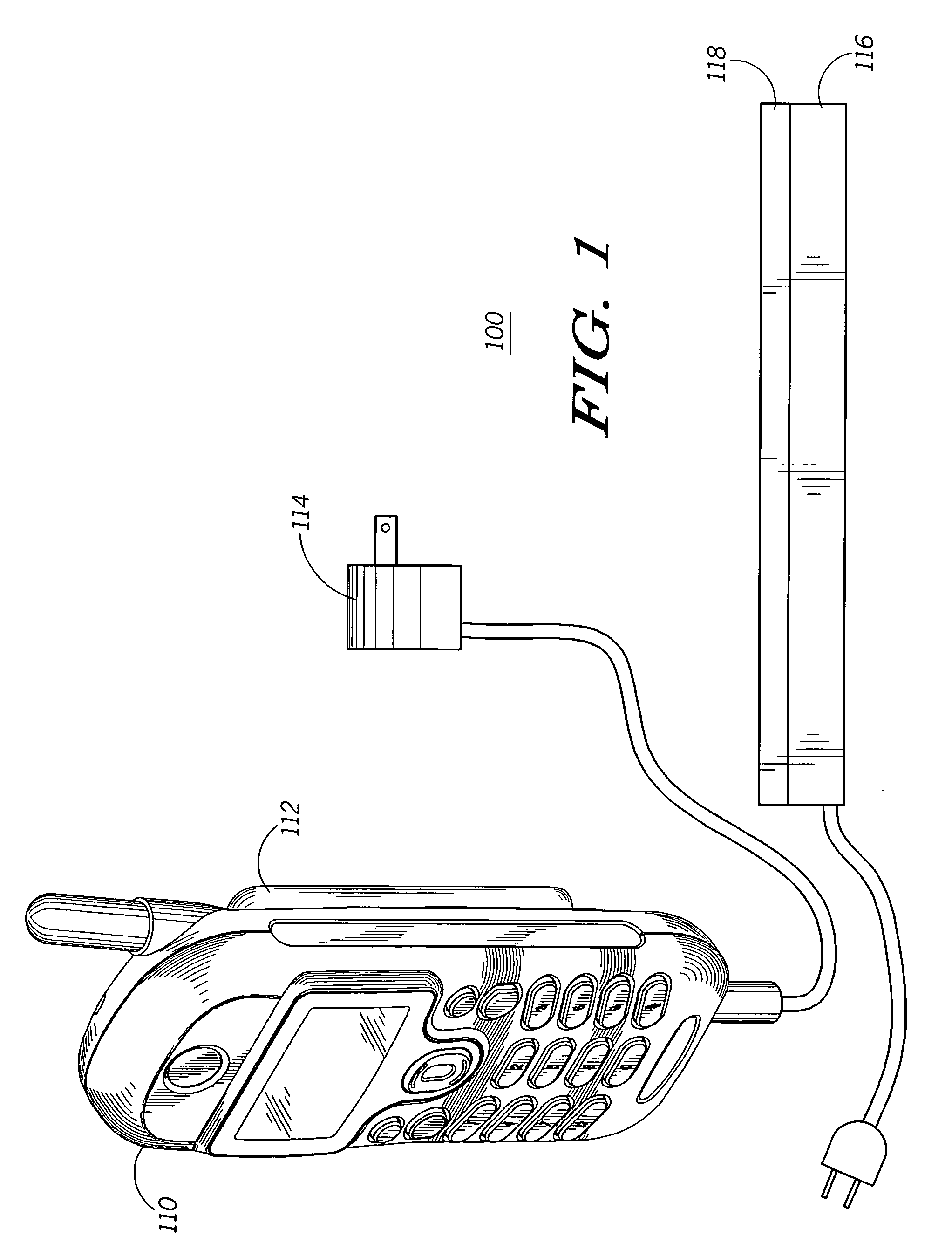

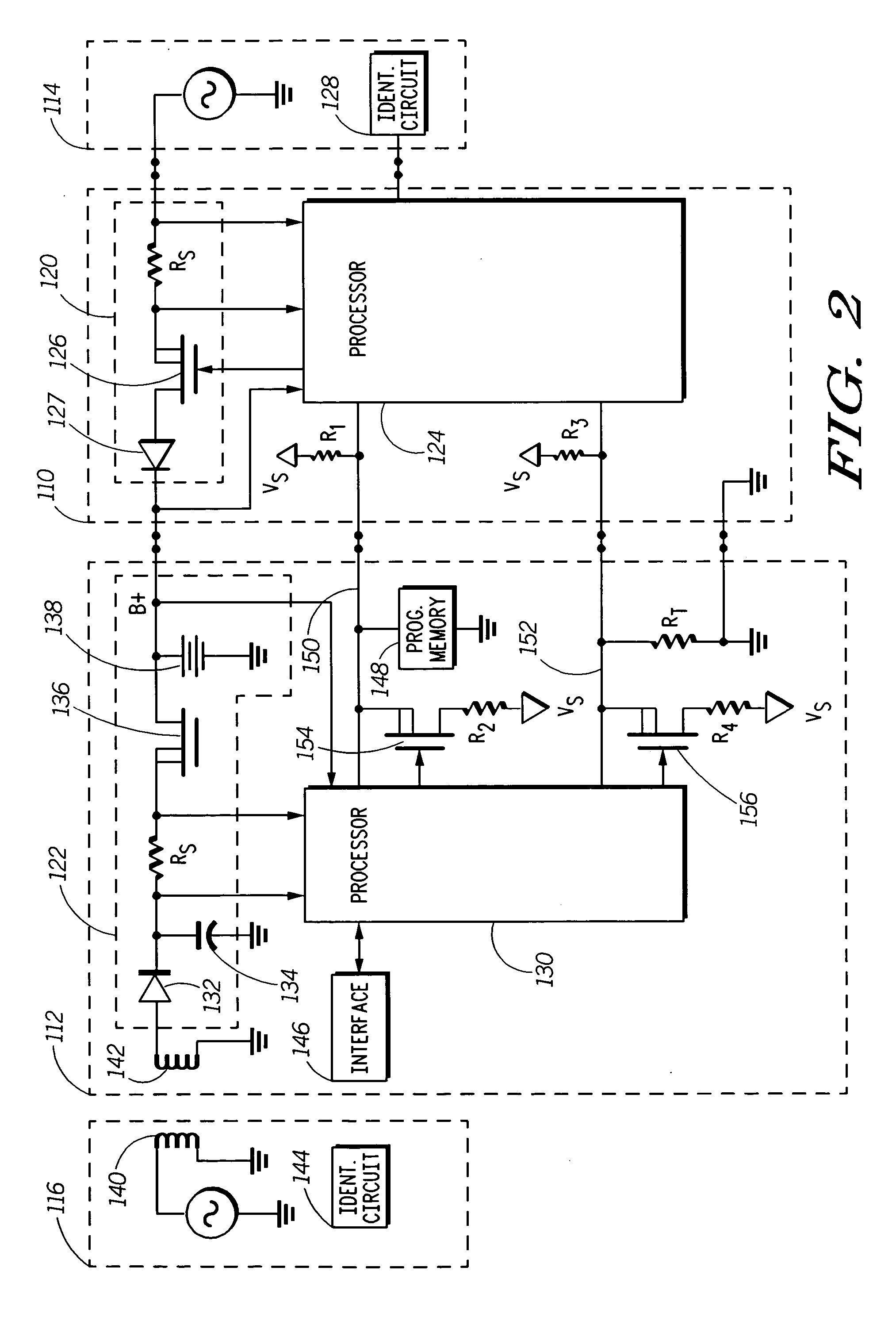

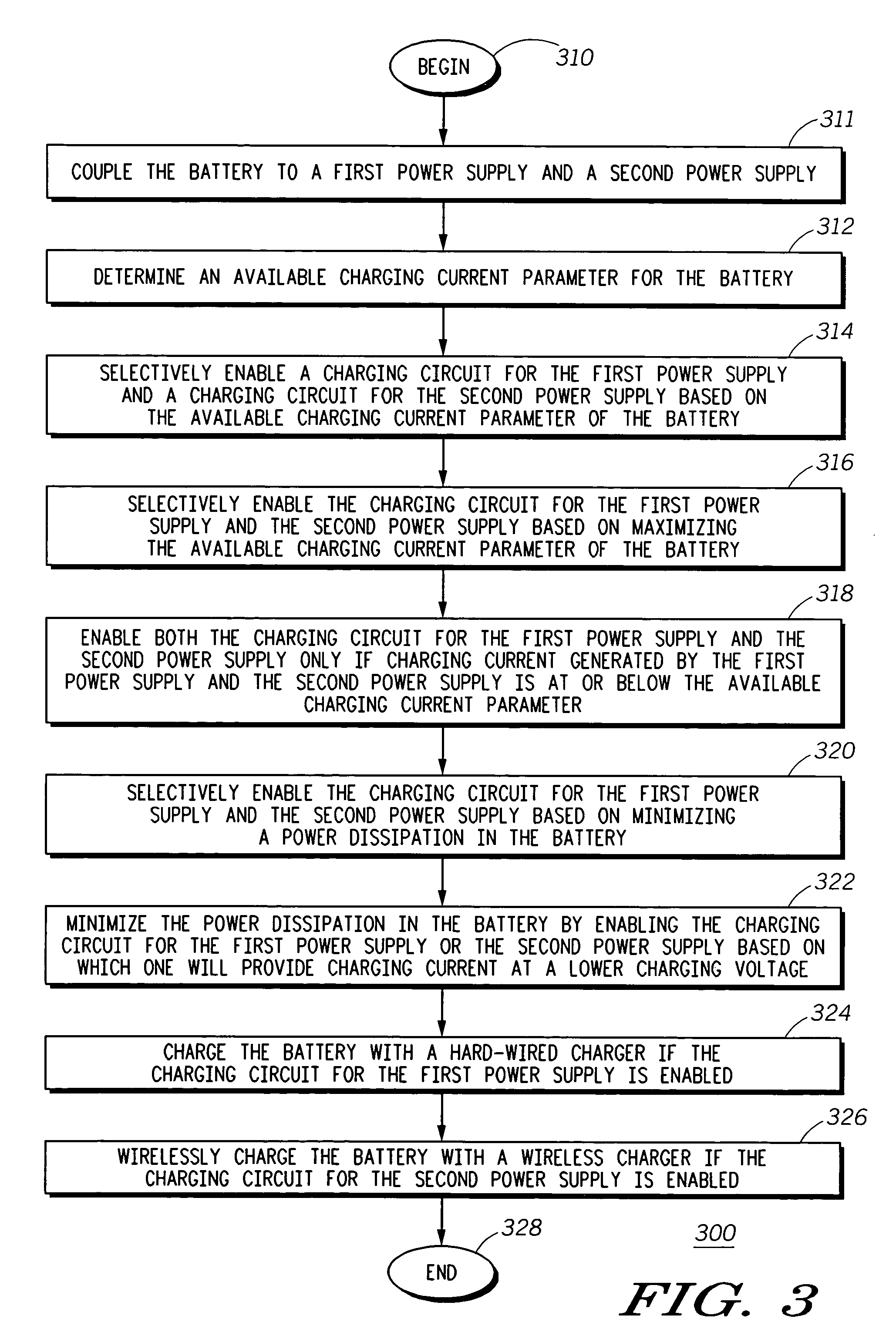

Method and system for selectively charging a battery

InactiveUS20060103355A1Maximizing available charging current parameterMinimize power consumptionElectric powerCharge maintainance charging/dischargingCharge currentCoupling

The invention concerns a method (300) and system (100) for selectively charging a battery (112). In one arrangement, the method can include the steps of coupling (311) the battery to a first power supply (114), coupling (311) the battery to a second power supply (116), determining (312) an available charging current parameter for the battery and selectively enabling (314) a charging circuit (120) for the first power supply and a charging circuit (122) for the second power supply based on the available charging current parameter of the battery. The selectively enabling process can be based on maximizing (316) an available charging current of the battery and minimizing (320) a power dissipation of the battery. As an example, the first power supply can be a hard-wired charger (114), and the second power supply can be a wireless charger (116).

Owner:MOTOROLA INC

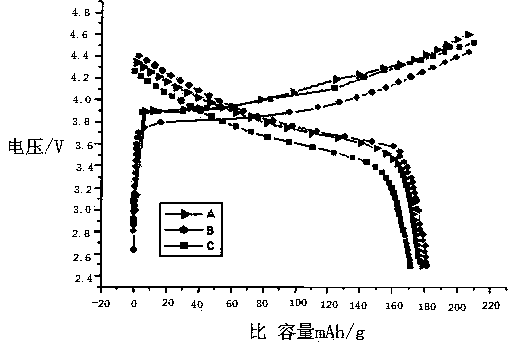

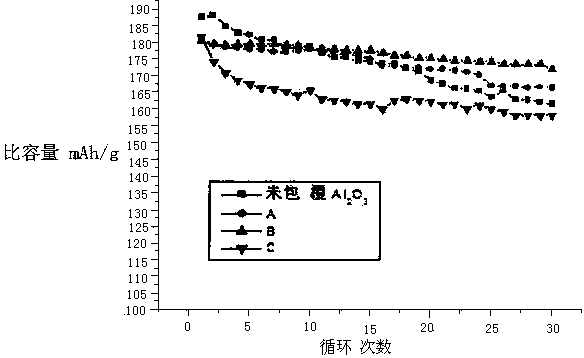

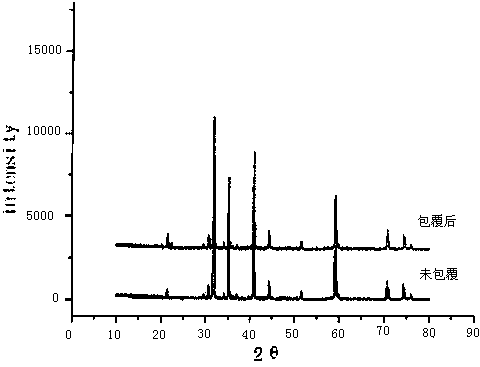

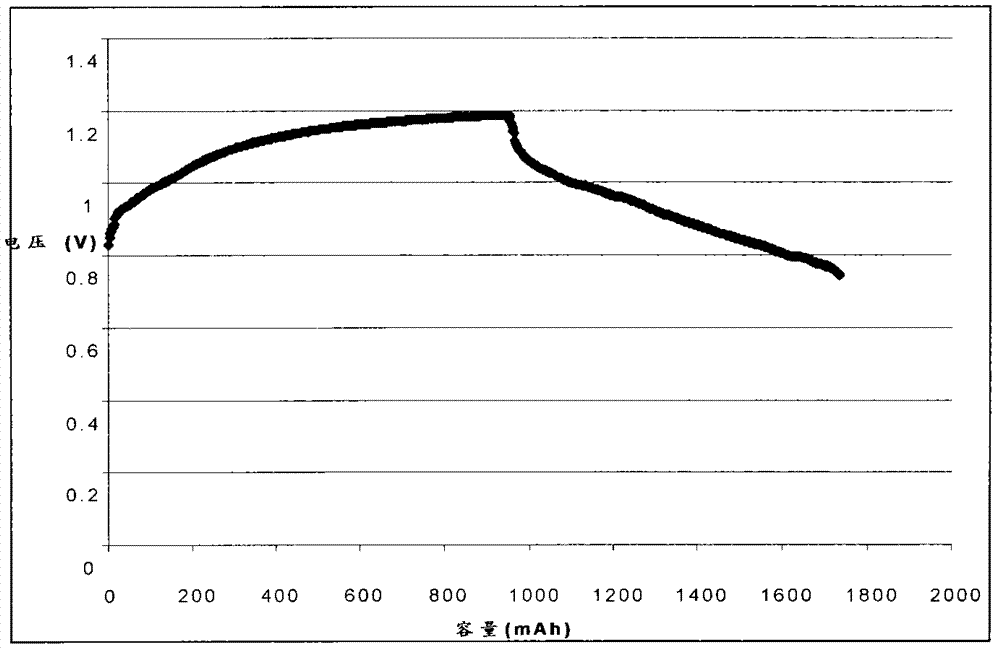

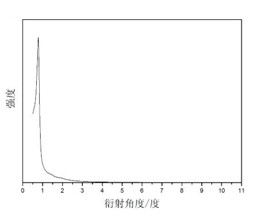

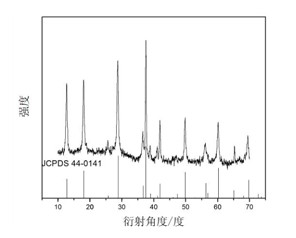

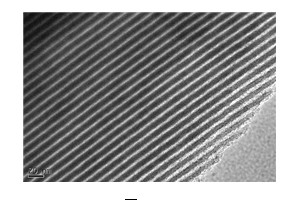

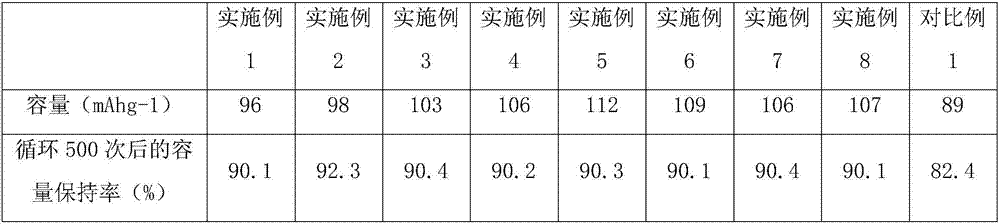

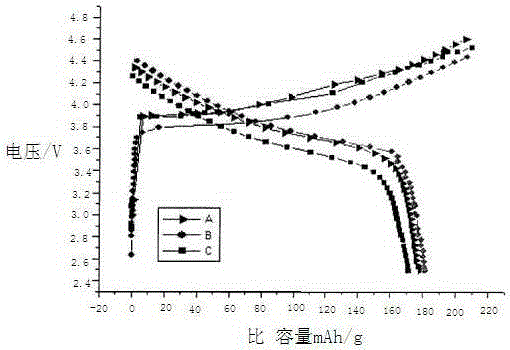

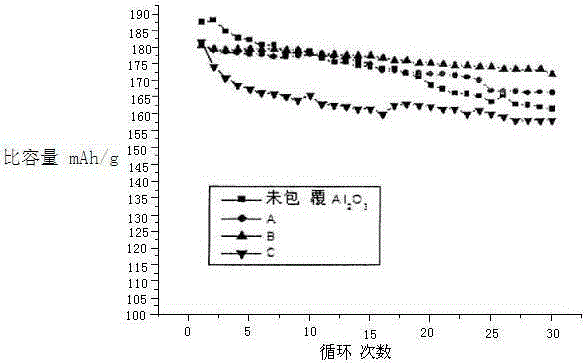

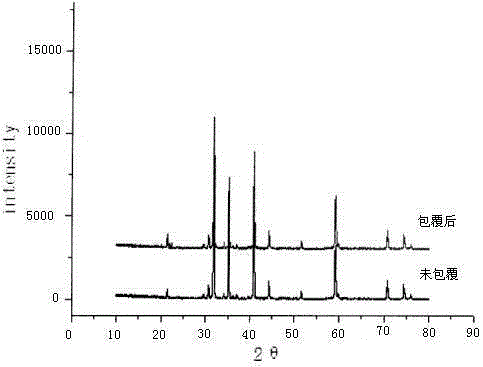

Preparation method of alumina composite nickel-cobalt lithium manganate ternary material

ActiveCN103618064AImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseAlumina composite

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

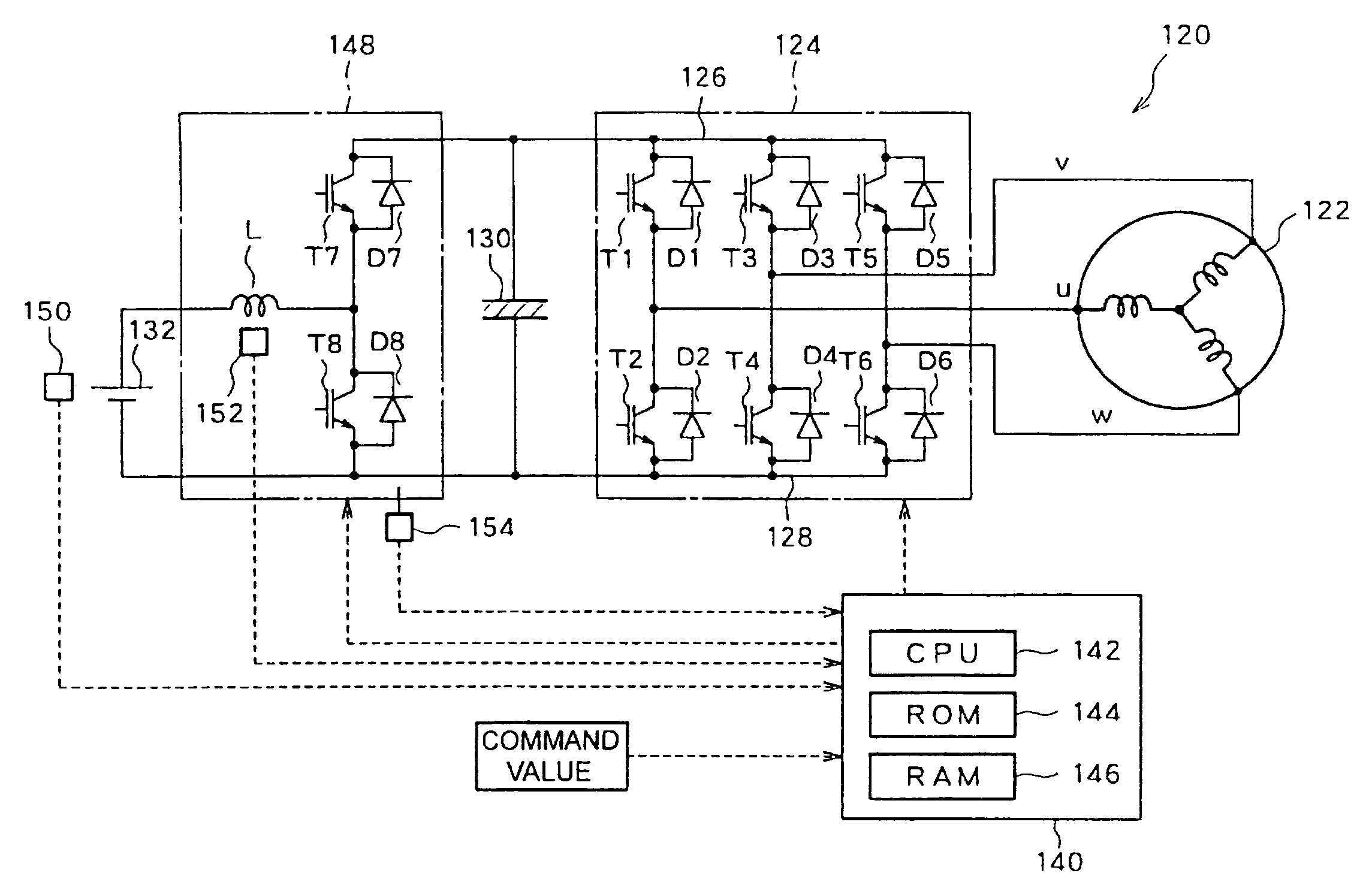

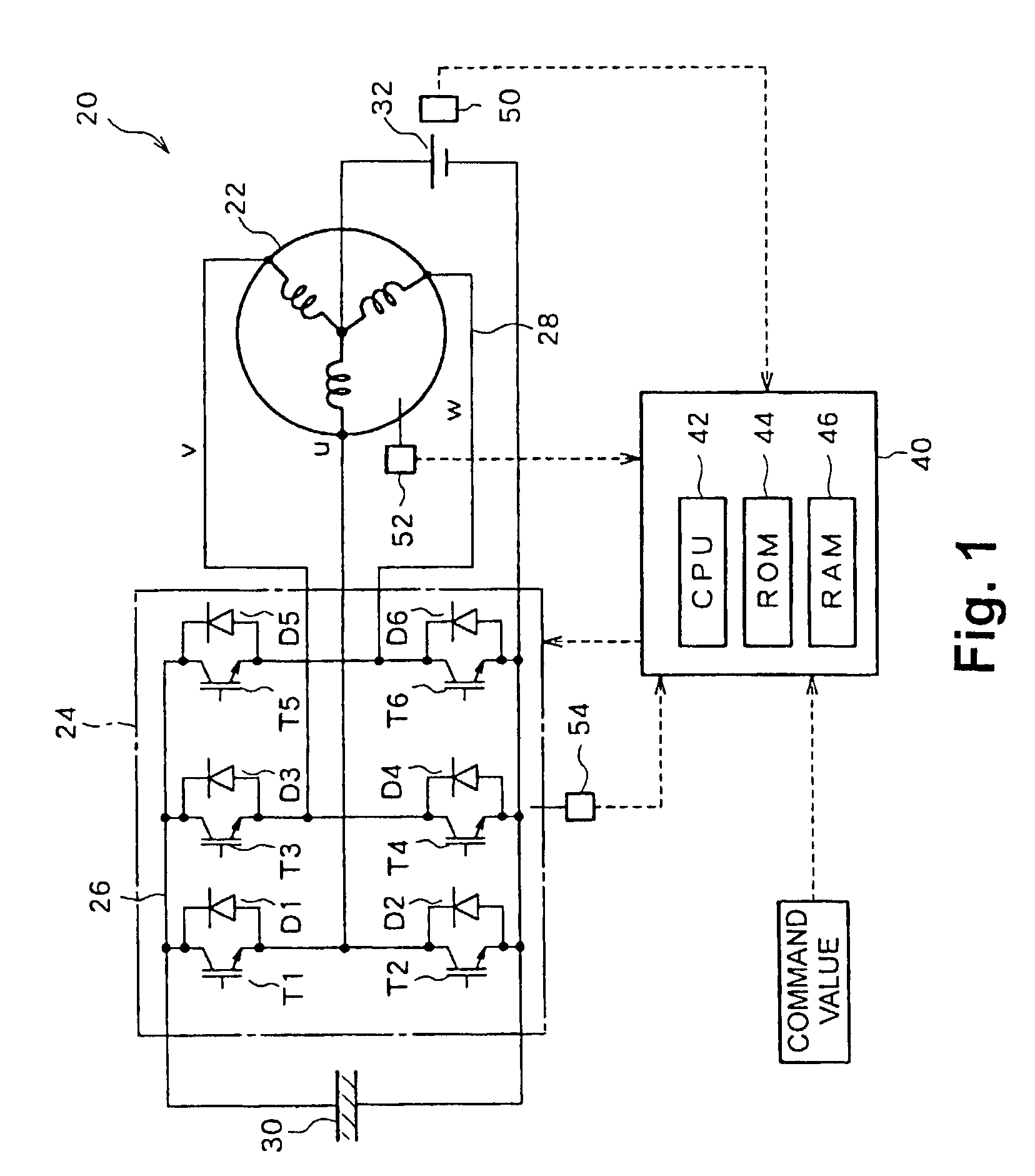

Power outputting device and vehicle mounting it, control method, storing medium and program for the power outputting device, drive device and vehicle mounting it, and, control method, storing medium and program for the drive device

InactiveUS7120037B2Simple constitutionIncrease charging voltageTorque ripple controlConversion with intermediate conversion to dcCarrier signalElectric power

A power plant outputs motive power by driving a motor (22) using electric power from a direct-current power source (32). When the direct-current power source (32) has a low temperature, the direct-current power source is rapidly heated, whereby the performance can fully be demonstrated. In the power plant in which a capacitor (30) is installed so as to connect a positive electrode bus (26) and a negative electrode bus (28) of an inverter circuit (24) and the direct-current power source (32) is also installed so as to connect the negative electrode bus (28) of the inverter circuit (24) and a neutral point of the motor (22), when a power source temperature (Tb) of the direct-current power source (32) detected by a temperature sensor (50) is less than or equal to a threshold temperature (Tblow) at which supply of required electric power to the motor (22) is possible, an electronic control unit (40) sets a voltage between terminals of the capacitor (30) higher than normal and also sets a frequency of a carrier wave lower than normal, and performs switching control of transistors (T1 to T6) Thus, a ripple of a neutral point current which flows into the direct-current power source (32) can be increased, whereby it is possible to promote calorification of the direct current power source (32).

