Friction stir welding tool and method for repairing keyhole defects using the tool

A technology of friction stir welding and keyhole, which is applied in the direction of manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve the problem of not fundamentally eliminating volume defects, reducing the thickness of the repair area of metal components, and difficult to repair keyhole defects and other problems, to achieve the effect of easy control of material flow at the interface position, lower temperature, and promotion of plastic flow and atomic diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with drawings and embodiments.

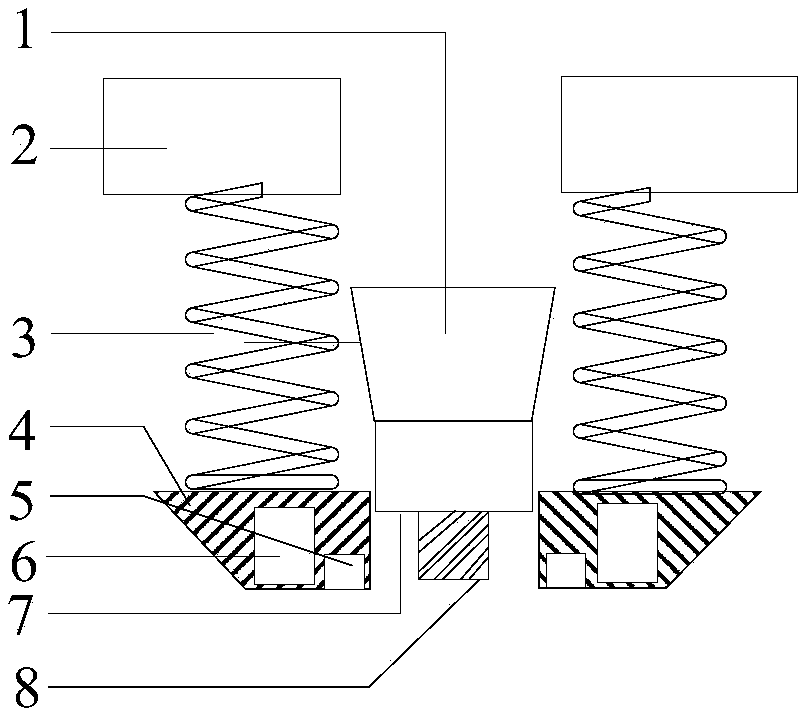

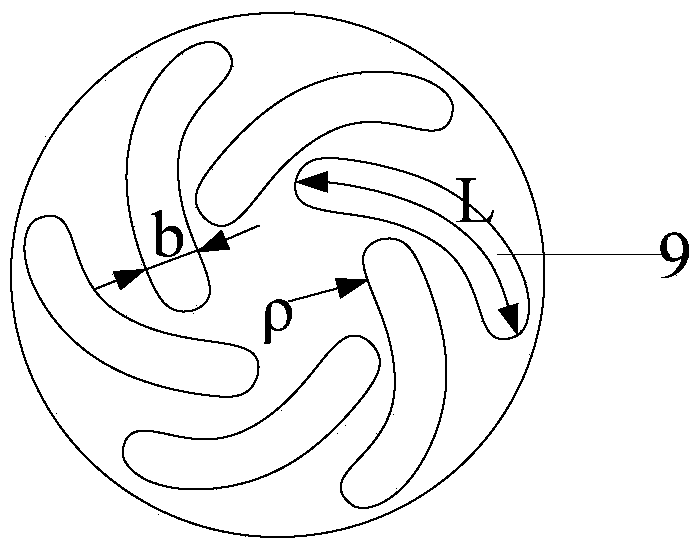

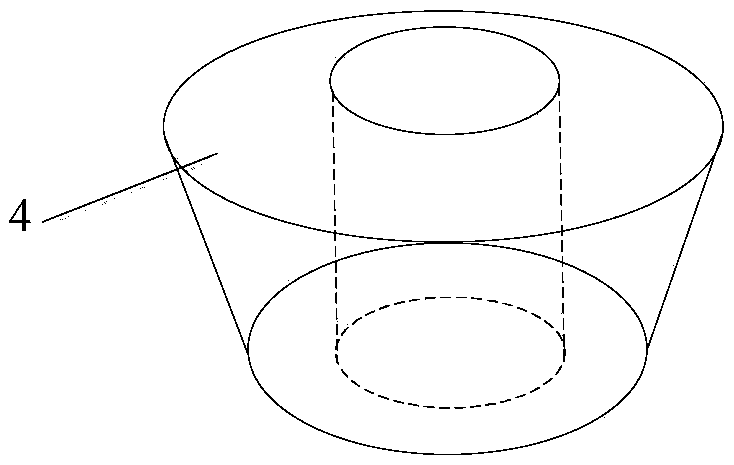

[0042] combine Figure 1 to Figure 4 , The friction stir tool of the present invention includes a stirring head 1 and a stationary shoulder 4 matched with the stirring head. The bottom surface of the stirring needle 8 of the stirring head has six helical grooves 9, and the maximum curvature radius ρ, arc length L and width b of the six helical grooves are respectively 0.7 times, 0.5 times and 0.1 times the diameter of the stirring needle. The static shoulder is in the shape of a truncated cone with a large top and a small bottom. Its inner diameter is 0.1-0.3mm larger than the diameter of the stirring head shoulder 7 of the stirring head, the outer diameter of the lower end is 5-10mm larger than the inner diameter, and the outer diameter of the upper end is 20-50mm larger than the inner diameter. Height and mixing head details ( figure 1 The middle stirring head is loca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com