Patents

Literature

151 results about "Blended cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blended cement can be defined as uniform mix of ordinary Portland cement (OPC) and blending materials such as silica fumes, fly ash, limestone and slag to enhance its properties for different uses. Blended cement can improve workability, strength, durability and chemical resistance of concrete.

Composition and method for forming a sprayable materials cover

InactiveUS20050084334A1Improve performanceImprove adhesionSolid waste disposalLandfill technologiesWater dispersibleSlurry

An alternative cover for landfill may be formed from a slurry mixture of water, cementitious binder, adhesion enhancing admixture and fiber. These constituents may be mixed and applied to cover landfilled wastes, granular material piles or for soil erosion control. The cover will harden to minimize water infiltration, wind blown dust, odor and affinity to birds, flies and other insects. The water may include tap water, landfill leachate and wastewater. The binder may include Portland cement, blended cement, cement kiln dust, class C fly ash, and / or calcium sulphate hemihydrate. The adhesion enhancing admixture includes water-dispersible polymers. The fibers may comprise shredded paper or wood or plastic fibers.

Owner:CJS TECH

Chemical Admixtures for Hydraulic Cements

InactiveUS20130074736A1Improve propertiesImprove economySolid waste managementChemical admixtureHardness

This invention relates to a new class of chemical admixtures for hydraulic cement compositions such as pastes, mortars, grouts and concretes. The cement compositions are comprised of ordinary Portland cement, blended cements, or non-Portland cements made with Supplementary Cementitious Materials. The admixtures contain complexes of metals with derivatives of hydroxycarboxylic acids, and improve properties of cement compositions, including setting, hardness, compressive strength, shrinkage, and freeze-thaw resistance. The invention discloses a method for improving the properties of hydraulic cements by adding the disclosed chemical admixtures to cement compositions, and also discloses methods of preparing said admixtures.

