Preparation method of aluminum-ion battery positive electrode material

A technology of aluminum ion battery and positive electrode material, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of aluminum ion battery not being practical, commercial development is not smooth, and rechargeable batteries cannot be used, so as to overcome the edge of graphite. Limited issues, excellent cycle stability, effect of low charge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

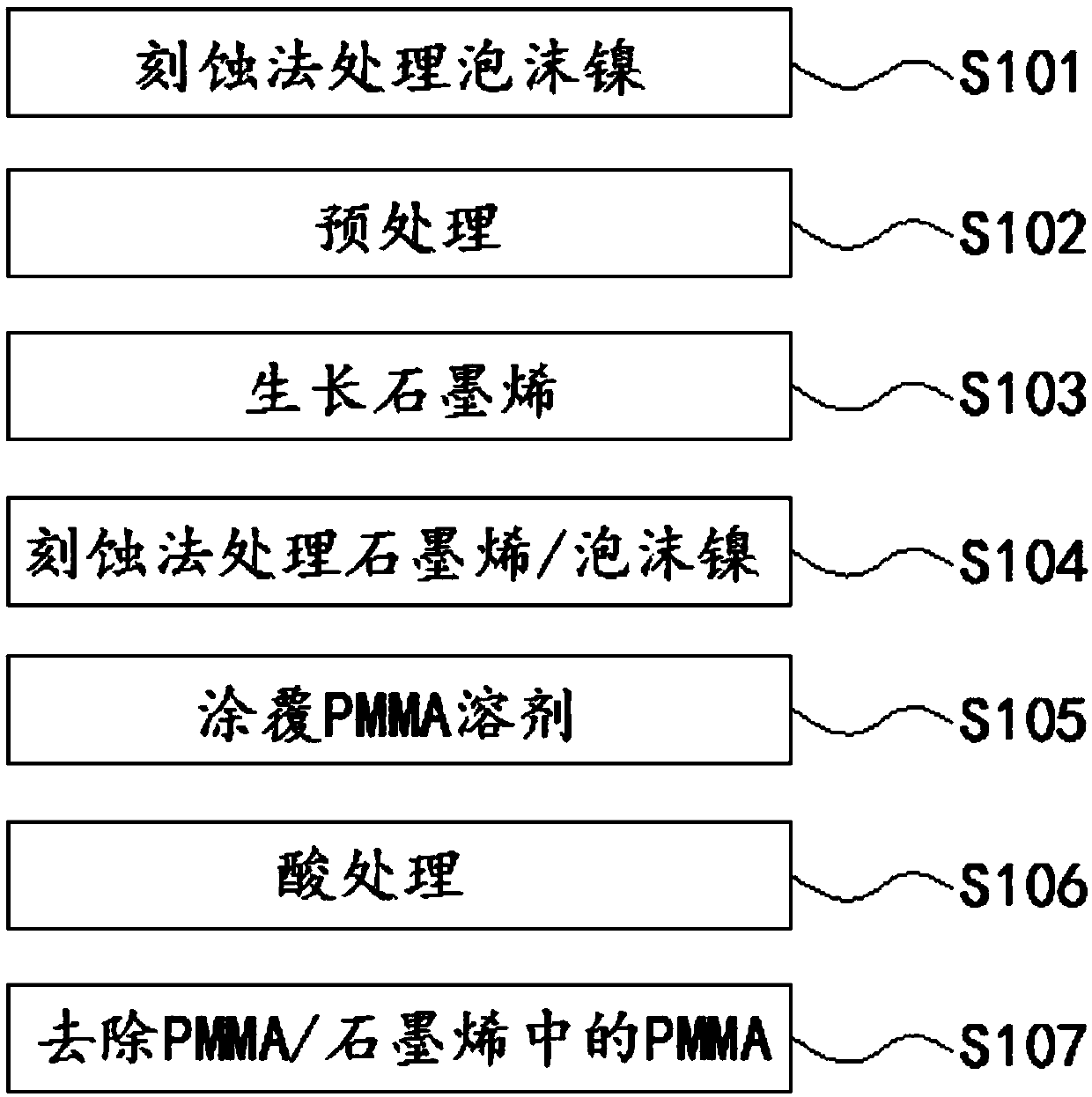

[0034] refer to figure 1 , a kind of preparation method of aluminum ion battery cathode material, described method comprises the following steps:

[0035] S101, use Ar + The plasma etching method is used to process nickel foam, put the foam nickel into the plasma etching reactor, the selected power is 50w, and use Ar + The plasma treatment time is 10min;

[0036] S102, to Ar + The foamed nickel after plasma etching process is carried out surface pretreatment, foamed nickel is put into tube furnace, feeds Ar (flow rate is 500sccm) and H 2 (The flow rate is 200sccm), heated to 1000°C, and annealed for 20 minutes to clean the surface and remove surface oxides;

[0037] S103, grow graphene on the pretreated nickel foam surface by CVD, feed 10sccm flow methane into the tube furnace for reaction, the corresponding total gas flow volume fraction is 1.4%, and the reaction time is 10 minutes, then the sample is cooled rapidly To room temperature, the gas atmosphere is Ar (the flow...

Embodiment 2

[0046] refer to figure 1 , a preparation method of an ultra-stable aluminum ion battery cathode material, the method comprising the following steps:

[0047] S101, use Ar + The plasma etching method is used to process nickel foam, put the foam nickel into the plasma etching reactor, the selected power is 40w, and use Ar + The plasma treatment time is 10min, and nanopore bands are formed on the pore wall of nickel foam; then, the nickel foam is treated by chemical etching to further increase the size of nanopores, which is beneficial to AlCl 4 - Diffusion and penetration of anions in electrode materials.

