Flow battery

An electrochemical and battery technology, applied in electrochemical generators, fuel cells, battery electrodes, etc., can solve problems such as high price, low battery performance, and easy corrosion of conductive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0090] Example 2: Complexed iron / bromine flow battery.

[0091] negative electrode:

[0092] positive electrode:

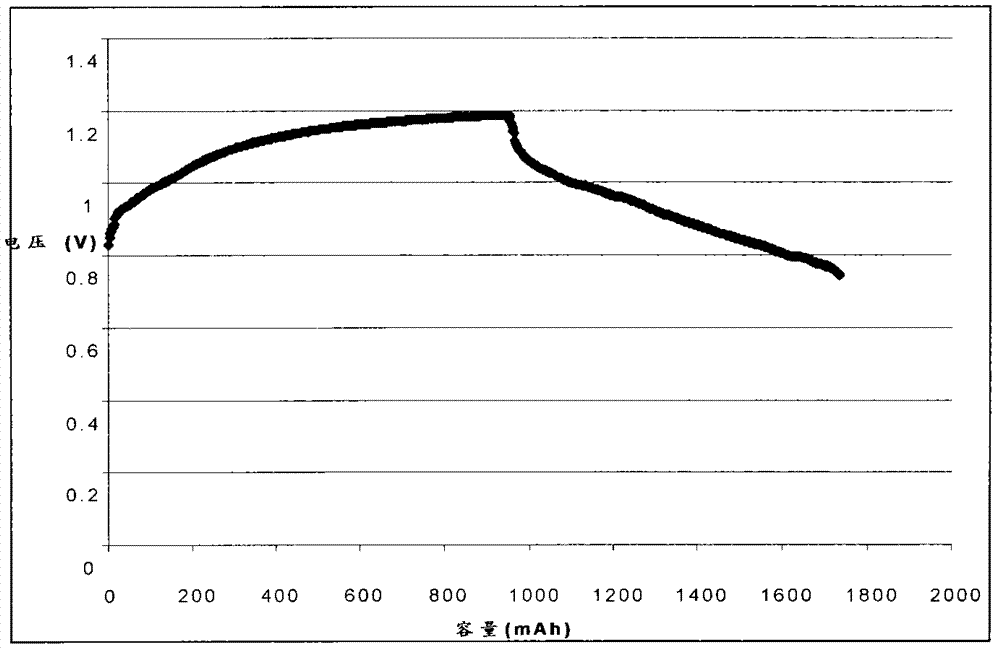

[0093] At the beginning of charging, 50 ml of negative electrolyte (1M K 3 [Fe(CN) 6 ] And 1M NaOH solution) were injected into the negative electrode structure. 50 ml of catholyte solution (1M NaBr and 1M NaOH solution) was injected into the positive electrode structure. Constant current charging 20mA / cm 2 About 1 hour. Figure 4 Given that the battery is at 20mA / cm 2 Charging and discharging curve characteristics. by Figure 4 It can be seen that the charge and discharge voltage of the battery is relatively low, about 0.6 to 0.7V.

example 3

[0094] Example 3: Complexed copper / bromine flow battery.

[0095] negative electrode:

[0096] positive electrode:

[0097] m is usually 4, n is usually 2, water molecules and hydroxide radicals can also participate in coordination. At the beginning of charging, 75 ml of anolyte solution, 1M complex ion [Cu(NH 3 ) 4 (H 2 O)x] 2+ The solution is injected into the negative structure. 75 milliliters of catholyte and 1M NaBr solution are injected into the positive electrode structure. Constant current charging 20mA / cm 2 About an hour. Figure 4 Given that the battery is at 20mA / cm 2 Charging and discharging curve characteristics. by Figure 5 It can be seen that the charge and discharge voltage of the battery is relatively reasonable, which is below the electrolysis voltage of water, but very close. The steps of charge and discharge voltage are relatively gentle, showing good dynamic characteristics.

[0098] The invention provides a flow battery for storing electric energy by elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com