Secondary composite casting bimetal forming method

A composite casting, bimetal technology, applied in the field of bimetal casting, can solve the problems of poor strength stability, reduced bearing capacity, reduced engine life, etc., to achieve the effect of good interface bonding performance, increased service life, and reduced time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

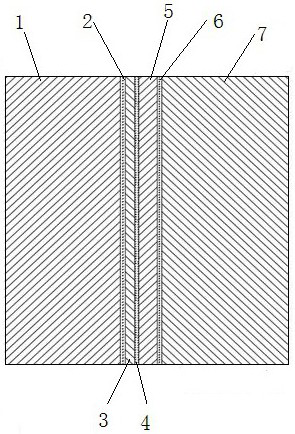

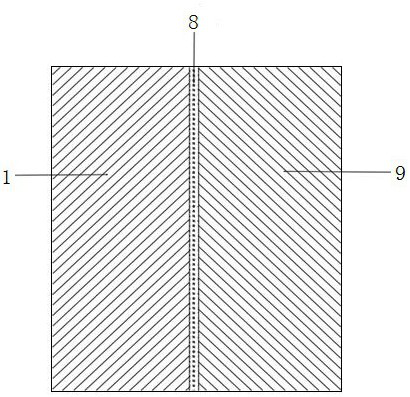

[0027] 1. The surface of the steel substrate is cleaned, and a layer of bonding material 3 is plated on the surface of the steel substrate 1 by electroless plating. The bonding material 3 is copper with a thickness of 1 mm. A first bonding interface 2 is formed between the bonding material 3 and the steel matrix 1 .

[0028] 2. Clean and purge the mold with argon, then place the copper-plated steel substrate in the mold, and turn on the intermediate frequency induction heating coil to preheat the steel substrate; the preheating temperature is 600°C, and the power is 45KW.

[0029] 3. Put the aluminum alloy ingot into the crucible furnace for melting, and the melting temperature is 780°C.

[0030] 4. Turn off the intermediate frequency induction heating coil, and pour the smelted aluminum alloy melt into the mold to form the first casting melt 5 on the surface of the copper-coated steel substrate.

[0031] 5. After the pouring is finished, after the mold is cooled, the workpie...

Embodiment 2

[0037] 1. The surface of the steel substrate is cleaned, and a layer of nickel is plated on the surface of the steel substrate by electroless plating, with a thickness of 0.7mm.

[0038] 2. Clean and purge the mold with argon, then place the copper-plated steel substrate in the mold, and turn on the intermediate frequency induction heating coil to preheat the steel substrate; the preheating temperature is 600°C, and the power is 45KW.

[0039] 3. Put the aluminum alloy ingot into the crucible furnace for melting, and the melting temperature is 780°C.

[0040] 4. Turn off the intermediate frequency induction heating coil, and pour the smelted aluminum alloy melt into the mold.

[0041] 5. After the pouring is finished, take out the workpiece after the casting mold is cooled for finishing. The thickness of the aluminum alloy is 7mm.

[0042] 6. Preheat the workpiece after processing; the preheating temperature is 600°C and the power is 45KW.

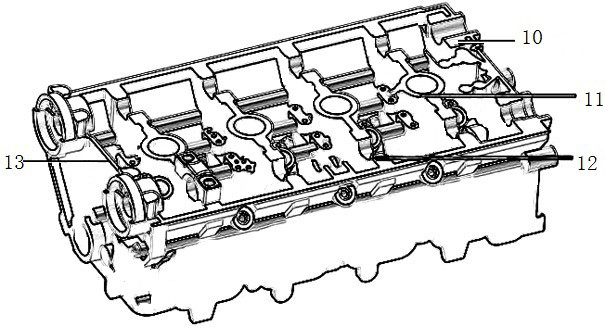

[0043] 7. Clean and purge the eng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com