Owner:TOYOTA JIDOSHA KK

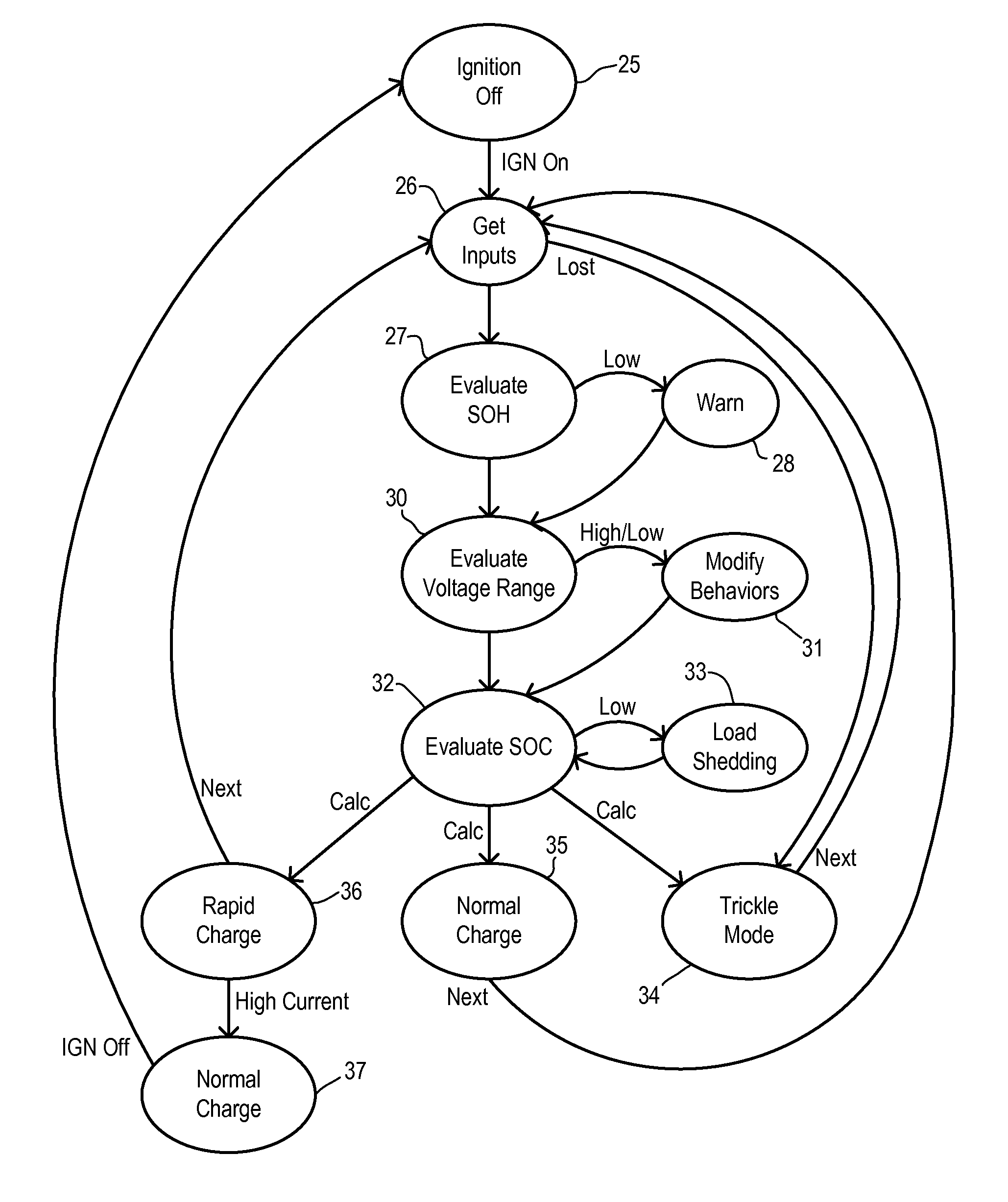

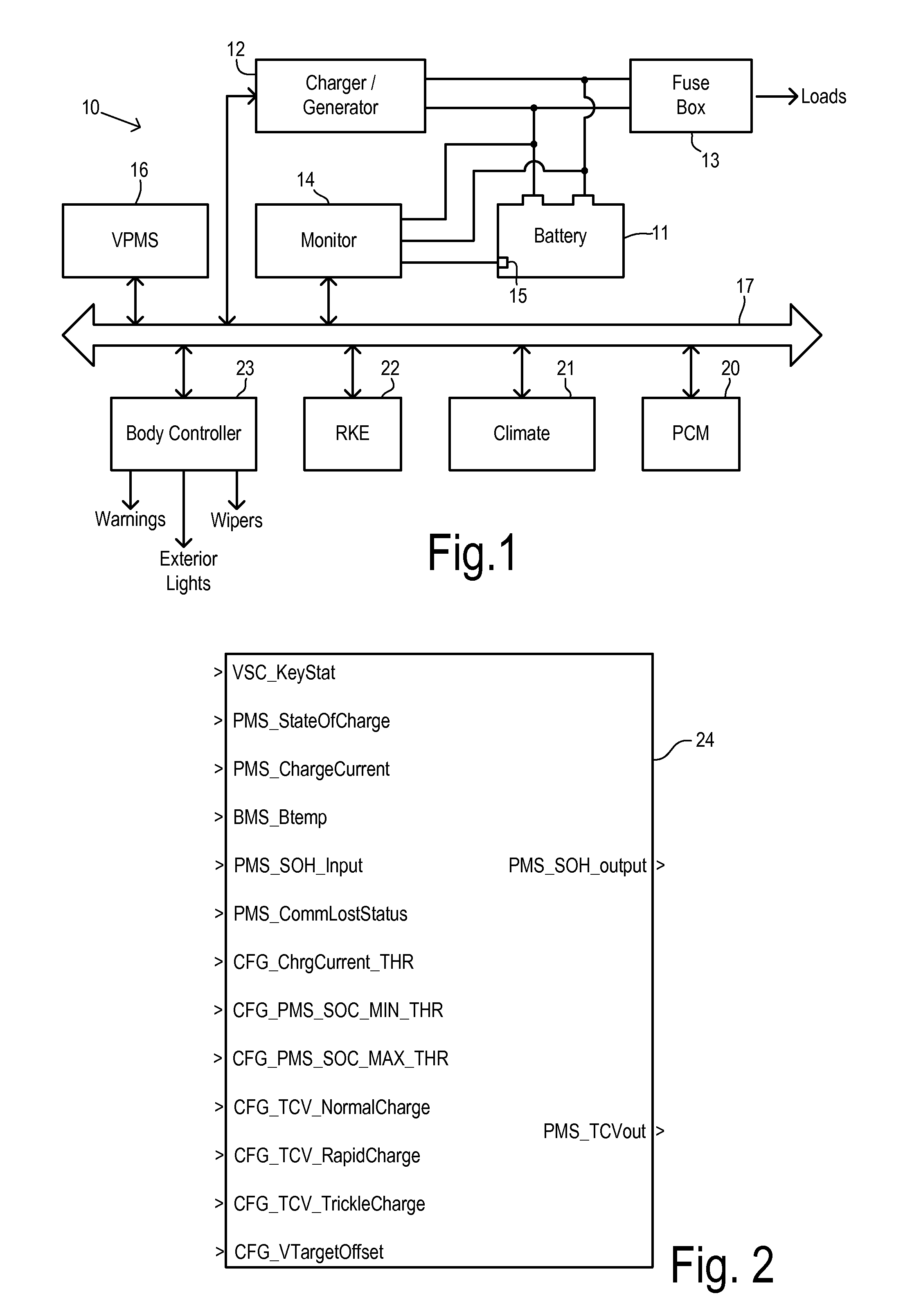

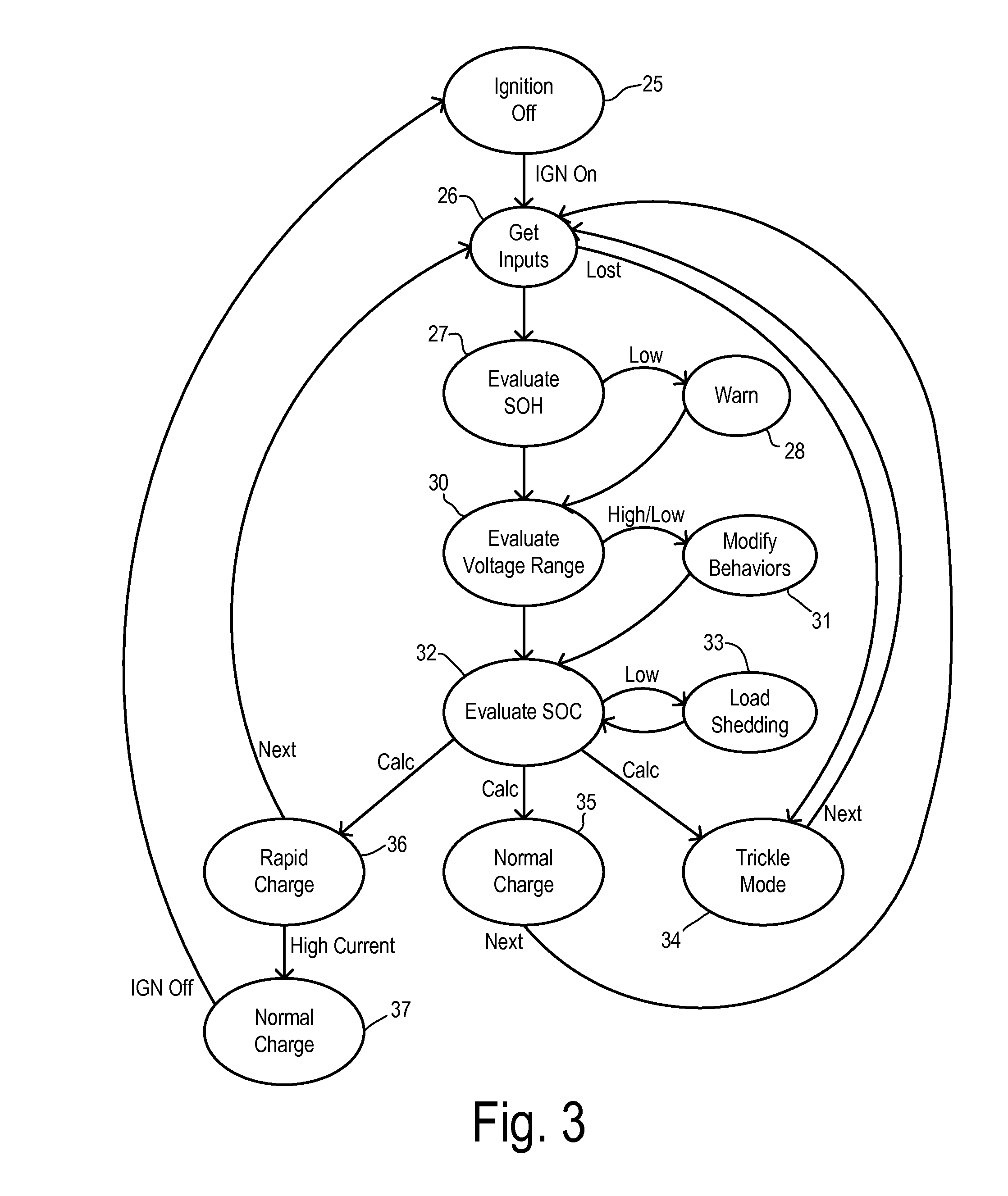

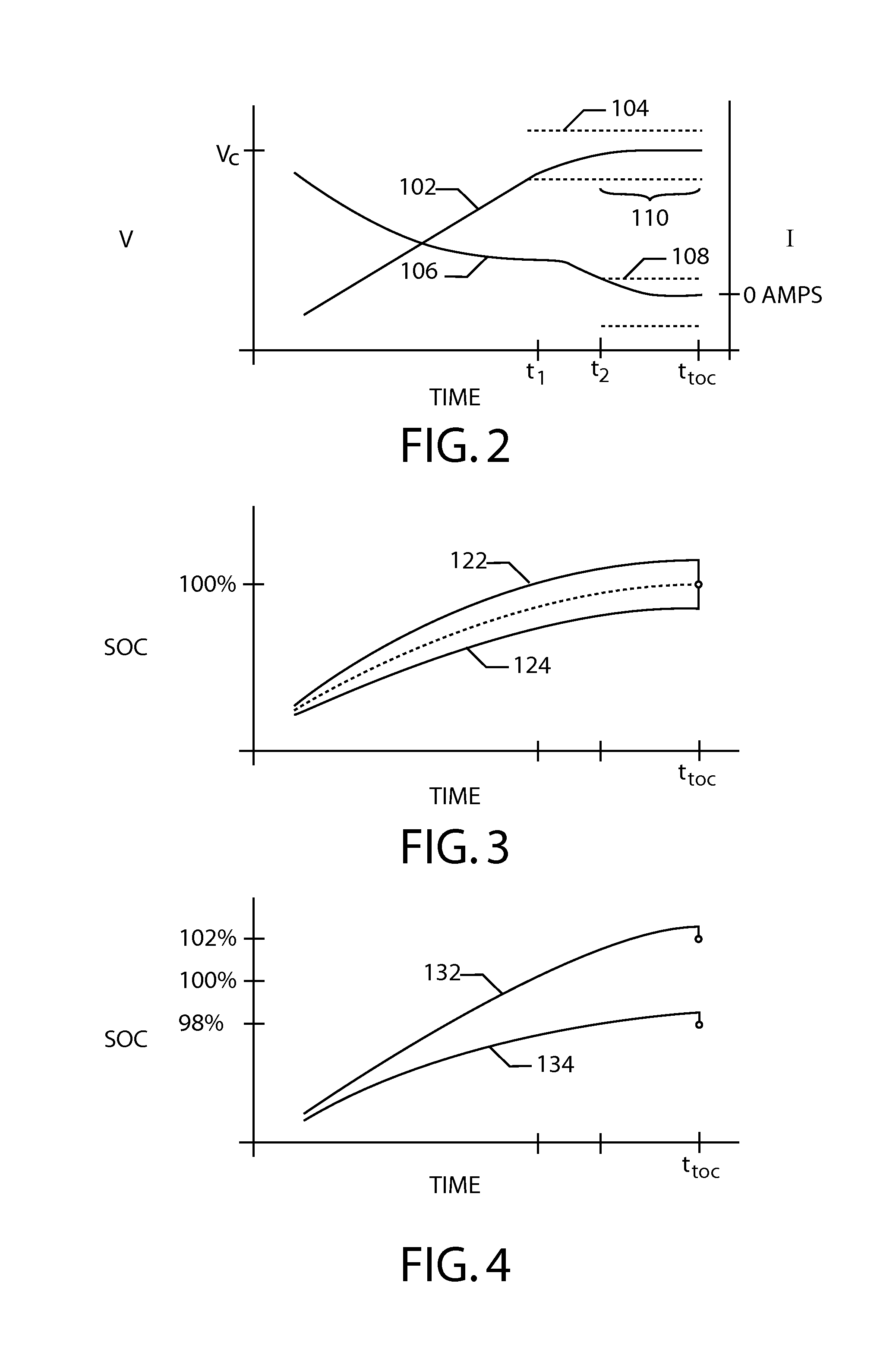

Vehicle Power Management System

InactiveUS20110298624A1Reduce charging voltageHybrid vehiclesBatteries circuit arrangementsBattery chargeState of charge

A vehicle power management system (VPMS) controls a charging voltage of a battery in a vehicle, wherein a VPMS controller evaluates state-of-charge (SOC), battery temperature, and battery charging current to determine a charge mode. A rapid charge mode is used when the SOC is less than a first threshold, wherein the VPMS controller selects a target rapid charge voltage, compensates the target rapid charge voltage for the battery temperature, and transmits the compensated rapid charge voltage to the charging source. A normal charge mode is used when the SOC is greater than the first threshold and less than a second threshold, wherein a target normal charge voltage is selected and compensated which is less than the target rapid charge voltage. A trickle charge mode is used when the SOC is greater than the second threshold, wherein a target trickle charge voltage is less than the target normal charge voltage. The VPMS controller also enters the trickle charge mode in the event of a failure to receive the SOC, battery temperature, or battery charging current from a battery monitor.

