Hydraulic booster assembly device with pre-filling function

A technology of hydraulic boosting and pre-charging, applied in brake transmission, brake, transportation and packaging, etc., can solve the problems of large total idle stroke and affect pedal feel, etc., to reduce idle stroke, compact structure, and increase power stroke. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

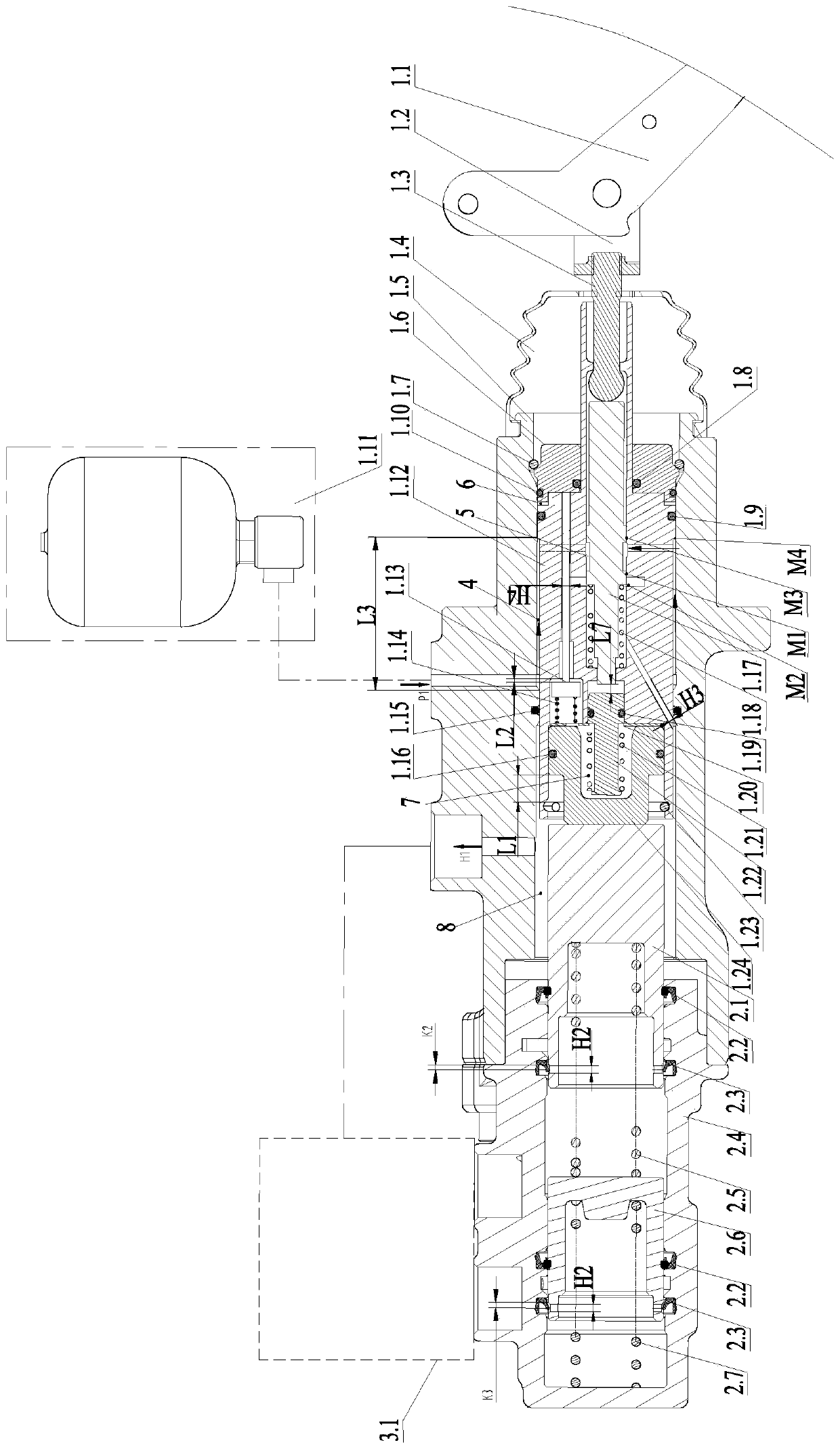

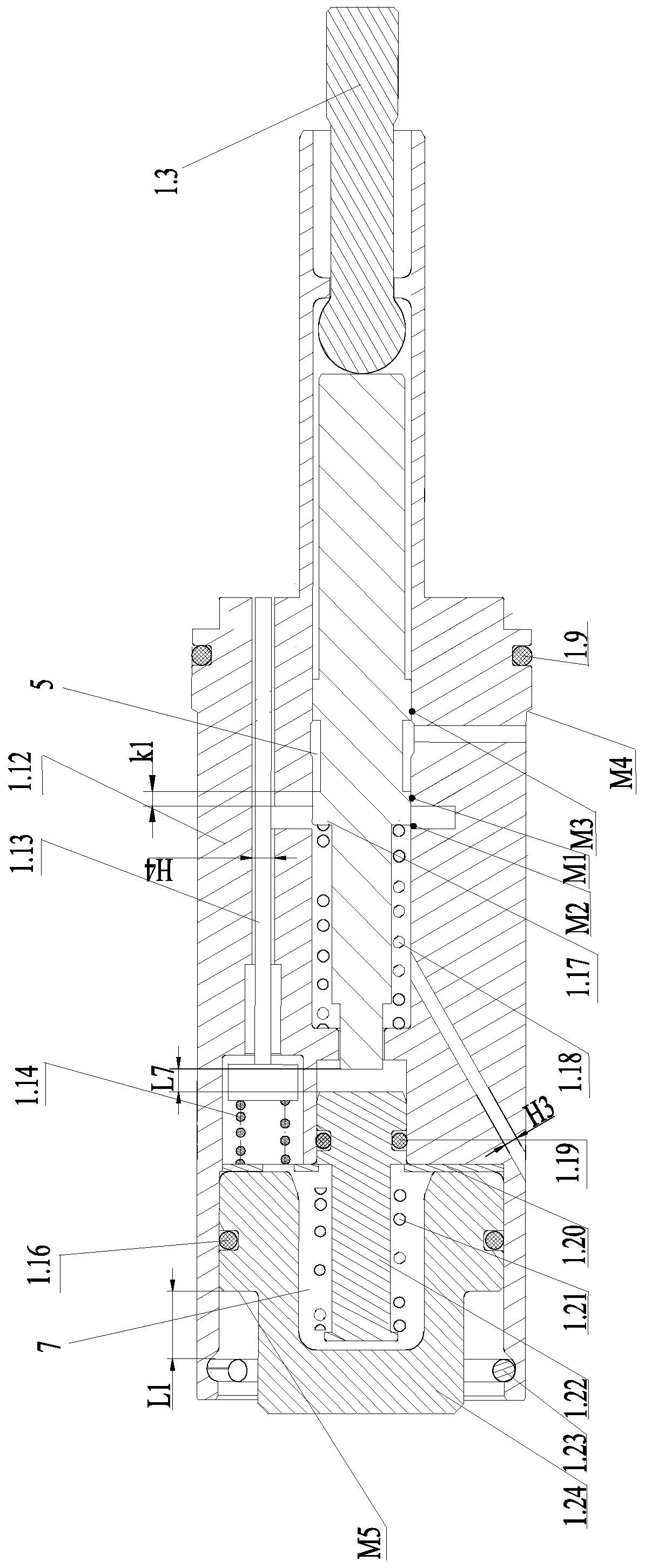

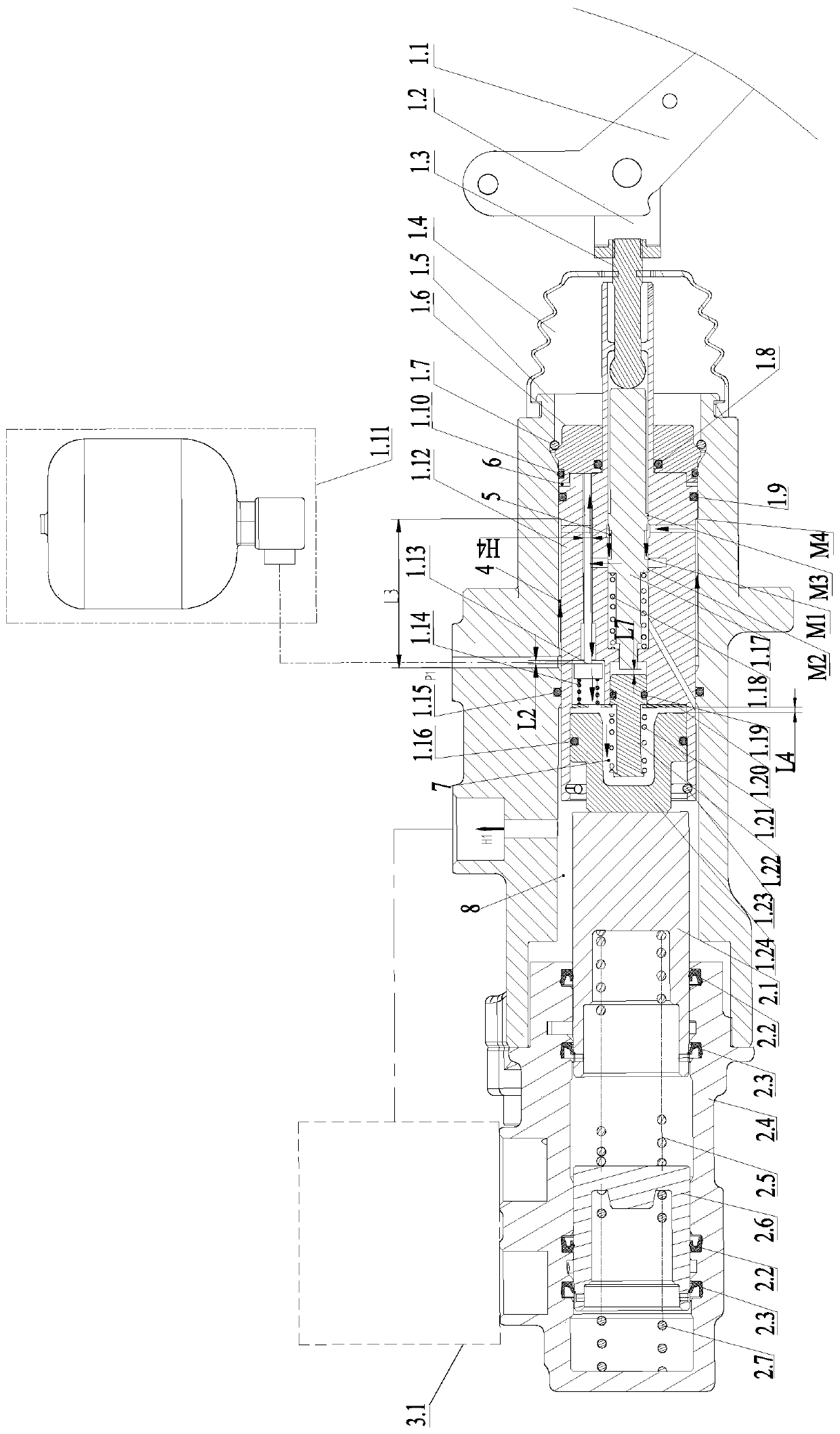

[0032] Such as Figure 1-2 As shown, this embodiment provides a hydraulic booster assembly with a pre-charging function, including:

[0033] The main cylinder housing 1.5 includes two cylinder holes with different diameters in the middle. The diameter of the front cylinder hole is smaller than that of the rear cylinder hole. The front cylinder hole is connected with an oil return hole H1, and the rear cylinder hole is connected with a high hydraulic pressure The liquid inlet P1 has a mounting hole behind the cylinder hole at the rear end, which is used to install the seal seat 1.6, and there is a brake master cylinder mounting hole in front of the cylinder hole at the front end, which is connected to the brake master cylinder assembly;

[0034] The booster piston assembly is arranged in the above-mentioned two sections of the cylinder bore, and precisely cooperates with the inner cavity of the master cylinder housing 1.5 to form a high-pressure chamber, and is limited by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com