Composite bag made of non-woven fabric material

A technology of composite bags and non-woven fabrics, which is applied in the field of packaging materials, can solve the problems of low tear strength and bag leakage, and achieve the effects of good composite fastness, improved tear resistance, and easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

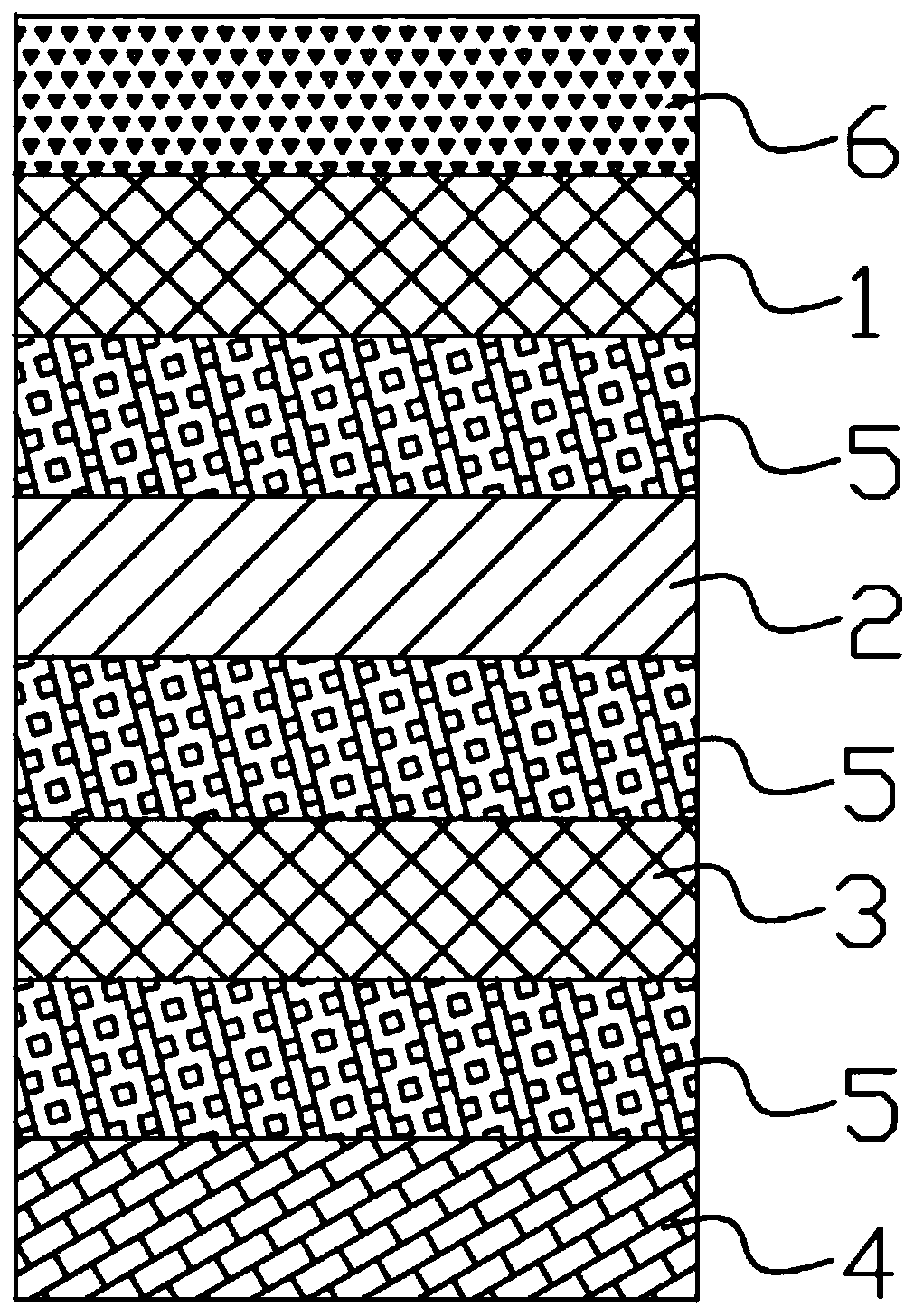

[0035] This embodiment relates to a composite bag made of non-woven fabric material, which includes a surface printing layer 1 , a reinforcement layer 2 , a barrier layer 3 and an inner film layer 4 arranged in sequence.

[0036] Wherein, the surface printing layer 1 is a PET layer, the reinforcement layer 2 is a non-woven fabric, the barrier layer 3 is an aluminum foil layer, and the inner film layer 4 is a PE layer.