Owner:LEAR CORP

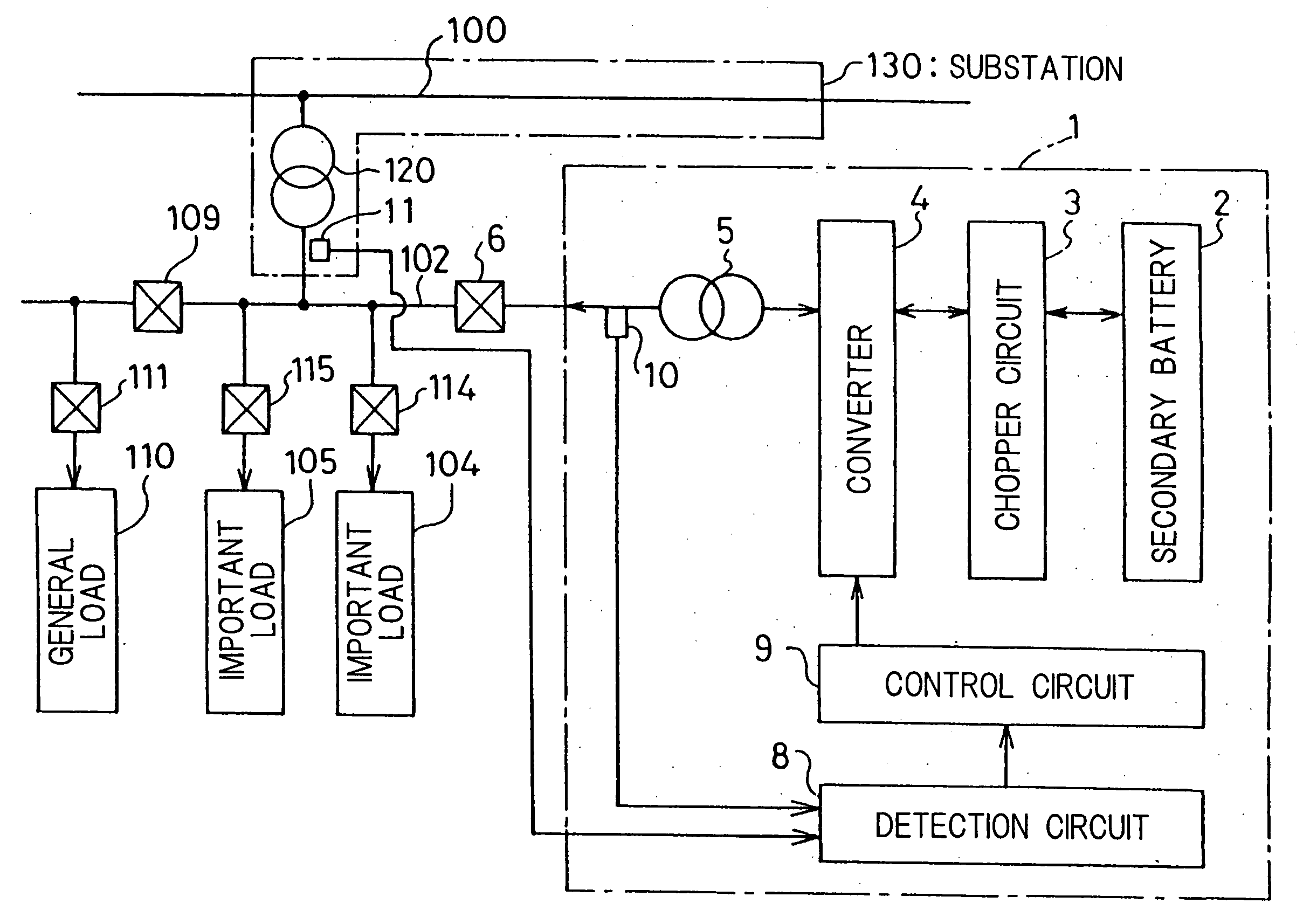

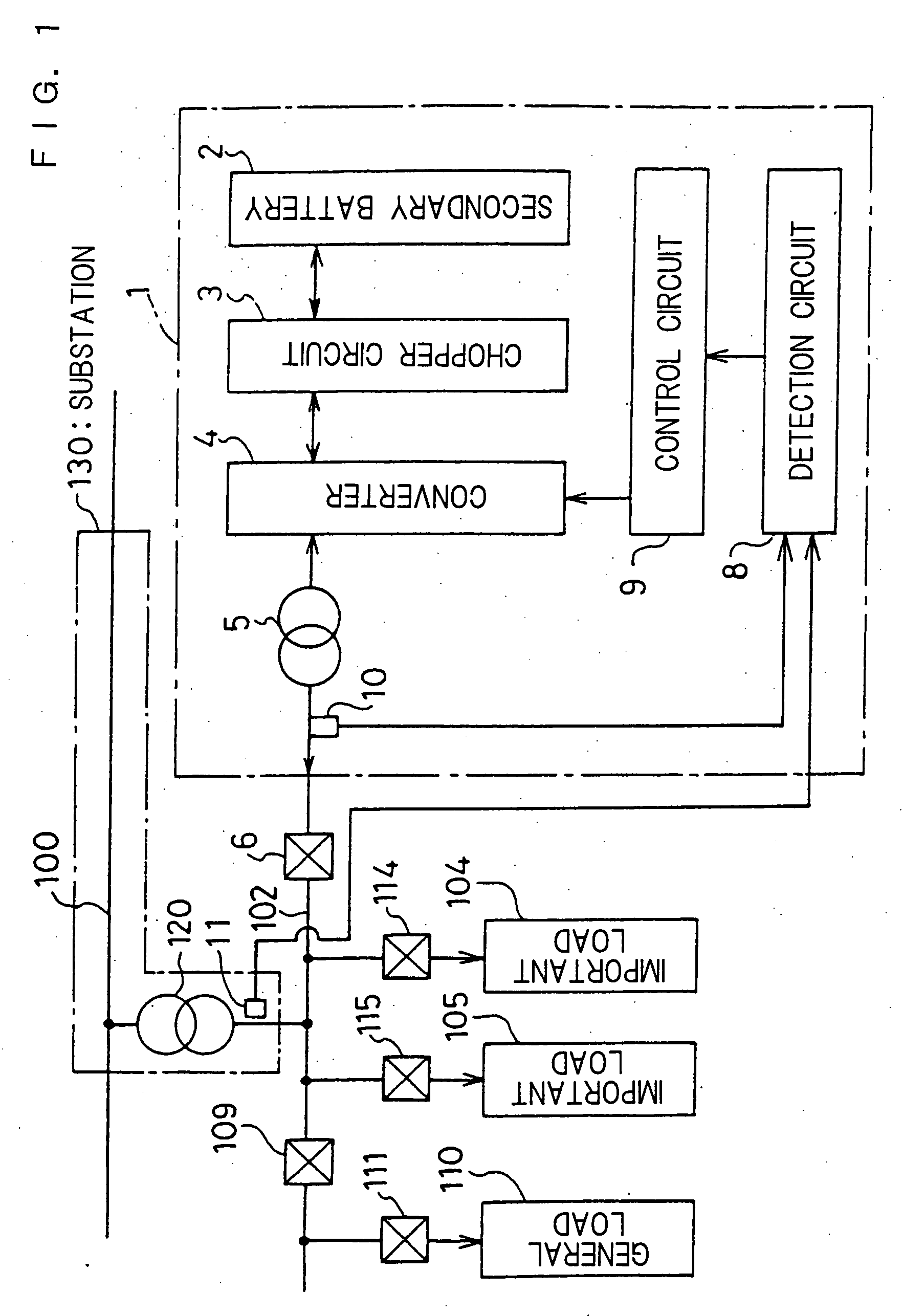

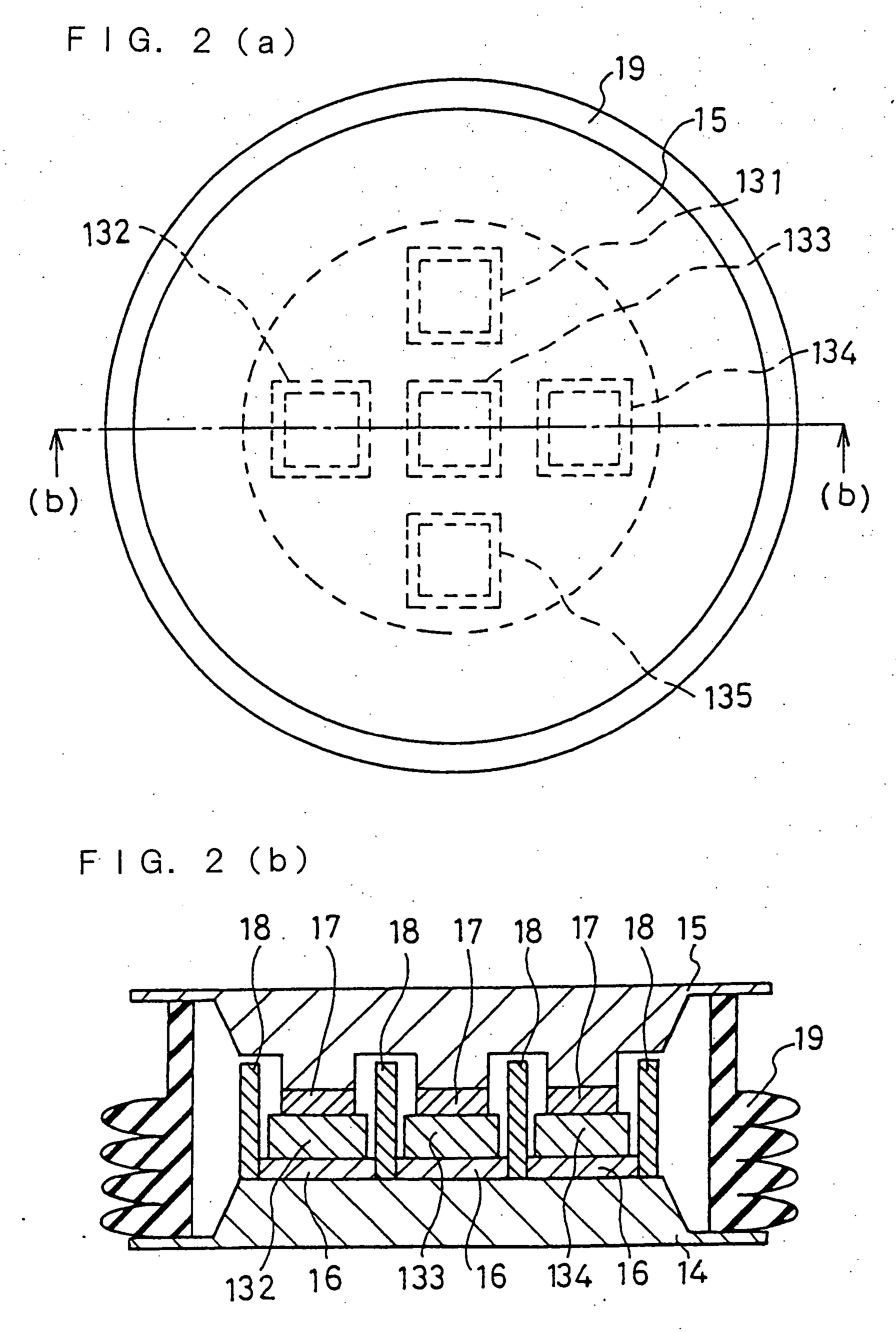

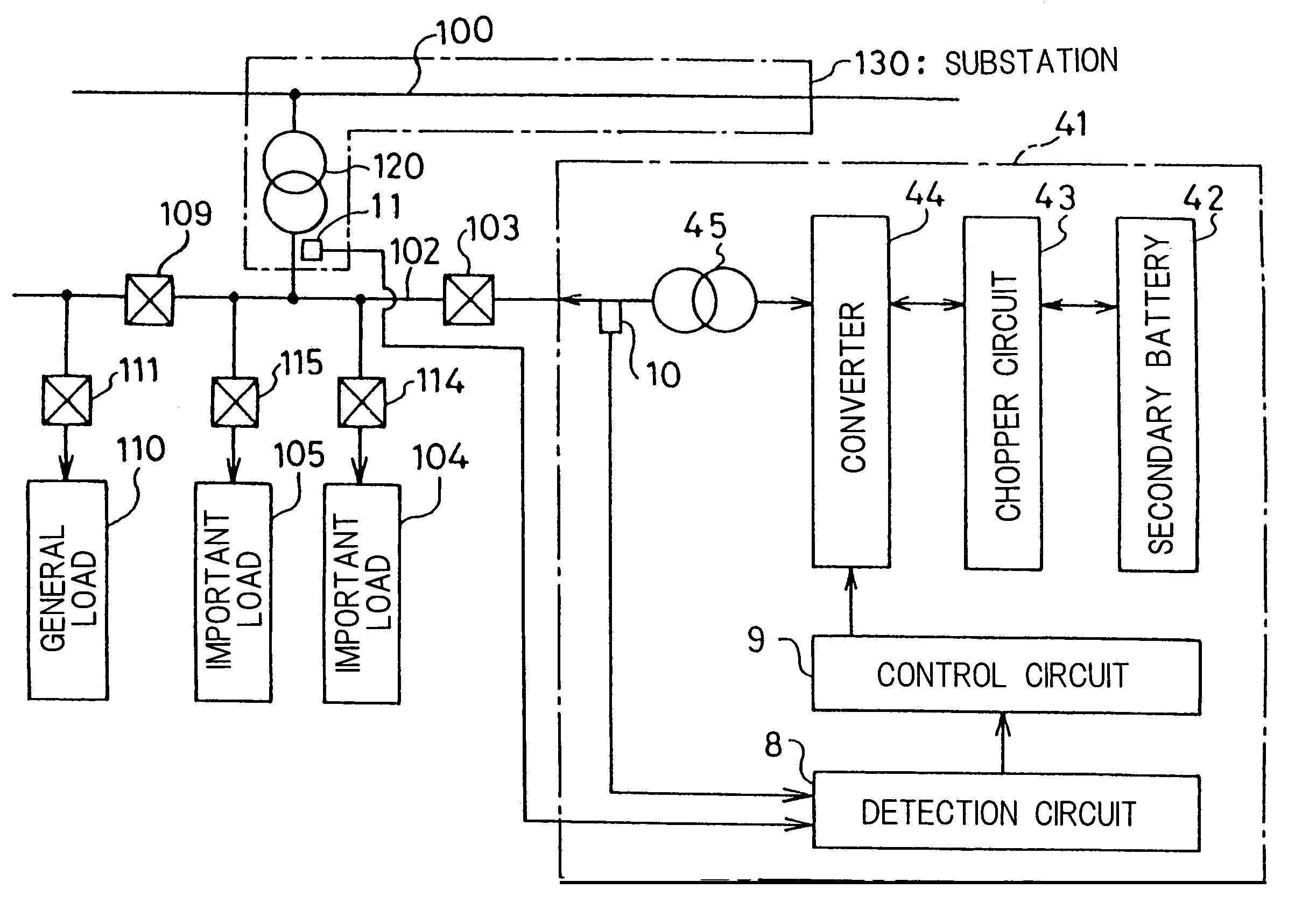

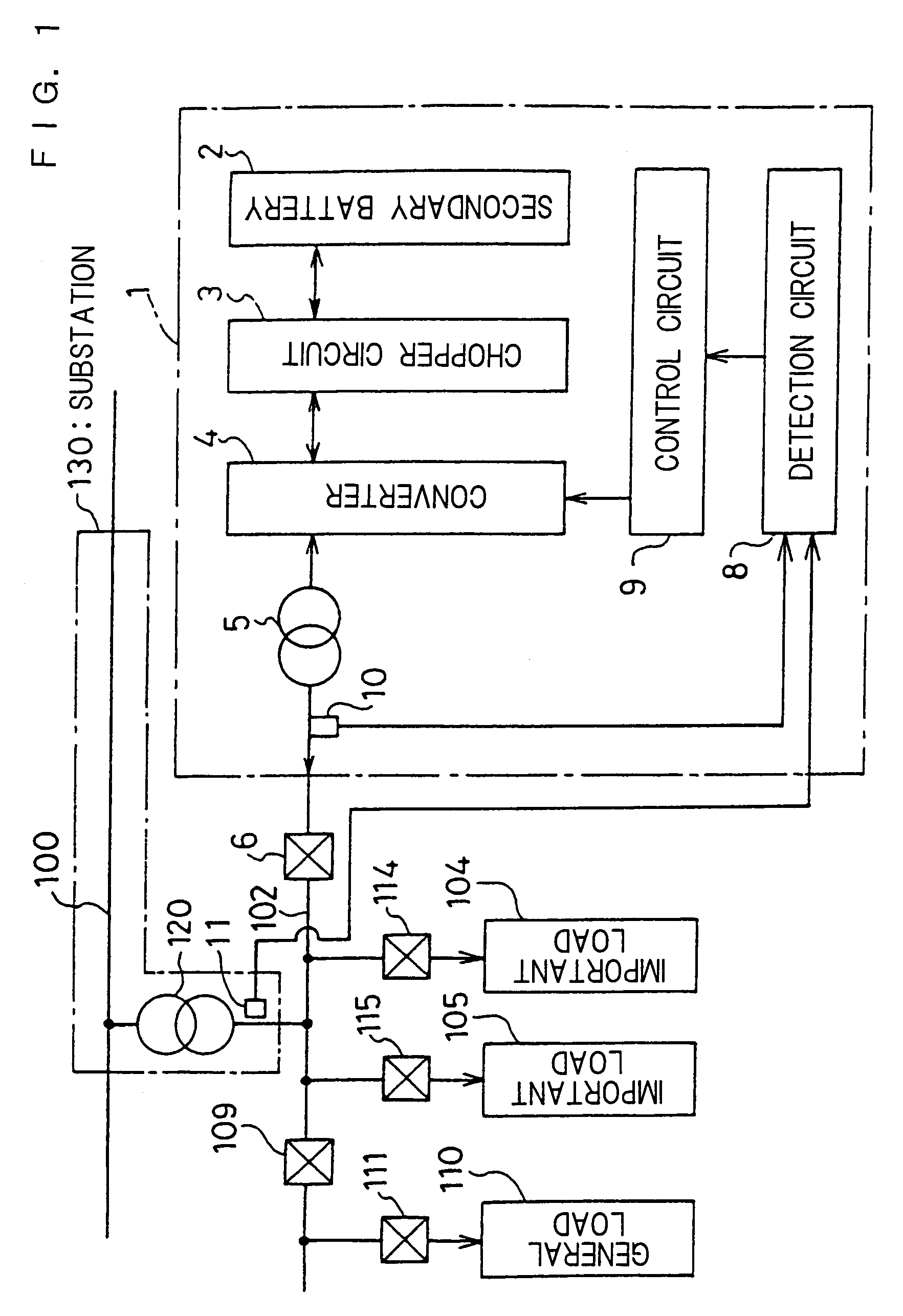

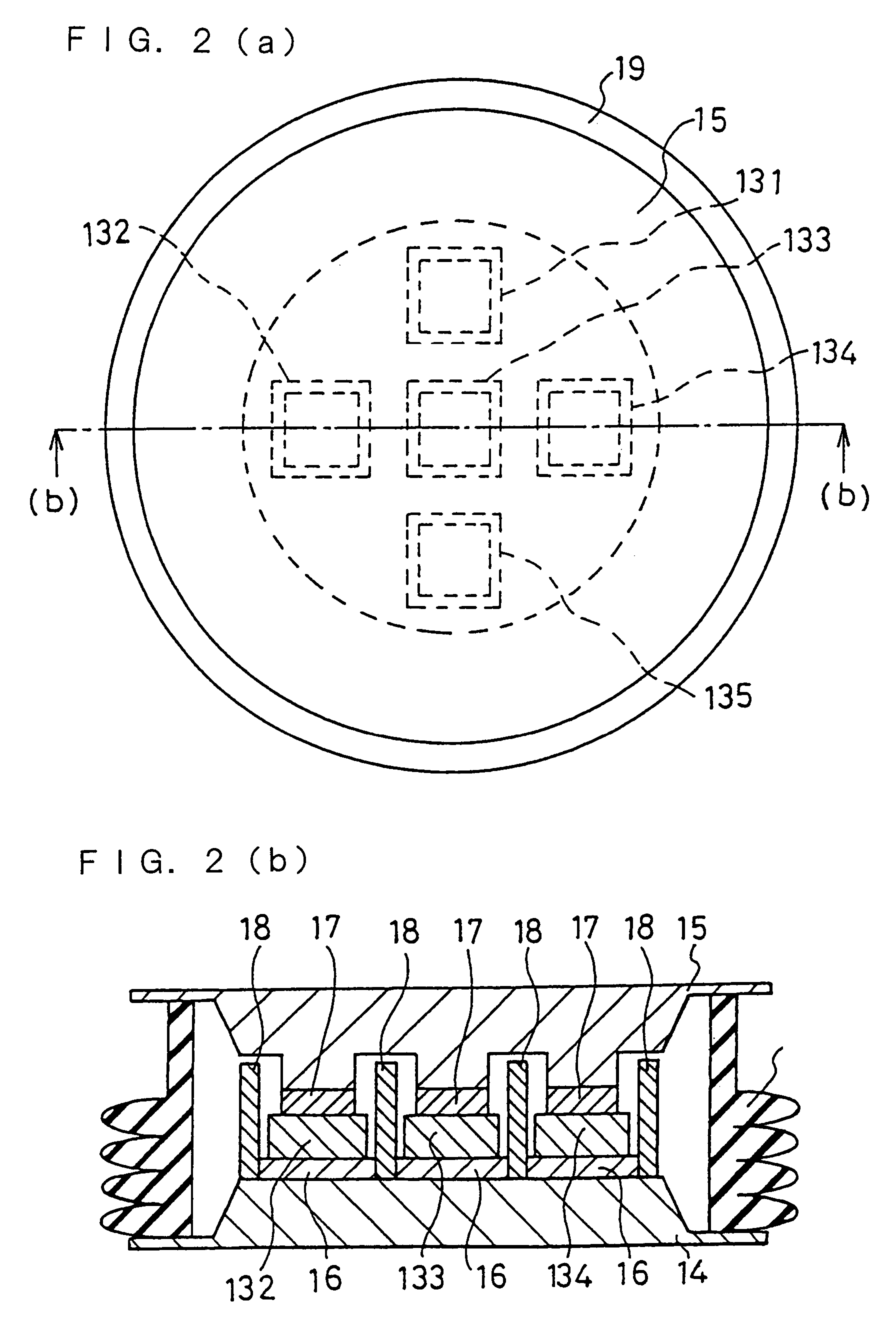

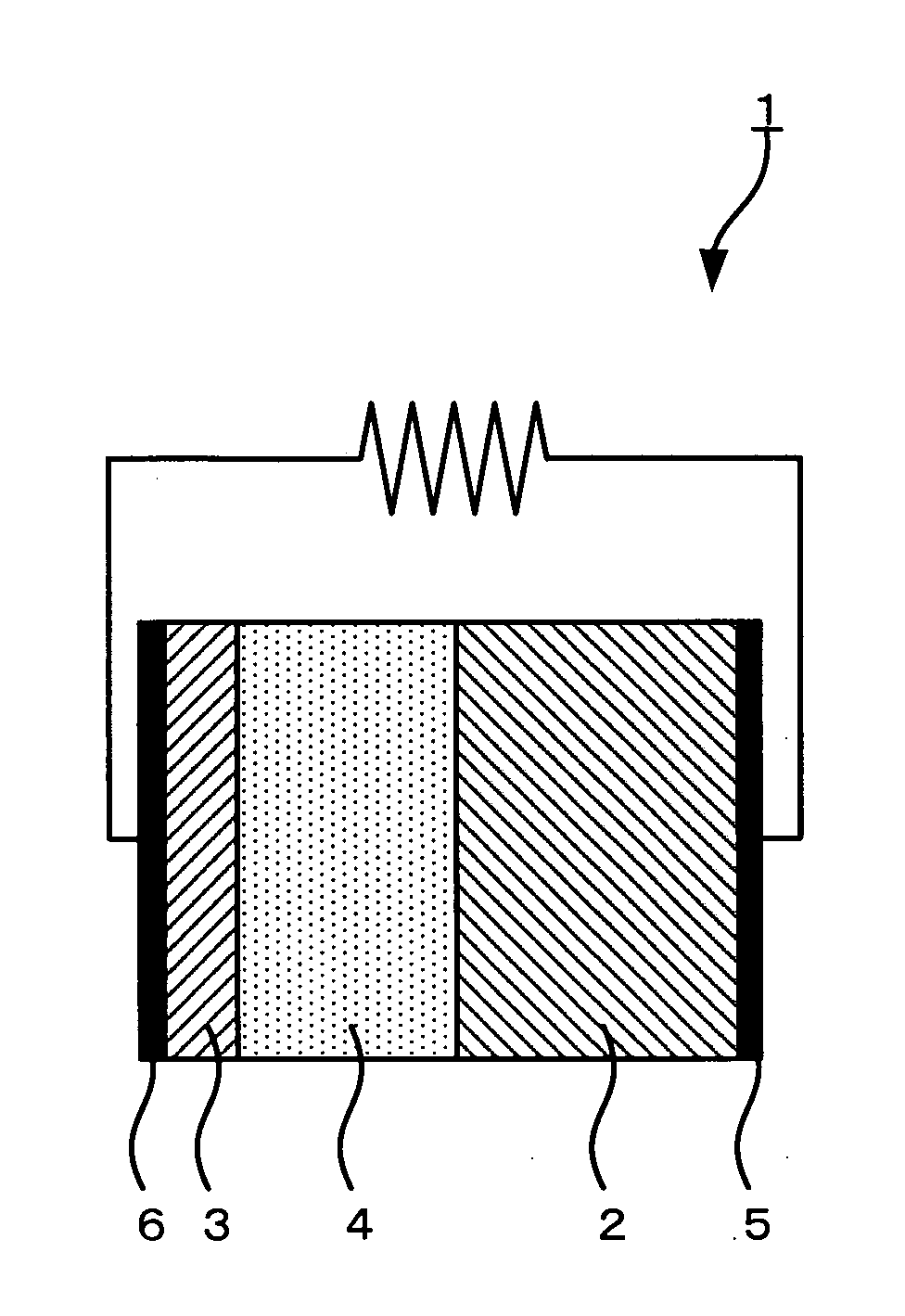

Stable power supplying apparatus

InactiveUS20060014054A1Small sizeLight weightBatteries circuit arrangementsCells structural combinationElectric forceDevice material

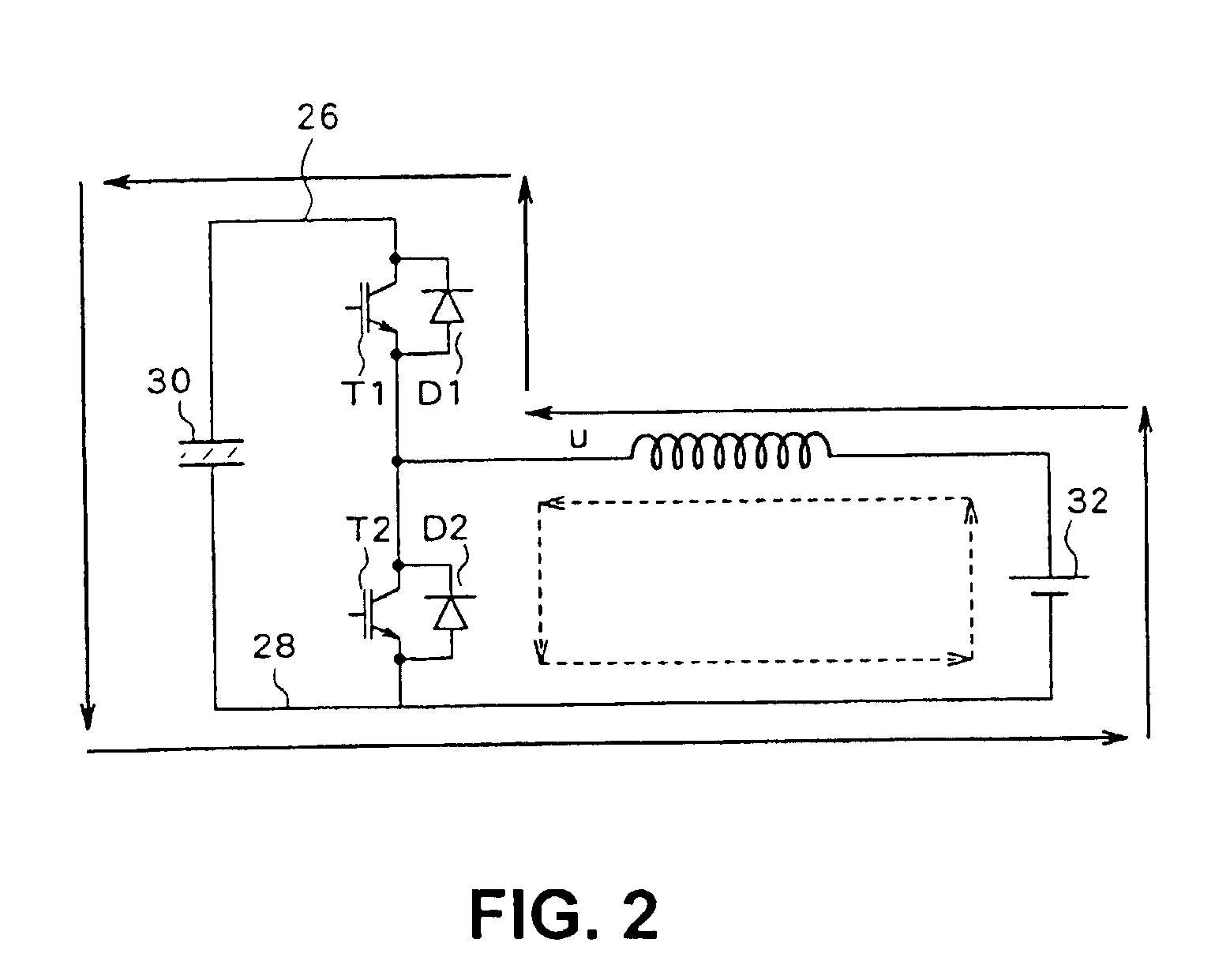

A stable power supply apparatus in accordance with the present invention comprises a secondary battery, a bidirectional chopper circuit and a bidirectional converter, wherein the secondary battery, the chopper circuit and the converter are connected in this order in the direction from the secondary battery side to a system bus line side. The converter is formed of a wide-gap semiconductor device, more particularly, a wide-gap bipolar semiconductor device, and the instantaneous large-power operation capability of the wide-gap bipolar semiconductor device and the instantaneous large-power supplying capability of the secondary battery are utilized. For a short time during which the influence of an instantaneous drop is prevented, the converter is operated as a converter having capability exceeding the instantaneous large-power supplying capability of the secondary battery and having power capacity several times or more the rating of the converter.

Owner:THE KANSAI ELECTRIC POWER CO

Stable power supplying apparatus

InactiveUS7554220B2Small sizeLight weightBatteries circuit arrangementsCells structural combinationWide gap semiconductorsEngineering

A stable power supply apparatus in accordance with the present invention comprises a secondary battery, a bidirectional chopper circuit and a bidirectional converter, wherein the secondary battery, the chopper circuit and the converter are connected in this order in the direction from the secondary battery side to a system bus line side. The converter is formed of a wide-gap semiconductor device, more particularly, a wide-gap bipolar semiconductor device, and the instantaneous large-power operation capability of the wide-gap bipolar semiconductor device and the instantaneous large-power supplying capability of the secondary battery are utilized. For a short time during which the influence of an instantaneous drop is prevented, the converter is operated as a converter having capability exceeding the instantaneous large-power supplying capability of the secondary battery and having power capacity several times or more the rating of the converter.

Owner:THE KANSAI ELECTRIC POWER CO

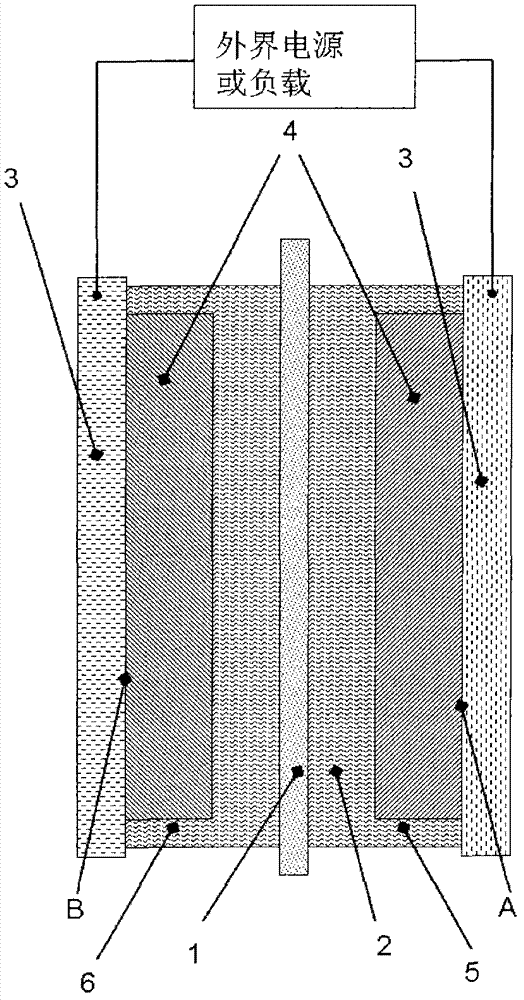

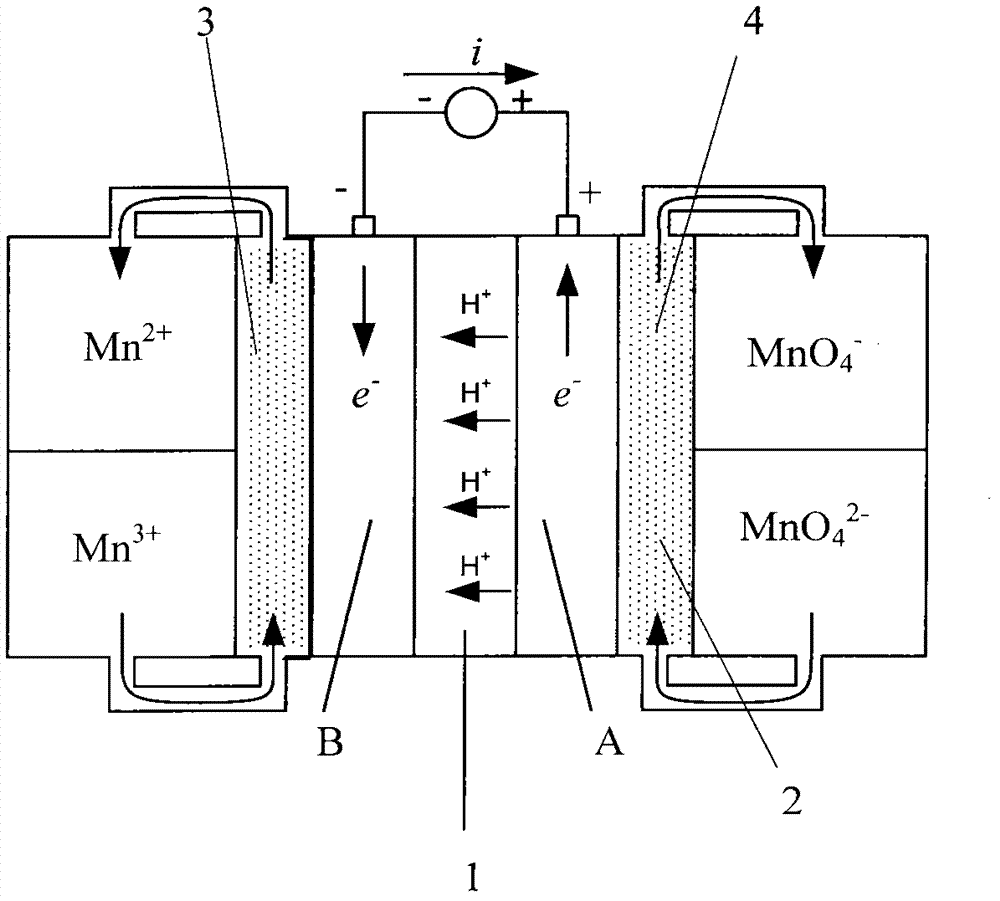

Flow battery

InactiveCN102790233ALow costIncrease charge and discharge currentCell electrodesRegenerative fuel cellsElectrical energy storageElectrical battery

The present invention provides an electrochemical flow battery for electric energy storage, the said battery uses anode reactive materials (the material being oxidized during battery discharge) selected from complexed ionic form of late 3d transition metals, i.e., Mn, Fe, and Cu. The battery has significantly low cost due to use of these relative inexpensive metals.

Owner:罗臬 +1

Composite material used as lithium air battery positive electrode and preparation method thereof

InactiveCN102664277ALarge specific surface areaEvenly dispersedFuel and secondary cellsCell electrodesPtru catalystElectrical battery

The invention discloses a composite material used as a lithium air battery positive electrode and a preparation method thereof. The composite material comprises nanometer manganese dioxide (MnO2) and porous carbon which are compounded on the molecular level and are bonded by a hydrogen bond; and the molar ratio of the porous carbon to the nanometer MnO2 is 10:1 to 20:1. The porous carbon is uniform in aperture and large in specific surface area; the nanometer MnO2 is low in cost, non-toxic, high in average voltage and energy compatibility and extremely high in catalytic activity; and moreover, overpotential can be effectively reduced. The nanometer MnO2 used as a catalyst is deposited on the surface of the porous carbon material by a hydrothermal method or an oxidation-reduction method, so that precious metal salt is avoided, the cost is low, the practicability is high, the composite material is clean and environment-friendly, and the requirement on environment protection is met; and in addition, the method is simple and feasible, and complicated and harsh reaction conditions and side reaction are avoided.

Owner:SOUTHEAST UNIV

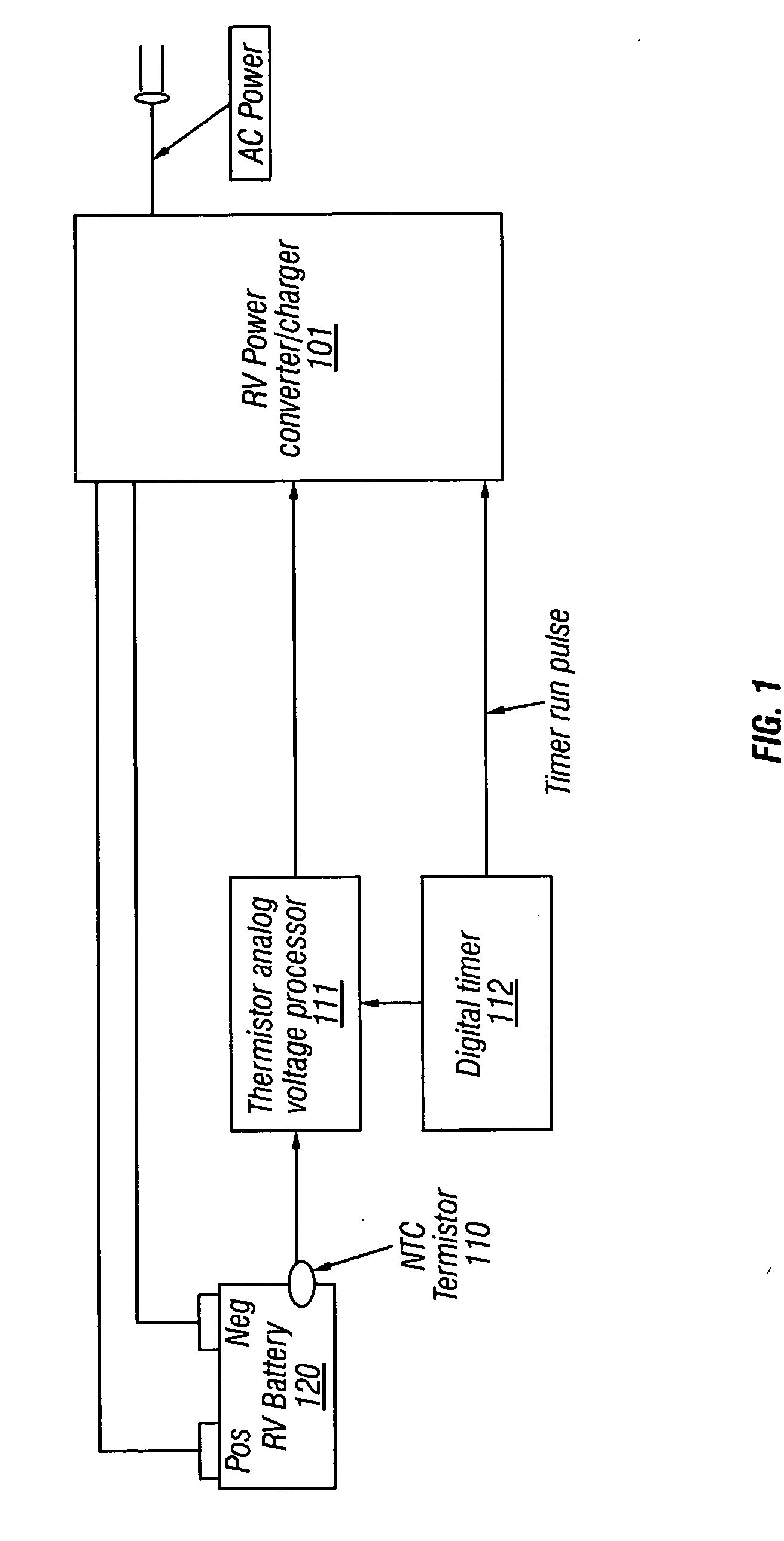

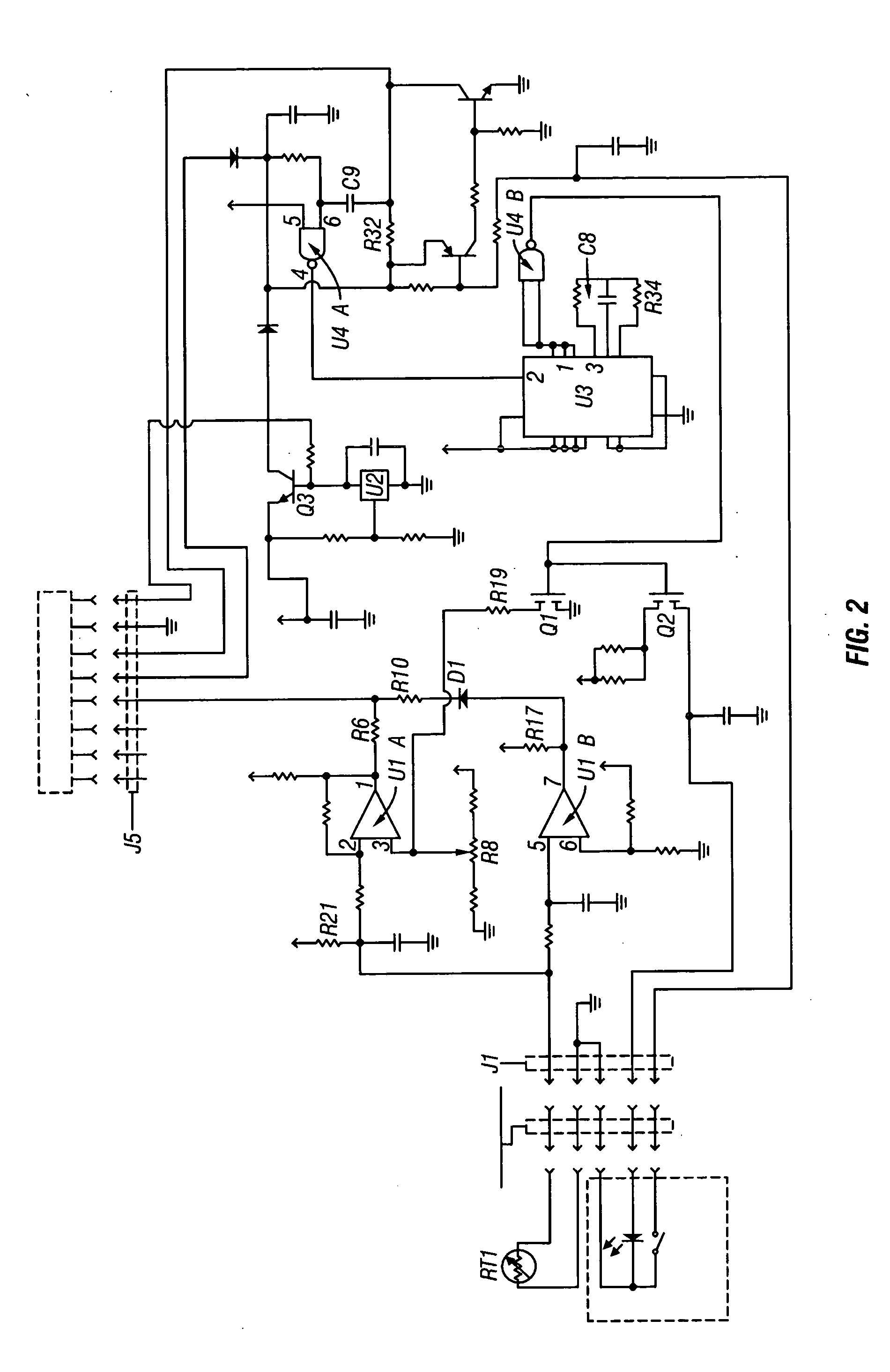

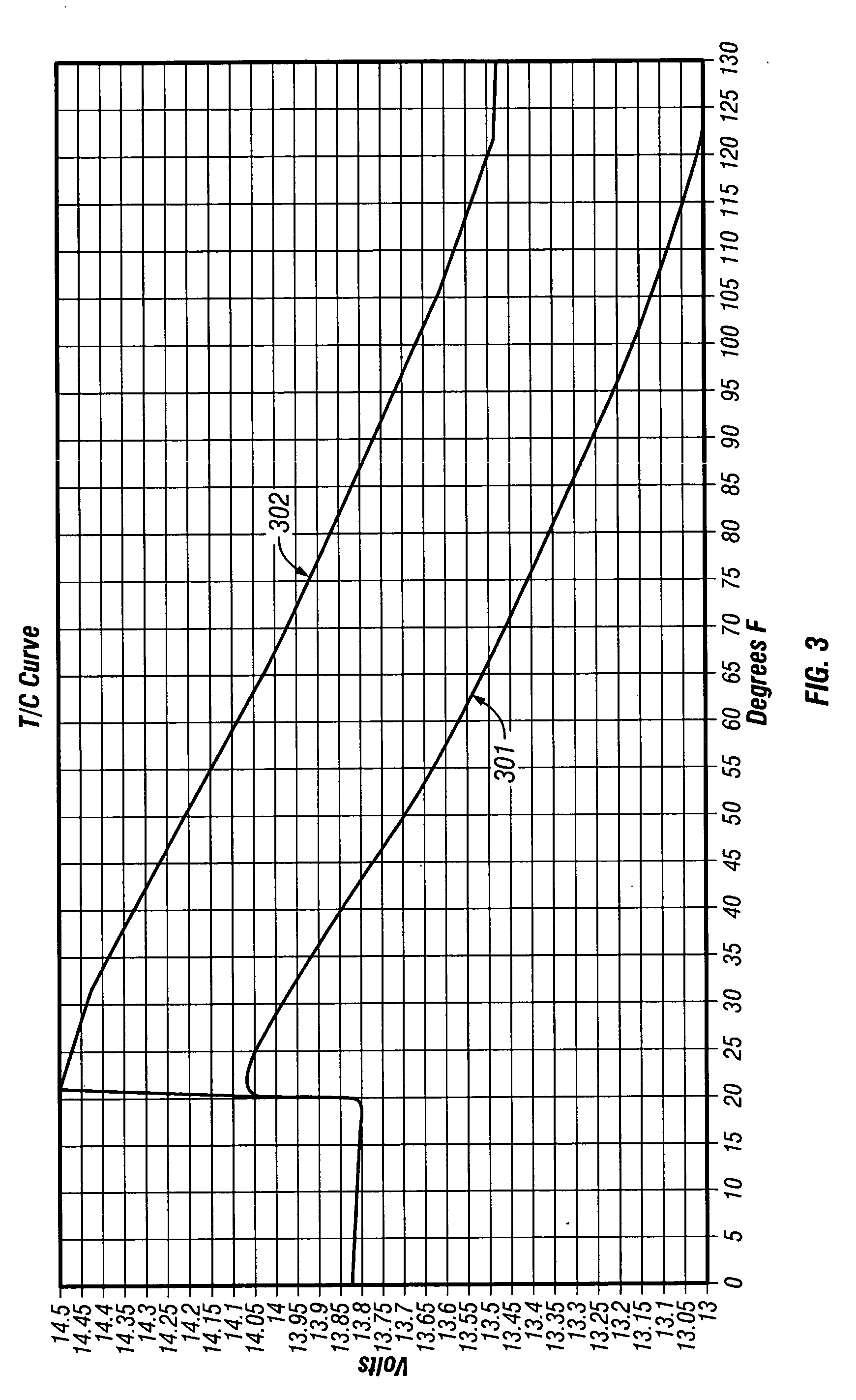

Temperature sensitive power converter

ActiveUS20070120535A1Avoid damageExtend lamp lifeBatteries circuit arrangementsElectric powerElectricityTemperature curve

The present invention provides a power converter for recreational vehicle (RV) batteries that uses time and ambient temperature to control output voltage. By employing a remote temperature sensor attached to the battery post, temperature information is sent to an output voltage control circuit in the power converter. When the power converter is powered up an internal timing circuit increases the output voltage by a preset amount for a timed period for rapid charging but is also adjusted to predetermined temperature curve controlled by the remote temperature sensor to prevent overcharge. The output voltage is held at the increased value until the internal timing circuit times out and the output voltage is reduced (setback) to the float voltage determined by the remote temperature sensor.

Owner:CONNECTICUT ELECTRIC

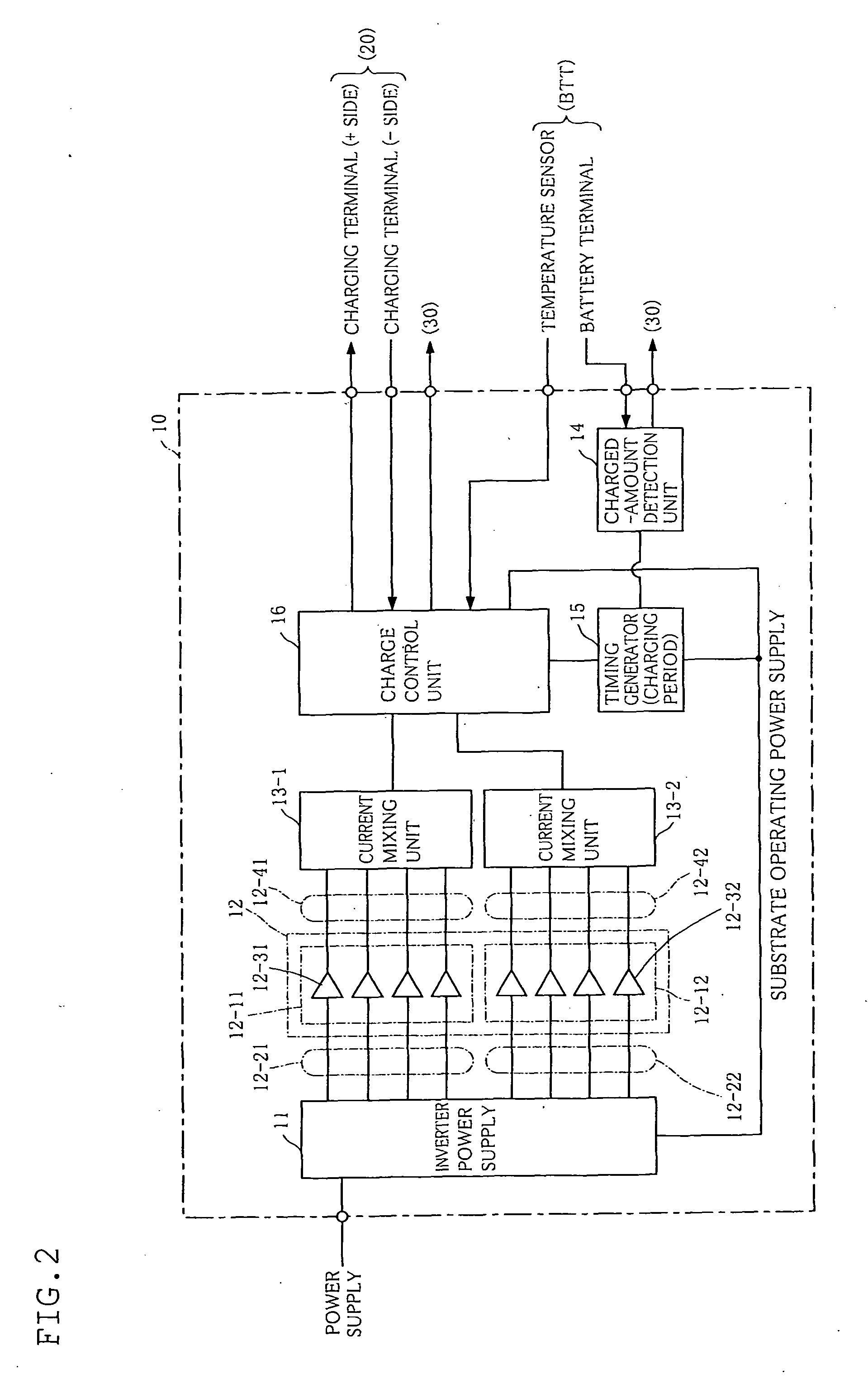

Charger and charging apparatus

ActiveUS20130009593A1Reduce charging voltageShorten charging timeBatteries circuit arrangementsElectric devicesElectrical batteryRechargeable cell

A reduction in breakdown voltage and mechanical deterioration of an electrode plate of a rechargeable battery are suppressed, and a charging time is shortened.There is provided a charger 10 which charges a rechargeable battery, comprising: a first output unit which outputs a first voltage; a second output unit which outputs a second voltage having a predetermined voltage value different from that of the first voltage; a charge control unit 16 which inputs the first voltage and the second voltage, alternately outputs these voltages, and supplies them to the rechargeable battery as charging voltages; a charged-amount detection unit 14 which measures a charged amount of the rechargeable battery; and an output control unit 15 which carries out control in such a manner that an output time of the first voltage and / or the second voltage in the charge control unit 15 is prolonged as the charged amount increases.

