Bimetallic hot regeneration amino battery system, flow battery system and use method

A technology of amino batteries and liquid flow batteries, which is applied in the direction of regenerative fuel cells, battery electrodes, fuel cells, etc., and can solve problems such as limiting power density and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

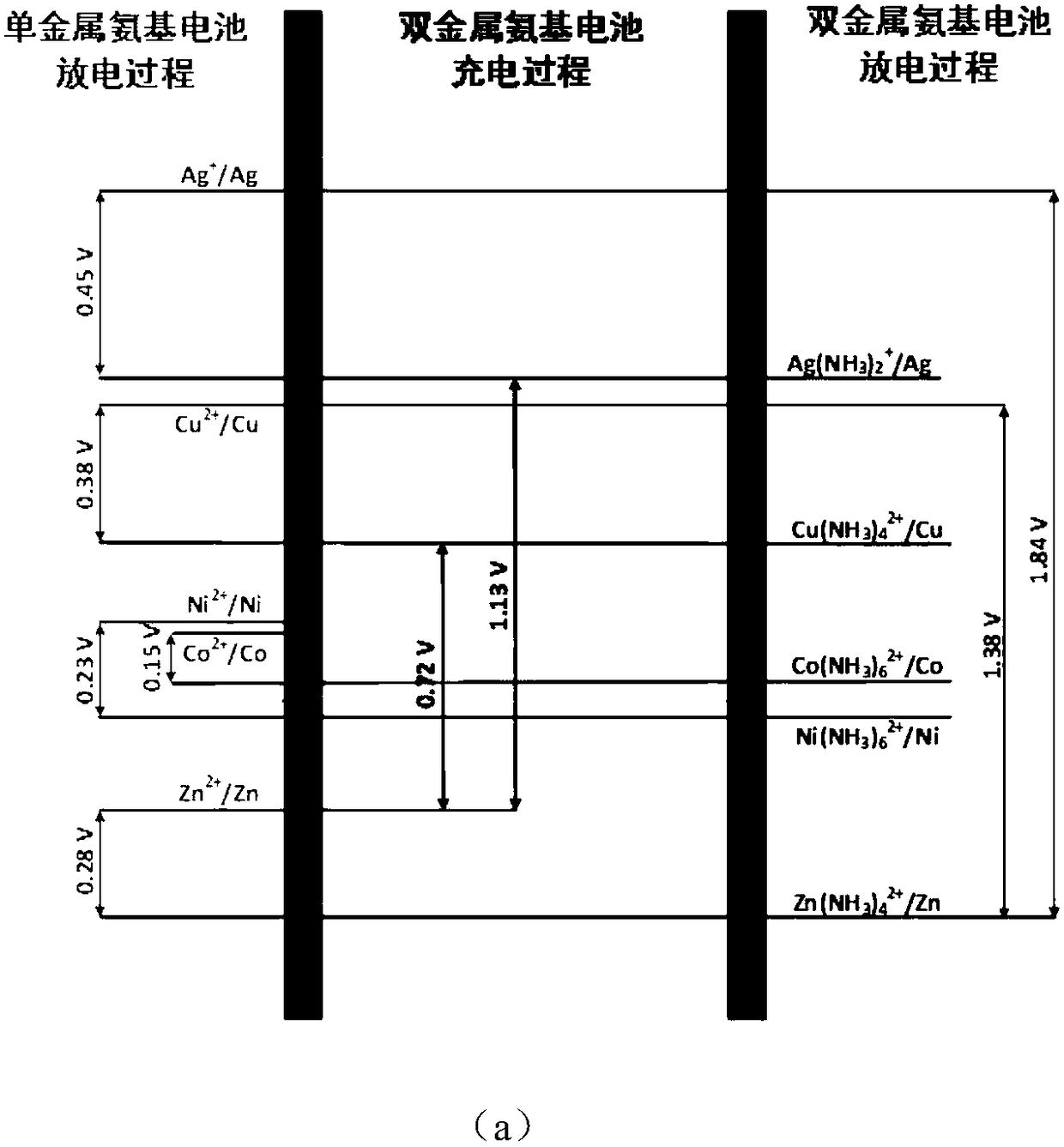

[0096] like figure 1As shown in (a), the monometallic thermally regenerative amino battery (TRAB) only includes the discharge process and thermal regeneration process, but the discharge voltage is very low. When the metal silver Ag is used as the electrode, the highest voltage is only 0.45V; the bimetallic thermal regeneration Although the amino battery (B-TRAB) needs to be charged, it has two thermal regeneration processes, which can recover more waste heat energy; and the charging voltage is much lower than the discharging voltage. The discharge voltage of Ag / Zn-TRAB can reach 1.84V, while the charge voltage is only 1.13V; the discharge voltage of Cu / Zn-TRAB can reach 1.38V, while the charge voltage is only 0.72V. Similarly, Ag / Ni-TRAB, Ag / Co-TRAB, Ag / Cu-TRAB, Cu / Ni-TRAB, Cu / Co-TRAB, etc. also belong to the category of bimetallic thermally regenerative amino batteries (B-TRAB).

