Packaging paste based on multi-dimensional nano material and preparation method of packaging paste

A technology of nanomaterials and pastes, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. Effects of improving shear strength, mild execution conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

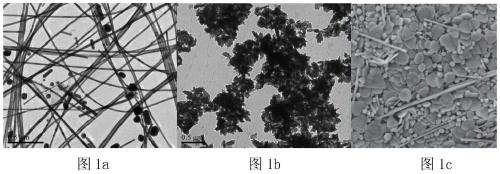

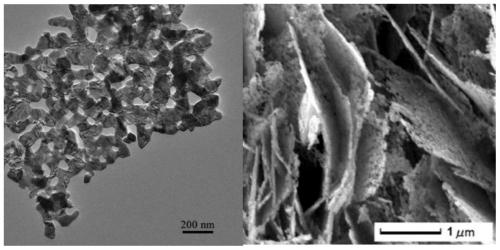

[0034] During the research and development and practical application, the applicant found that the sintering effects of nano-metals with different forms are different. The bonding strength is about 9MPa, which is lower than that of the zero-dimensional nanoparticle paste. This is because the ability of nanowires to form an interconnected network during sintering is weaker than that of nanoparticles. After repeated verification by a large number of experiments, based on the size effect and shape effect, the enhancement of low activation energy and high surface energy diffusion at the nanoscale, the sintering temperature is significantly reduced, and the sintering rate is greatly improved. In order to be able to combine different forms of nano-metals such as zero-dimensional nanoparticles, one-dimensional nanowires or nanotubes, and two-dimensional nanosheets and other multi-dimensional nanometals to provide packaging paste materials with better sintering performance. At the sam...

Embodiment 1

[0053] In a preferred embodiment of the present invention 1, the following steps are used to prepare the packaging paste:

[0054] Use dry etching to form a number of holes with a diameter of 10nm on the surface of the nano silver wire and the nano silver sheet, configure the ascorbic acid solution with a mass concentration of 0.5wt%, soak the nano silver particles, the etched nano silver wire and the etched After etching the nano-silver sheet for 24 hours, the mass ratio of the ascorbic acid solution to the above-mentioned nano-silver materials was 5:2; after that, the soaking solution was centrifuged, separated, washed, and dried, and the cleaned nano-silver particles, nano-silver wires, Nano-silver flakes are mixed at a mass ratio of 8:3:4, and the mixed nano-silver material is mixed with adipic acid, phenolic resin, and terpineol at a mass ratio of 0.8:0.05:0.01:0.2, and the mixture is ultrasonicated for 20 minutes, shaken Rotary steaming under reduced pressure for 1 hour ...

Embodiment 2

[0056] In a preferred embodiment of the present invention 2, the following steps are used to prepare the packaging paste:

[0057] Use dry etching to form a number of holes with a diameter of 40nm on the surface of nano silver wires and nano silver sheets, configure a solution of ascorbic acid with a mass concentration of 0.5wt%, soak nano silver particles, etched nano silver wires and etched After etching the nano-silver sheet for 24 hours, the mass ratio of the ascorbic acid solution to the above-mentioned nano-silver materials was 5:2; after that, the soaking solution was centrifuged, separated, washed, and dried, and the cleaned nano-silver particles, nano-silver wires, Nano-silver flakes are mixed at a mass ratio of 8:3:4, and the mixed nano-silver material is mixed with adipic acid, phenolic resin, and terpineol at a mass ratio of 0.8:0.05:0.01:0.2, and the mixture is ultrasonicated for 20 minutes, shaken Rotary steaming under reduced pressure for 1 hour obtained a unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com