Owner:TAKAHASHI SACHIO +1

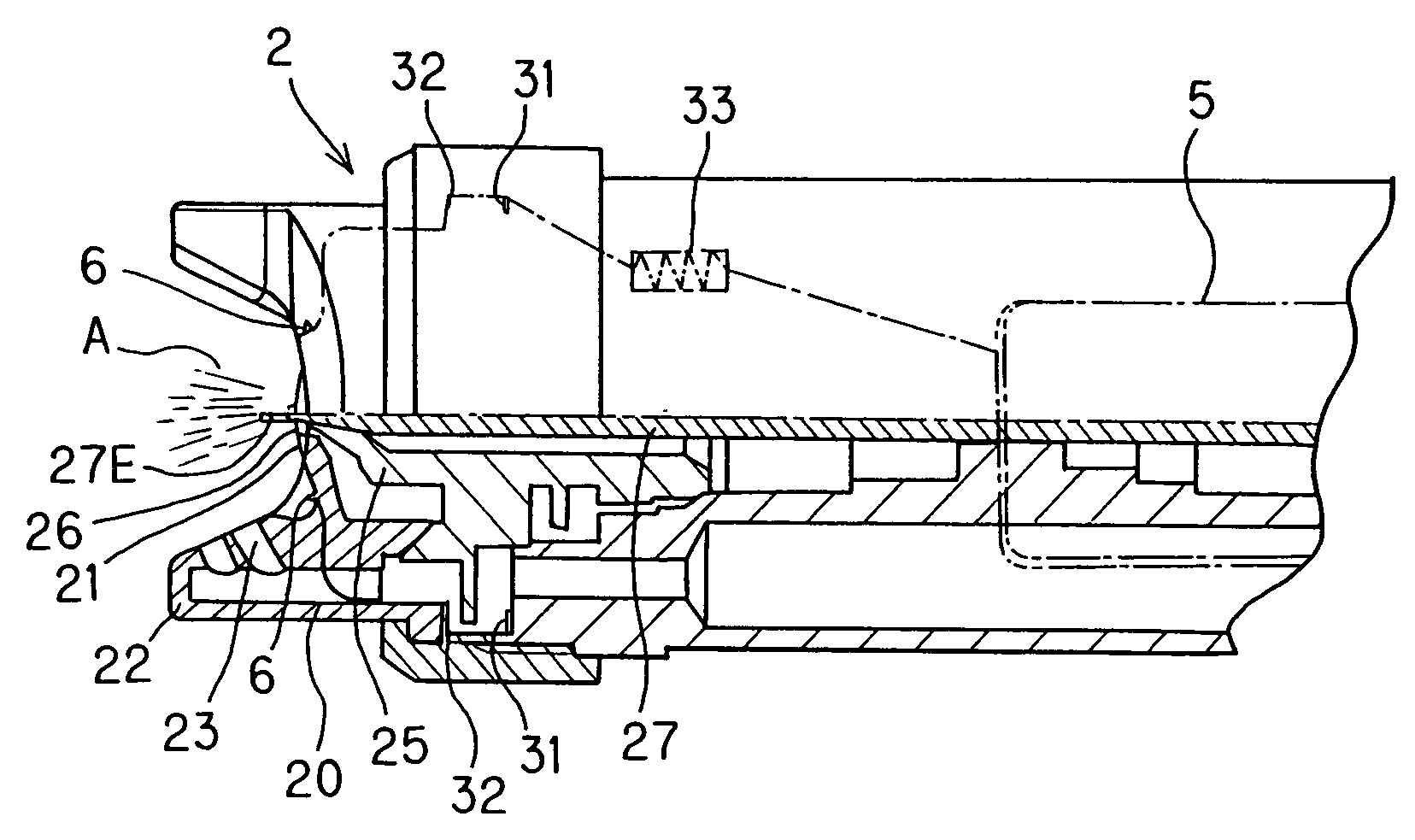

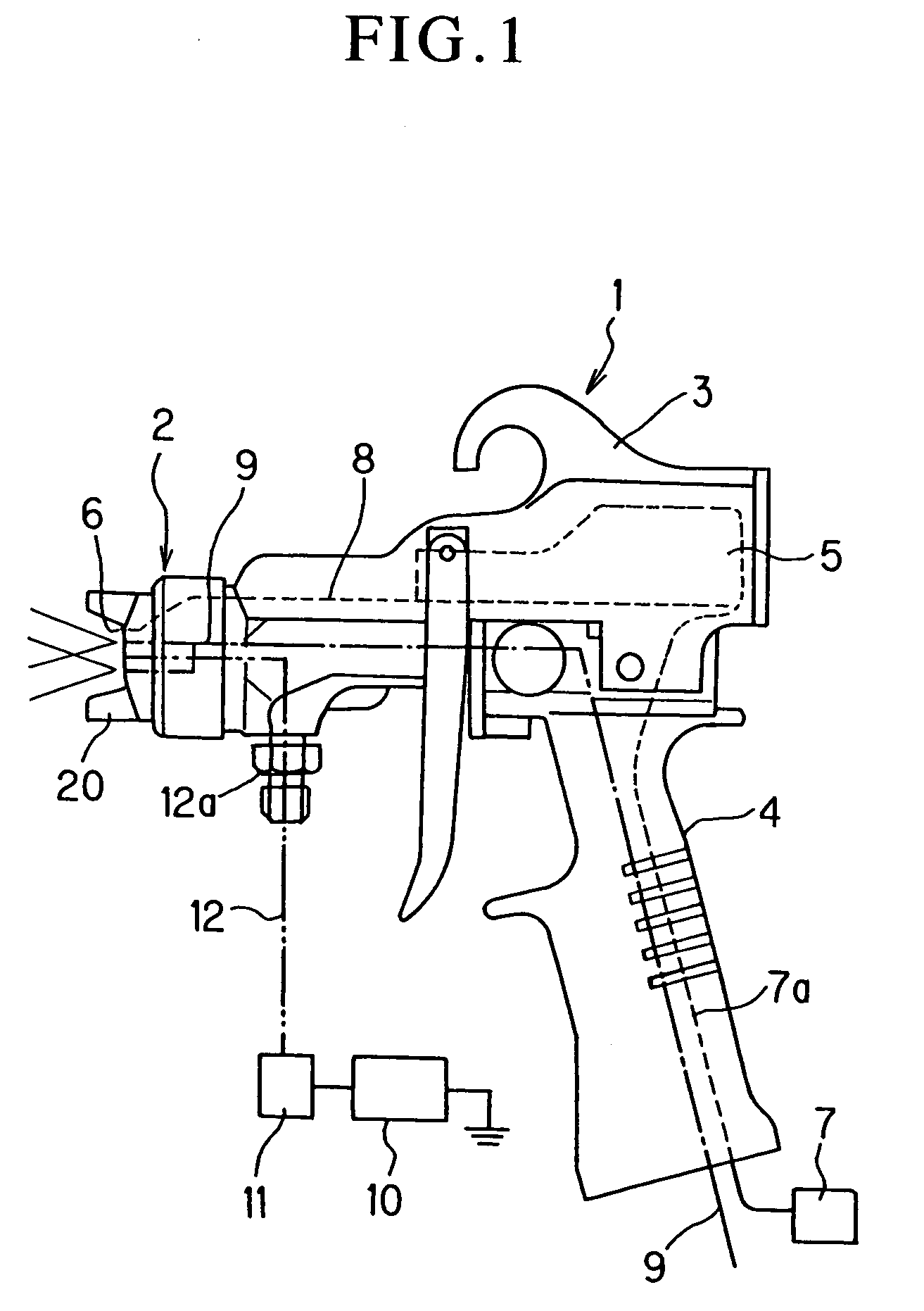

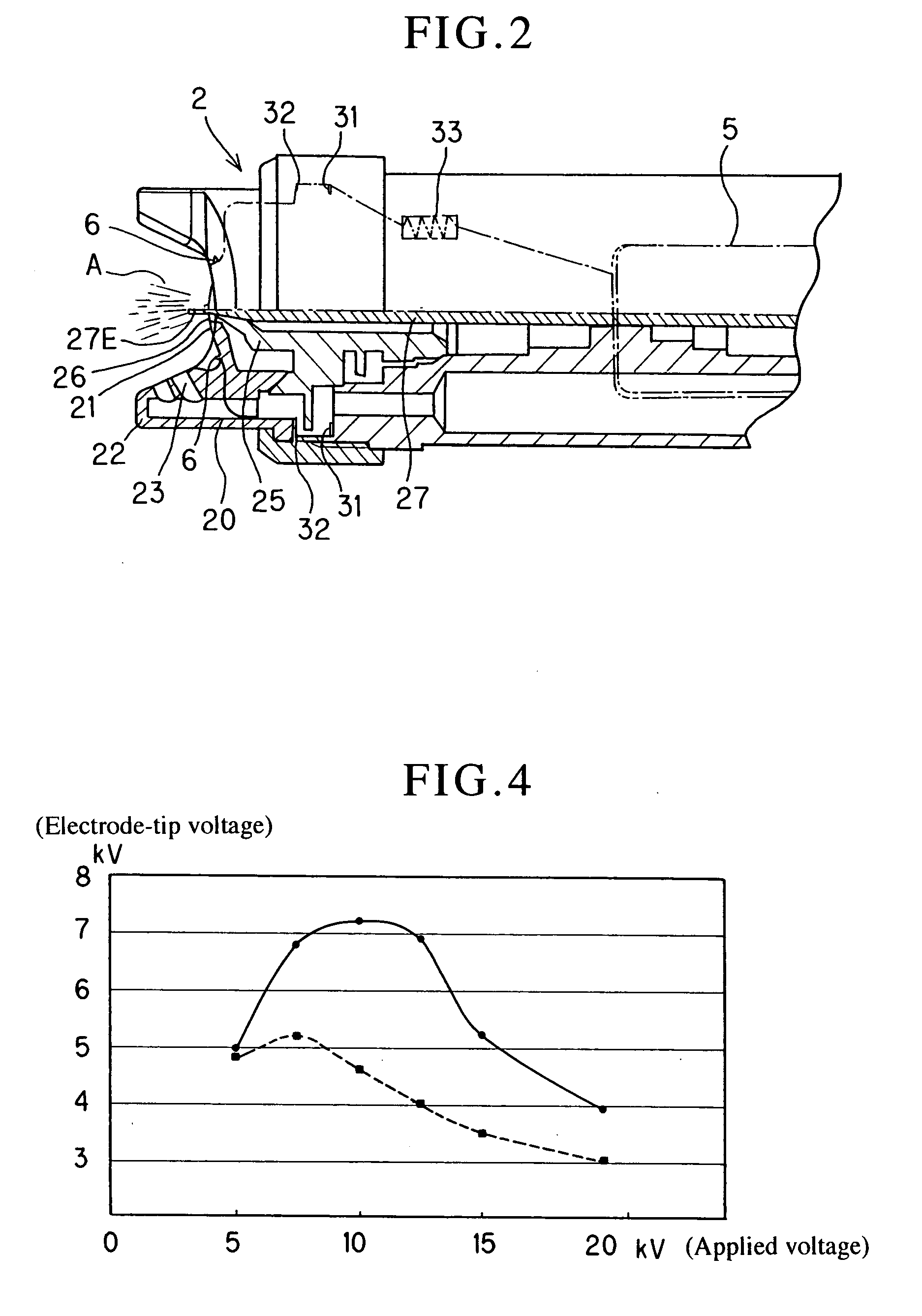

Electrostatic Coating Spray Gun and Electrostatic Coating Method

InactiveUS20080213499A1Easy to operateImprove securityLiquid surface applicatorsLiquid spraying apparatusElectricityLow voltage

When conductive paint is coated by electrostatic coating, the electrostatic charging has many problems. The external electrode is prevailingly used in most of the electrostatic coating spray guns but has many problems in operability, safety, practical usability, etc. when the guns are designed compact. The electrostatic coating spray guns need to be improved in operability, safer with electrostatic charging at a lower voltage, and smaller in structure. To solve such problems, there is provided an improved electrostatic coating spray gun (1) in which an atomizer (2) is provided at the front end thereof to atomize paint jet from a paint nozzle (25) disposed at the center of the atomizer (2) and electrostatically charge the atomized paint particles at a high voltage for attraction to an object to be coated, set at ground potential, charging electrodes (6) as external electrodes are provided on the inner front surface of an air cap (20) or the inner surface of the air cap (20) and a compressed air passage is formed between a paint jet port (26) at the ground potential and the charging electrodes (6). At charging, compressed air prevents discharge from the charging electrodes toward the paint at the ground potential to efficiently ensure ionizing discharge with necessary potential being retained at the charging electrodes (6) and effective charging of paint particles. Since voltage drop is thus prevented, a lower voltage may be used for necessary charging of the paint particles.

Owner:ANEST IWATA CORP

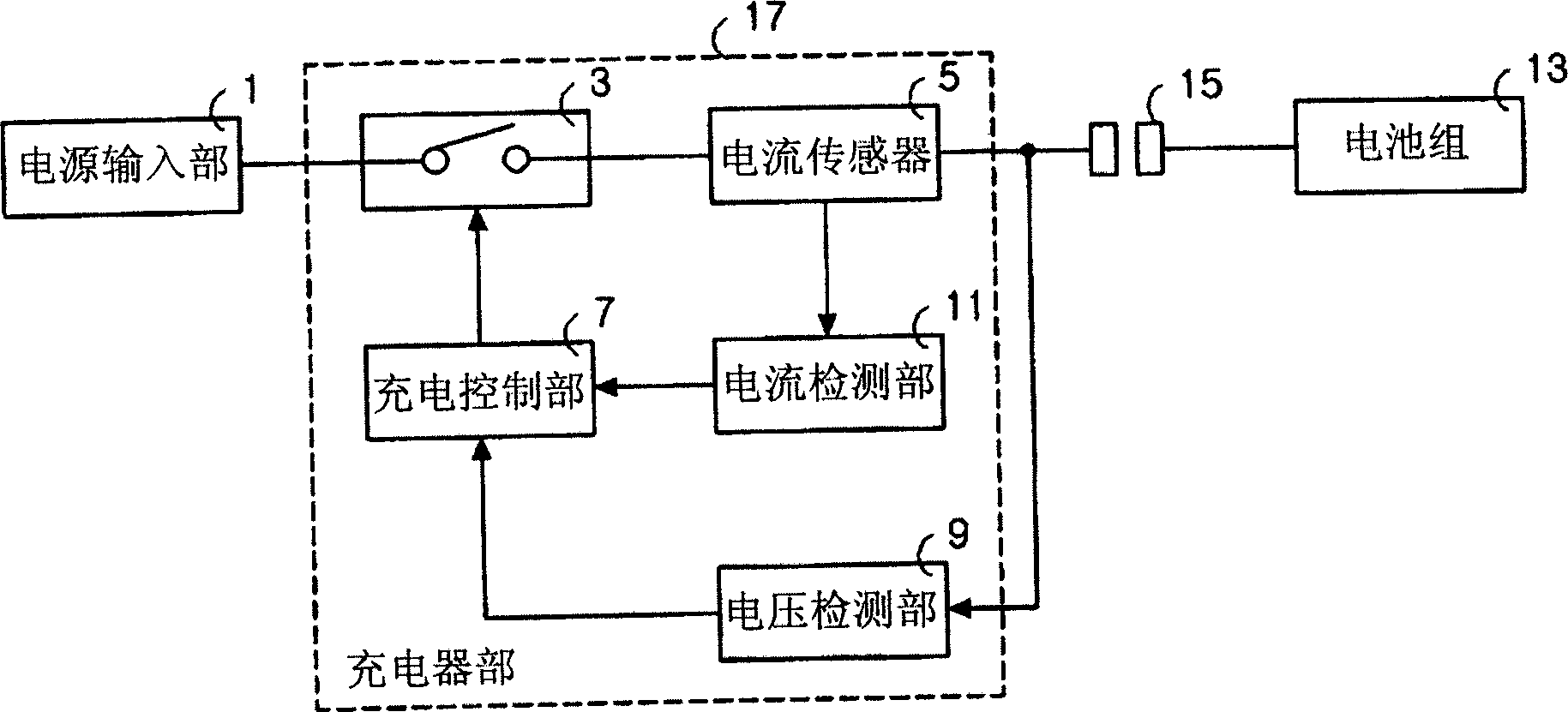

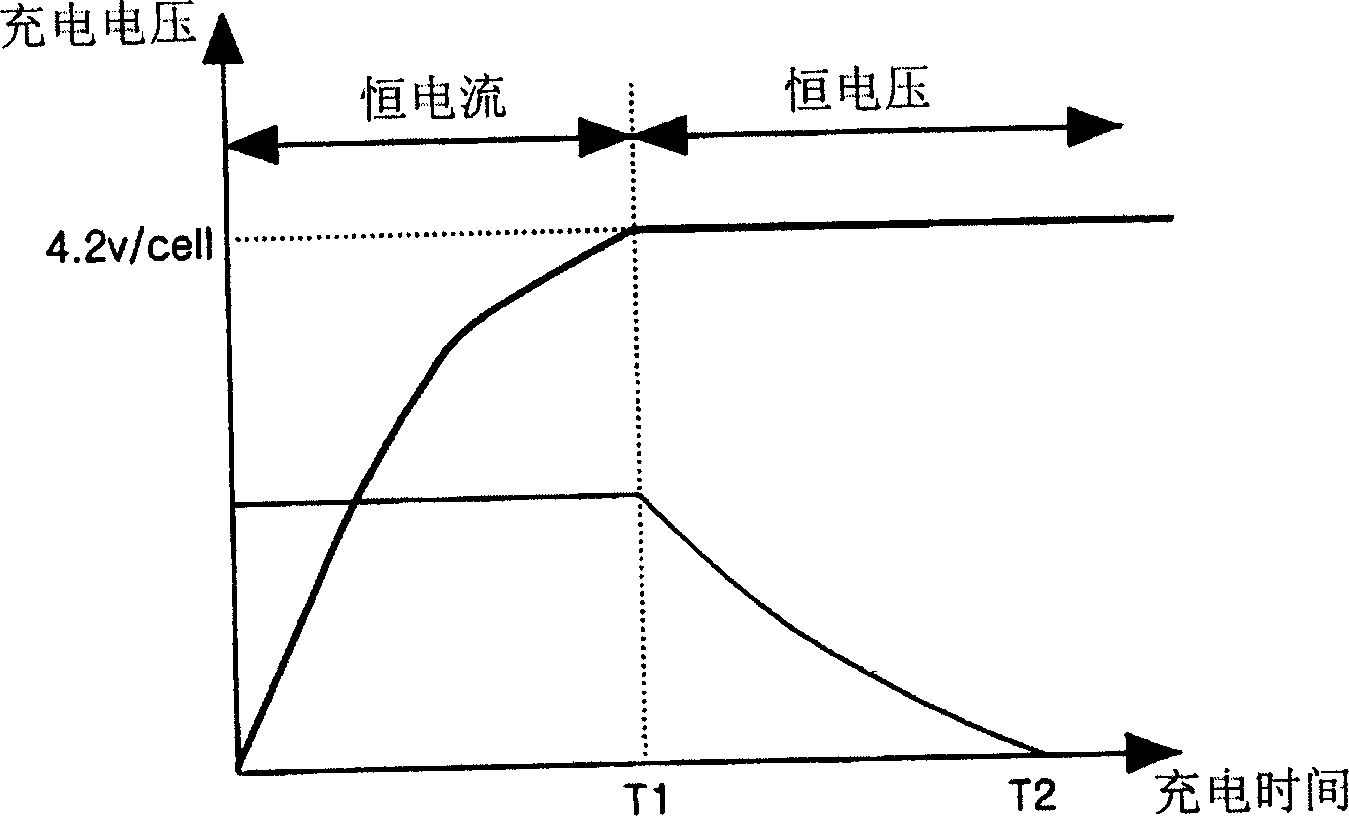

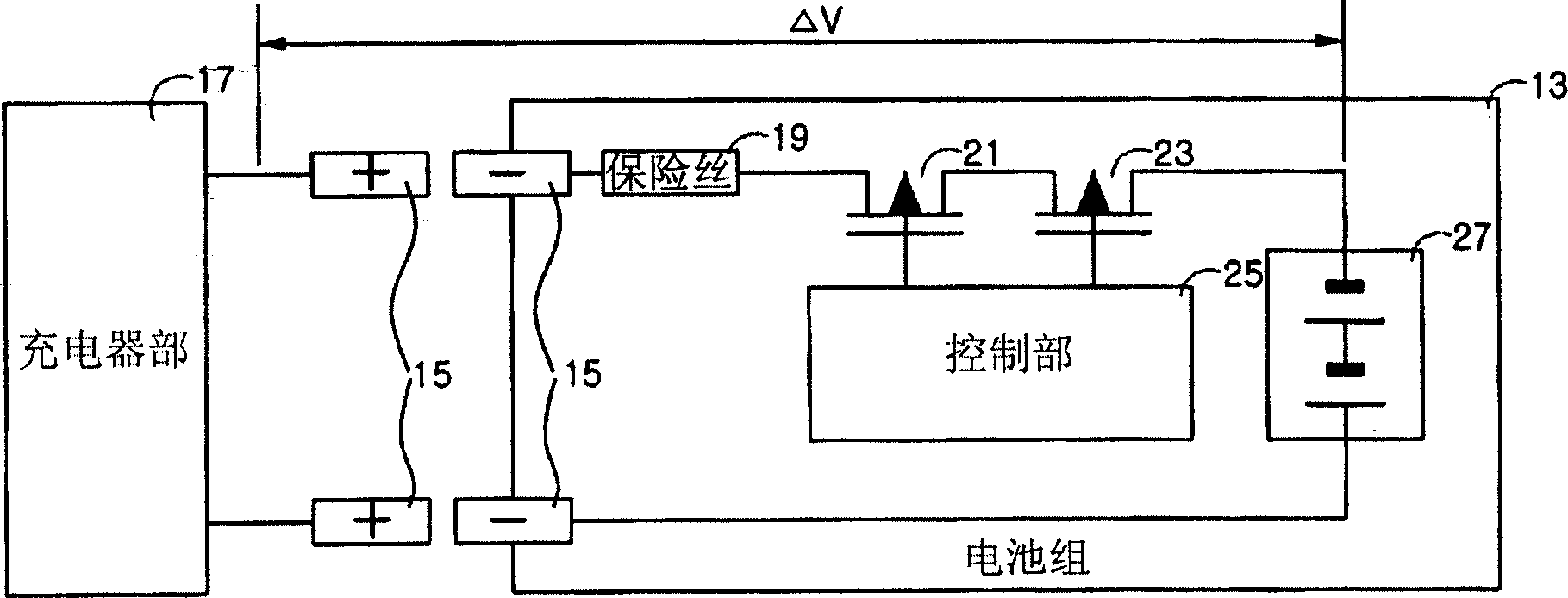

Controlling a charging operation of a battery

InactiveCN1897398AImprove charging efficiencyCharge capacity adjustmentBatteries circuit arrangementsSecondary cells charging/dischargingCharge voltageCharging station

The invention relates to a controlling device and a controlling method for charging operation of a battery, that is to say, it is a device and method to optimize charging stations of the batteryby adjusting charging capacity of the battery. The method includes reading an actual full charge capacity of the battery and a design capacity of the battery. The actual full charge capacity of the battery is compared with the design capacity of the battery. A charge voltage and a charge current are adjusted if the actual full charge capacity is less than the design capacity. The charge voltage and the charge current in adjusting step is used for controlling the charging operation of the battery. This invention determines the charging station, if the nonce full charge capacity is less than the design capacity, the charging operation of the battery is controlled by the adjusted charge voltage and charge current which are adjusted by decreasing charge current and increasing charge voltage. This invention can properly adjusts the full charge capacity of the battery and increases the charging efficiency.

Owner:LEJIN ELECTRONICS KUNSHAN COMPUTER CO LTD

Method for coating and mixing metal M alpha-Co(OH)2 on ball shape nickel hydroxide surface

InactiveCN1588676AImprove conductivityImprove performanceElectrode manufacturing processesAlkaline accumulator electrodesNickel oxide hydroxideCharge discharge

The invention relates to a technology for cladding a-Co(OH)2 on spheral nickel hydroxide. Tap density of prepared cobalt coated spheral nickel hydroxide can reach about 2.2g / cm3. The main method is to clad a layer alpha-Co(OH)2 mixed with one of more than one metal M from Y, Al, Cr, Mn, Yb, Sc, La, In, Ti, Zn, when (Co+M) / Ni ratio (mole ratio) is 0.3-0.1, conductive performance of sphere nickel hdyroxide product is abvisouly improved, Ni(OH)2 electrode performance is increased, further the cell performance as specific capacity, out power, charge-discharge circulating life, rapid charging ability, over charge / discharge resistance ability and oxygen separating overtention etc. are obviously increased.

Owner:TSINGHUA UNIV

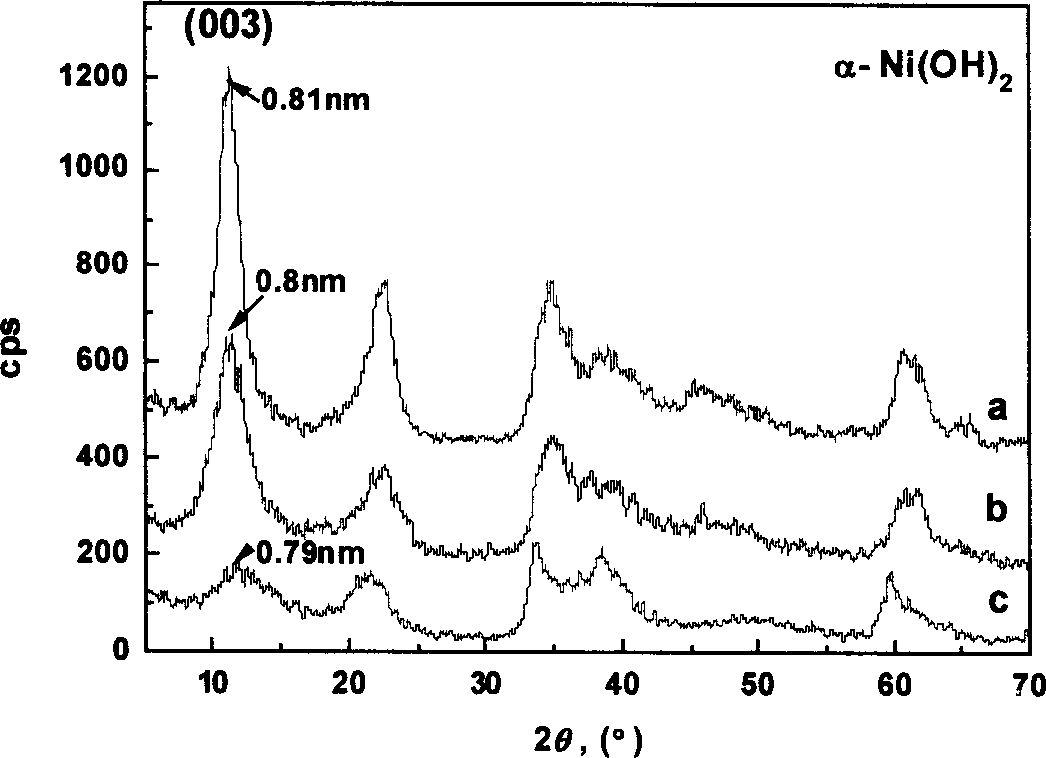

Nanometer alpha-nickel hydroxide and its prepn

InactiveCN1772629AImprove conductivityImprove proton conductivityNickel oxides/hydroxidesPotassium hydroxideUltrasonic dispersion

The present invention provides one kind of nanometer alpha-nickel hydroxide and its preparation process. The preparation process adopts bivalent nickel slat as main material, and includes the steps of: adding doping metal salt to compound reaction solution, compounding precipitant solution with potassium hydroxide or sodium hydroxide, adding the precipitant solution to the reaction solution under stirring and ultrasonic dispersing to obtain nickel hydroxide, washing and drying to constant weight. Thus prepared nanometer alpha-nickel hydroxide has small and homogeneous particle size, great specific surface area, high heat stability, stability in alkali medium, high specific discharge capacity, and other features, and may be used as the positive pole material in secondary alkali ZnNi cell, H-Ni cell and FeNi cell.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of sodium ion battery based on graphite/prussian blue anode material

InactiveCN107039622AImprove cycle stabilityPositive electrode capacity is not easy to decayCell seperators/membranes/diaphragms/spacersFinal product manufactureFreeze-dryingArgon atmosphere

The invention provides a preparation method of a sodium ion battery based on a graphite / prussian blue anode material. The preparation method comprises the specific steps of mixing a ferrous chloride solution and a sodium ferrocyanide solution, performing programmed heating to be 70-90 DEG C, performing programmed cooling to be a room temperature, performing washing and drying to obtain a prussian blue nanosphere, adding the prussian blue nanosphere to a graphite oxide solution, performing stirring and mixing, performing separation, cold quenching and freeze-drying to obtain a graphite oxide cladded prussian blue nanosphere, performing reduction in hydrazine hydrate to obtain graphite / prussian blue, performing grinding, vacuum drying and tabletting on the graphite / prussian blue, a conductive agent, isopropanol and polytetrafluoroethylene to serve as an anode, taking a metal sodium sheet as a cathode, taking NaClO4 as an electrolyte, taking a chitosan film as a membrane, and then performing assembling in an argon atmosphere to form the sodium ion battery based on the graphite / prussian blue. The sodium ion battery prepared by the method has stable cycle performance; and a capacity maintenance rate is above 90%.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