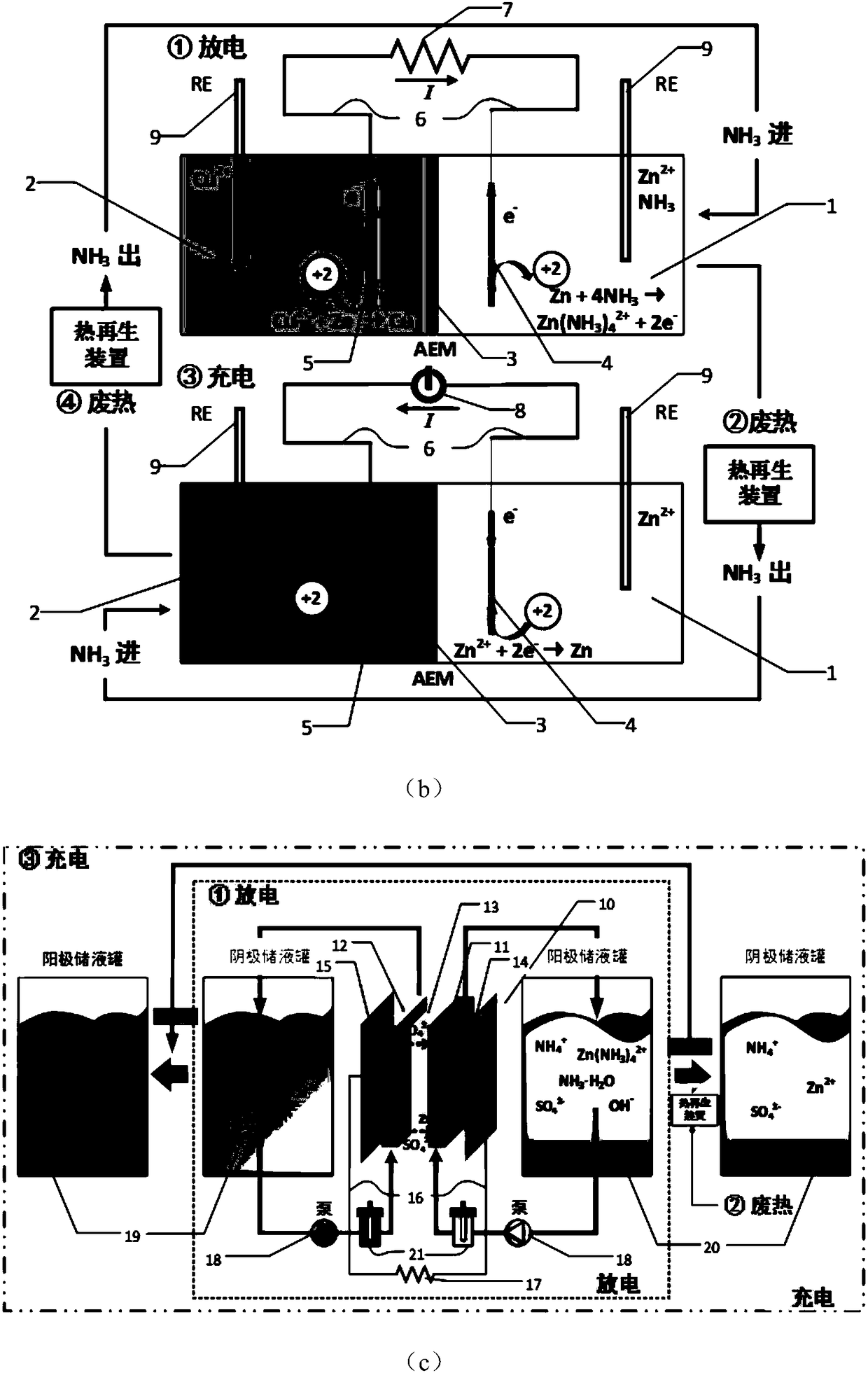

[0097] Battery device: such as figure 1 As shown in (b), a single Cu-Zn thermally regenerative...

