Transparent high-barrier film applicable to high-speed automatic packaging and production method thereof

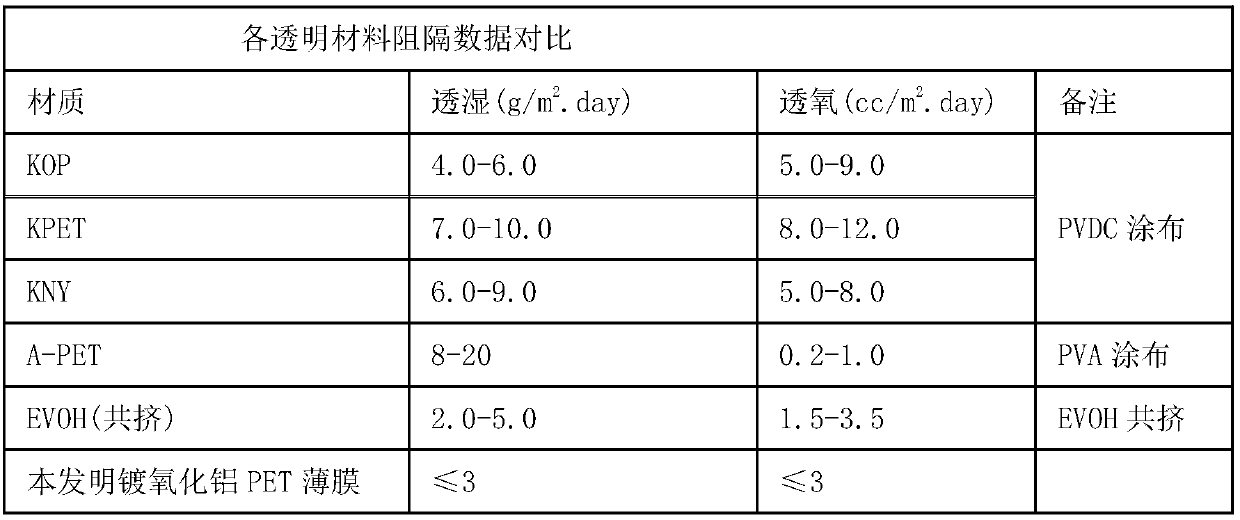

An automatic packaging and transparent technology, applied in the direction of chemical instruments and methods, applications, household components, etc., can solve the problems of poor transparency, low heat-sealing strength, and not very good barrier performance, so as to achieve cost control, improve comprehensive performance, and excellent The effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

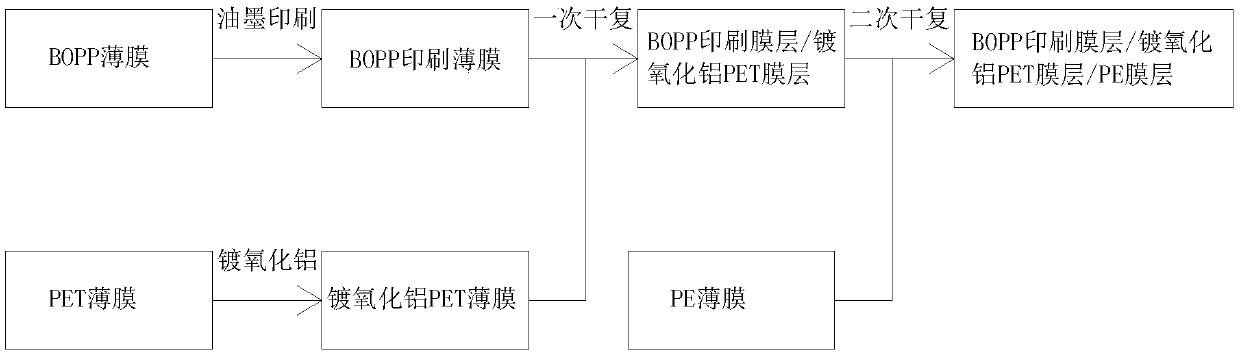

[0023] 1. For BOPP printing film

[0024] The BOPP printed film is a product purchased from Anhui Guofeng Plastic Industry. The BOPP printed film not only maintains excellent optical properties, smoothness and heat shrinkability, but also has good stiffness, high elastic modulus, uniform thickness, and a smooth film surface. It also has a certain degree of wear resistance and can be applied to high-speed automatic packaging processes.

