Preparation method of sodium ion battery based on graphite/prussian blue anode material

A technology of sodium ion battery and Prussian blue, which is applied in the field of preparation of sodium ion battery, can solve the problems such as capacity stability to be improved, and achieve the effects of improving electrochemical performance, increasing discharge voltage and reducing charging voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

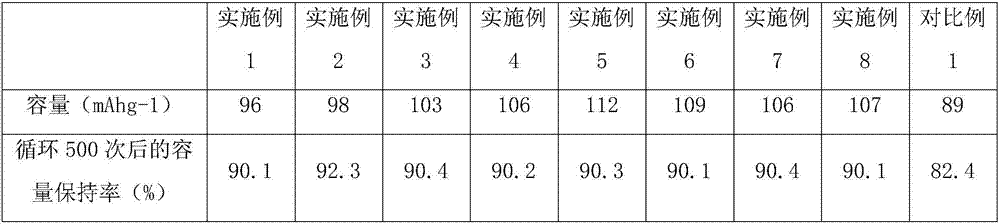

Examples

Embodiment 1

[0027] (1) Dissolve 4mmol of ferrous chloride in 100ml of deionized water, add 50mg of surfactant F127, and ultrasonically stir until clear liquid is recorded as solution A, dissolve 2mmol of sodium ferrocyanide in 100ml of deionized water , ultrasonically stirred to a clear solution, which was recorded as solution B.

[0028] (2) Transfer solution A and solution B to the reaction kettle, tighten the lid of the kettle and transfer to the oven, first program the temperature to 70°C, the heating rate is 1°C / min, react for 10h, and then lower the temperature at 0.1°C / min Cool down to room temperature with a rate program, first use deionized water to wash twice at a rate of 5000rpm, and then use methanol to wash once at a rate of 5000rpm, and vacuum-dry at 110°C for 5h to obtain Prussian blue nanospheres with a particle size of 400nm. .

[0029] (3) Add 200mg of Prussian blue nanospheres to 150ml of 10% graphite oxide solution, stir at room temperature for 4 hours to obtain graph...

Embodiment 2

[0033] (1) Dissolve 5mmol of ferrous chloride in 100ml of deionized water, add 50mg of surfactant F127, and ultrasonically stir until the clear liquid is recorded as solution A, dissolve 2.5mmol of sodium ferrocyanide in 100ml of deionized water In water, ultrasonically stirred to a clear liquid, which was recorded as solution B.

[0034](2) Transfer solution A and solution B to the reaction kettle, tighten the lid of the kettle and transfer to the oven, first program the temperature to 84°C, the heating rate is 1.3°C / min, react for 12.6h, and then 0.4°C / min The cooling rate program lowered the temperature to room temperature, first centrifuged washing with deionized water at a rate of 5000rpm for three times, and then with methanol for one time at a rate of 5000rpm, and vacuum dried at 113.4°C for 12h to obtain Prussian blue nanoparticles with a particle size of 320nm. ball.

[0035] (3) Add 200 mg of Prussian blue nanospheres to 150 ml of a 40% graphite oxide solution, stir...

Embodiment 3

[0039] (1) Dissolve 6mmol of ferrous chloride in 100ml of deionized water, add 50mg of surfactant F127, and ultrasonically stir until clear liquid is recorded as solution A, dissolve 3mmol of sodium ferrocyanide in 100ml of deionized water , ultrasonically stirred to a clear solution, which was recorded as solution B.

[0040] (2) Transfer solution A and solution B to the reaction kettle, tighten the lid of the kettle and transfer to the oven, first program the temperature to 84.6°C, the heating rate is 1.6°C / min, react for 15.1h, and then 0.7°C / min The temperature was lowered to room temperature with a program of cooling rate, and the deionized water was used to wash twice at a rate of 5000rpm, and then washed once with methanol at a rate of 5000rpm, and then vacuum-dried at 115.7°C for 10h to obtain Prussian blue nanoparticles with a particle size of 200nm. ball.

[0041] (3) Add 200 mg of Prussian blue nanospheres to 150 ml of a 20% graphite oxide solution, stir at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com