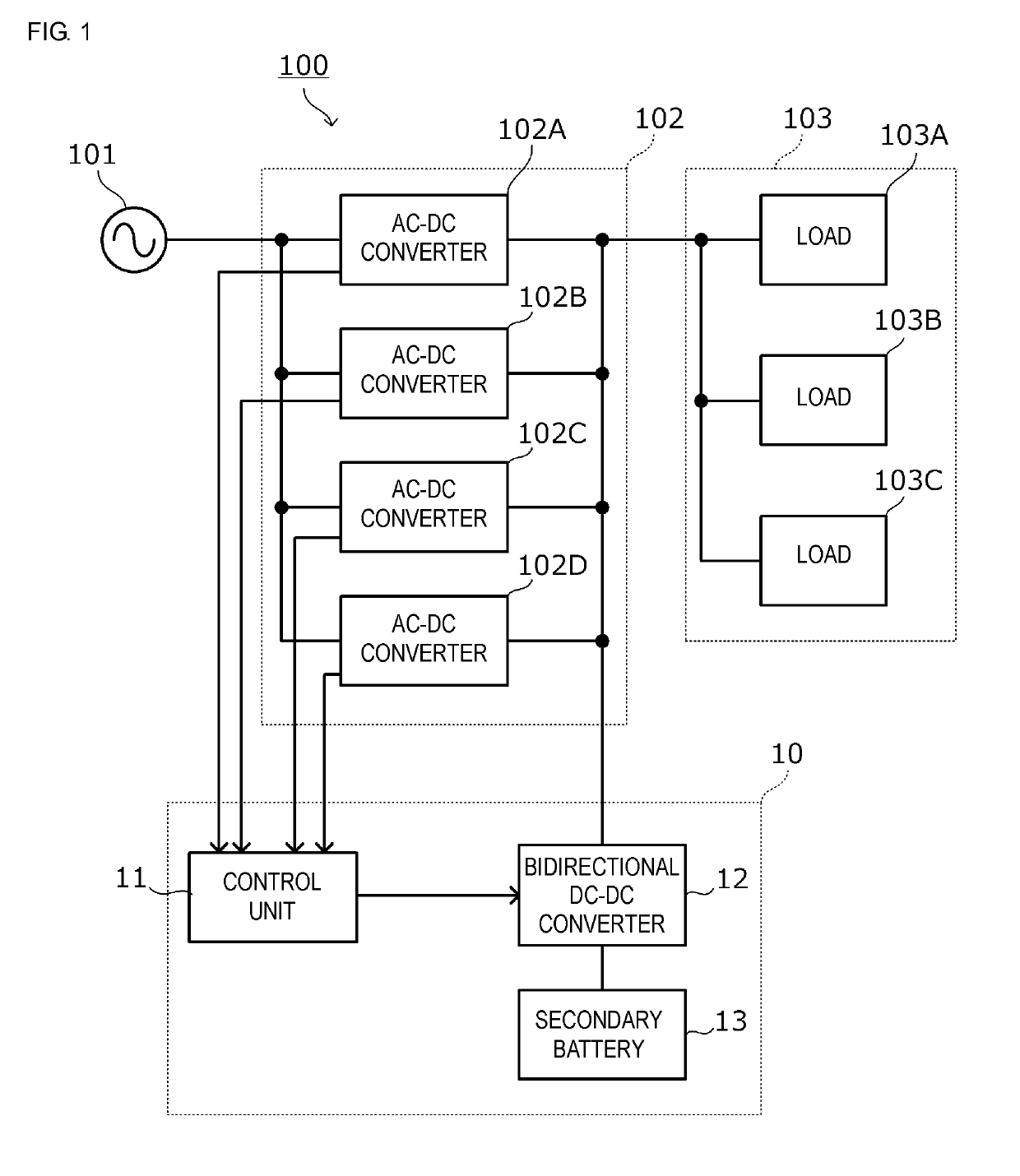

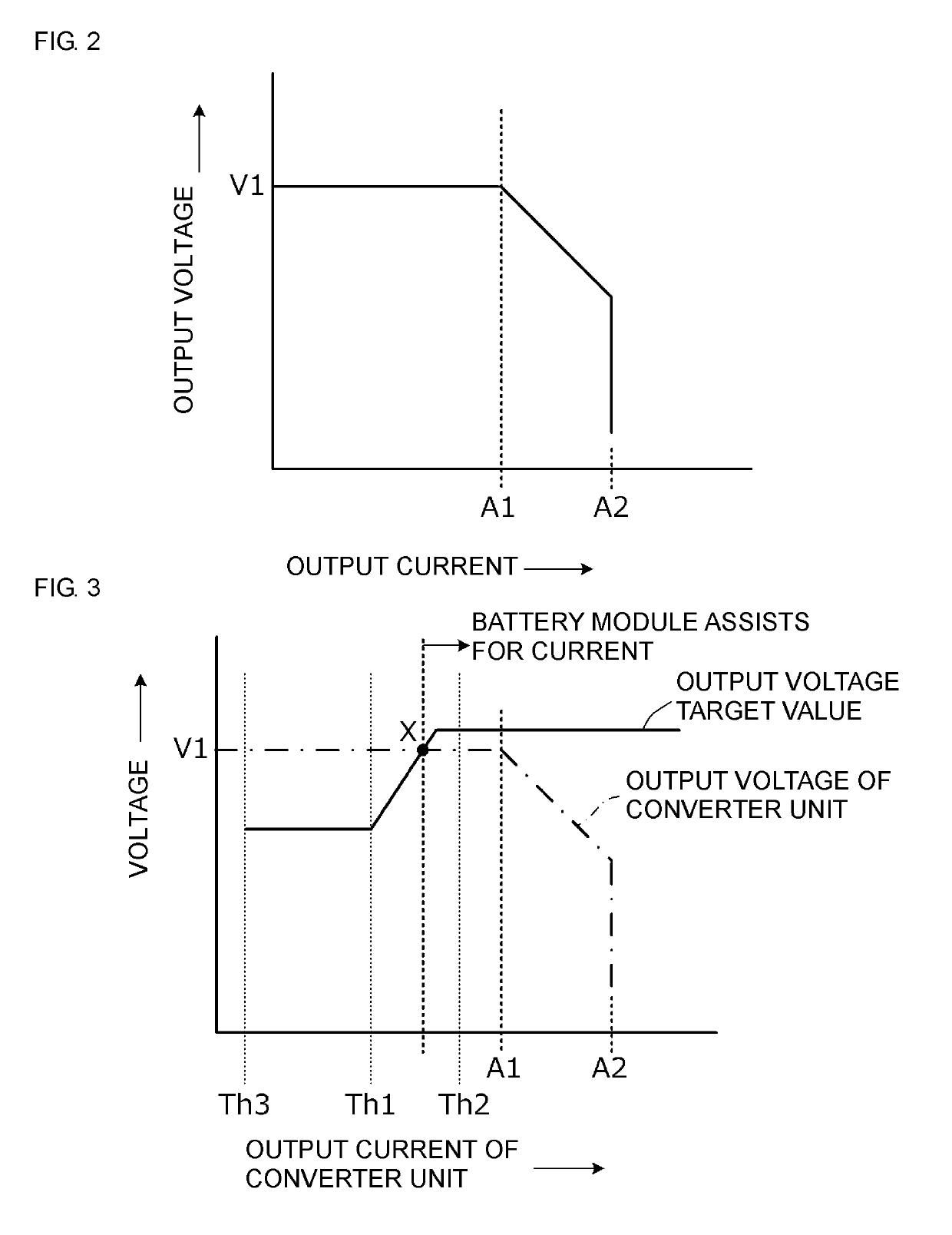

Battery module voltage control device, battery module, and power supply system

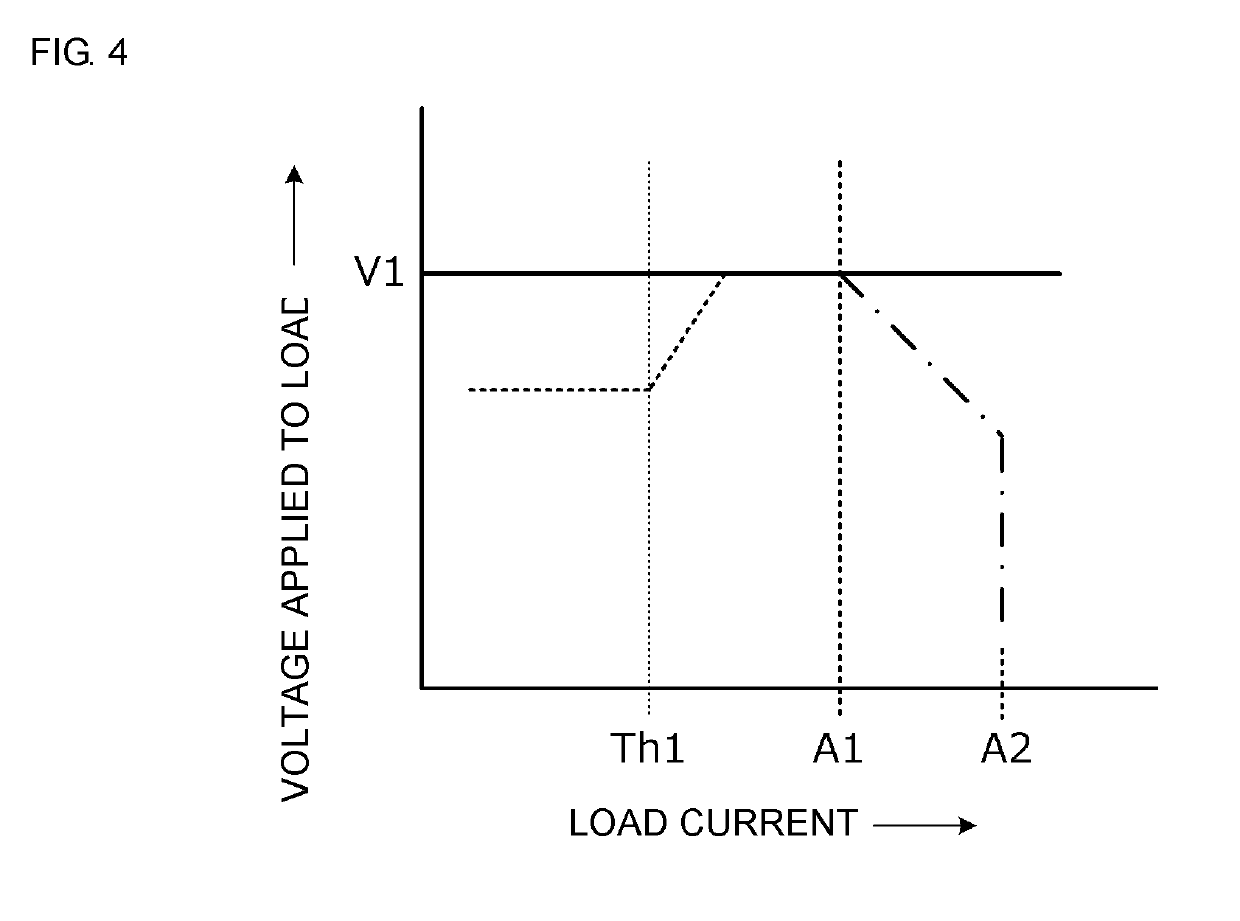

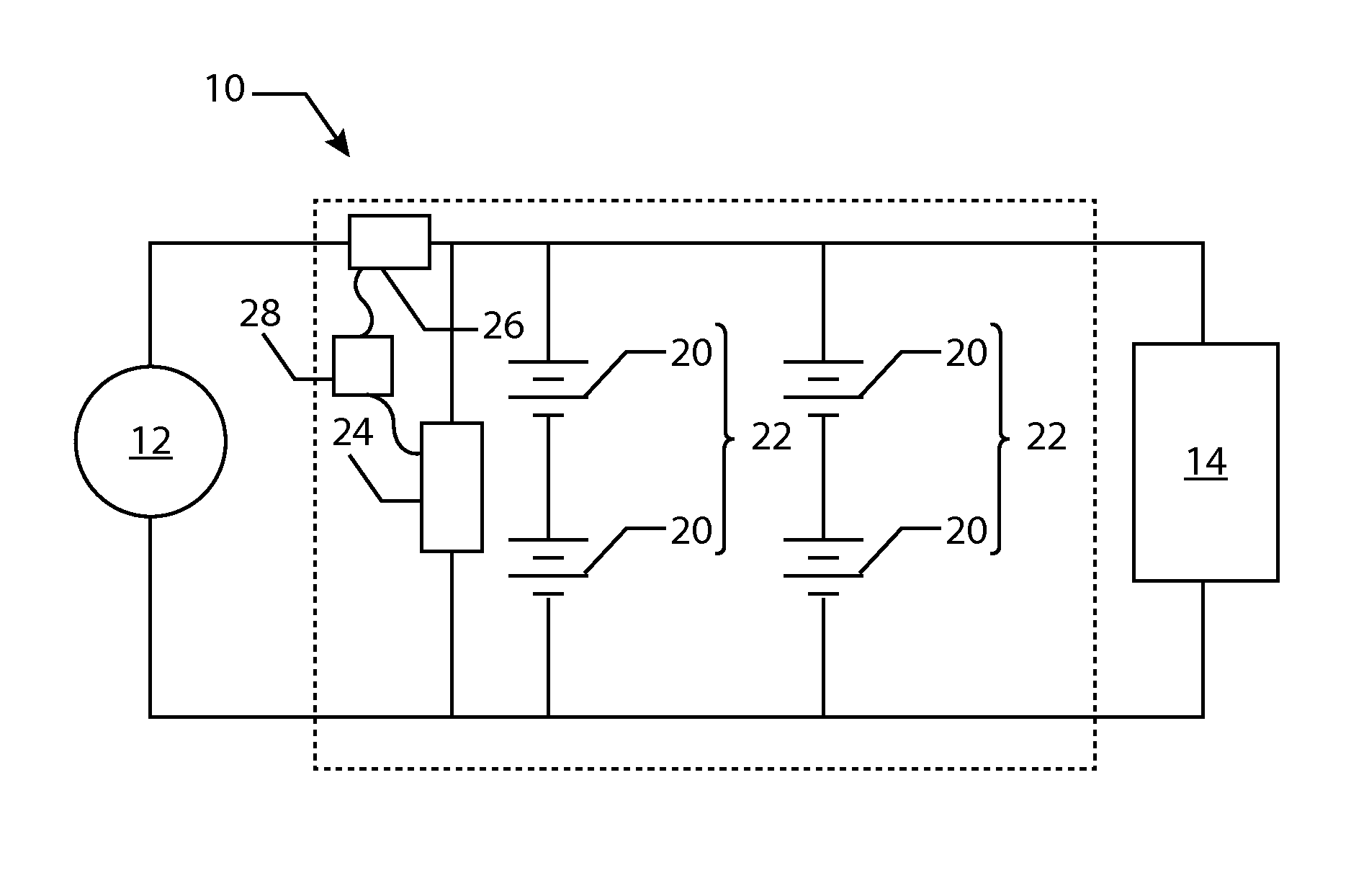

ActiveUS20190097452A1Stable voltagePrevent erroneous operation of loadElectric signal transmission systemsFlicker reduction in ac networkDc dc converterElectrical battery

A power supply system including a battery module and a converter unit. The system includes a bidirectional DC-DC converter as a component of a battery module voltage control device that is connected between a load and a secondary battery and that changes a discharge voltage of the secondary battery and outputs the discharge voltage to the load. Moreover, a voltage control unit, which can include a control unit and the bidirectional DC-DC converter, changes the discharge voltage of the secondary battery to an output voltage target value to be outputted to the load.

Owner:MURATA MFG CO LTD

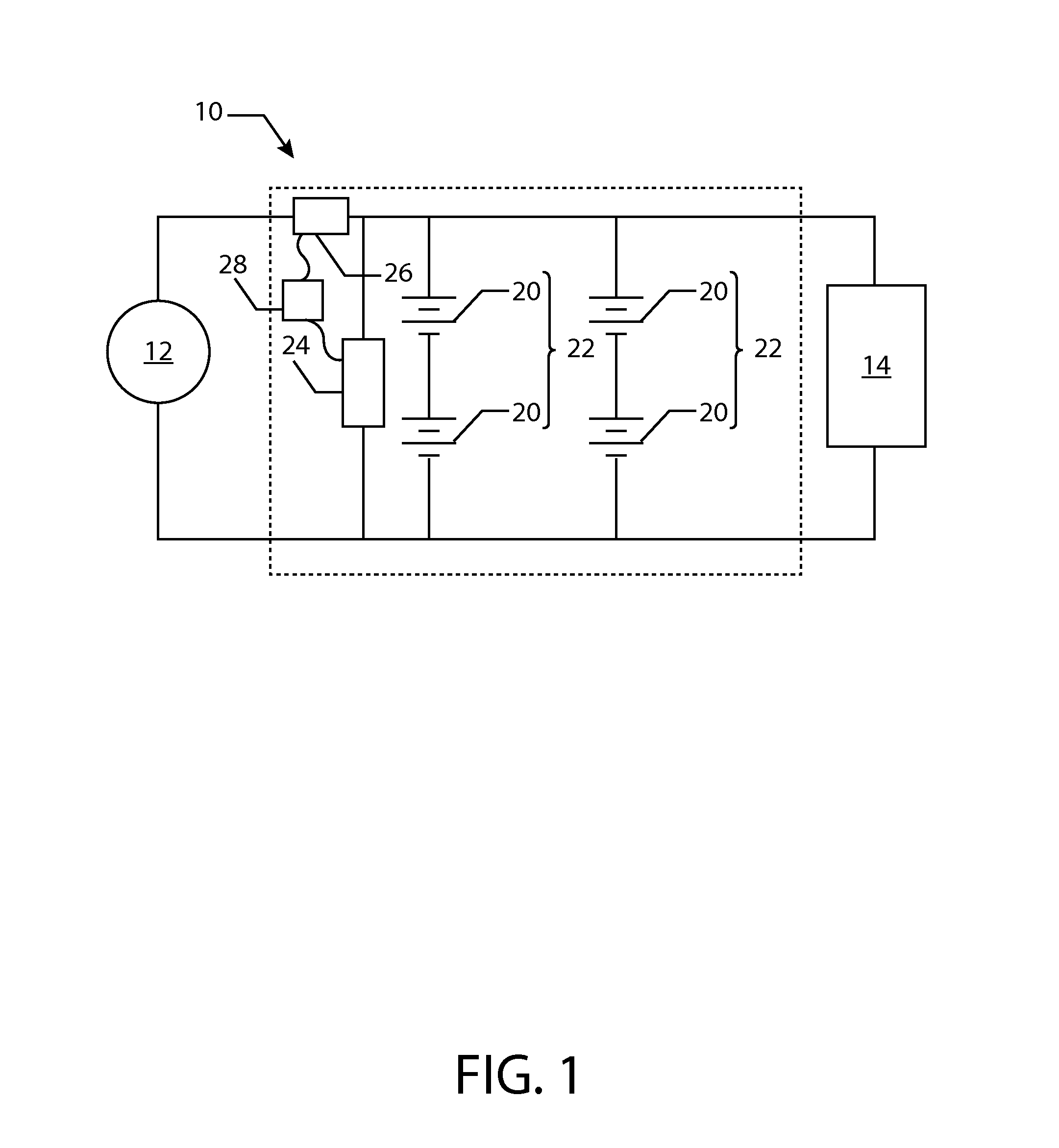

System and method for a rechargeable battery

ActiveUS20140028268A1Reduce charging voltageCircuit monitoring/indicationElectric powerRechargeable cellEngineering

A method for a rechargeable battery is disclosed that includes applying a charge voltage to the rechargeable battery; monitoring a battery voltage and a battery current of the rechargeable battery; and identifying a top of charge condition when for a defined time period the battery voltage is within a voltage tolerance of the charge voltage and the battery current is within a current tolerance of a threshold current. Also disclosed is a rechargeable battery system.

Owner:GENERAL ELECTRIC CO

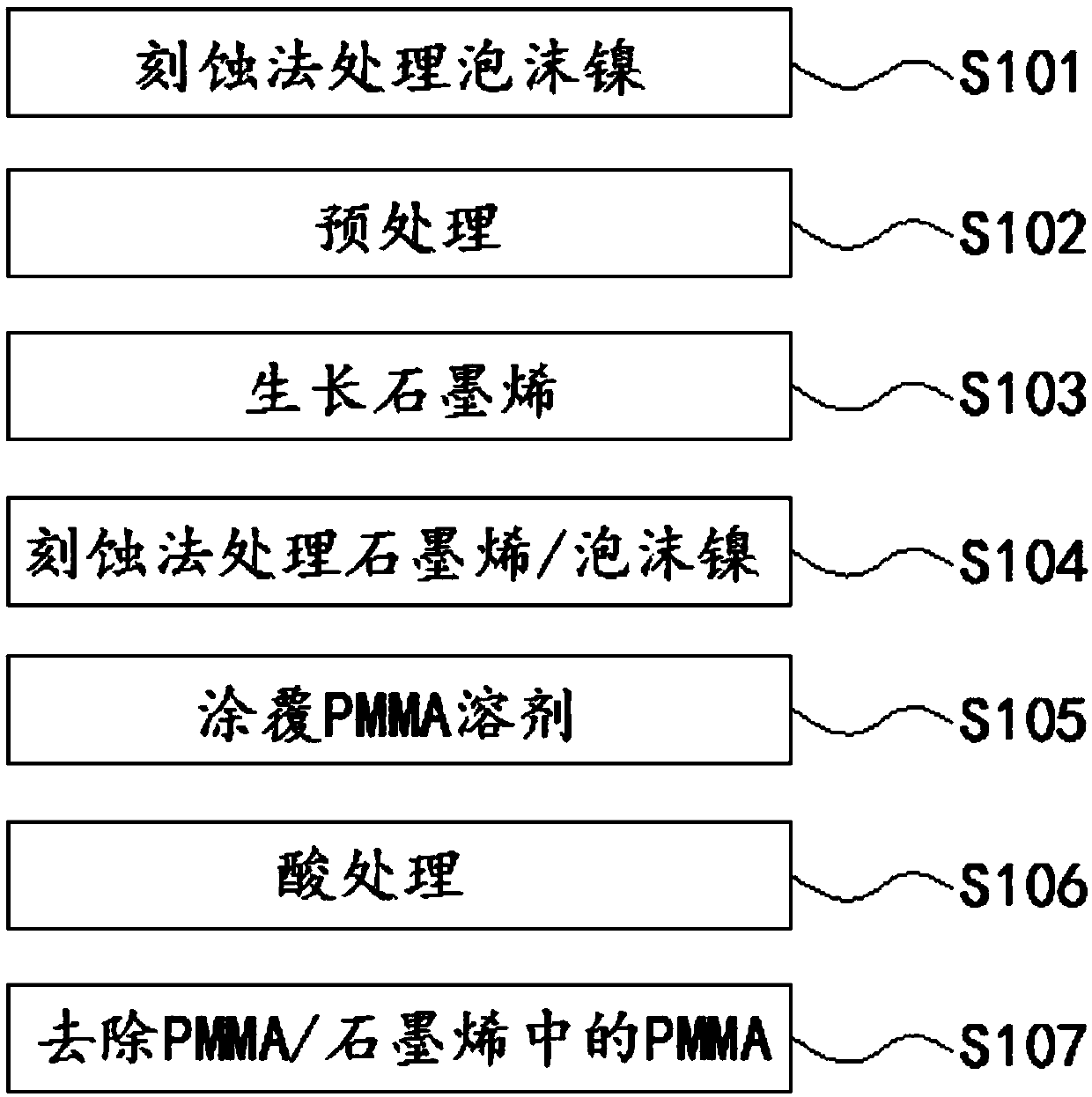

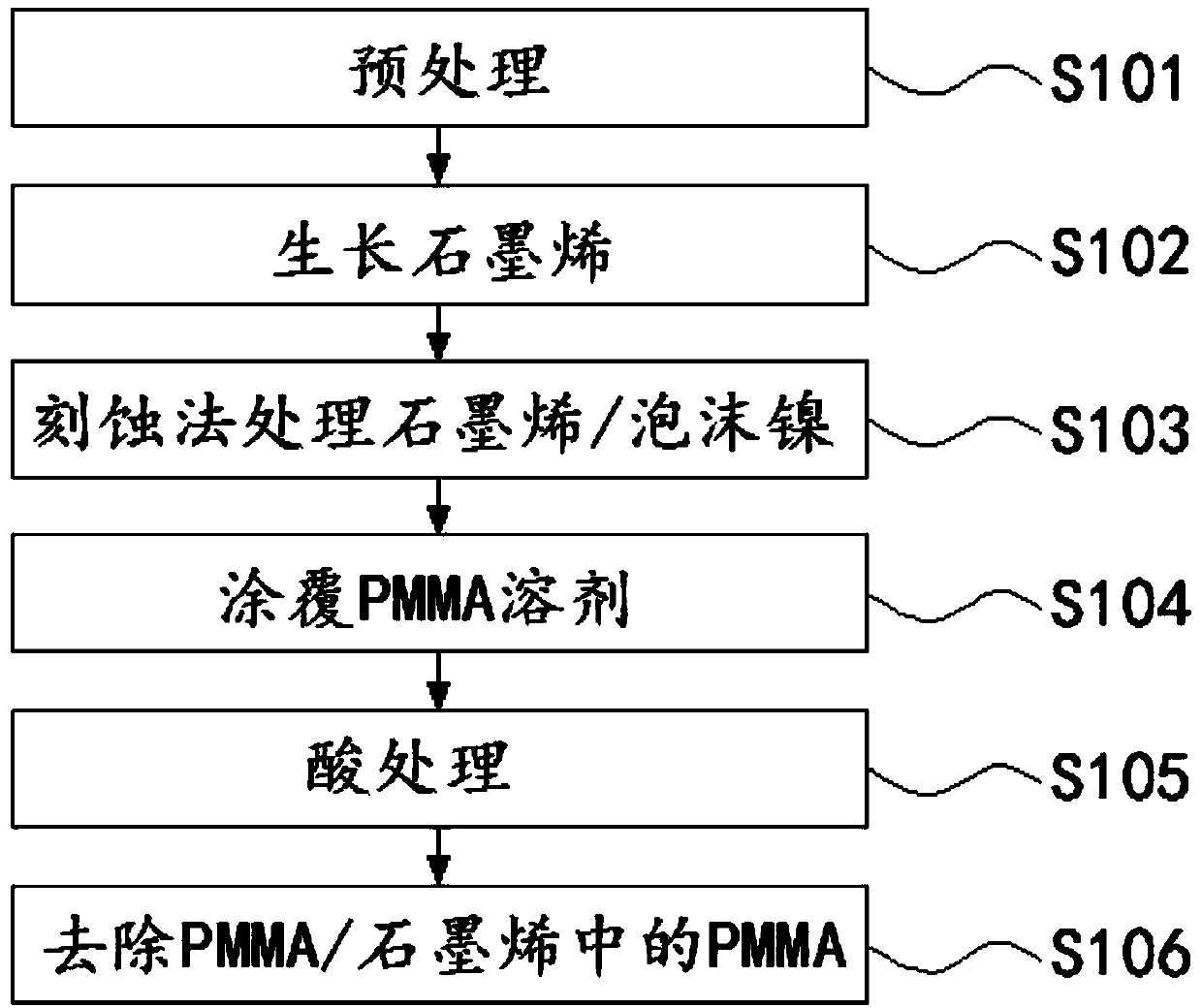

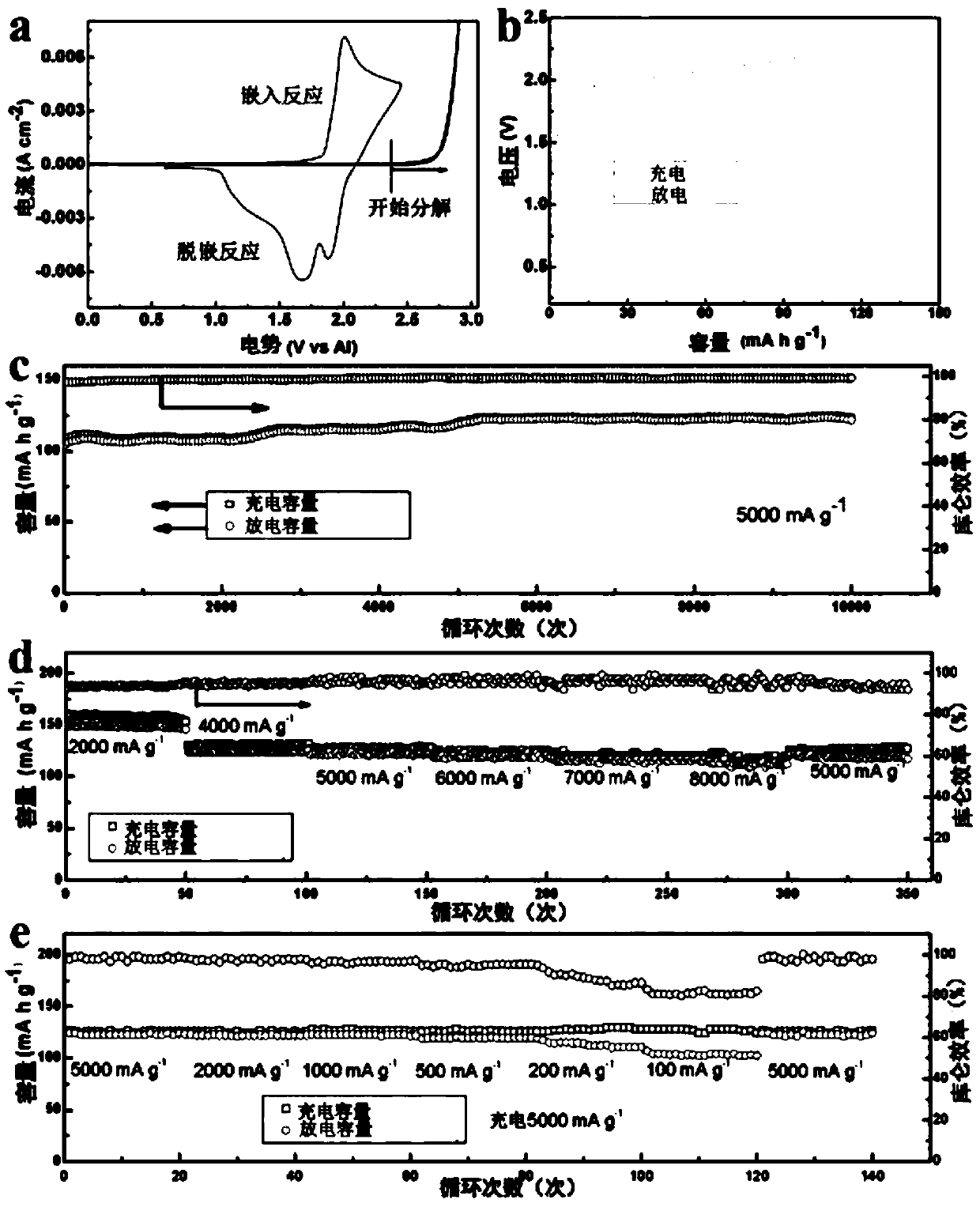

Preparation method of aluminum-ion battery positive electrode material

The invention discloses a preparation method of an aluminum-ion battery positive electrode material. The method comprises the following steps of firstly, processing foamed nickel by an etching method;secondly, pre-processing a surface of the foamed nickel; thirdly, growing graphene on the surface of the foamed nickel to form a graphene / foamed nickel structure; fourthly, etching the graphene / foamed nickel; fifthly, coating a layer of PMMA solvent on a surface of the graphene / foamed nickel, and performing baking and film formation to obtain a PMMA / graphene / foamed nickel structure; sixthly, performing acid processing on the PMMA / graphene / foamed nickel, and dissolving the foamed nickel to obtain a PMMA / graphene structure; and finally, removing PMMA in the PMMA / graphene to obtain foam structure-based graphene. The synthesis of the aluminum-ion battery positive electrode material without a binding agent is achieved by chemical vapor deposition and an etching technology, the aluminum-ion battery positive electrode material has ultra-large capacity, relatively low charging voltage and excellent cycle stability, and the volume expansion of the material during the charge-discharge process is prevented.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

