Temperature sensitive power converter

a technology of power converters and temperature sensors, applied in the direction of electric power, electric vehicles, transportation and packaging, etc., can solve the problem of limited output voltage, achieve the effect of reducing charging voltage, avoiding damage to appliances, and prolonging the life of tungsten lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

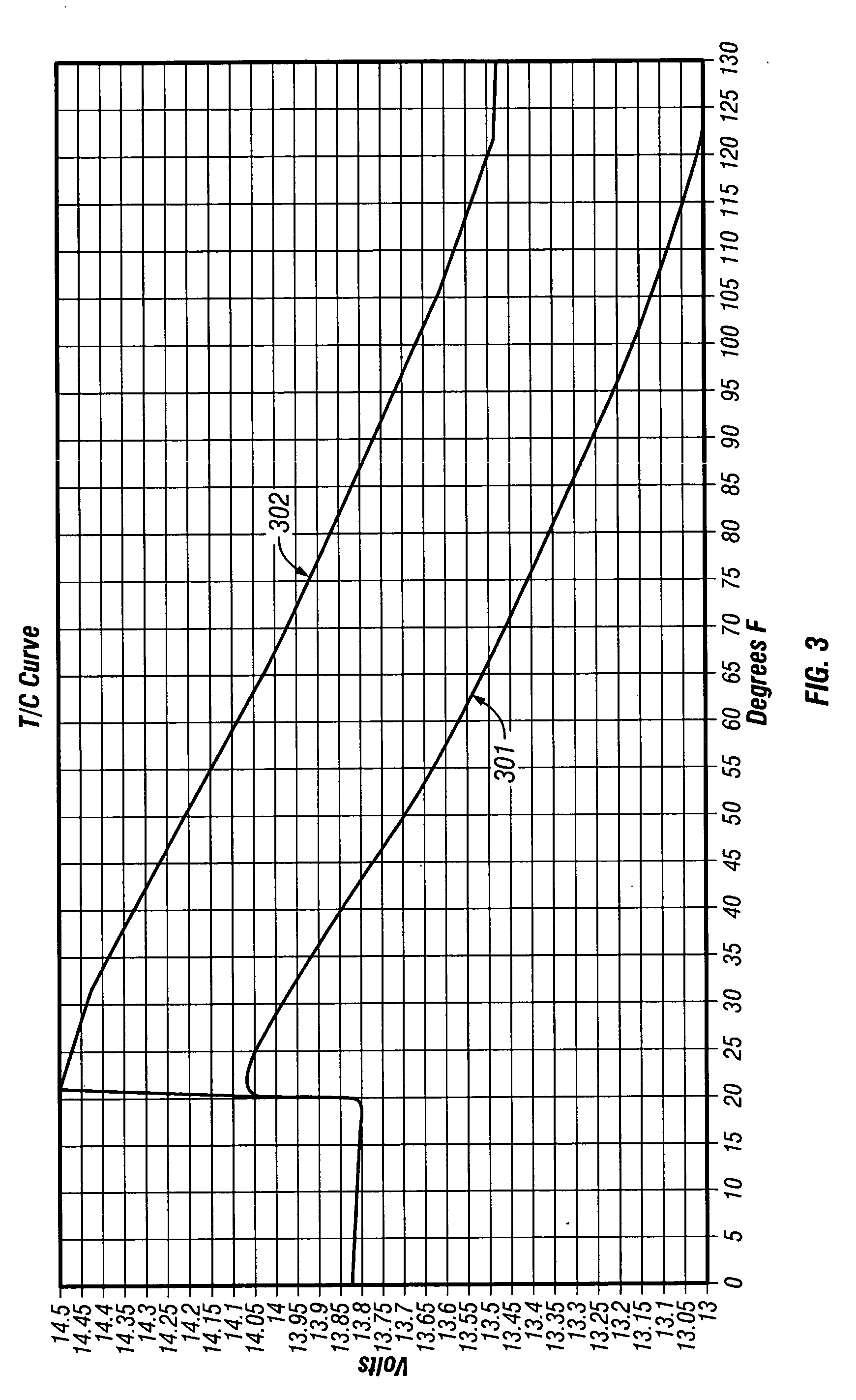

[0016] The present invention controls the output voltage of a converter / charger in a recreational vehicle for optimum battery charging and maintenance in relation to battery temperature.