[0025] 2. For aluminum oxide-coated PET film

[0026] The preparation of aluminum oxide coated PET film of the present invention:

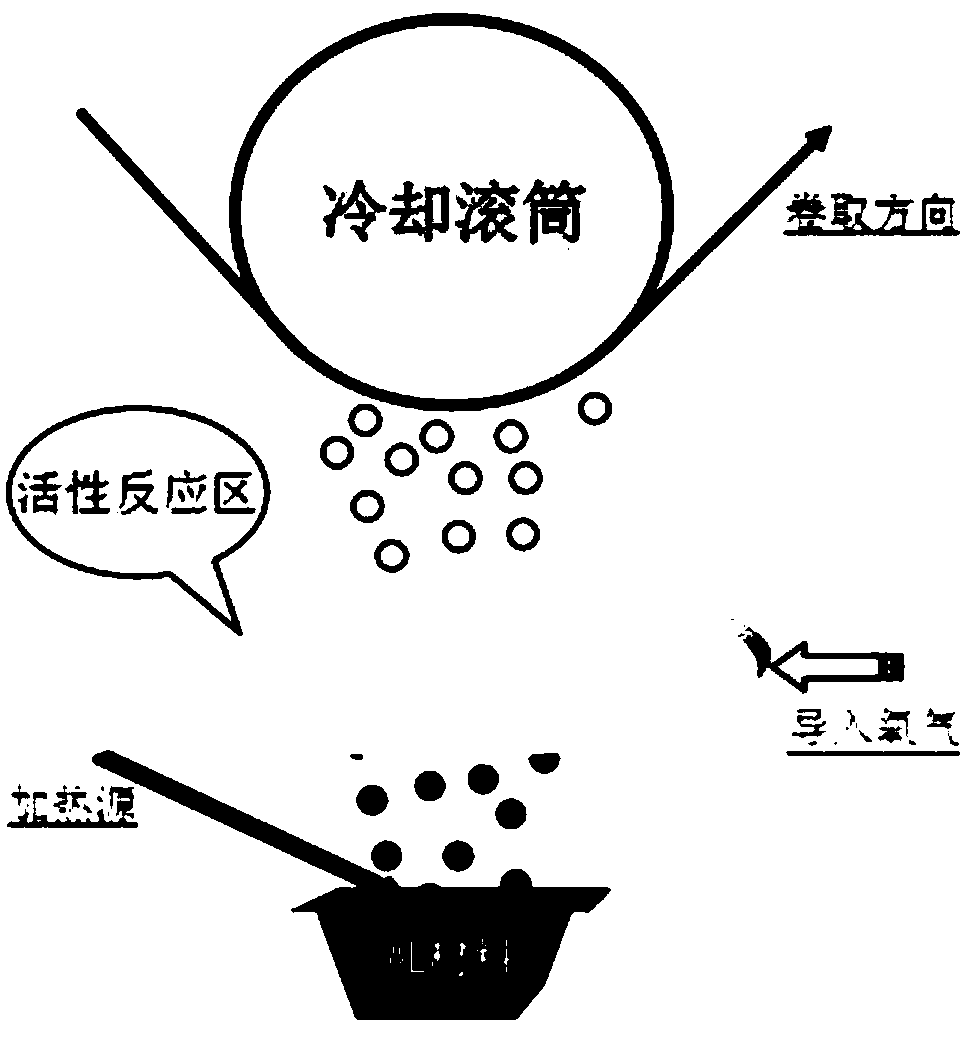

[0027] The first group: put the reel PET film base material in the vacuum chamber and then carry out the vacuuming operation. When the vacuum degree in the vacuum chamber reaches 4×10 -4 When the temperature is above mba, the evaporation boat is heated up to 1500°C, and then the aluminum wire with a purity of 99.9% is continuously sent to the evaporation boat, so that the aluminum wire is continuously melted and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com