Spreading machine

A squeegee machine and squeegee technology, applied in the field of squeegee, can solve the problems of manual separation difficulty, inability to reuse, low recycling rate, etc., to save squeegee time, improve work efficiency, and high recycling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

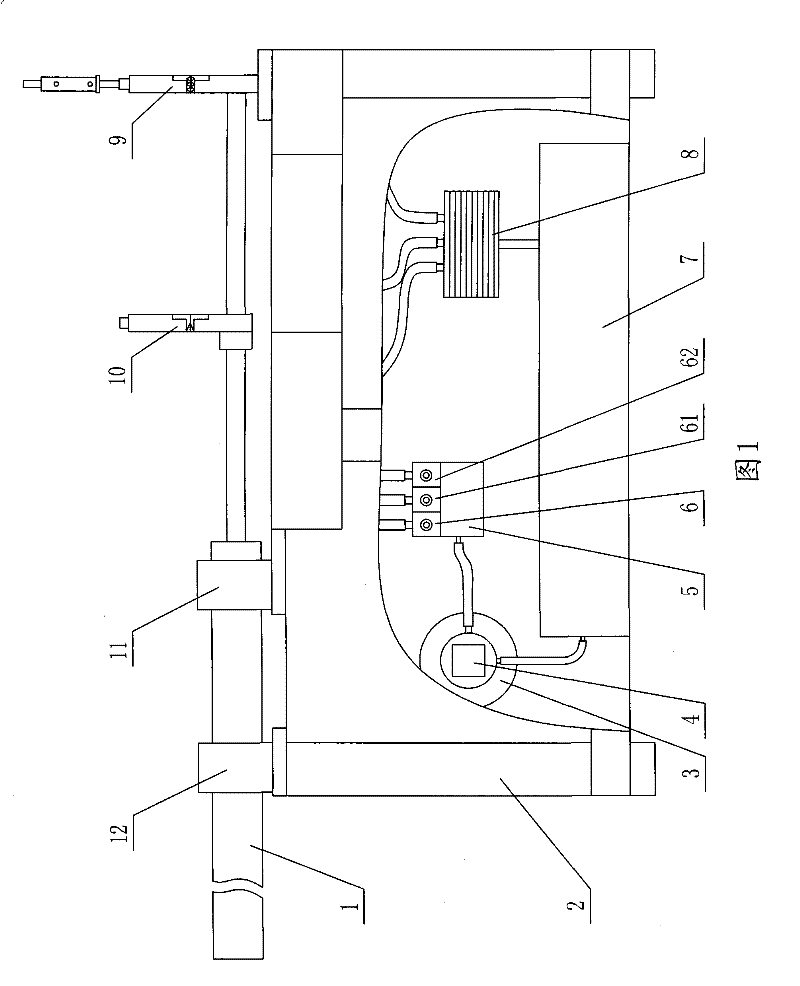

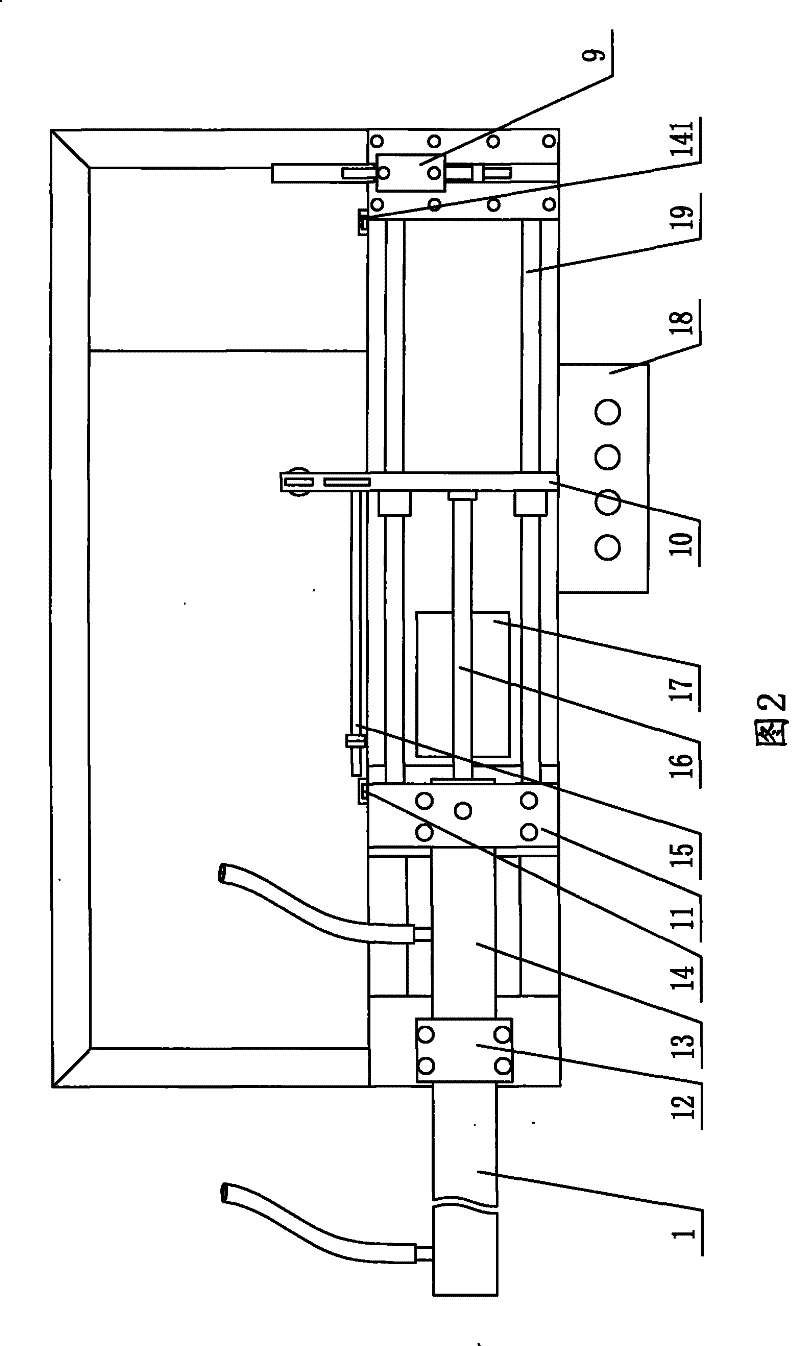

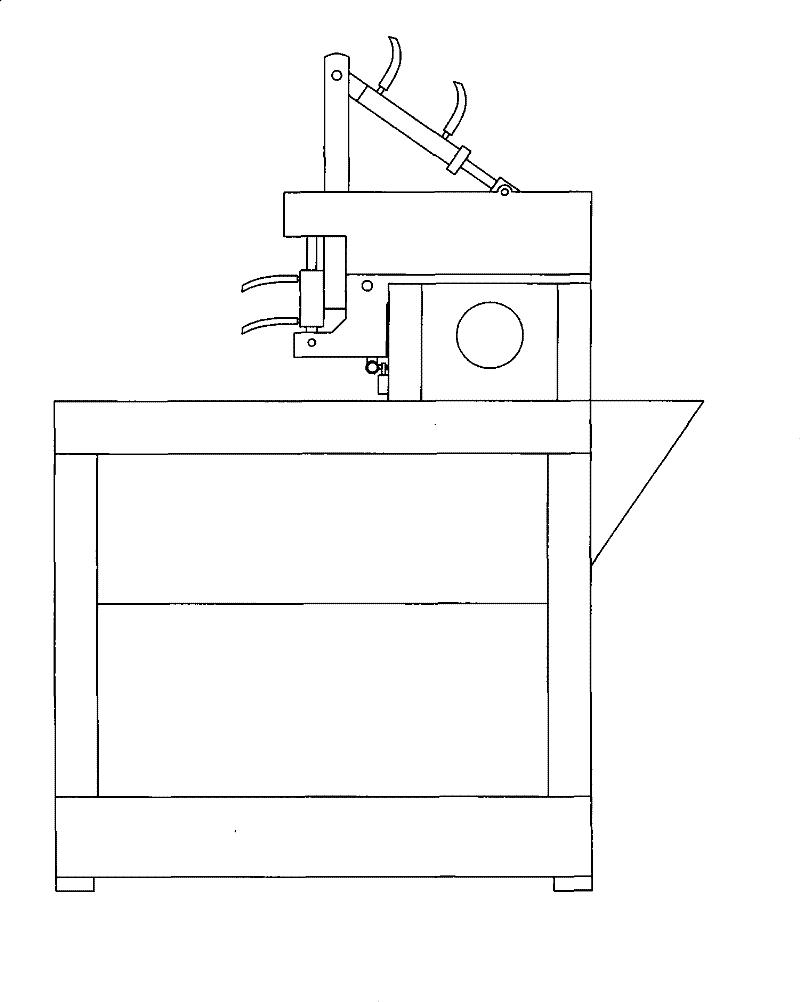

[0018] figure 1 , 2 1. A rubber scraper in 3, comprising a fuselage 2, a motor 3, a transmission, and an actuator, the transmission is installed in the fuselage 2, the actuator is installed on the fuselage 2, and a control panel 18 is installed on the side of the fuselage. There are control buttons on the control panel.

[0019] The transmission device includes an oil pump 4, an oil circuit manifold 5, a glue control valve 6, a glue control valve 61, a glue scraping control valve 62, an oil tank 7, a radiator 8, and oil pipes.

[0020] The executive mechanism includes a glue pulling mechanism 1 , a glue clamping mechanism 9 , and a glue scraping mechanism 10 , and the glue scraping mechanism 10 is installed between the glue pulling mechanism 1 and the glue clamping mechanism 9 .

[0021] The rubber pulling mechanism 1 comprises a front support base 11, a rear support base 12, a hydraulic actuator 13, and the cylinder body of the hydraulic actuator 13 is fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com