Anti-crack plaster mortar for outer wall of building and method for preparing anti-crack plaster mortar

A technology for anti-cracking mortar and building exterior walls, which is applied in the field of building materials, can solve the problems of affecting the service life of the thermal insulation system, affecting the durability of anti-cracking mortar, and the low bonding strength of plastering mortar, and achieves cheap raw materials, low cost, Good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

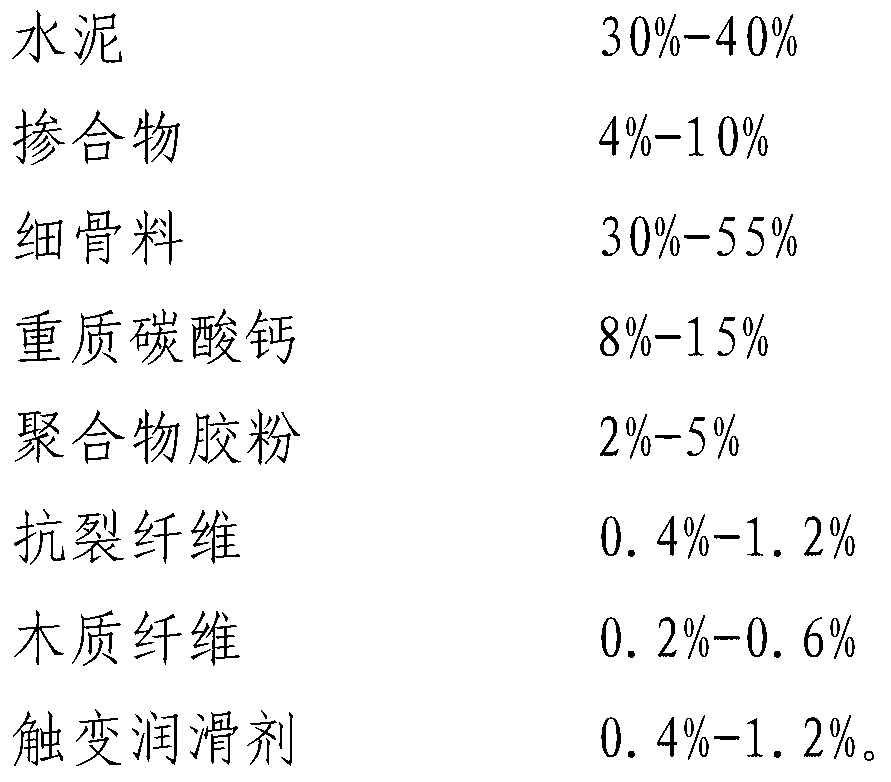

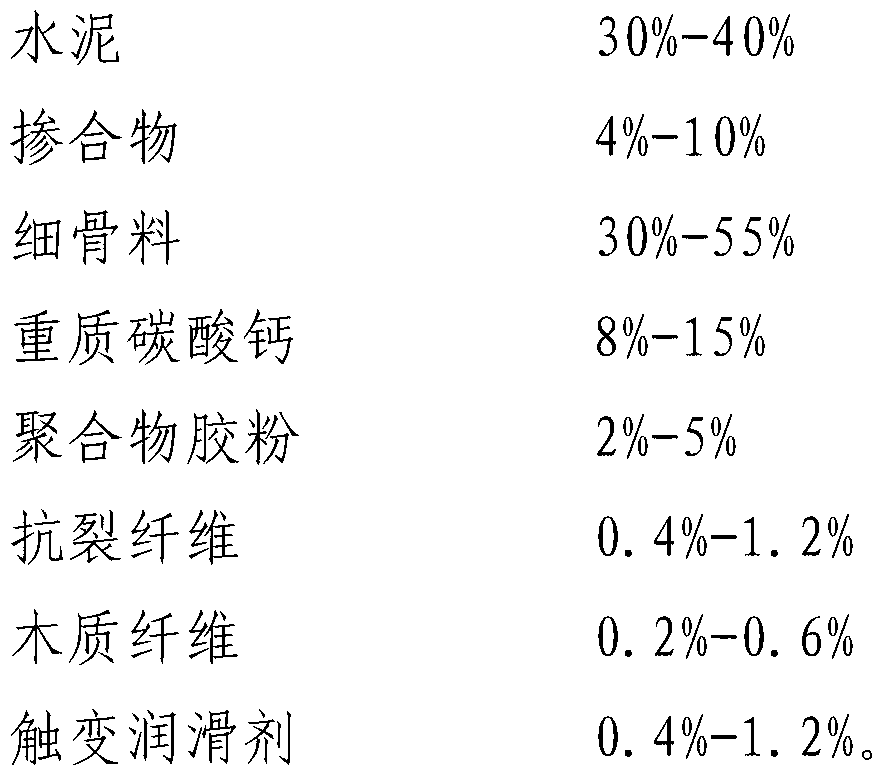

[0023] Mix the following raw materials according to the added amount (parts by weight), specifically:

[0024] Cement (PO42.5 Portland cement) 350 parts, Class I fly ash 50 parts, heavy calcium carbonate 100 parts, graded yellow sand (70-140 mesh) 470 parts, polymer rubber powder 25 parts, polypropylene anti- Add 1 part of cracking fiber, 3 parts of wood fiber and 1 part of thixotropic lubricant into a gravity-free mixing mixer and mix for 5 minutes to obtain an anti-cracking mortar for building exterior wall plastering. When in use, mix the obtained anti-cracking mortar and water in the ratio of 1:0.2 by weight to the exterior wall of the building, and stir for 2 minutes before being used for building construction.