[0037] In this embodiment, the surface printing layer 1, the reinforcing layer 2, the barrier layer 3 and the inner film layer 4 are all bonded together, so the surface printing layer 1, the reinforcing layer 2, the barrier layer 3 and the An adhesive layer is also formed between the inner film layers 4 , and the adhesive layer is a polyurethane adhesive layer 5 .

[0038] In order to enhance the performance of the composite bag, the PE layer is prepared by blending polyethylene materials. According to the total mass of polyethylene materials, it specifically i...

Embodiment 2

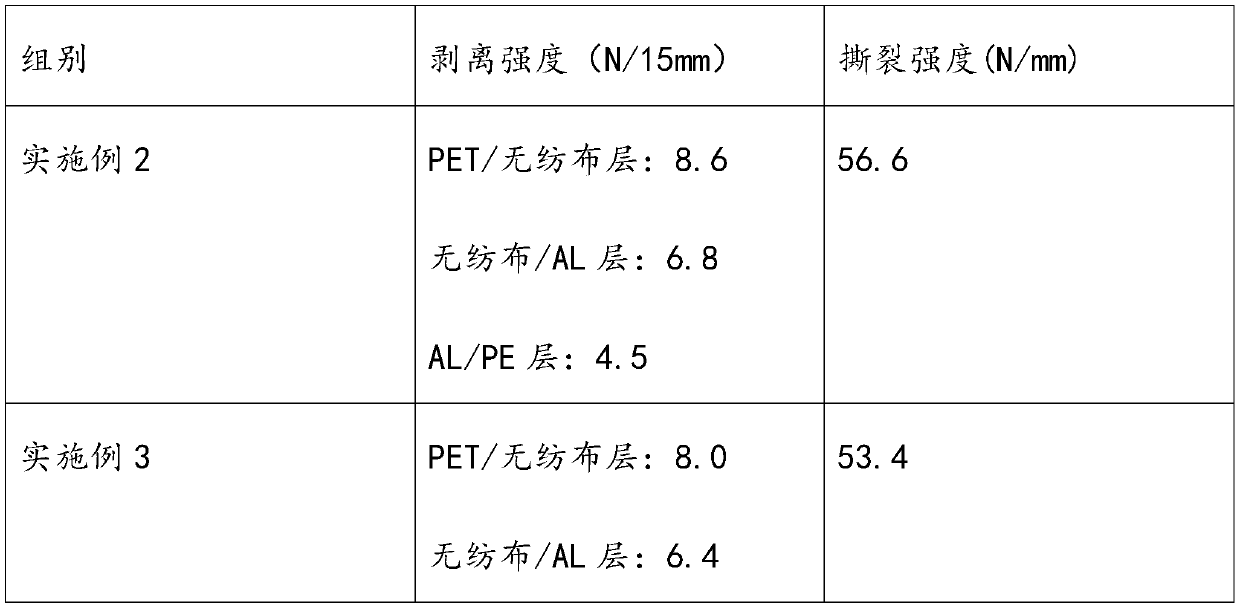

[0049] This embodiment relates to a composite bag of non-woven fabric material, and the composite bag is prepared according to the following steps:

[0050] S1. Composite PET / non-woven fabric layer: place the PET film and non-woven fabric film on a dry compound machine for compounding, and the glue amount of the polyurethane adhesive is 3.0g / m 2 , the composite speed is 200m / min, the drying temperature of the first drying tunnel is 10°C, the drying temperature of the second drying tunnel is 20°C, the drying temperature of the third drying tunnel is 25°C, and the temperature of the hot drum is 30°C.

[0051] S2. Composite PET layer / non-woven fabric layer / aluminum foil layer: Place the composite PET / non-woven fabric layer and aluminum foil obtained in S1 on a dry laminating machine for compounding, and the glue amount of polyurethane adhesive is 3.0g / m 2 , the composite speed is 180m / min, the drying temperature of the first drying tunnel is 10°C, the drying temperature of the se...

Embodiment 3

[0054] This embodiment relates to a composite bag of non-woven fabric material, and the composite bag is prepared according to the following steps:

[0055] S1. Composite PET / non-woven fabric layer: place the PET film and non-woven fabric film on a dry compound machine for compounding, and the glue amount of the polyurethane adhesive is 4.0g / m 2 , the composite speed is 200m / min, the drying temperature of the first drying tunnel is 25°C, the drying temperature of the second drying tunnel is 25°C, the drying temperature of the third drying tunnel is 25°C, and the hot drum temperature is 30°C.

[0056] S2. Composite PET layer / non-woven fabric layer / aluminum foil layer: Place the composite PET / non-woven fabric layer and aluminum foil obtained in S1 on a dry laminating machine for compounding, and the glue amount of polyurethane adhesive is 4.0g / m 2 , the composite speed is 200m / min, the drying temperature of the first drying tunnel is 25°C, the drying temperature of the second dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com