Owner:GILL IQBAL

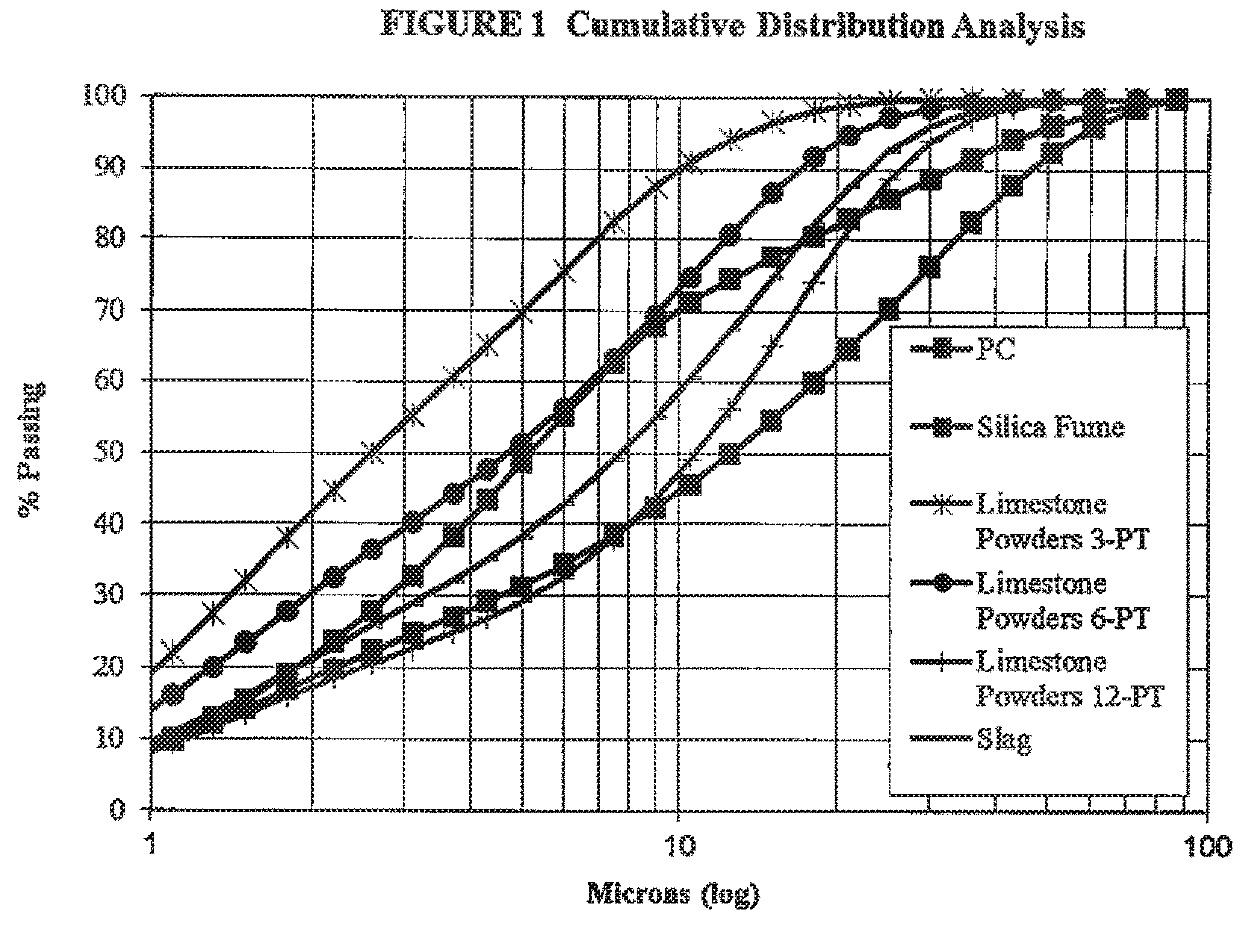

Process for producing blended cements with reduced carbon dioxide emissions

InactiveUS6936098B2Reduce carbon dioxide emissionsImprove carrying capacitySolid waste managementSlagFly ash