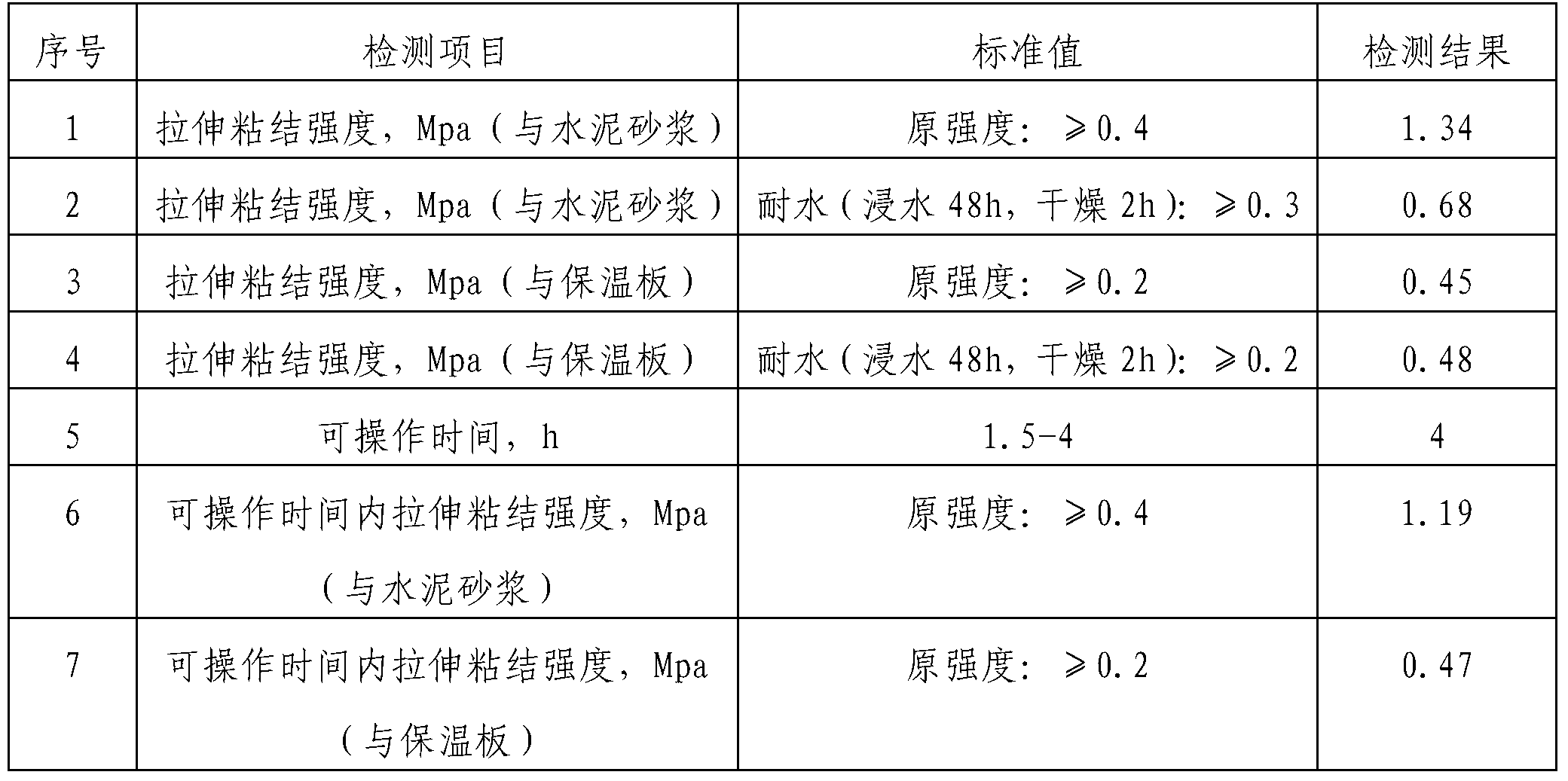

[0025] The anti-cracking mortar for plastering the exterior wall of the building prepared in this example is tested, and the specific test results are shown in Table 1 below:

[0026] Table 1

[0027]

[0028] Tested according to the experimental method of D...

Embodiment 2

[0030] Mix the following raw materials according to the added amount (parts by weight), specifically:

[0031] Cement (PO42.5 Portland cement) 330 parts, Class I fly ash 70 parts, heavy calcium carbonate 120 parts, graded yellow sand (70-140 mesh) 450 parts, polymer rubber powder 25 parts, polypropylene anti- Add 1 part of cracking fiber, 3 parts of wood fiber and 1 part of thixotropic lubricant into a gravity-free mixing mixer and mix for 4 minutes to obtain an anti-cracking mortar for building exterior wall plastering. When in use, mix the obtained anti-cracking mortar and water in the ratio of 1:0.2 by weight to the exterior wall of the building, and stir for 2 minutes before being used for building construction.

[0032] The performance test of the anti-crack mortar for plastering exterior walls of buildings in this embodiment shows that the workability and flexibility of the anti-crack mortar for plastering exterior walls of buildings are very good during construction ope...

Embodiment 3

[0034] Mix the following raw materials according to the added amount (parts by weight), specifically:

[0035] Cement (PO42.5 Portland cement) 360 parts, Class I fly ash 40 parts, heavy calcium carbonate 110 parts, graded yellow sand (70-140 mesh) 460 parts, polymer rubber powder 24 parts, polypropylene anti- Add 2 parts of cracking fiber, 3 parts of wood fiber and 1 part of thixotropic lubricant into a gravity-free mixing mixer and mix for 5 minutes to obtain an anti-cracking mortar for building exterior wall plastering. When in use, mix the obtained anti-cracking mortar and water in the ratio of 1:0.2 by weight to the exterior wall of the building, and stir for 2 minutes before being used for building construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com