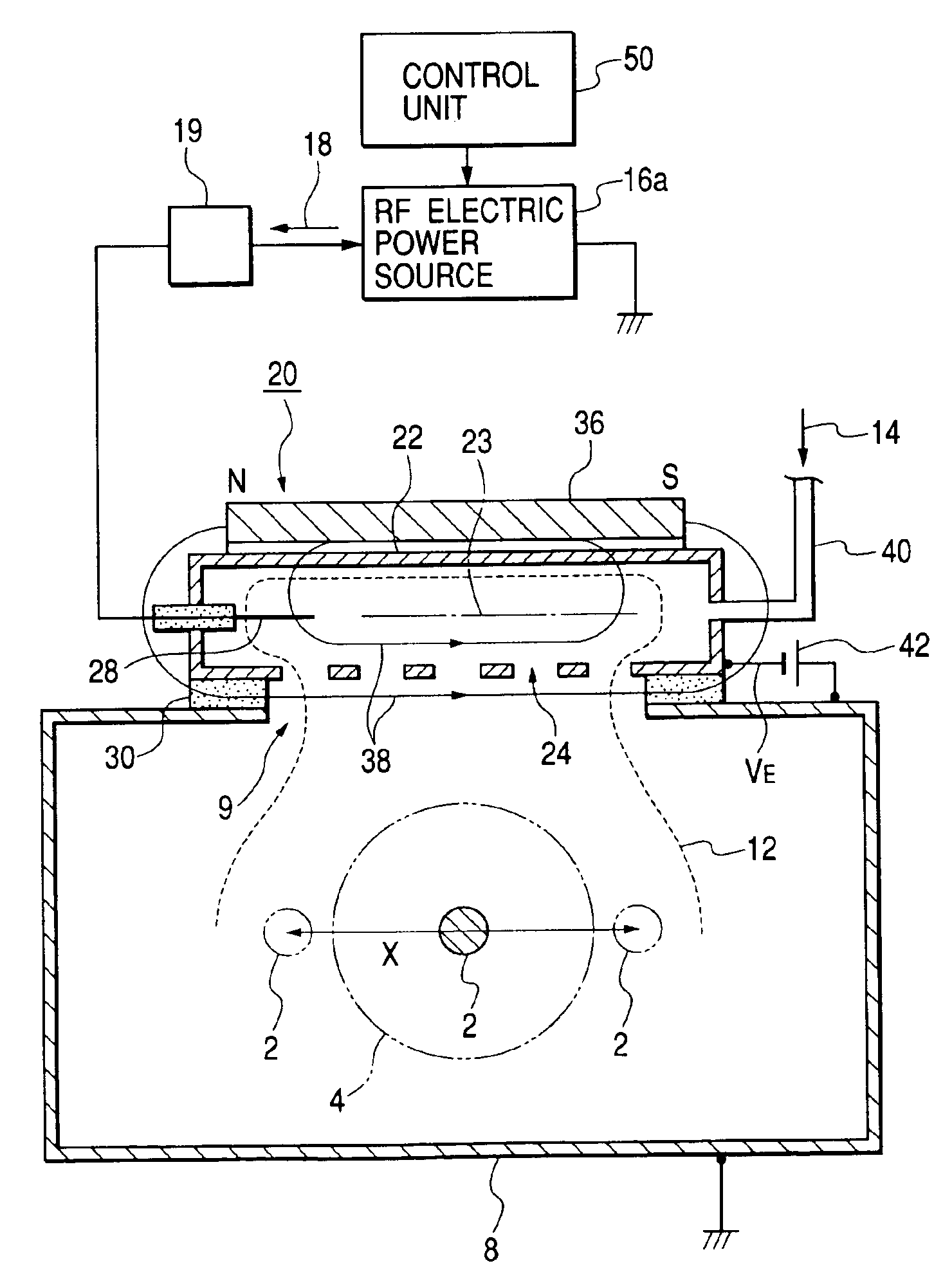

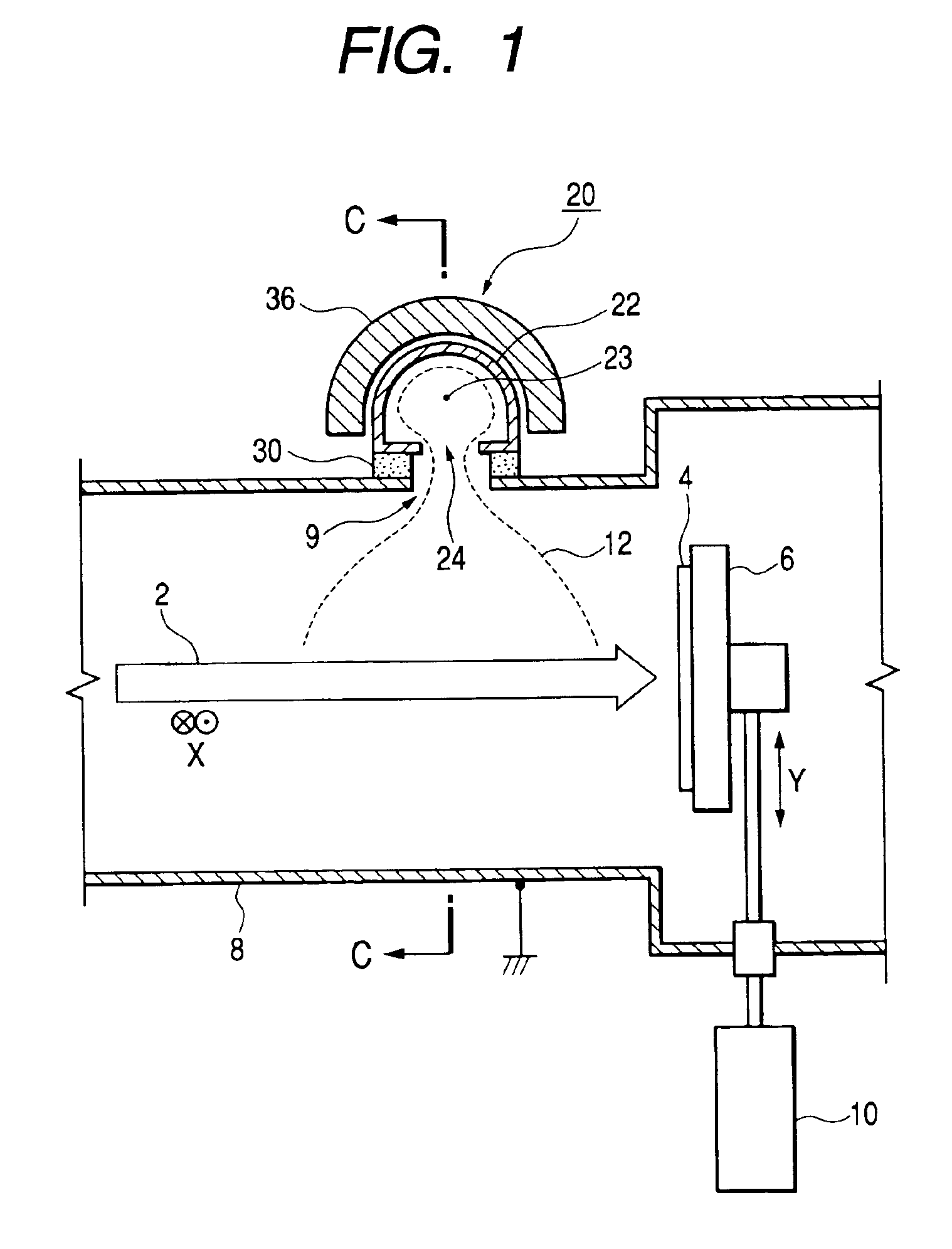

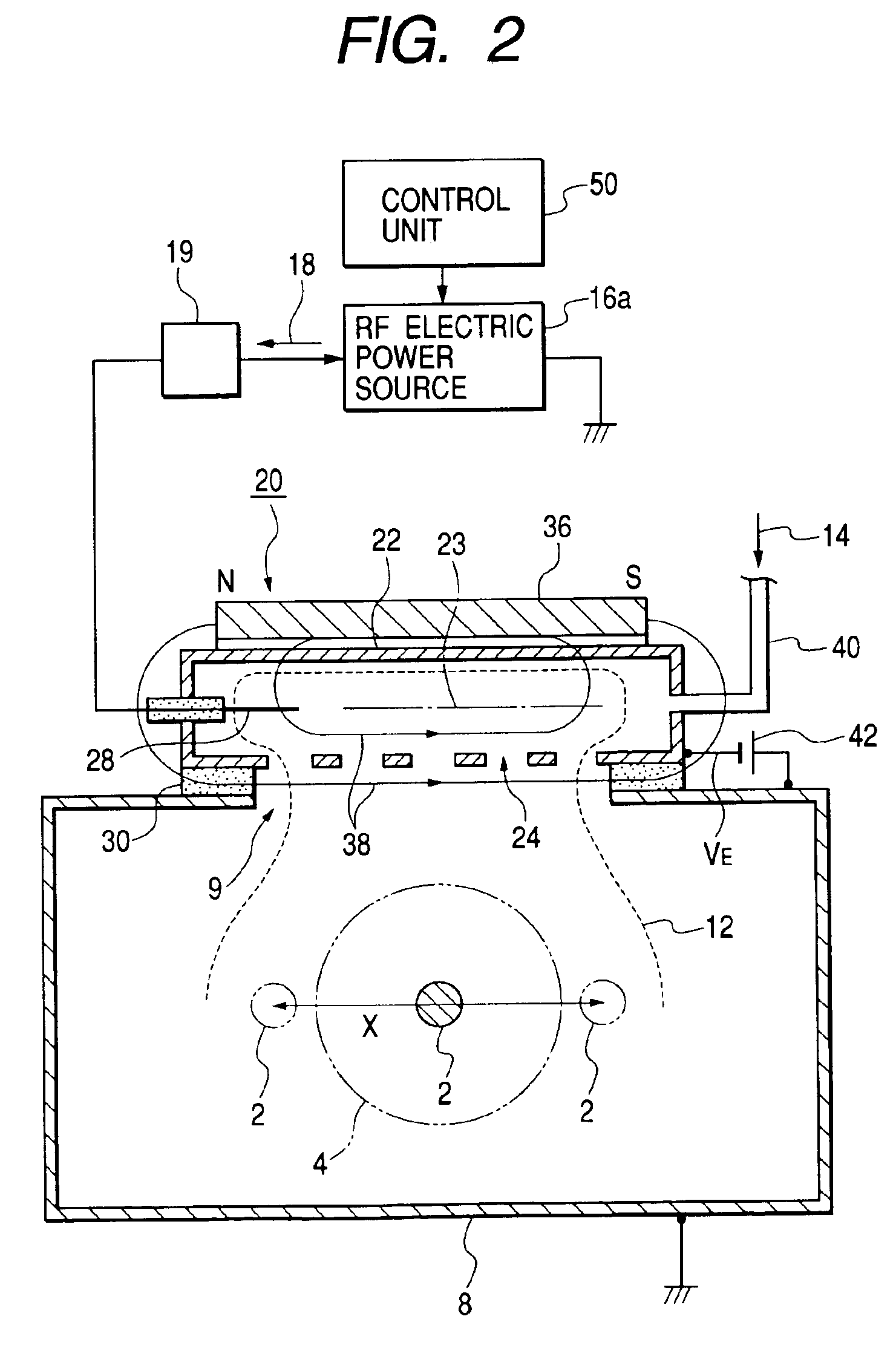

Ion beam irradiation apparatus for suppressing charge up of substrate and method for the same

InactiveUS7087912B2Weaken energyReduce voltageElectric discharge tubesVacuum evaporation coatingRadio frequency signalPlasma generator

An ion beam irradiation apparatus is equipped with a plasma generator which generates a plasma and supplies it to a region in the vicinity of the upstream side of a substrate, thereby suppressing a charging up of a surface of the substrate, which results from an irradiation of the ion beam. The radio frequency electric source for supplying the plasma for generating the plasma to a plasma generator is a radio frequency electric source for producing a radio frequency electric power formed by amplitude modulating an original radio frequency signal.

Owner:NISSIN ION EQUIP CO LTD

Method for coating surface of nano-alpha-phase nickel hydroxide with CoOOH

InactiveCN103094575AImprove conductivityImprove electrode performanceCell electrodesNickel oxide hydroxideOver potential

The invention discloses a method for coating the surface of nano-alpha-phase nickel hydroxide with CoOOH. The method is mainly characterized in that a precipitation conversion process is adopted to coat the surface of alpha-phase nickel hydroxide with a layer of CoOOH. The method obviously improves the conductive performance of the alpha-phase nickel hydroxide, and improves the electrode performance of nickel hydroxide, so the cell performances are obviously improved, for example, the specific capacity and the output power are improved, the large-rate discharge capability and the charge and discharge cycle performance are improved, and the oxygen evolution over-potential and the discharge plateau are improved. The discharge capacity of the cobalt coated nickel hydroxide prepared in the invention is high to 386mAh / g.

Owner:CHINA NAT ACAD NANOTECH & ENG

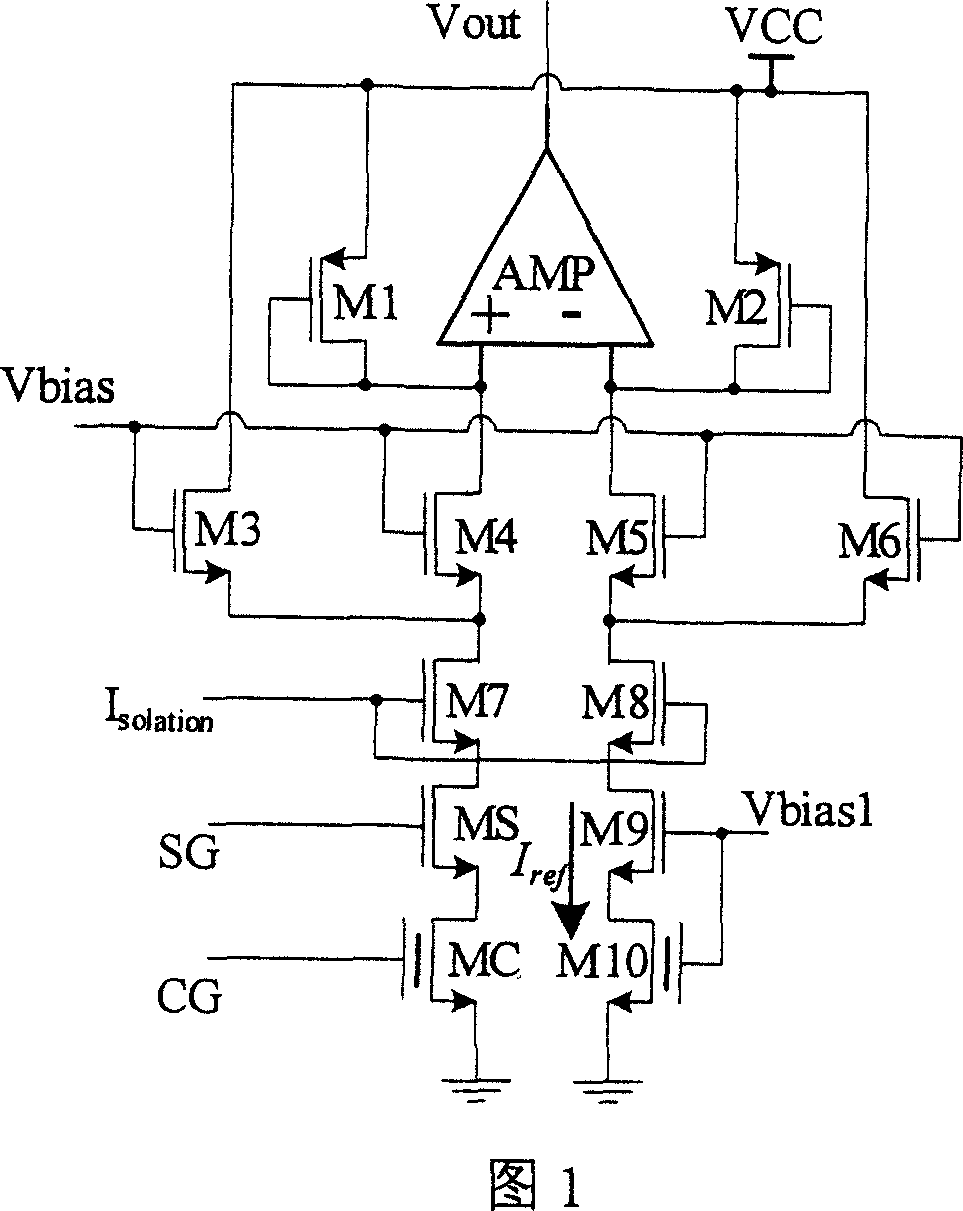

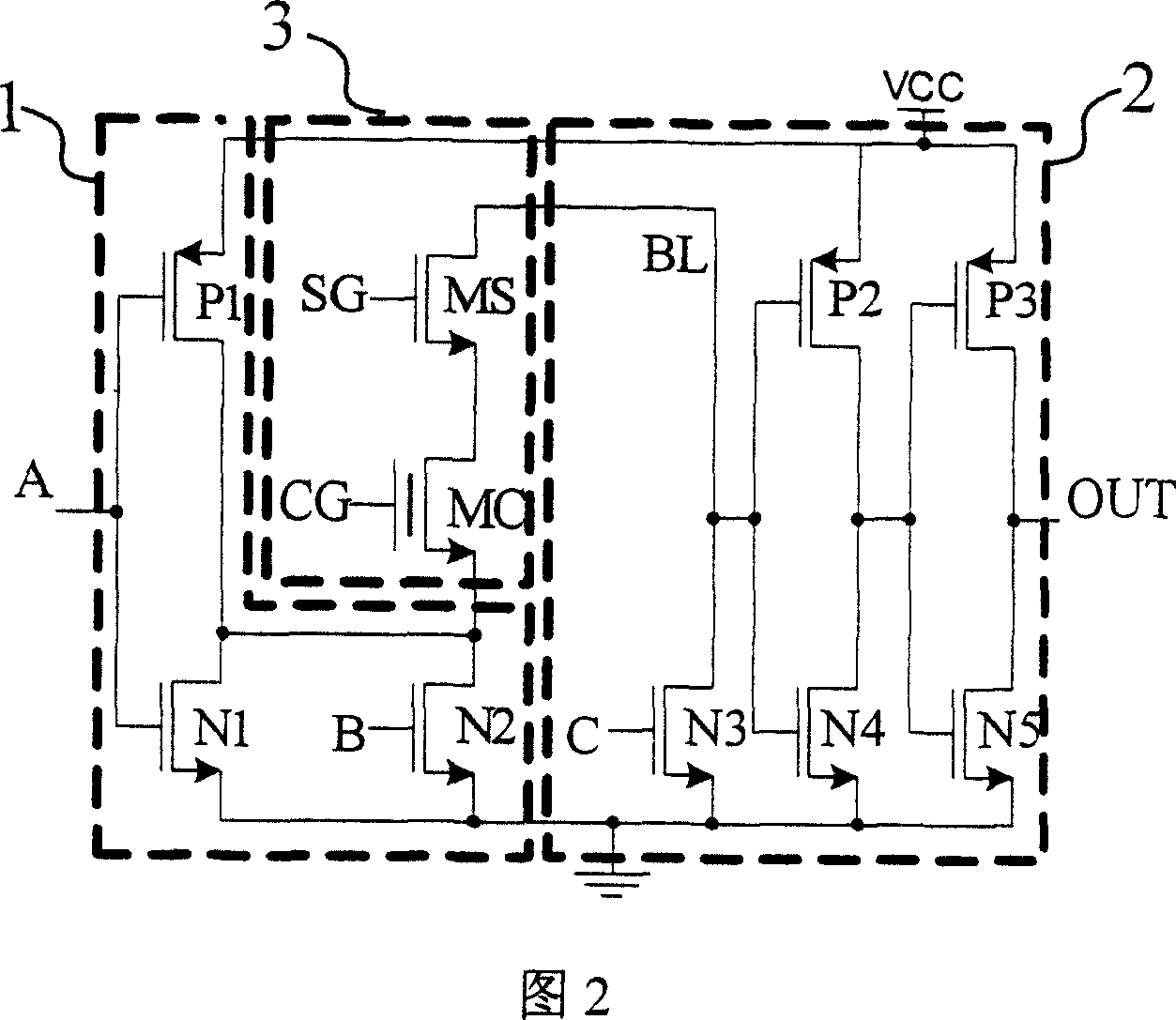

Sensitive amplifier for electric EPROM

InactiveCN1949394AReduce power consumptionAvoid Interfering ChargesRead-only memoriesAudio power amplifierHemt circuits

The invention discloses a sensitivity amplifier for EEPROM. It includes charge control circuit and detecting output circuit. The charge control circuit includes PMOS tube P1 and NMOS tubes N1, N2. Detecting output circuit includes PMOS tubes P2, P3 and NMOS tubes N3, N4, N5. The invention uses the bidirectional ducting ability of MOS tube to take charge to drain electrode. The source electrodes of floating grid tube are connected to each other to decrease charging circuit quantity. By modifying the reverse threshold value of the inverter, the charging voltage would be decreased, and read speed would be improved. The invention is especially suitable for embedded EEPROM.

