Manufacturing process for heat transfer film

A manufacturing process, heat transfer film technology, applied in the field of packaging materials to achieve excellent composite fastness, excellent flexibility, and rich printing patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

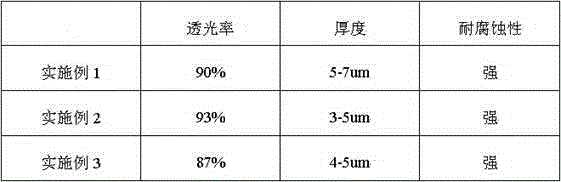

Embodiment 1

[0018] A heat transfer film manufacturing process, the steps comprising:

[0019] (1) Preparation of raw materials: prepare raw materials including substrate film, release agent, ink, adhesive, the substrate film is made of PET, the adhesive is hot melt adhesive, and the solid content of the release agent is controlled at 20%;

[0020] (2) Unwinding: Place the substrate film in the center of the unwinding shaft of the gravure printing machine, pass through the middle of the embossing roller and the printing plate cylinder, and then pass through the constant tension traction roller and enter the winding shaft;

[0021] (3) Coating release agent: first prepare the release agent, pour it into the coating tank and stir evenly, start the gravure printing machine to coat, and the coated substrate film is dried on the drying device, and the release agent The thickness of the agent coating is controlled at 4um, and the drying temperature is 80°C;

[0022] (4) Coating ink: pass the su...

Embodiment 2

[0026] A heat transfer film manufacturing process, the steps comprising:

[0027] (1) Preparation of raw materials: Prepare raw materials including substrate film, release agent, ink, and adhesive. The substrate film is made of PET, the adhesive is hot-melt adhesive, and the solid content of the release agent is controlled at 23%;

[0028] (2) Unwinding: Place the substrate film in the center of the unwinding shaft of the gravure printing machine, pass through the middle of the embossing roller and the printing plate cylinder, and then pass through the constant tension traction roller and enter the winding shaft;

[0029] (3) Coating release agent: first prepare the release agent, pour it into the coating tank and stir evenly, start the gravure printing machine to coat, and the coated substrate film is dried on the drying device, and the release agent The thickness of the agent coating is controlled at 5um, and the drying temperature is 90°C;

[0030] (4) Coating ink: pass th...

Embodiment 3

[0034] A heat transfer film manufacturing process, the steps comprising:

[0035] (1) Preparation of raw materials: Prepare raw materials including substrate film, release agent, ink, and adhesive. The substrate film is made of PET, the adhesive is hot-melt adhesive, and the solid content of the release agent is controlled at 25%;

[0036] (2) Unwinding: Place the substrate film in the center of the unwinding shaft of the gravure printing machine, pass through the middle of the embossing roller and the printing plate cylinder, and then pass through the constant tension traction roller and enter the winding shaft;

[0037] (3) Coating release agent: first prepare the release agent, pour it into the coating tank and stir evenly, start the gravure printing machine to coat, and the coated substrate film is dried on the drying device, and the release agent The thickness of the agent coating is controlled at 7um, and the drying temperature is 100°C;

[0038] (4) Coating ink: pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com