[0048] S102, carry out surface pretreatment to the foamed nickel after etching process, put foamed nickel into the tube furnace, pass into Ar (flow rate is 400sccm) and H 2 (The flow rate is 200sccm), heated to 1000°C, and annealed for 30 minutes to clean the surface and remove surface oxides.

[0049] S103, grow graphene on the pretreated nickel foam surface by CVD, fee...

Embodiment 3

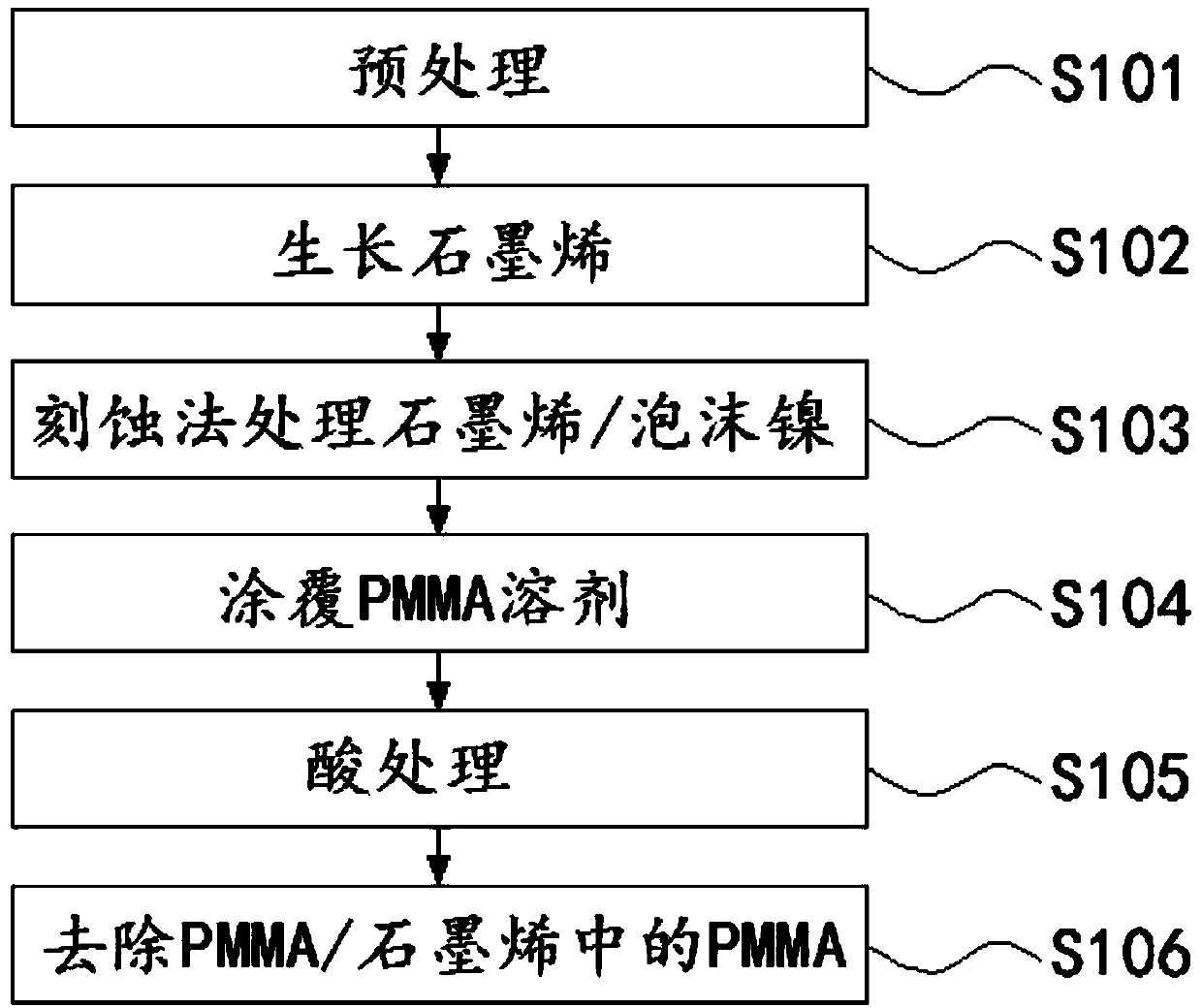

[0055] refer to figure 2 , a kind of preparation method of aluminum ion battery cathode material, described method comprises the following steps:

[0056] S101, surface pretreatment is carried out to nickel foam, nickel foam is put into tube furnace, feeds Ar (flow rate is 500sccm) and H 2 (The flow rate is 200sccm), heated to 1000°C, and annealed for 20 minutes to clean the surface and remove surface oxides;

[0057] S102, grow graphene on the pretreated nickel foam surface by CVD, feed 10sccm flow methane into the tube furnace for reaction, the corresponding total gas flow volume fraction is 1.4%, and the reaction time is 10 minutes, then the sample is cooled rapidly To room temperature, the gas atmosphere is Ar (the flow rate is 500sccm.) and H 2 (The flow rate is 200sccm.), the cooling rate is 300°C / min, forming a graphene / nickel foam structure;

[0058] S103, performing Ar on graphene / nickel foam + Plasma etching process, put graphene / nickel foam into plasma etching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com