Preparation method of copper-aluminum composite plate strip with composite side edges

A copper-aluminum composite plate and aluminum plate technology, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of affecting rolling fusion, difficult processing and forming of lateral tenons and grooves, and large difference in deformation amount. , to reduce the processing difficulty and cost, facilitate surface cleaning or grinding, and increase the lateral contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Select copper strips and aluminum strips with a thickness of 3mm, a width of 50mm, and a length of 5m, and set a corrugated groove on one side of the copper strip in the length direction. Mouth; the long side of one end of the copper and aluminum strips has a length of 20cm, and an oblique angle of 3° along the length direction. Place the long sides of the copper and aluminum strips to be connected by 10mm inward, clean them with a strong brush, polish the oxide layer with a wire brush, and then use a fine wire brush to polish the surface roughness to 75~85μm.

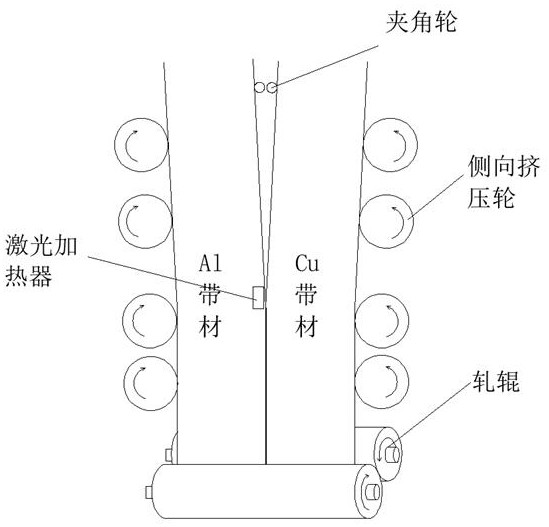

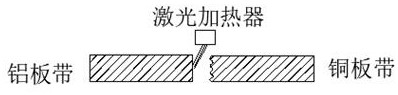

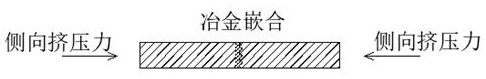

[0054] The schematic diagram of the copper-aluminum strip preparation device is as follows figure 1 As shown, the copper strip and aluminum strip are laid side by side on the roller conveyor. The side of the copper strip with the corrugated groove and the aluminum strip maintain a 60mm gap. , the copper plate belt and the aluminum plate belt are connected with an angle wheel, so that after the copper and alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com