Preparation method of ultra-high metal loading hydrogenation catalyst

A technology of hydrogenation catalyst and loading capacity, which is applied in the field of preparation of ultra-high metal loading hydrogenation catalyst, and can solve problems such as clogging, decrease in catalyst specific surface area, and decrease in catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

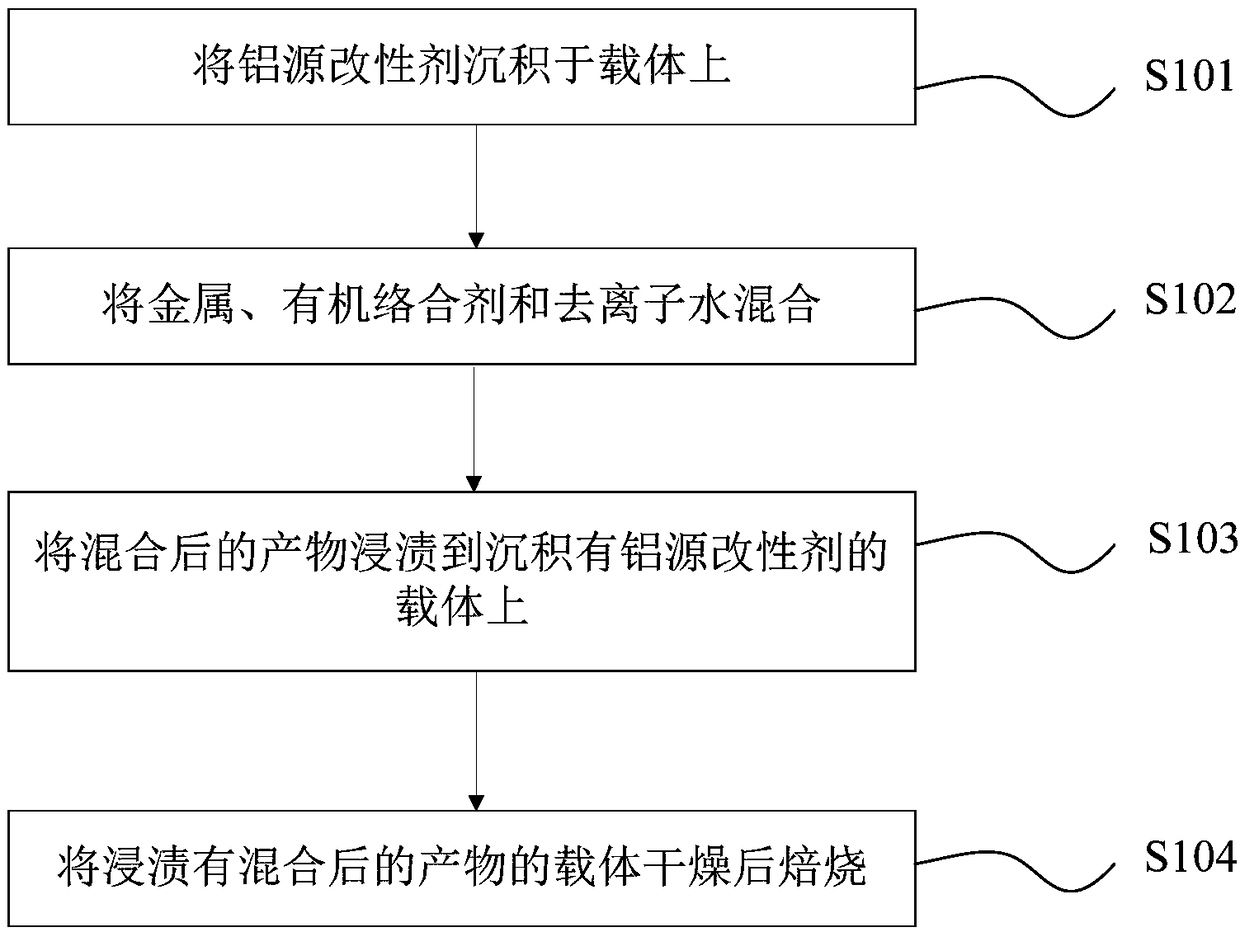

[0019] figure 1 It is a flow chart of the preparation method of the metal loading hydrogenation catalyst in the embodiment of the present invention, such as figure 1 Shown, the preparation method of the metal-loaded hydrogenation catalyst provided by the invention comprises the following steps:

[0020] S101: Depositing an aluminum source modifier on a carrier. Wherein, the aluminum source modifier is a composition of one or more of aluminum isopropoxide, aluminum chloride and aluminum nitrate; the carrier is a silica carrier, and the Si / Al atomic ratio is 5-25.

[0021] S102: Mixing the metal, the organic complexing agent and deionized water. Among them, the metal includes the main component and the auxiliary component; the main component is Mo and W of the VIB group, and the auxiliary component is Co and / or Ni of the VIII group; the aluminum source modifier is aluminum isopropoxide, chlorine Composition of one or more of aluminum chloride and aluminum nitrate; Ni(Co) / (M...

Embodiment 1

[0029] Weigh 50g of large pore volume SiO 2 Put it in a beaker, add 500ml of n-hexane, then weigh 11.3g of aluminum isopropoxide, Si / Al=15, dissolve it with a small amount of n-hexane under stirring and add it to the beaker; then add 1500ml of n-hexane, and continue stirring at room temperature 24 hours. Filter, wash with a large amount of n-hexane, dry at 127°C for 8 hours, and then heat up to 580°C at a rate of 2°C / min and calcinate for 6 hours to obtain an aluminum source-modified silica carrier, which is designated as S-1.