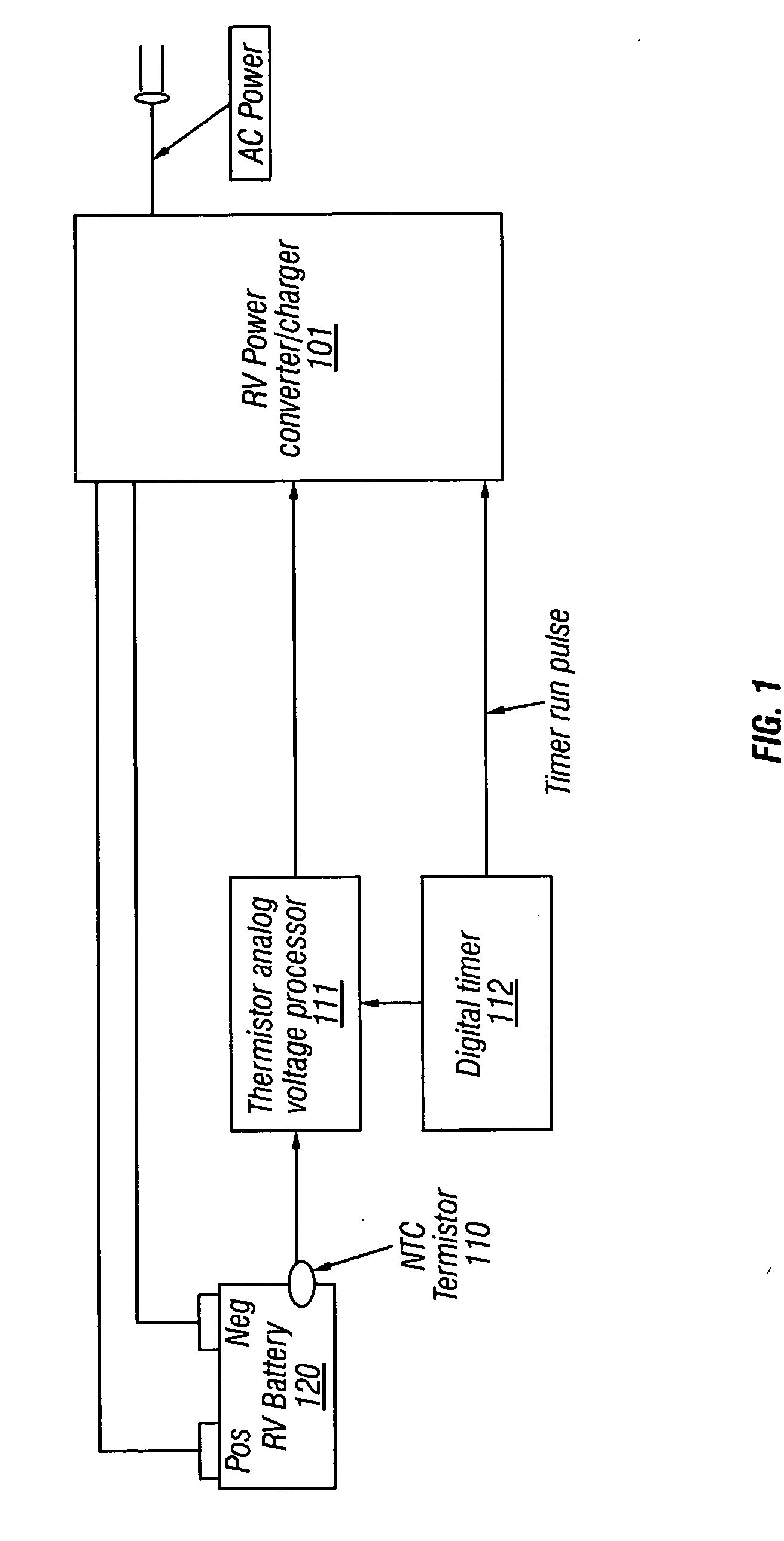

[0017]FIG. 1 is a block diagram of a power converter / charger system in accordance with an embodiment of the present invention. In this embodiment, the power converter / charger operates in two modes: a rapid charge mode and a float voltage (or setback) mode. The present invention solves the over / under charging problems of the prior art by controlling the charging voltage of these two modes as a function of temperature.

