Rapid repairing material for airport parking apron and preparation method thereof

A technology for repairing materials and aprons, which is applied in the field of rapid repair materials and preparations for airport aprons. It can solve problems affecting the normal operation of the airport, affecting aircraft take-off, cracks on the airport pavement, etc., and achieves enhanced heat resistance and water absorption of materials. Low rate, consistent thermal expansion and contraction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

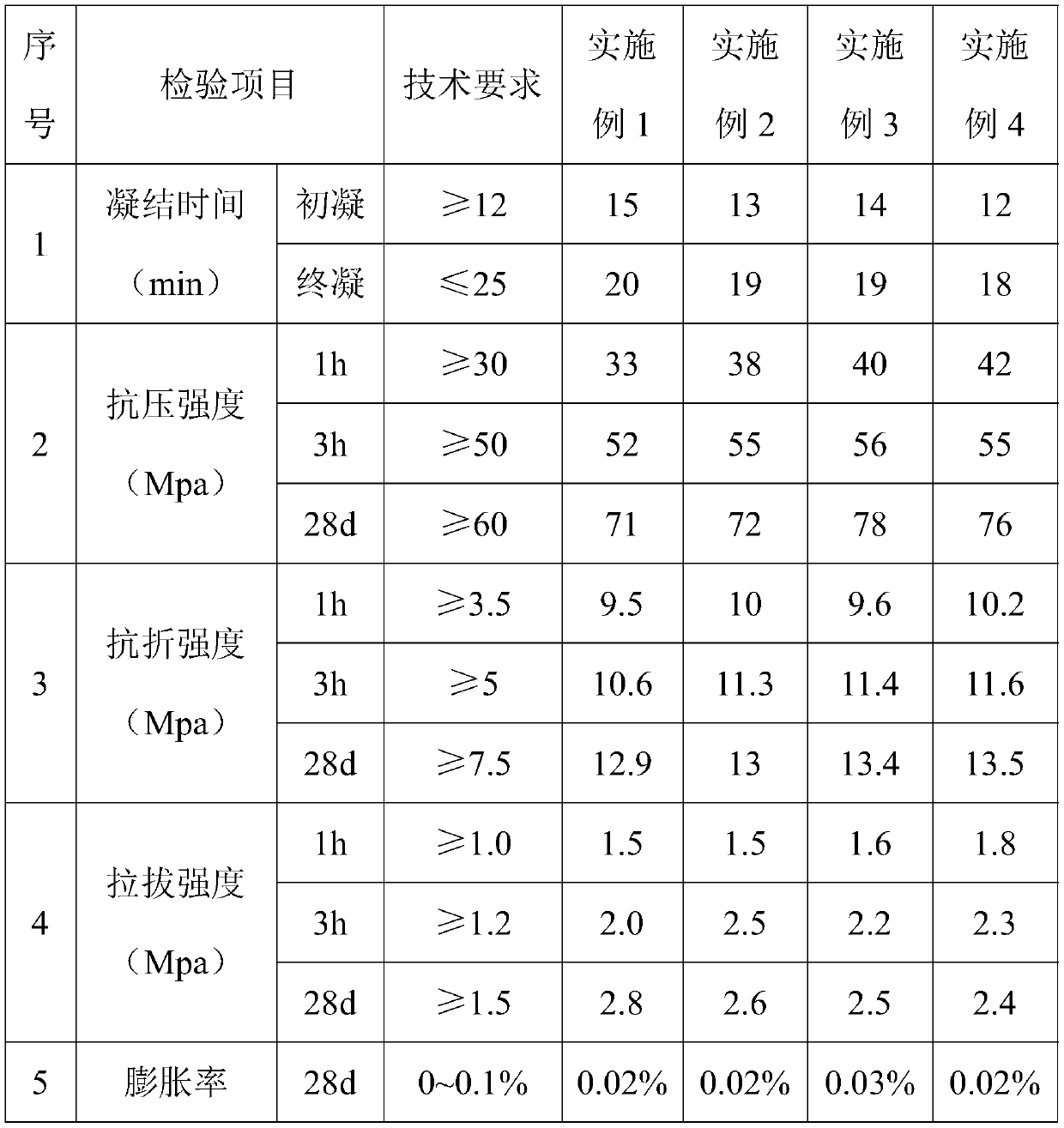

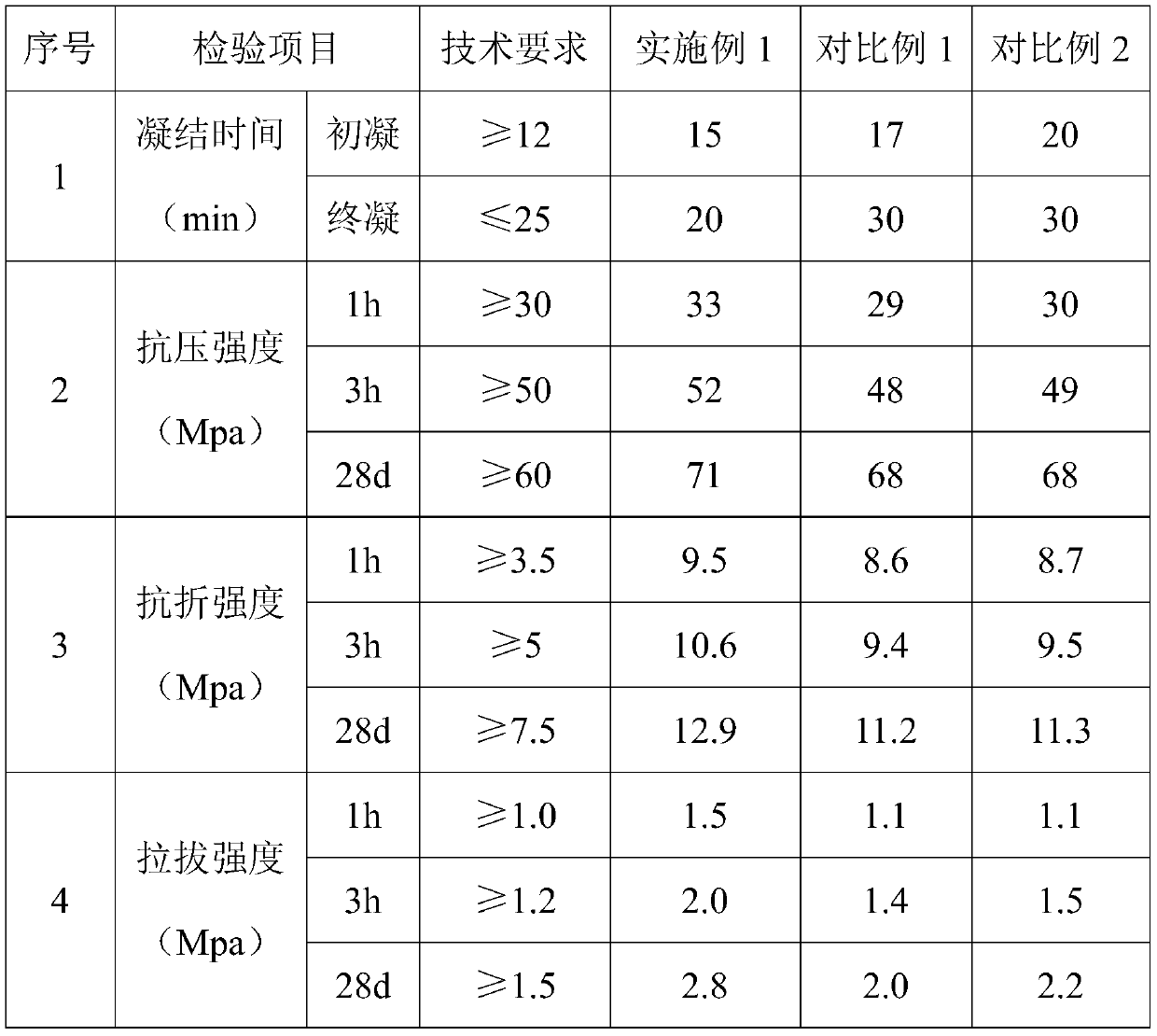

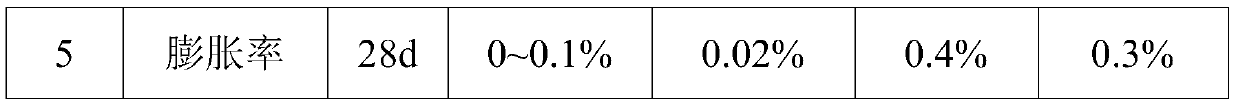

Embodiment 1

[0029] The composition ratio of a rapid repair material for airport aprons: 30% of high belite sulfoaluminate cement, 10% of wollastonite powder, 15% of ceramic micropowder, 10% of mica powder, and 0.5% of powder defoamer %, silicone water repellent 0.5%, acrylic acid redispersible latex powder 8%, polycarboxylate superplasticizer 0.5%, lithium carbonate 0.05%, tartaric acid 0.1%, low viscosity HPMC 0.1%, emery 25%, sea Paoyrite fiber 0.05%, polyester fiber 0.2%.

Embodiment 2

[0031] The composition ratio of a rapid repair material for airport aprons: high belite sulfoaluminate cement 38%, wollastonite powder 6%, ceramic micropowder 25%, mica powder 15%, powder defoamer 0.1 %, silicone water repellent 0.1%, acrylic acid redispersible latex powder 5.25%, polycarboxylate superplasticizer 0.1%, lithium carbonate 0.1%, sodium gluconate 0.01%, low viscosity HPMC 0.09%, corundum 10% , Glass fiber 0.15%, polypropylene staple fiber 0.1%.

Embodiment 3

[0033]The composition ratio of a rapid repair material for airport aprons: 42% of high belite sulfoaluminate cement, 3% of wollastonite powder, 20% of ceramic micropowder, 5% of mica powder, and 0.1% of powder defoamer %, silicone water repellent 0.5%, acrylic acid redispersible latex powder 15%, polycarboxylate superplasticizer 0.5%, lithium sulfate 0.07%, sodium citrate 0.08%, low viscosity HPMC 0.1%, corundum 13.4% , ceramic fiber 0.2%, polyacrylonitrile fiber 0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com