[0030] Weigh 50g of large pore volume SiO 2 Put it in a beaker, add 500ml of absolute ethanol, then weigh 7.4g of anhydrous aluminum chloride, Si / Al=5, dissolve it with a small amount of absolute ethanol under stirring and add it to the beaker; then add 1500ml of absolute ethanol, Stirring was continued at room temperature for 24 hours. Filter, wash with a large amount of absolute ethanol, dry at 127°C for 8 hours, and then heat up to 580°C at a rat...

Embodiment 2

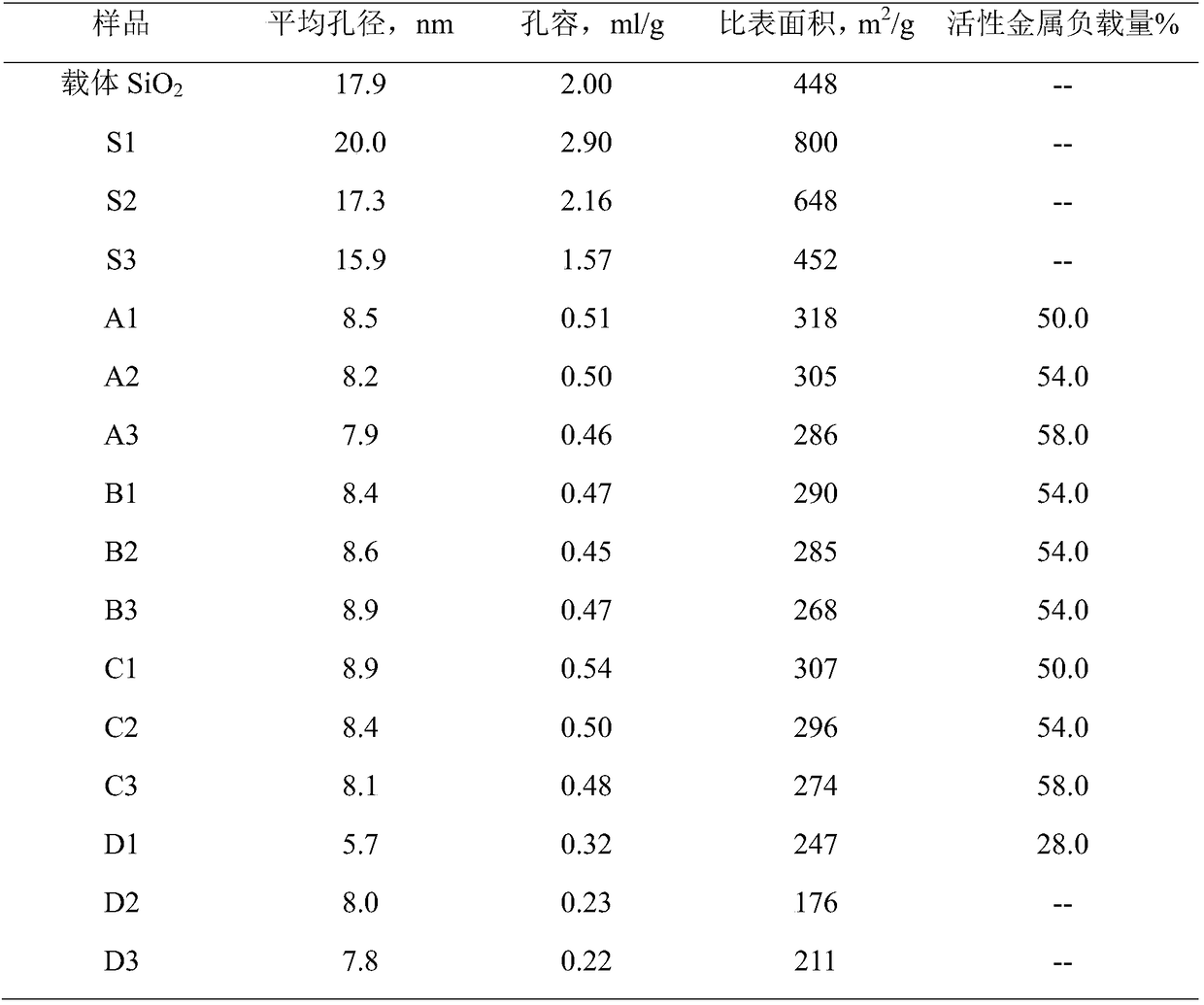

[0034] The water absorption rate of measuring carrier S-1 is 1.8ml / g, takes by weighing the silicon dioxide carrier S-1 of 100g aluminum source modification, 110.7g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), 33.6g ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O), 46.9g ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 ·XH 2 O) and 53.4g citric acid (C 6 h 8 o 7 ·H 2 O). Dissolve nickel nitrate with an appropriate amount of water first, add citric acid until completely dissolved, then add ammonium molybdate and ammonium metatungstate, continue stirring at 60°C until completely dissolved to form a NiMoW co-impregnation solution, and finally make the solution volume up to 200ml. The catalyst was prepared by an equal-volume impregnation method. After the impregnation, it was dried at 100°C for 6 hours, calcined at 450°C for 4 hours, and the heating rate was 2°C / min to obtain catalyst A1. The constant volume V satisfies V=θm; where, θ is the water absorption rate of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com