A Diffusion Welding Method for Improving the Strength of gh4099 Welded Joints

A technology of GH4099 and welded joints, which is applied in the field of diffusion welding, can solve the problems that the performance of welded joints cannot meet the needs of engineering applications and the deterioration of base metals, etc., and achieve the effects of small axial deformation rate, high welding rate, and mutual diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Vacuum diffusion welding of GH4099 welded joints, the steps are as follows:

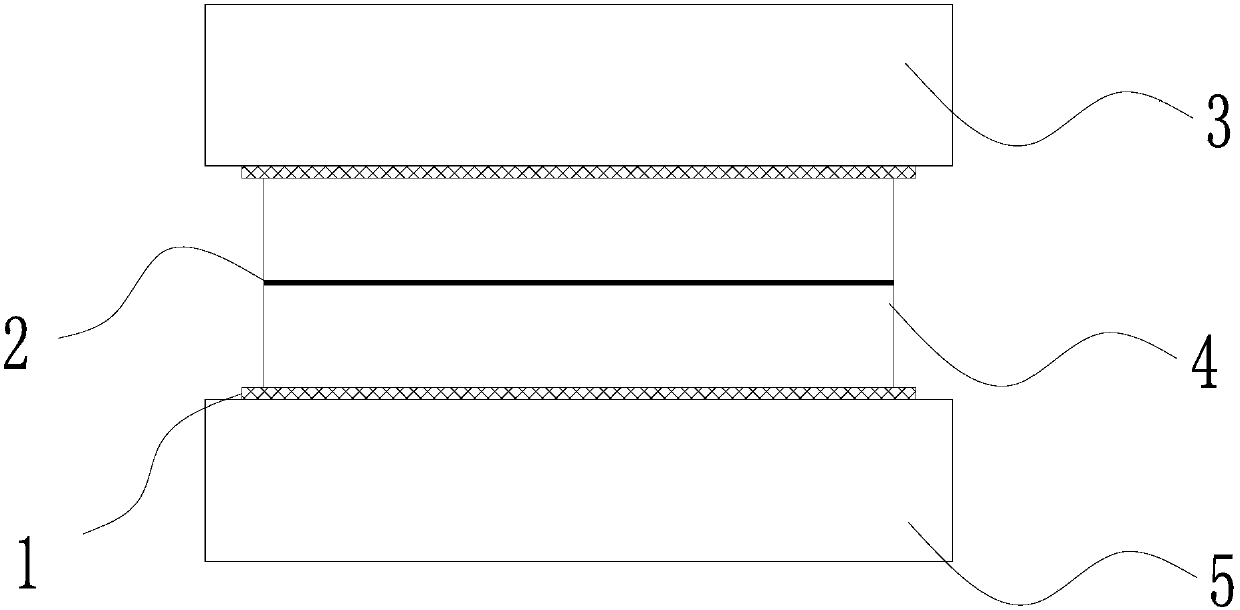

[0026] Such as figure 1 The workpiece to be welded is a rod-shaped GH4099 of φ38mm×35.5mm.

[0027] Select 4μm thick nickel-chromium alloy foil (Cr 25wt.% and Ni 75wt.%) as the intermediate layer, use sandpaper to polish the surface of nickel-chromium alloy foil 2 and GH4099 workpiece to be welded, so that the surface roughness is less than 1μm, after alcohol solution After ultrasonic cleaning for 5 minutes, dry with cold air for later use.

[0028] The above-mentioned materials are clamped, and the nickel-chromium alloy foil 2 is placed between the GH4099 welding joint 4 substrates, and the components to be welded are placed between the upper pressure head 3 and the lower pressure head 5 of the diffusion welding furnace, Solder resist layer 1 is respectively set between the upper indenter 3, the lower indenter 4 and the workpiece to be welded, and a pre-pressure of 0.5MPa is applied to clos...

Embodiment 2

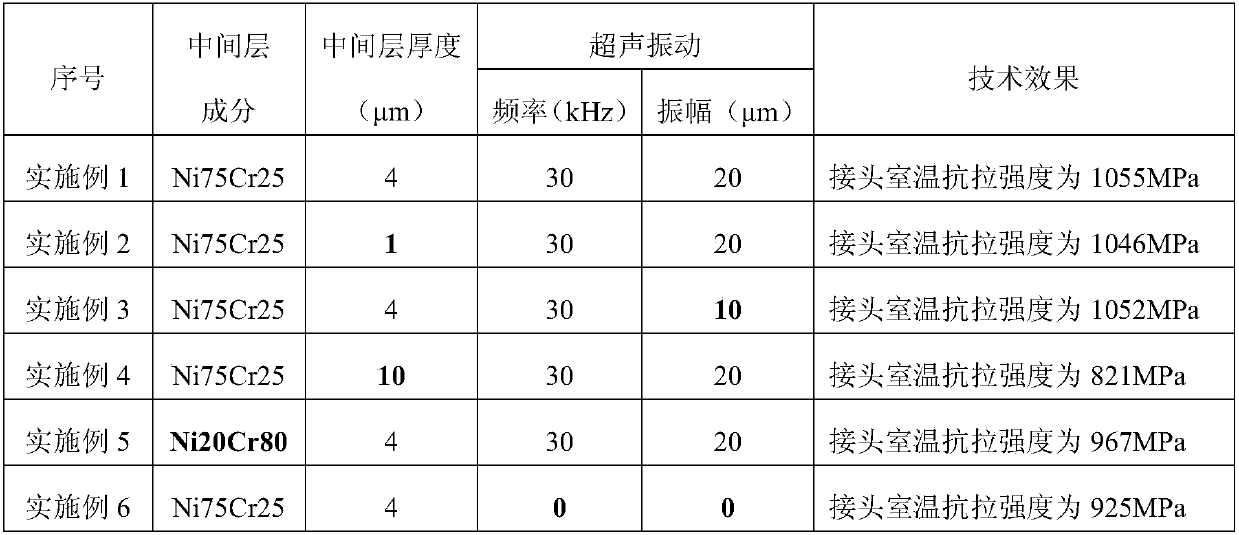

[0037] Different from Example 1, the thickness of the middle layer of the nickel-chromium alloy foil is reduced from 4 μm to 1 μm, and the welding pressure is reduced from 30Mpa to 27Mpa. The test results of the joint after butt welding show that the tensile sample is broken from the base material, and the joint is at room temperature The tensile strength is 1046MPa.

Embodiment 3

[0039] Different from Example 1, during the welding process, the ultrasonic vibration amplitude changed from 20 μm to 10 μm. The test results of the joint after butt welding showed that the tensile sample was broken from the base metal, and the tensile strength of the joint at room temperature was 1052 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com