A kind of preparation method of large size lightweight magnesium-aluminum base amorphous alloy

An amorphous alloy, magnesium-aluminum-based technology, which is applied in the field of preparation of large-scale lightweight magnesium-aluminum-based amorphous alloys, can solve problems such as large differences in deformation modes, low performance of composite materials, and difficulties in realizing interfacial metallurgical bonding. Achieve good deformation coordination, high interface bonding strength, and good reinforcement/toughening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

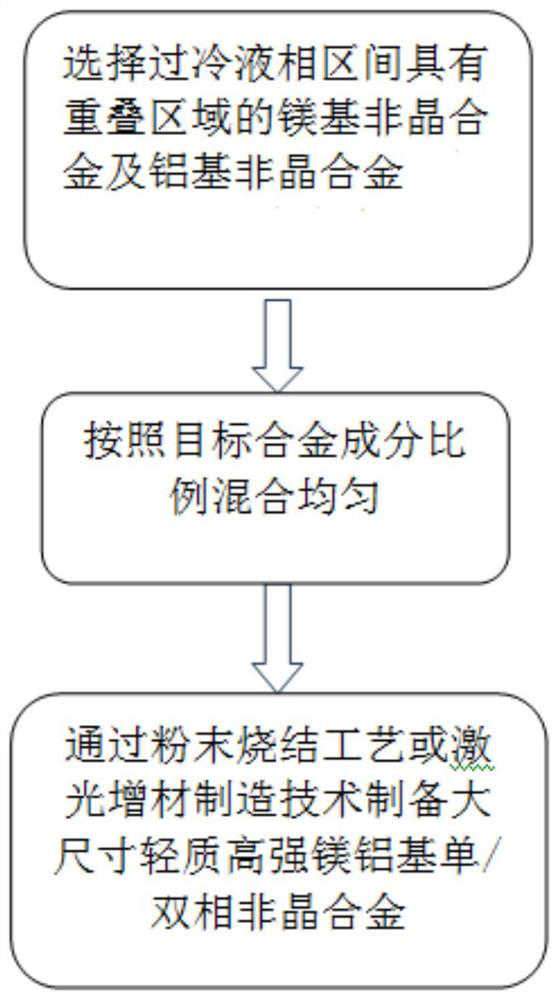

[0022] A kind of preparation method of magnesium-aluminum base amorphous alloy provided by the invention, such as figure 1 shown, including the following steps:

[0023] (1) Take the powdered magnesium-based amorphous alloy and aluminum-based amorphous alloy according to the target alloy composition ratio, and mix them uniformly to obtain magnesium-aluminum-based amorphous alloy mixed powder; the magnesium-based amorphous alloy and aluminum-based amorphous alloy The subcooled liquid phase intervals of the components overlap;

[0024] (2) Prepare the magnesium-aluminum-based amorphous alloy mixed powder into a magnesium-aluminum-based amorphous alloy through a powder sintering process or laser additive manufacturing technology.

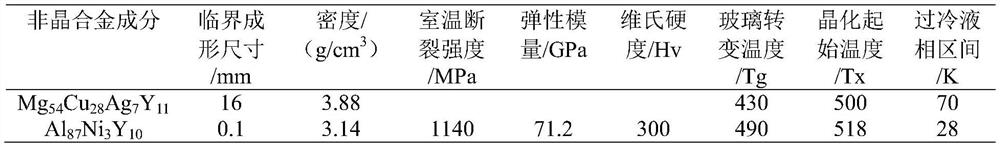

[0025] According to the performance requirements of the target amorphous alloy, in order to obtain a magnesium-aluminum-based amorphous alloy with strong amorphous forming ability, in some embodiments, the selection criteria for the magnesium-based am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com