Owner:HUAZHONG UNIV OF SCI & TECH

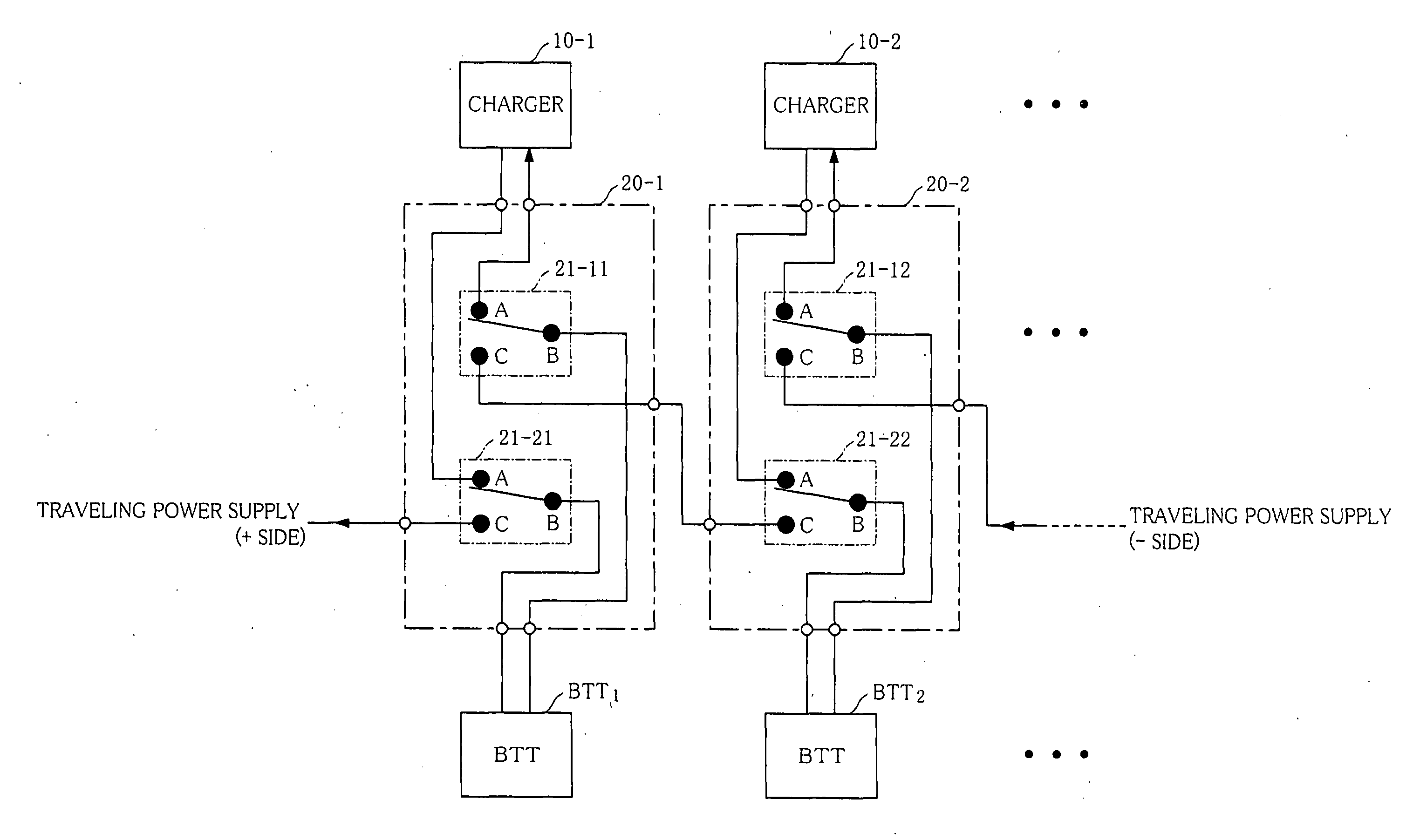

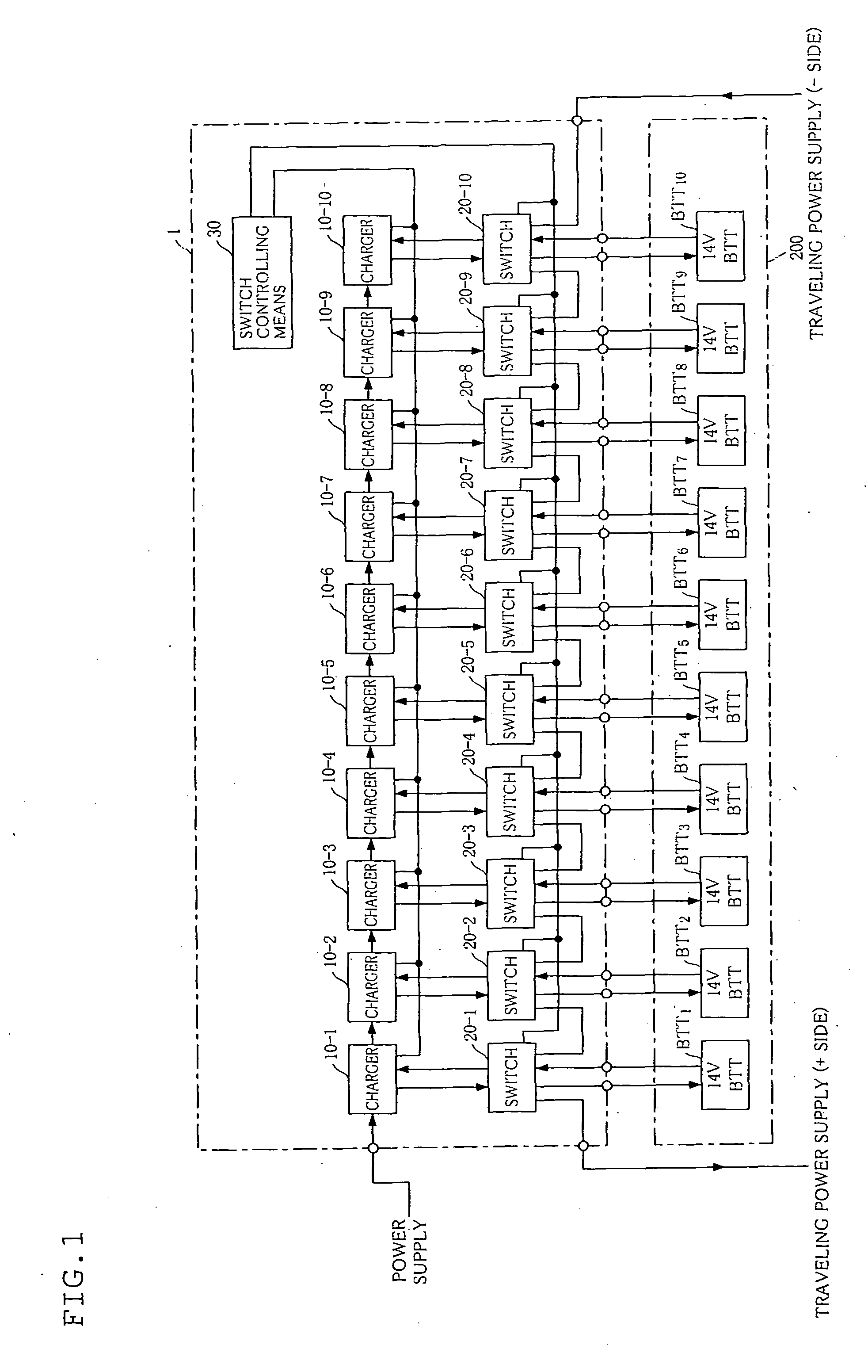

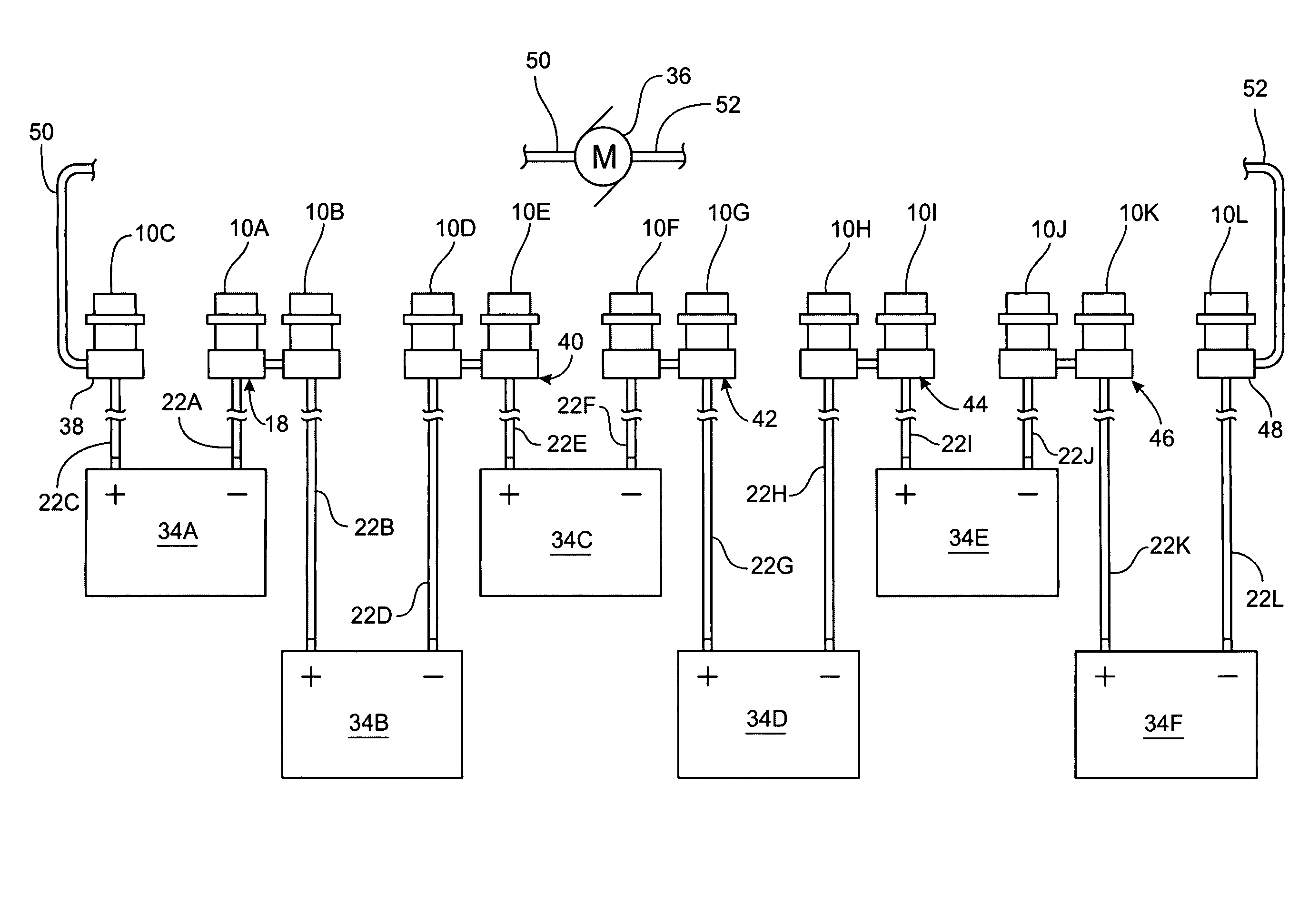

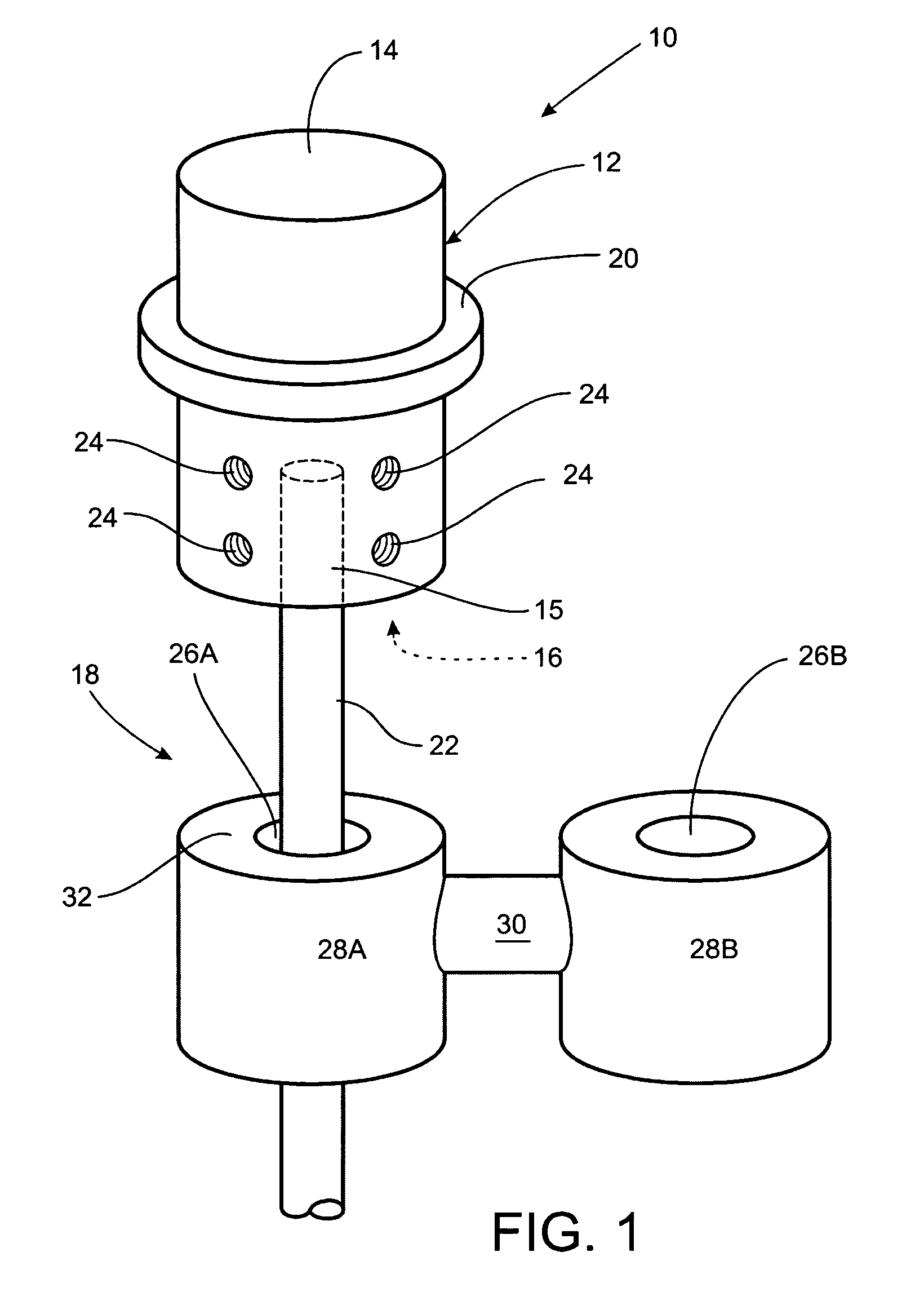

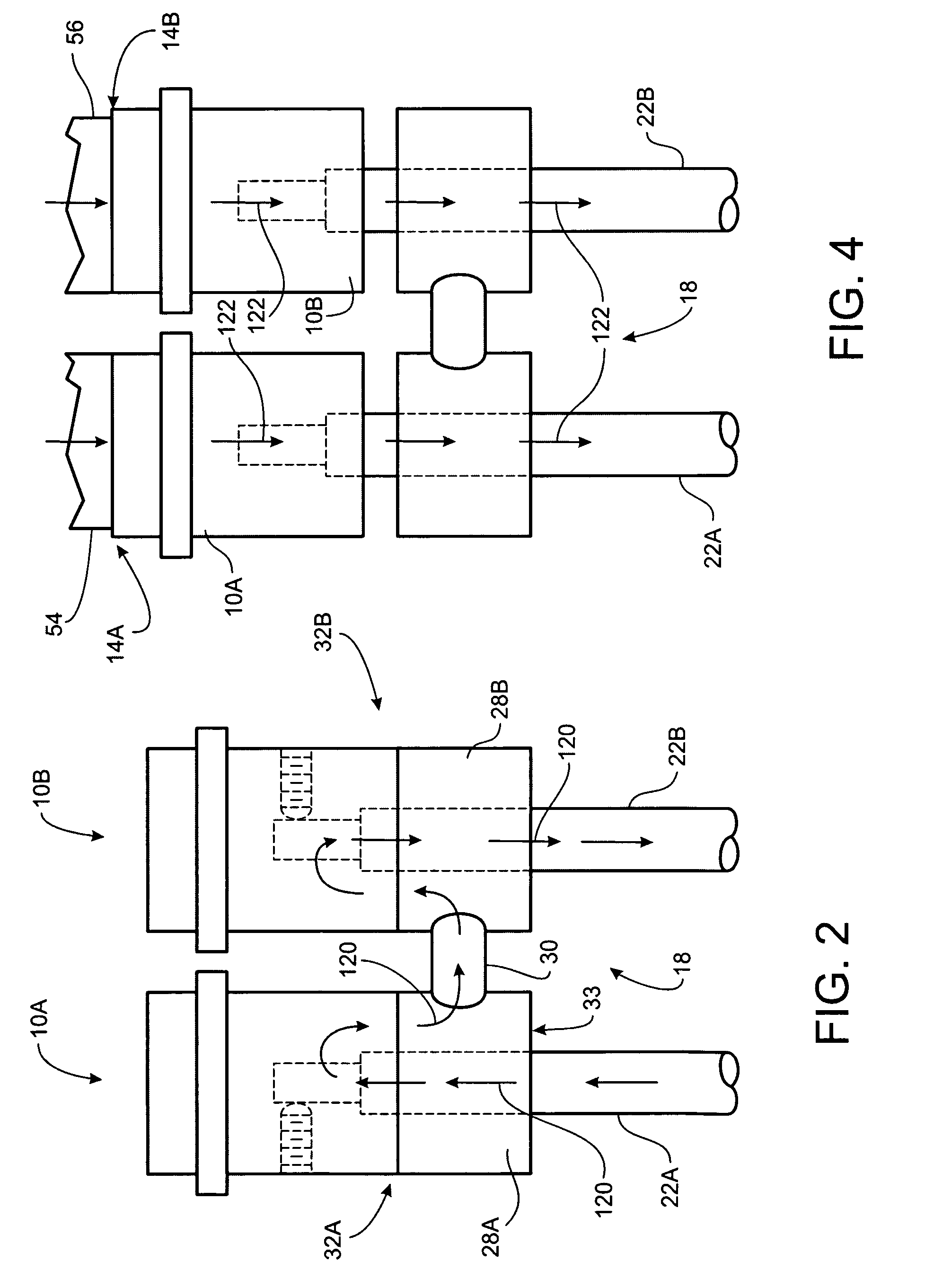

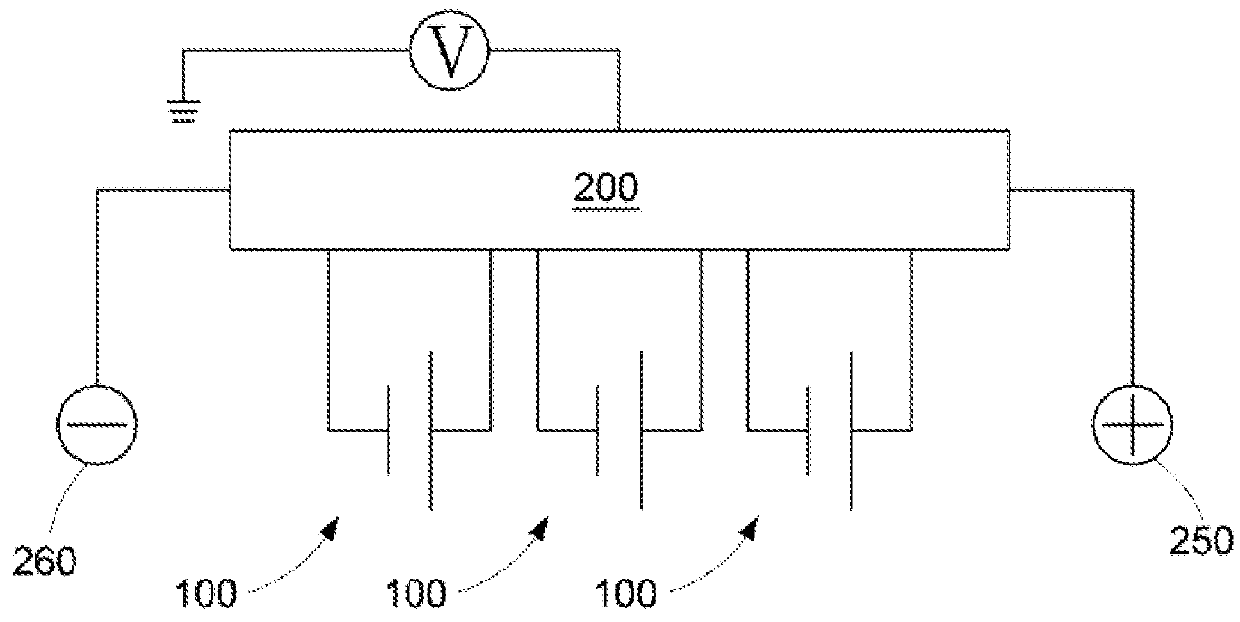

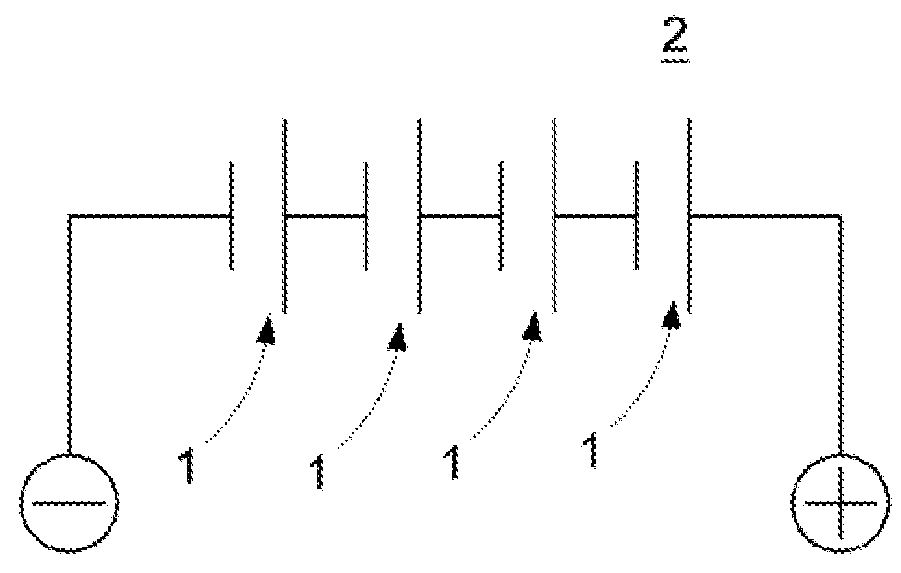

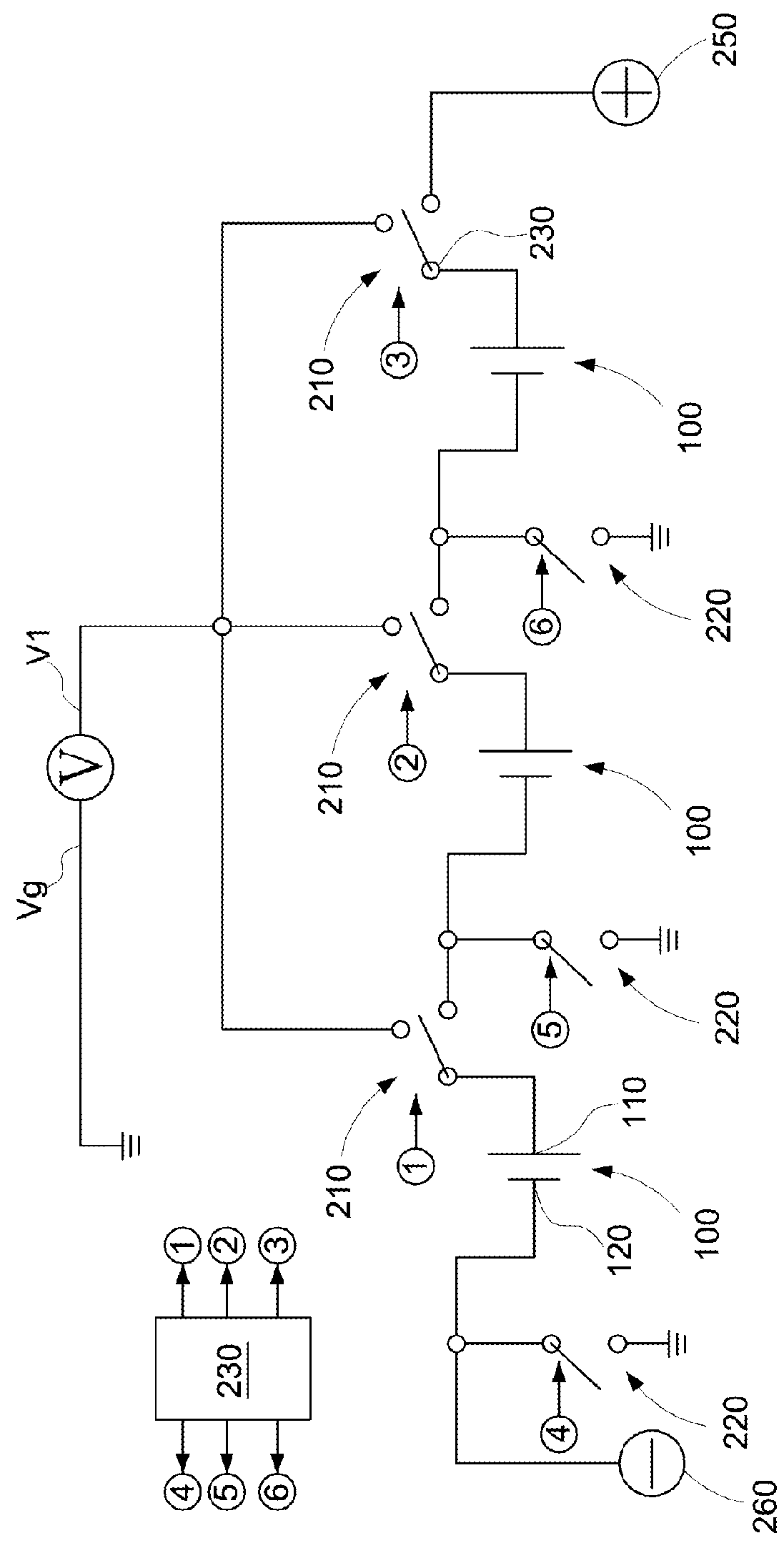

Charging contact array for enabling parallel charging and series discharging of batteries

ActiveUS8174238B2Reduce charging voltageHigh voltageHybrid vehiclesBatteries circuit arrangementsElectrical conductorBattery charge

Owner:BADGER BERKLEY C

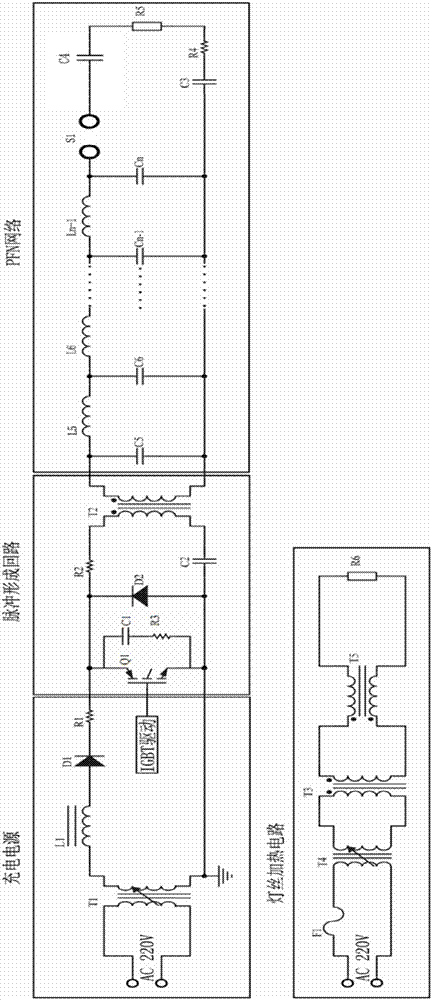

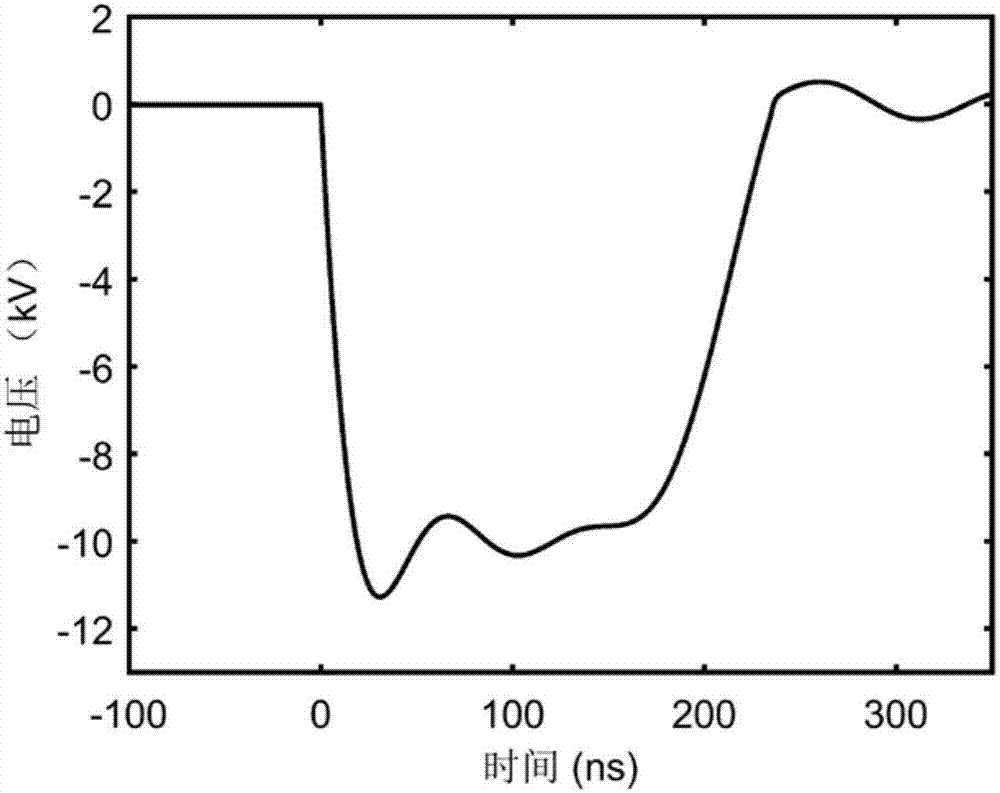

High voltage nanosecond pulse trigger used for hydrogen thyratron

PendingCN107257209ASimple and compactMiniaturizationElectronic switchingPulse generation by energy-accumulating elementCapacitanceTransformer

The invention discloses a high voltage nanosecond pulse trigger used for a hydrogen thyratron. The high voltage nanosecond pulse trigger comprises a charging power supply, a pulse forming circuit, a PFN network, and a filament heating circuit. The charging voltage of the energy storage capacitor of the pulse trigger is low, and a problem that high voltage is required by a common pulse trigger isolating a primary side of a transformer is well solved, and then the pulse trigger is compact and miniaturized. A pulse forming circuit adopts a rapid IGBT used as a switch used for switching on and switching off, and output pulse jitter is small, an amplitude is stable, and at the same time, a required IGBT voltage-withstanding value is low, and costs are low. The output pulse of the pulse trigger passes the PFN network, and cascaded capacitance, cascaded inductance, and cascade number are adjusted conveniently, and therefore the rising time and the pulse width of the output pulse are changed conveniently. The pulse trigger is integrated with a hydrogen thyratron filament heating circuit, and the current of the circuit is adjusted accurately, and dozens of kV high voltage are isolated at the same time. The pulse trigger adopts suspension output, and is capable of satisfying requirements of different occasions on the positive pulse and the negative pulse.

Owner:UNIV OF SCI & TECH OF CHINA

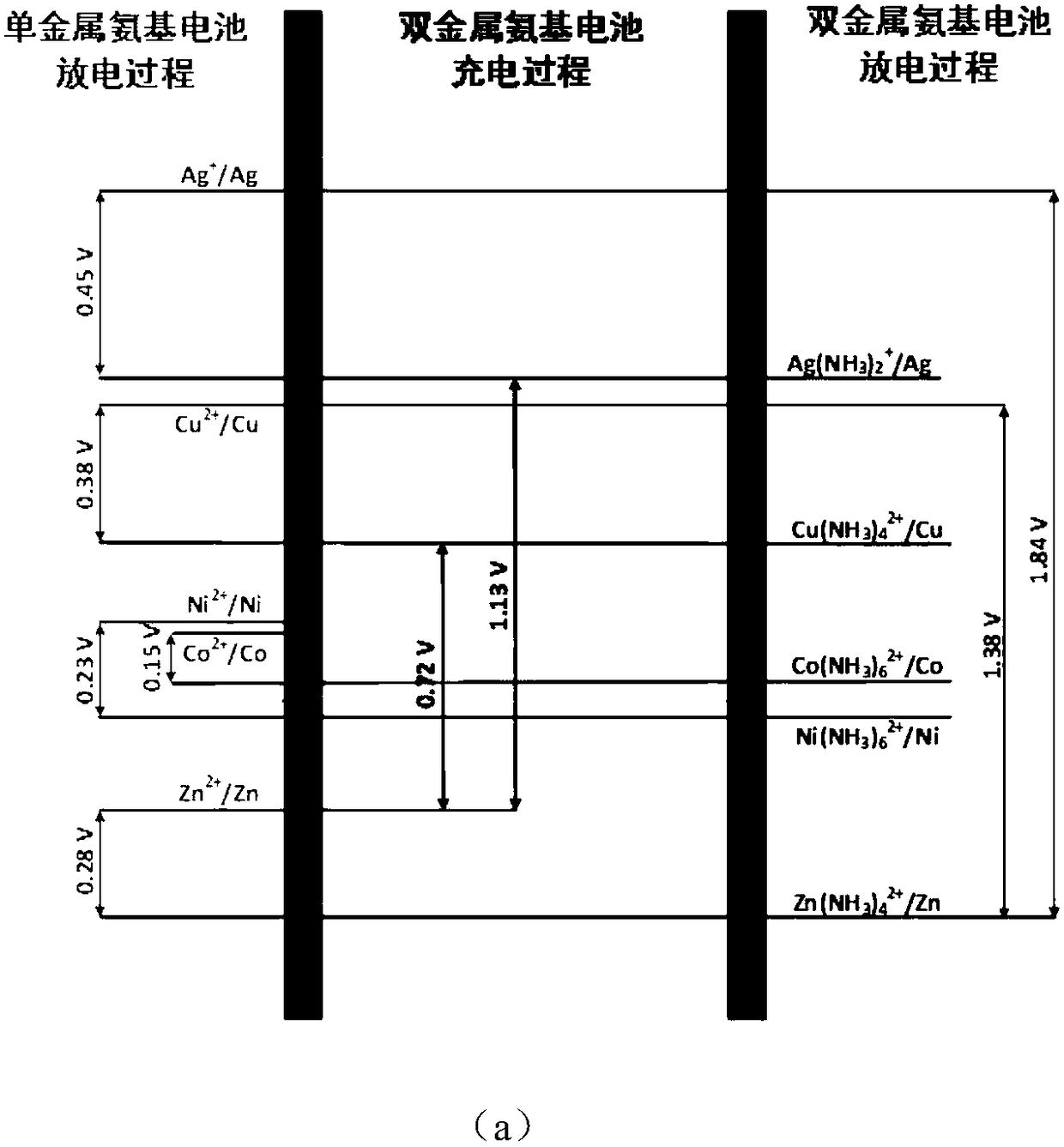

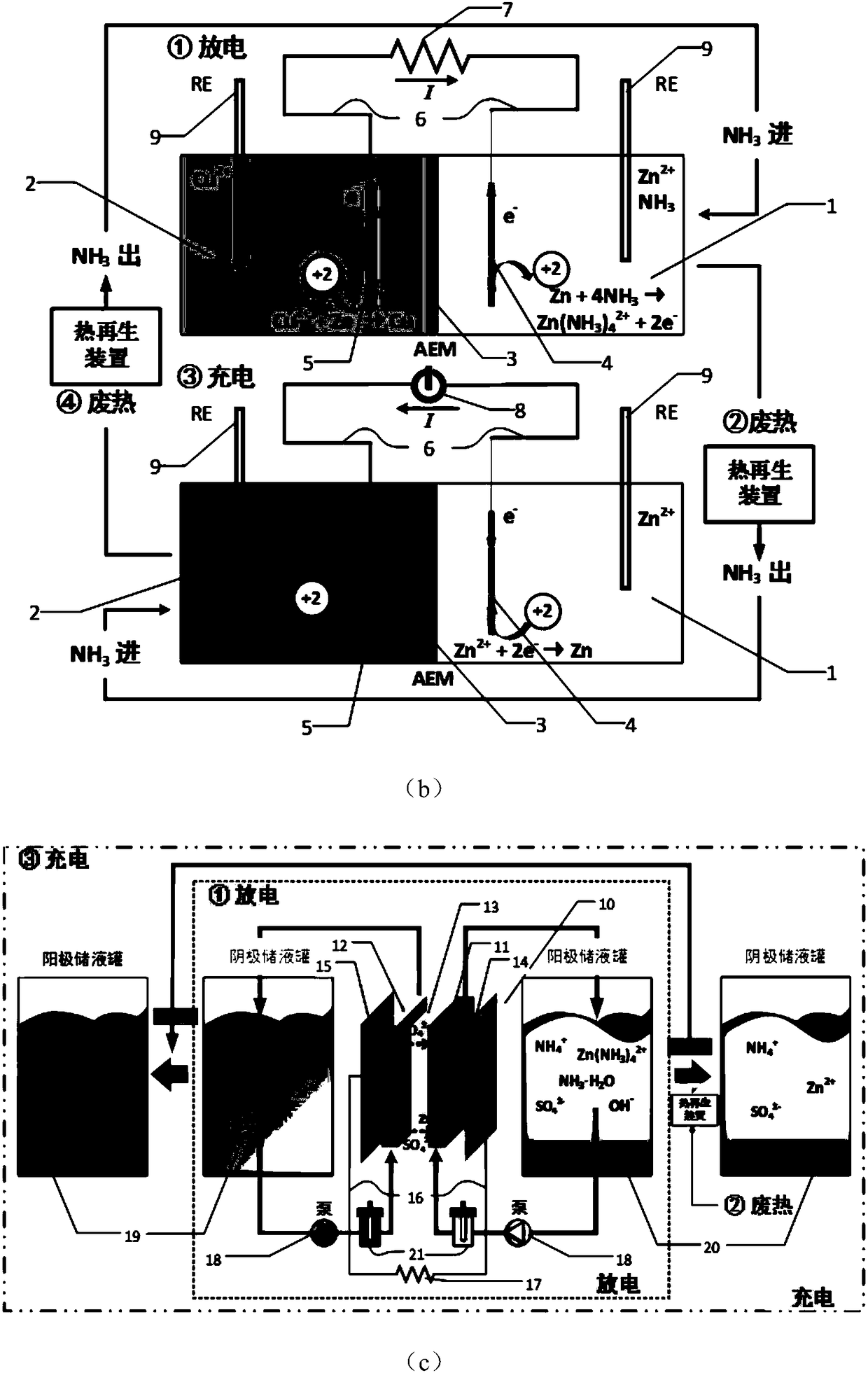

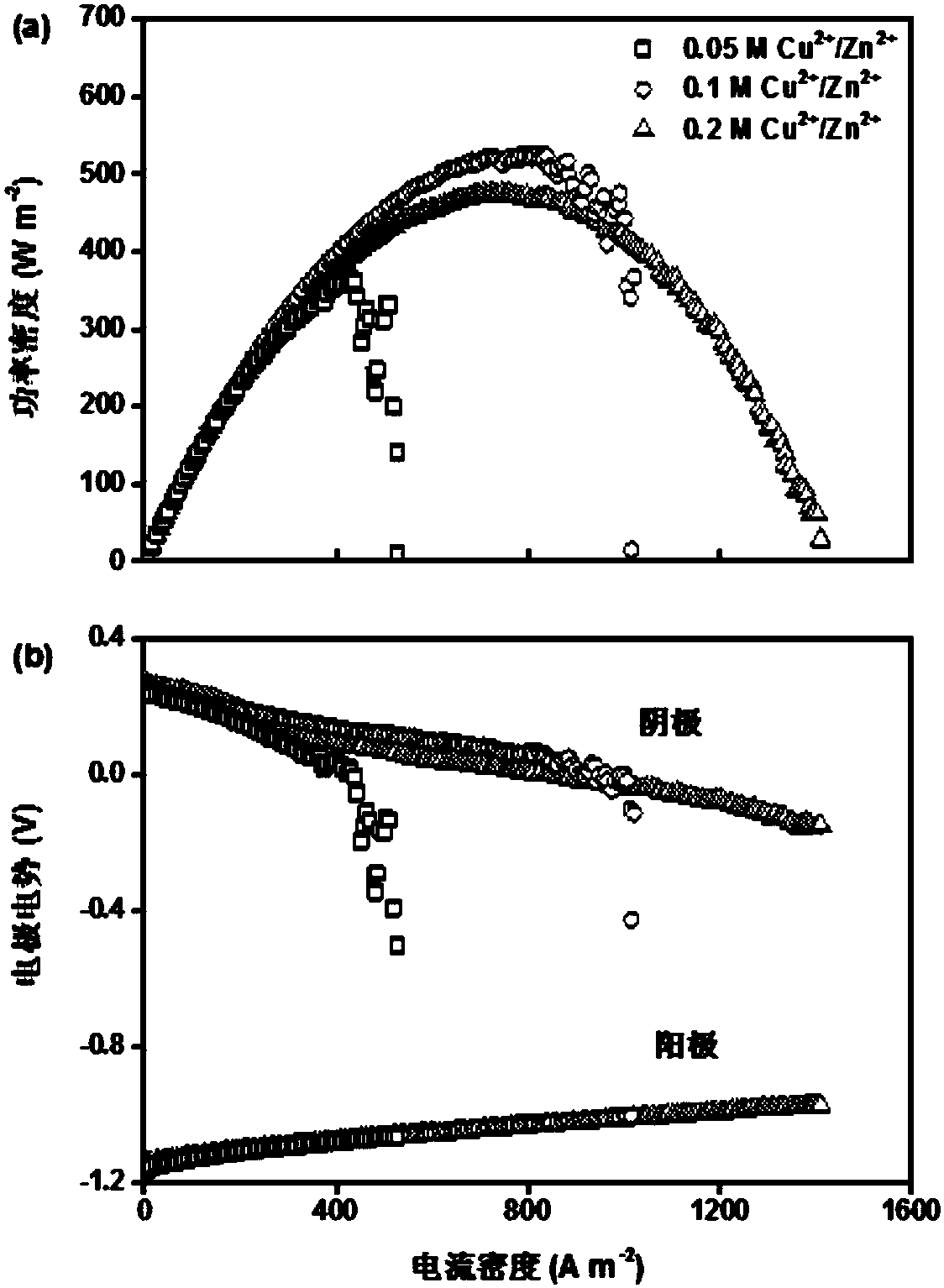

Bimetallic hot regeneration amino battery system, flow battery system and use method

PendingCN108321399AEfficient use ofIncrease discharge voltageCell electrodesRegenerative fuel cellsElectrode potentialCorrosion reaction

The invention discloses a high-voltage discharging and low-voltage charging bimetallic hot regeneration amino battery system for low grade waste heat utilization and a use method. Two different metalscapable of forming an ammonia complex are adopted as electrodes, a metal M1 with negative electrode potential is used as the negative electrode, and a metal M2 with positive electrode potential is used as the positive electrode. One closed cycle consists of a discharging process, a charging process and two hot regeneration processes. Deposition / corrosion reaction cyclically occurs to the electrode M1 / M2 during charging / discharging, the separation of NH3 can convert waste heat energy into chemical energy, and then the chemical energy can be converted into electric energy. The discharging voltage is greatly enhanced, and then the power density and energy density of a heat regenerated battery. The discharging voltage is greater than the charging voltage, so that the heat regenerated batterycan have high coulomb efficiency, energy efficiency and voltage efficiency. The invention also discloses a bimetallic hot regeneration amino flow battery system that can enable a compact battery structure and continuous charging and discharging and the use method thereof.

Owner:TIANJIN UNIV

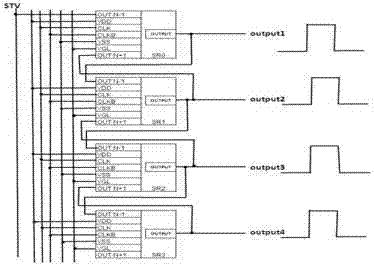

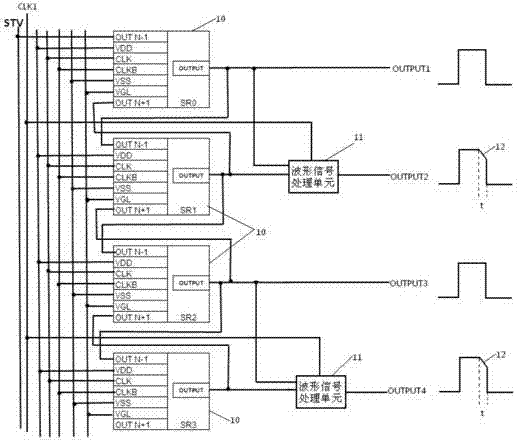

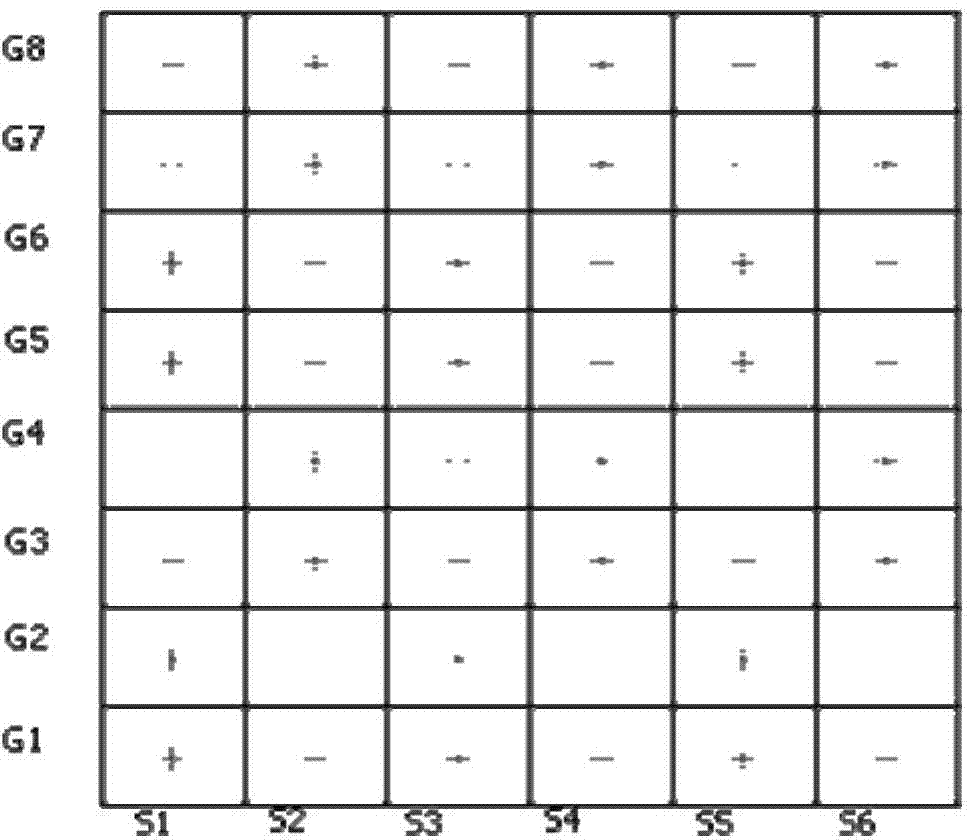

Grid driving circuit, array substrate and display device

ActiveCN104778937AImprove qualitySolve the problem of horizontal stripesStatic indicating devicesDisplay deviceVIT signals

The invention provides a grid driving circuit, an array substrate and a display device. The grid driving circuit is used for sequentially inputting scanning signals to a plurality of grid lines line-by-line, the grid driving circuit comprises a plurality of driving units and waveform processing units which are arranged in a cascade connection mode and in one-to-one correspondence with the grid lines, the waveform processing units are arranged between the output ends of the driving units corresponding to the grid lines arranged on the even number lines and the grid lines, the waveform processing units are used for processing the waveforms of the output signals of the driving units corresponding to the grid lines into angle cutting weaves and take signals with the waveforms being angle cutting weaves as scanning signals to input the signals into the grid lines. The grid driving circuit can achieve equal charging voltages of sub-pixels of the even number lines and the sub-pixels of the odd number lines, and therefore the problem that cross stripes occur due to the fact that the grid driving circuit is driven by a two-point mode is solved, and therefore the quality of the array substrate and the display device is improved.