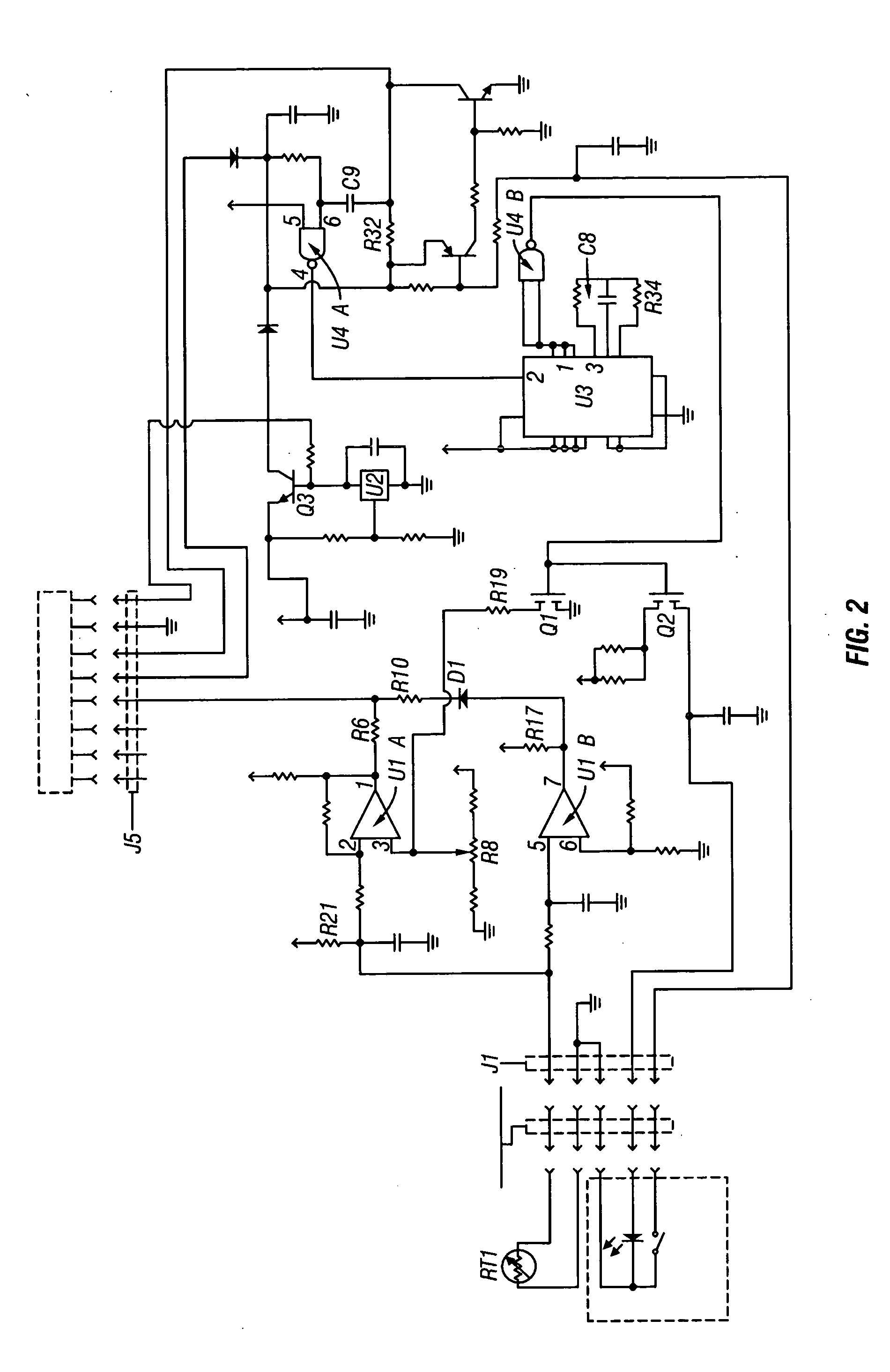

[0018] Power converters / chargers have a set reference voltage against which they compare the output voltage of the battery. The charger immediately compensates for any deviation from this reference voltage. The present invention adds a temperature compensation circuit to a standard power converter / charger that alters the voltage that the charger sees coming from the battery. In this man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com