Embodiment 2

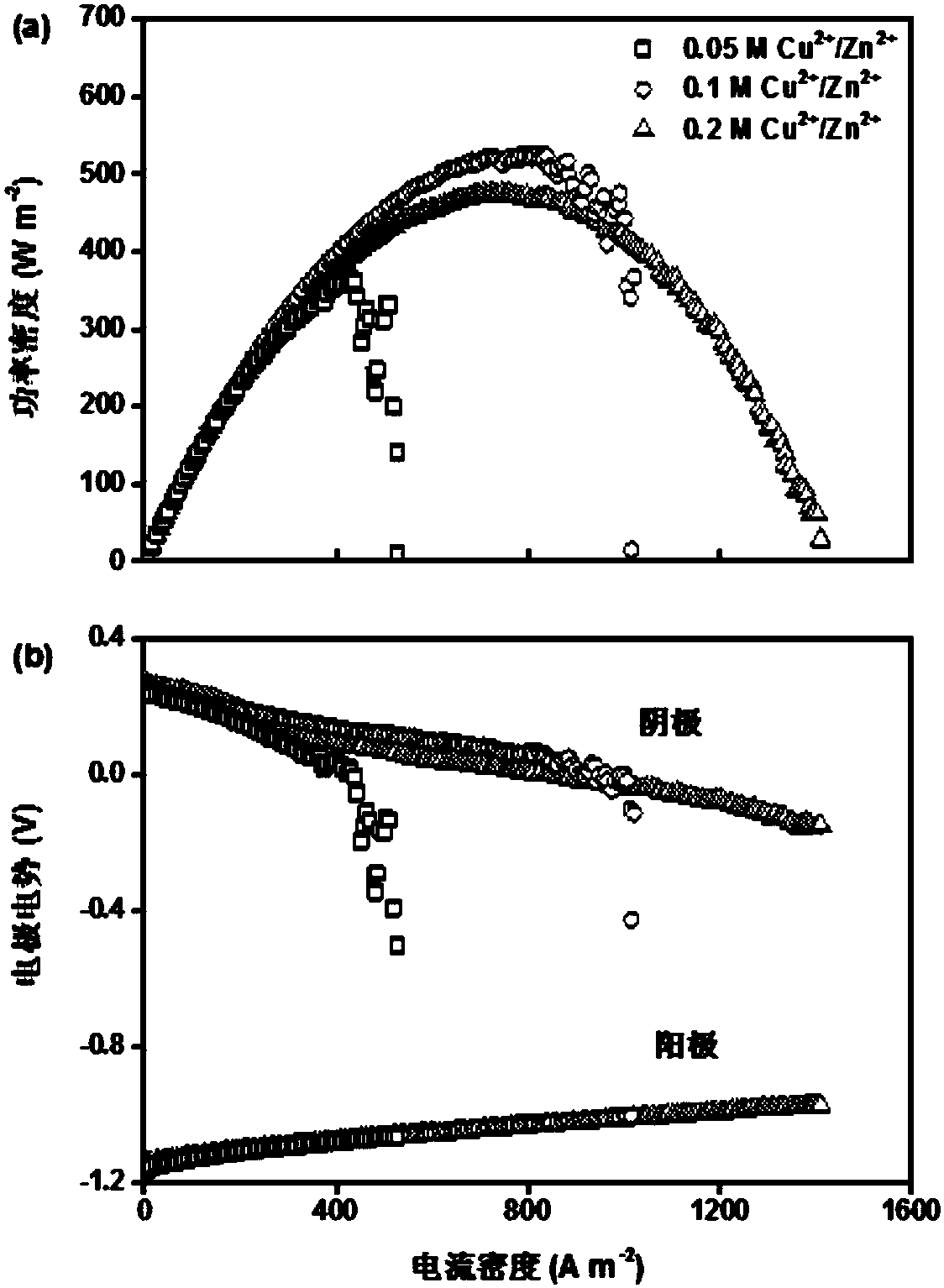

[0118] The theoretical discharge voltage of Ag / Zn-TRAB can reach 1.84V, while the charging voltage is only 1.13V. Replace copper grid electrodes with silver electrodes (thickness 0.2mm, 0.8cm×2cm), 0.1M Ag + / Zn 2+ , 3M NH 4 NO 3 , 2M NH 3 As an electrolyte, a discharge polarization test was performed. like Figure 9 As shown in (a), the maximum power density of Ag / Zn-TRAB reaches 1175W m -2 , which is more than twice that of Cu / Zn-TRAB under the same concentration conditions, and there is a possibility of further optimization. like Figure 9 As shown in (b), the anode potential of Ag / Zn-TRAB is lower than that of Cu / Zn-TRAB, which may be due to the anion (NO 3 - , SO 4 2- ), Zn will form a passivation film ZnO / Zn(OH) on the surface during the anode process 2 , so that the pH near the electrode surface decreases, thereby reducing the surface NH 3 concentration. Different anions have a decisive influence on the difficulty of breaking the passivation film, SO 4 2...

Embodiment 3

[0120] like Figure 10 As shown in (a) and 10(b), a single Cu-Zn thermally regenerative ammonia flow battery (Cu / Zn-TRAFB) consists of a positive electrode (copper plate, 50×50×0.5 mm, McMaster-Carr), a negative electrode (zinc plate , 50×50×0.5mm, McMaster-Carr), anion membrane (AEM, Selemion AMV, Japan; effective surface area is 8cm 2 ) and positive and negative flow channels (thickness 1.5mm, cross-sectional area 2×4cm, high-purity silica gel, McMaster-Carr), the flow paths of cathode and anode liquid during charging and discharging are as follows: Figure 10 (c) and 10(d). From the outside to the inside, the flow battery module is fixed and sealed by compression of polycarbonate (PC) end plates, polytetrafluoroethylene blocks and single-sided adhesive silicone plates, as well as bolts and nuts.

[0121] The construction of two Cu / Zn-TRAFB in series and in parallel is as follows Figure 11 As shown in (a) and 11(b), the middle Cu and Zn electrodes are separated by insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com