Owner:BOE TECH GRP CO LTD +1

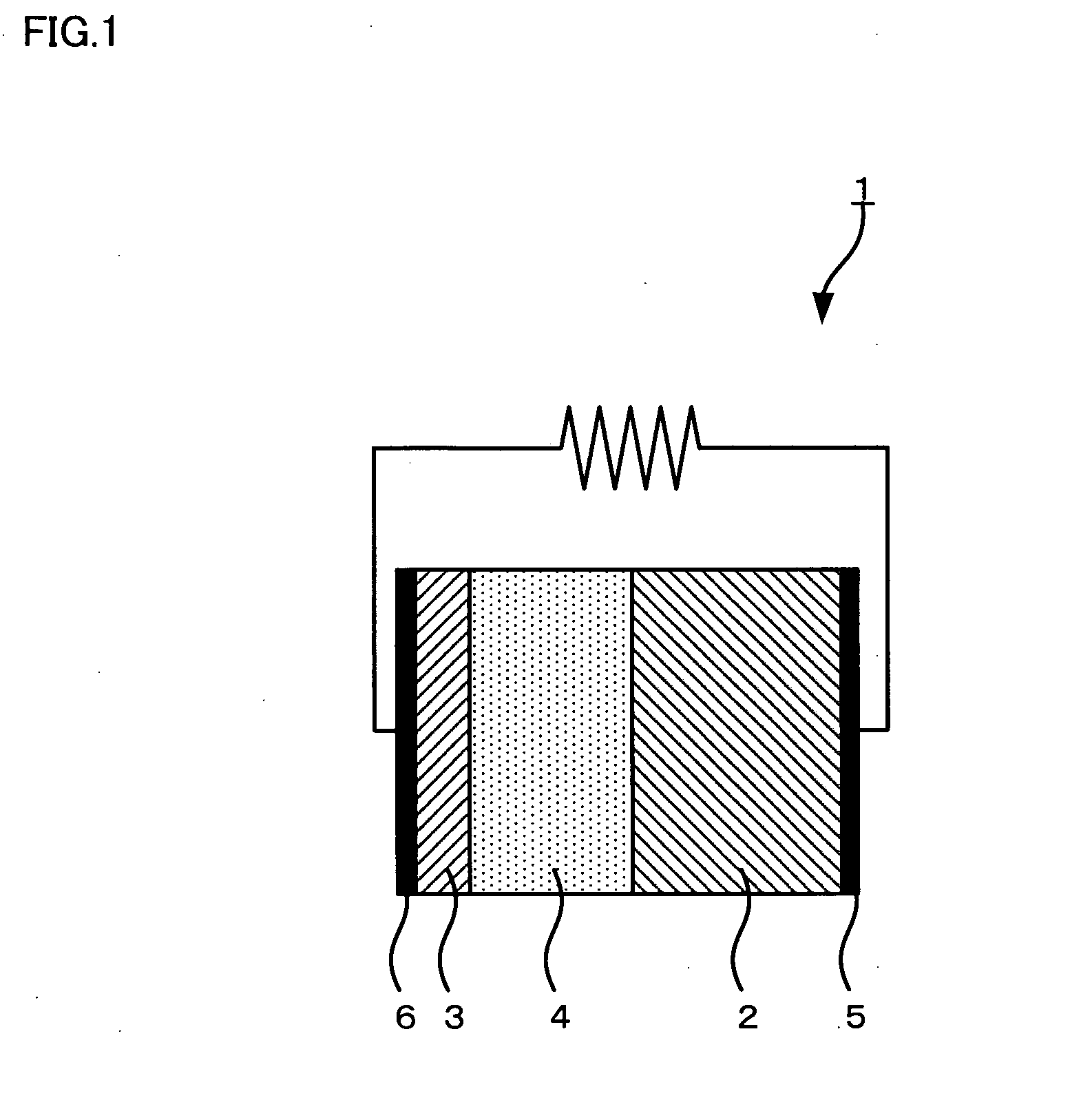

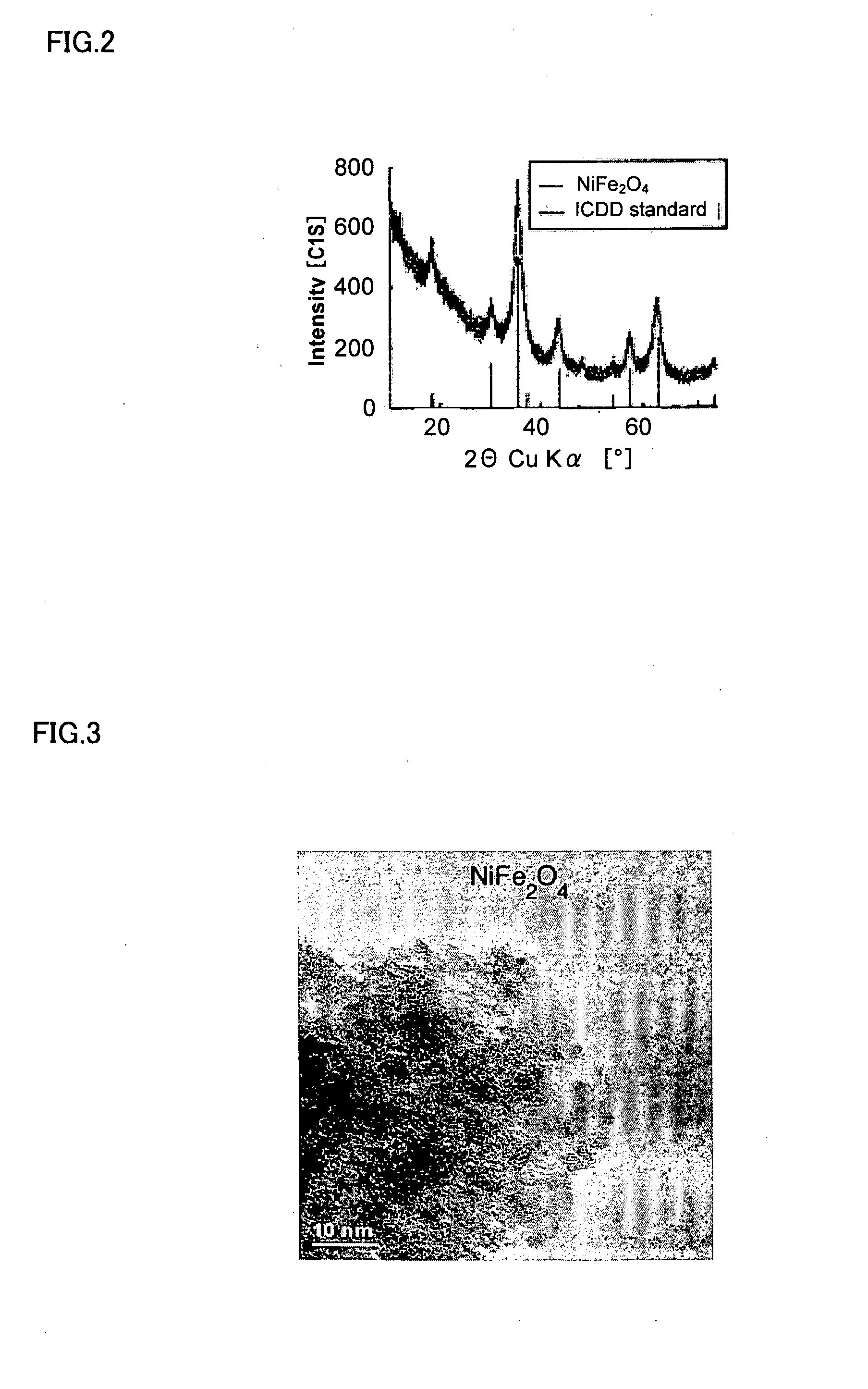

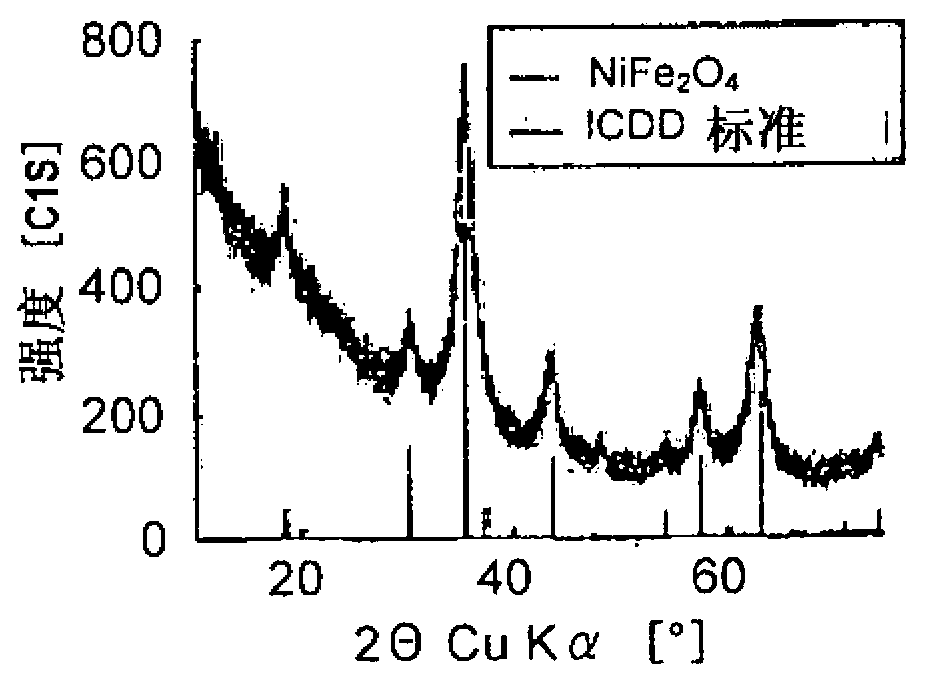

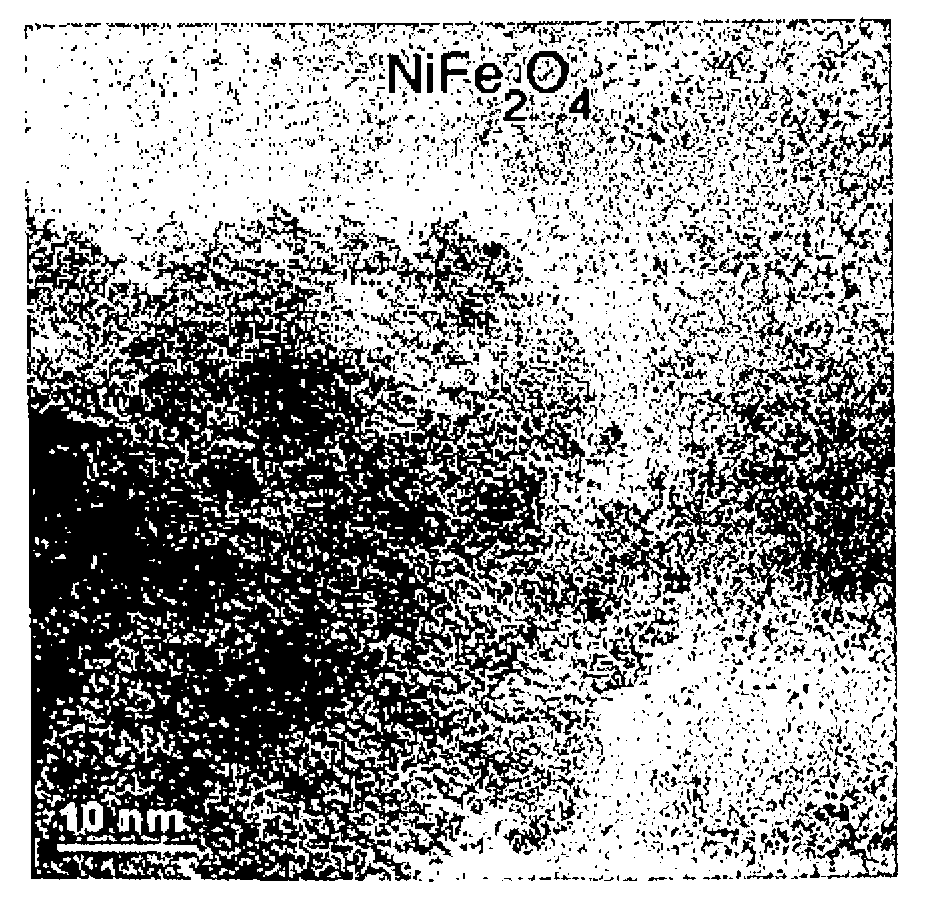

Cathode catalyst for rechargeable metal-air battery and rechargeable metal-air battery

InactiveUS20130143133A1Increase capacityReduce charging voltageFuel and primary cellsFuel and secondary cellsCharge dischargeEngineering

The present invention is to provide a cathode catalyst capable of increasing the initial capacity, decreasing the charging voltage and improving the capacity retention of a rechargeable metal-air battery, and a rechargeable metal-air battery having high initial capacity, excellent charge-discharge efficiency, and excellent capacity retention. A cathode catalyst for a rechargeable metal-air battery comprising NiFe2O4, and a rechargeable metal-air battery comprising an air cathode containing at least NiFe2O4, an anode containing at least a negative-electrode active material and an electrolyte interposed between the air cathode and the anode.

Owner:TOYOTA JIDOSHA KK +1

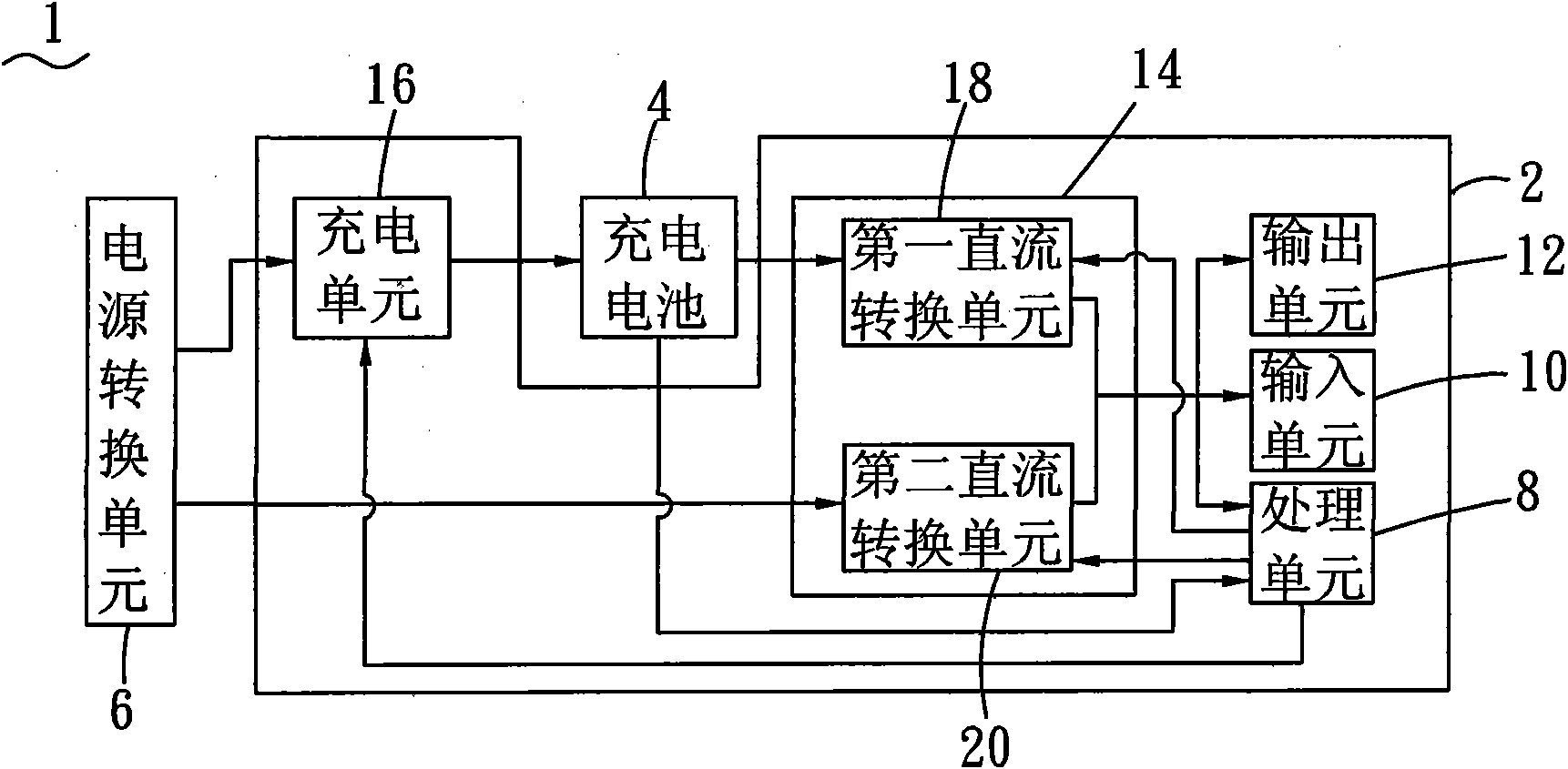

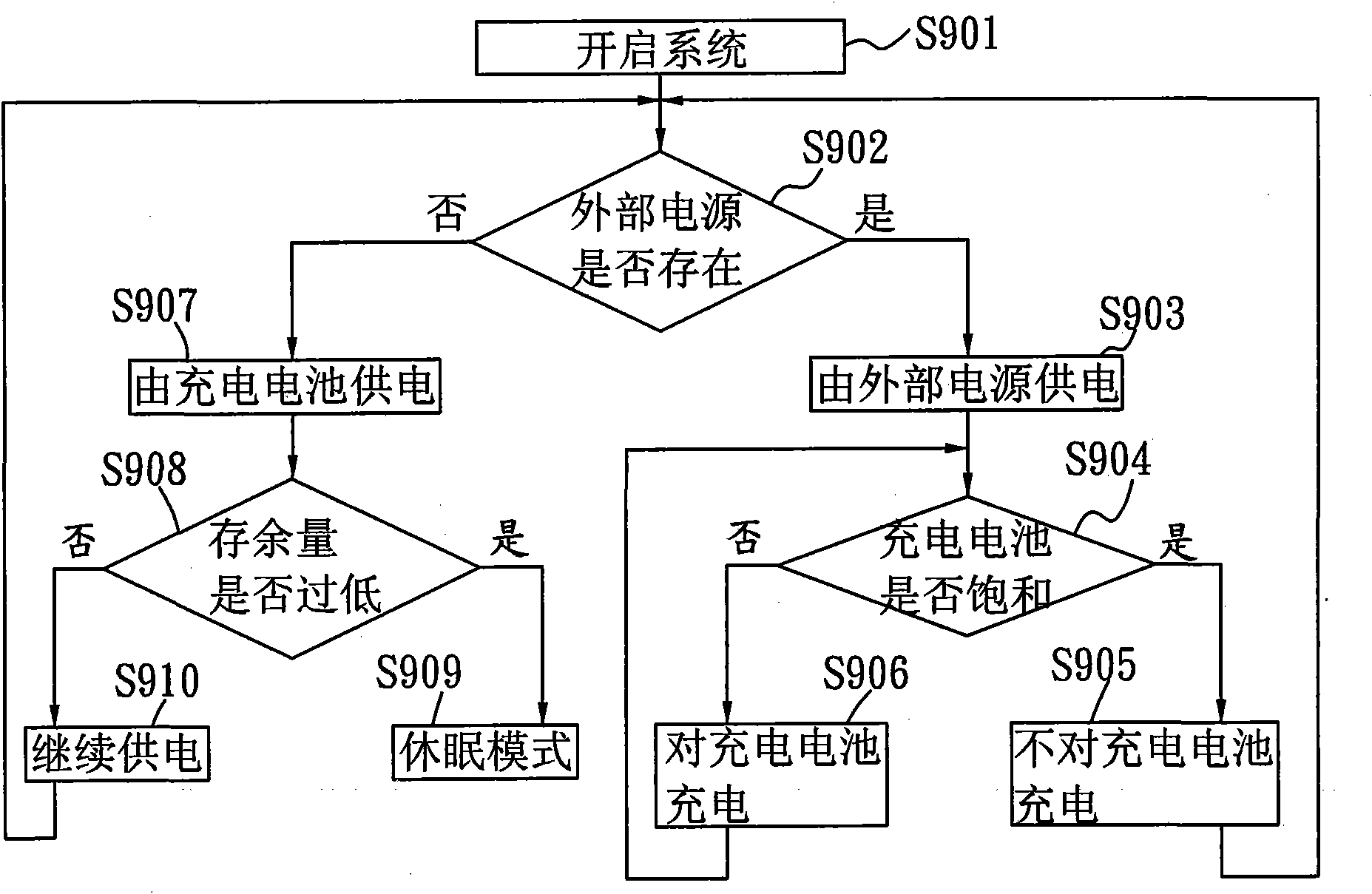

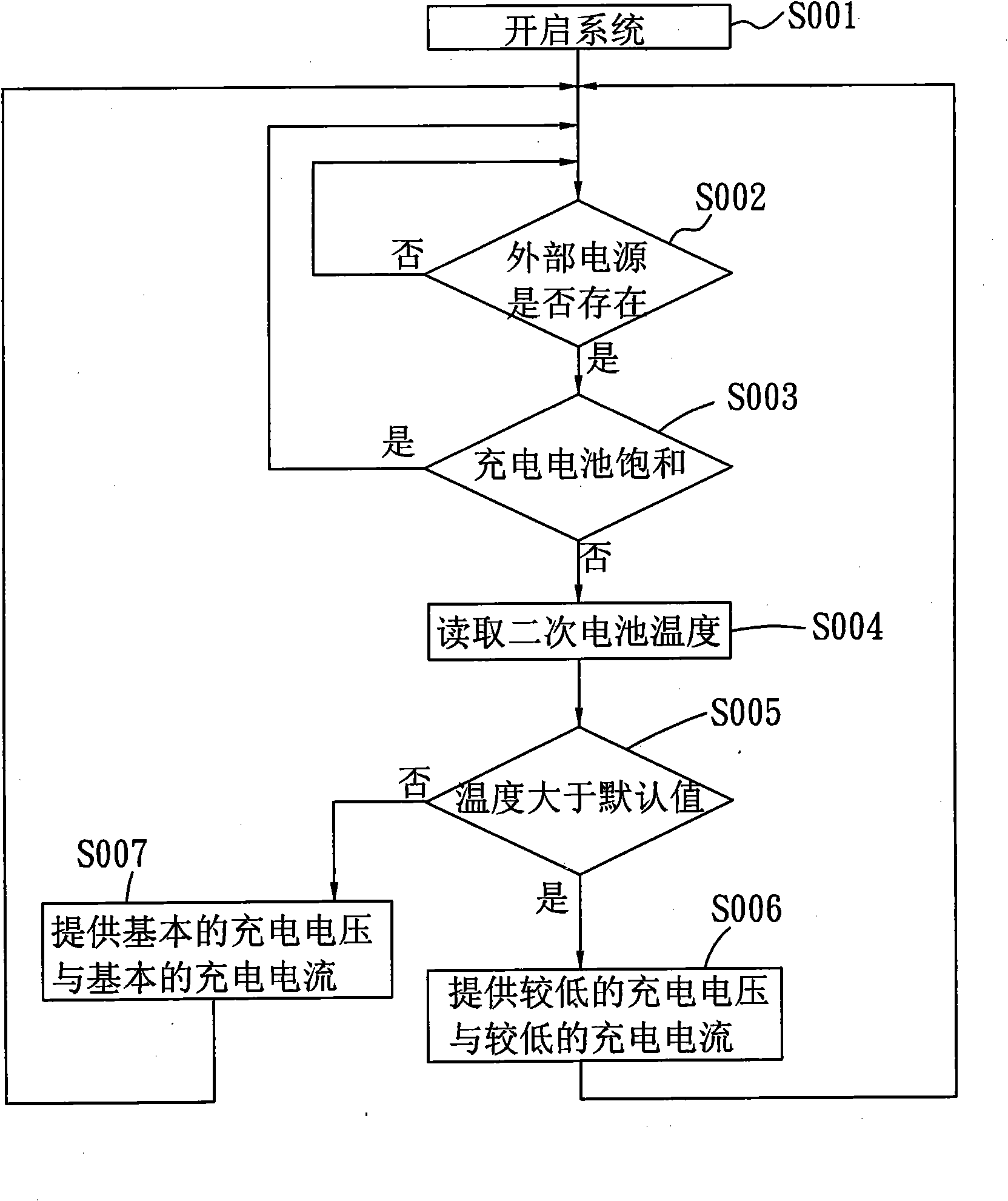

Management method of rechargeable battery of electronic device

InactiveCN102044716APrevent agingExtend your lifeSecondary cells charging/dischargingPower flowCharge current

The invention provides a management method of a rechargeable battery of an electronic device, which is used for detecting and controlling the rechargeable battery on the electronic device. The management method comprises the following steps of: firstly, obtaining the temperature of the rechargeable battery by a processing unit arranged in the electronic device; secondly, judging whether the temperature is greater than a temperature default by the processing unit; finally, when the temperature of the rechargeable battery is greater than the temperature default, transmitting a first signal by the processing unit to reduce the charging voltage or the charging current of the rechargeable battery; and therefore, if the temperature of the rechargeable battery rises, a charging unit can be controlled to reduce the charging voltage and the charging current in order to avoid the accelerated aging of the rechargeable battery and prolong the service life of the rechargeable battery.

Owner:FUGANG ELECTRONICS KUNSHAN +1

A kind of preparation method of aluminum oxide composite nickel cobalt lithium manganese oxide ternary material

ActiveCN103618064BImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseManganese

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

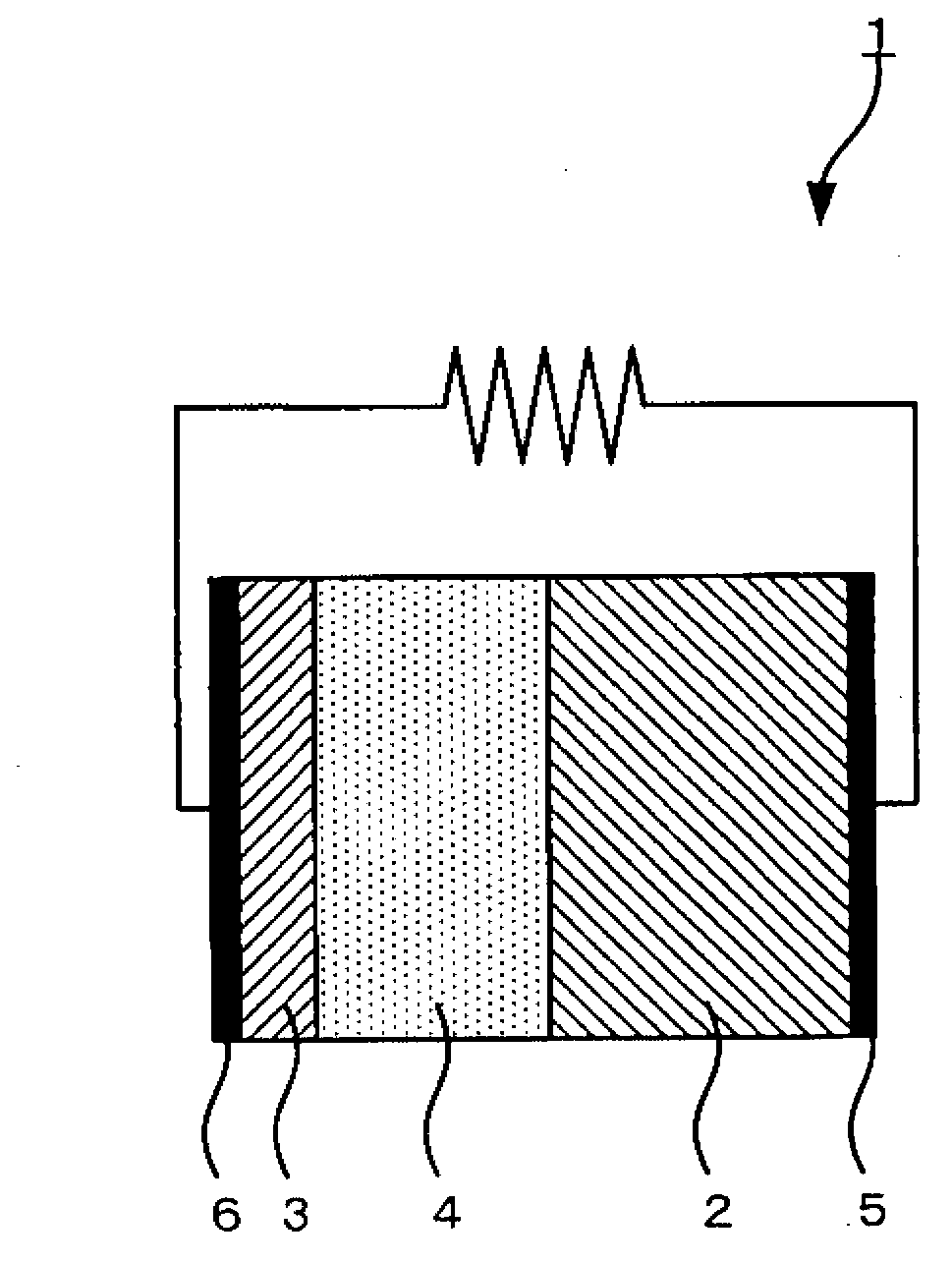

Quick low-voltage rechargeable battery

InactiveUS20160036251A1Short timeLower impedanceParallel/serial switchingSecondary cells charging/dischargingLow voltageElectrical battery

A quick low-voltage rechargeable battery is switched between a charging mode and a discharging mode. The battery includes plural battery cells and a power management circuit. Each battery cell includes a battery positive terminal and a battery negative terminal. The battery positive terminal of each battery cell corresponds to the battery negative terminal of another battery cell sequentially, so as to constitute a battery cell sequence. Respectively, the battery cells connect the power management circuit. The power management circuit includes a loading positive terminal and a loading negative terminal used to connect to a load. In the discharging mode, the power management circuit switches the battery cells to a series connection state; in the charging mode, the power management circuit switches the battery cells to respectively connect to a charging source and to be charged, and the battery cells are not connected in series.

Owner:GIGA BYTE TECH CO LTD

Cathode catalyst for rechargeable metal-air battery and rechargeable metal-air battery

InactiveCN103026545AHigh initial capacityReduce charging voltageFuel and primary cellsFuel and secondary cellsCharge dischargeEngineering

The present invention is to provide a cathode catalyst capable of increasing the initial capacity, decreasing the charging voltage and improving the capacity retention of a rechargeable metal-air battery, and a rechargeable metal-air battery having high initial capacity, excellent charge-discharge efficiency, and excellent capacity retention. A cathode catalyst for a rechargeable metal-air battery comprising NiFe2O4, and a rechargeable metal-air battery comprising an air cathode containing at least NiFe2O4, an anode containing at least a negative-electrode active material and an electrolyte interposed between the air cathode and the anode.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com