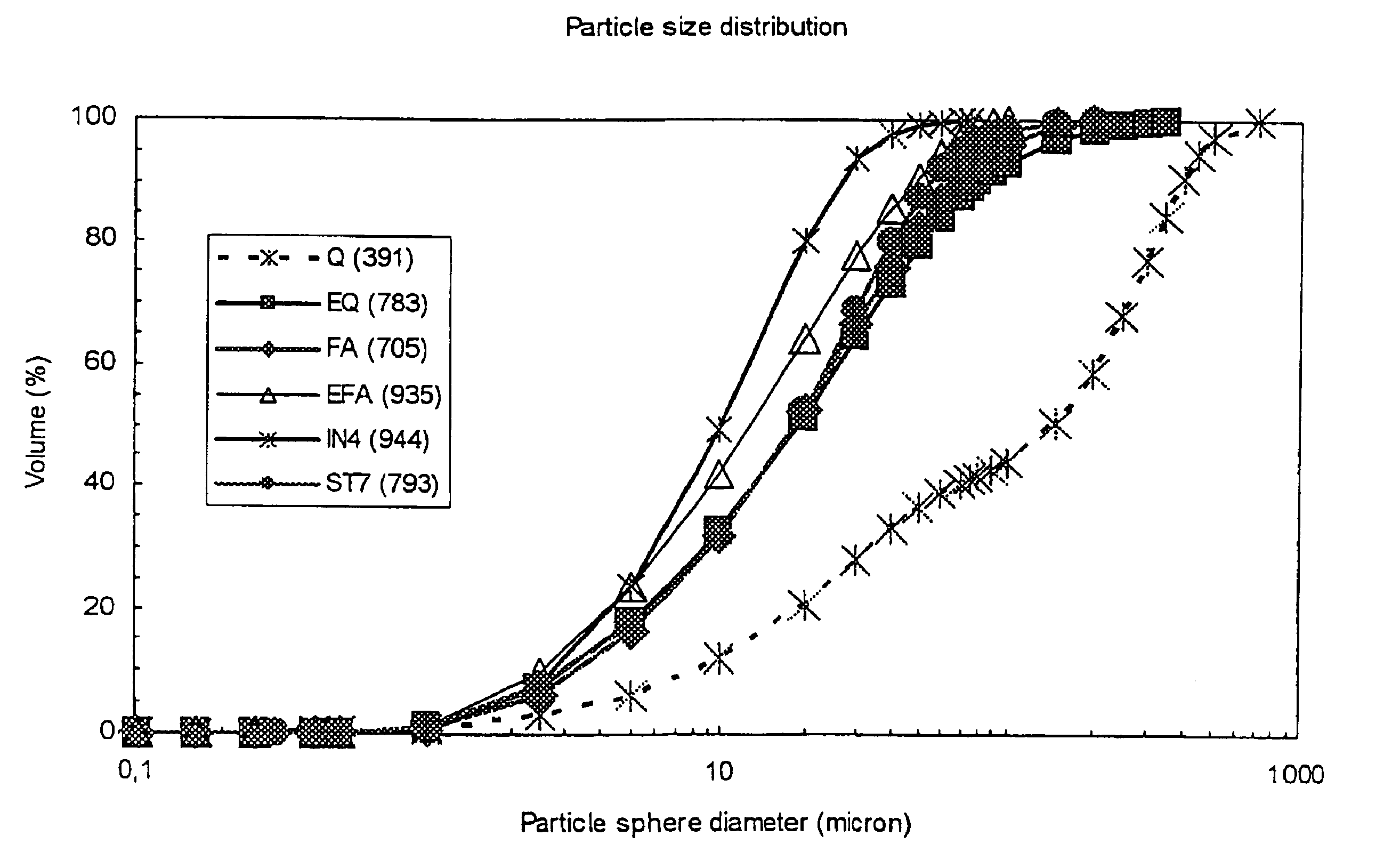

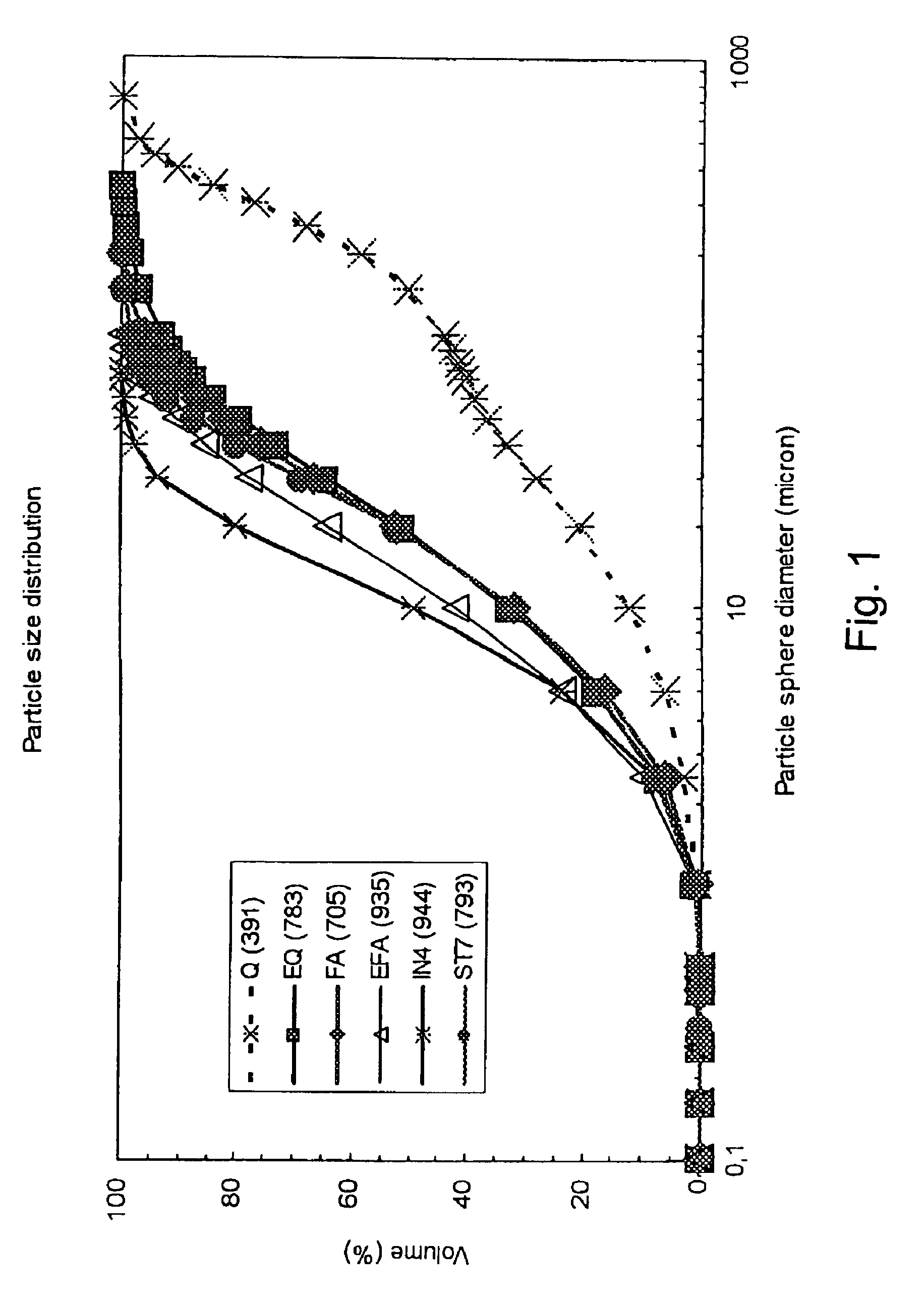

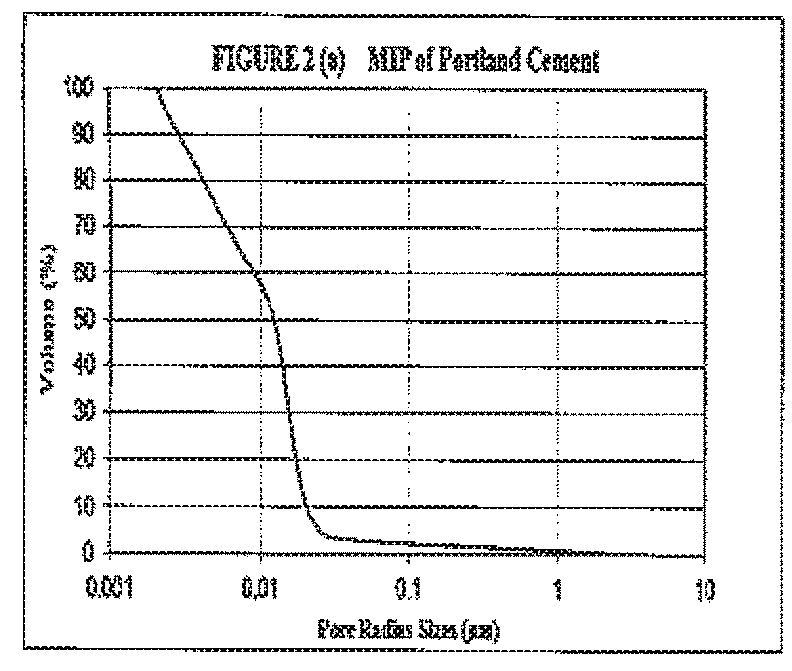

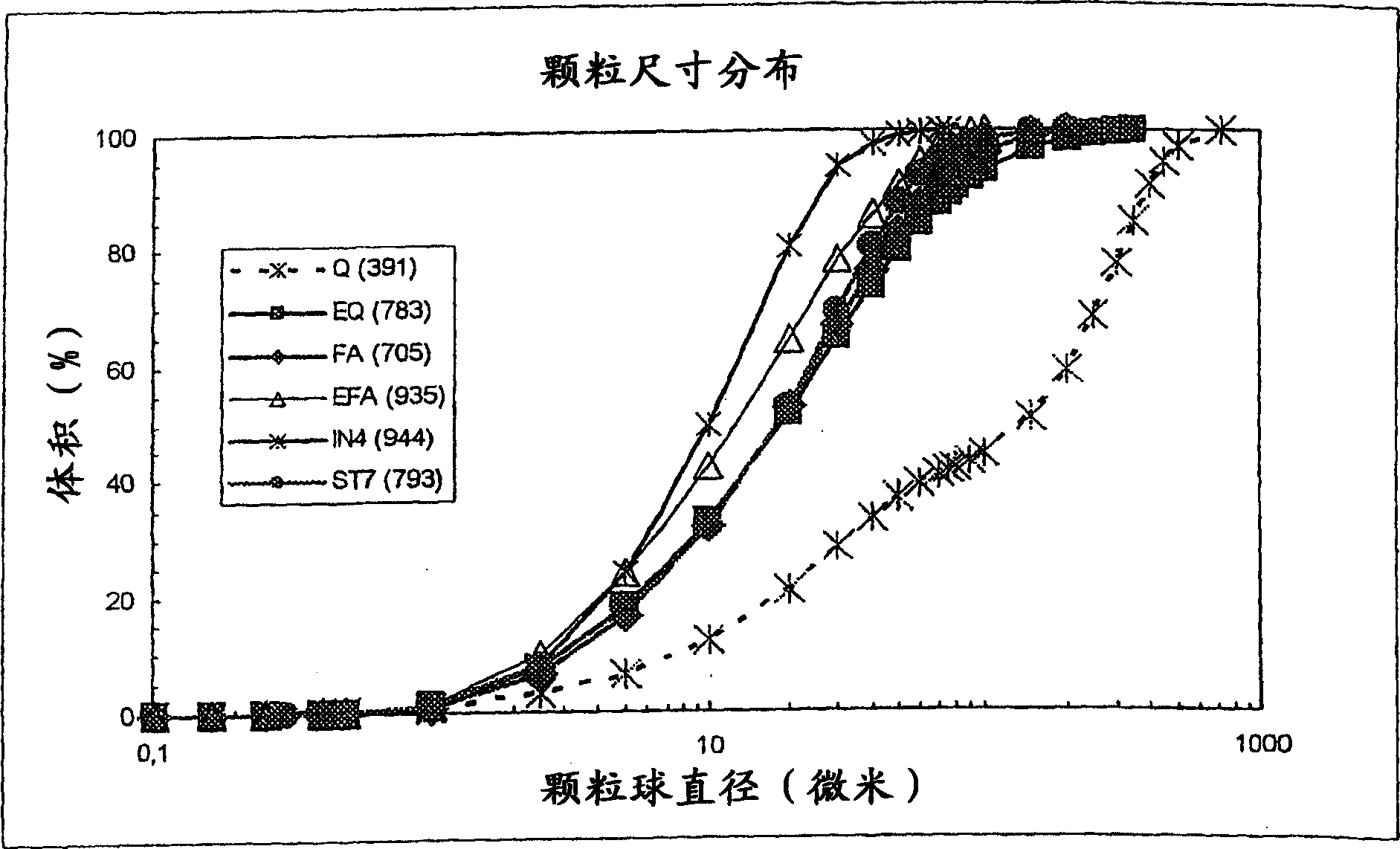

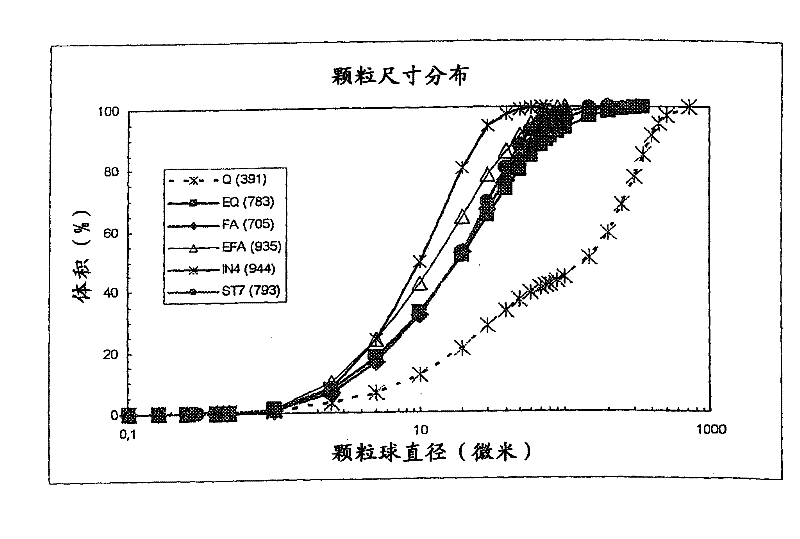

A process for producing blended cement in which the cement contains Portland Cement mixed thoroughly with a microfiller, and possibly a water reducing agent, to provide a dry cement mixture, and fine supplementary cementitious materials selected from the materials blast furnace slag, fly ash, quartz, silica, amorphous silicon dioxide, limestone, and recycled concrete. The supplementary materials are first subjected to a grinding step in a dry state to a specific surface of at least 1000 cm2 / g (Blaine). In a second step the ground supplementary materials are subjected to a grinding step together with at least 20% by weight of the total grinding mass of a highly reactive cement mixture in a dry state, to achieve a specific surface of at least 3000 cm2 / g (Blaine).

Owner:PROCEDO ENTERPRISES ETAB

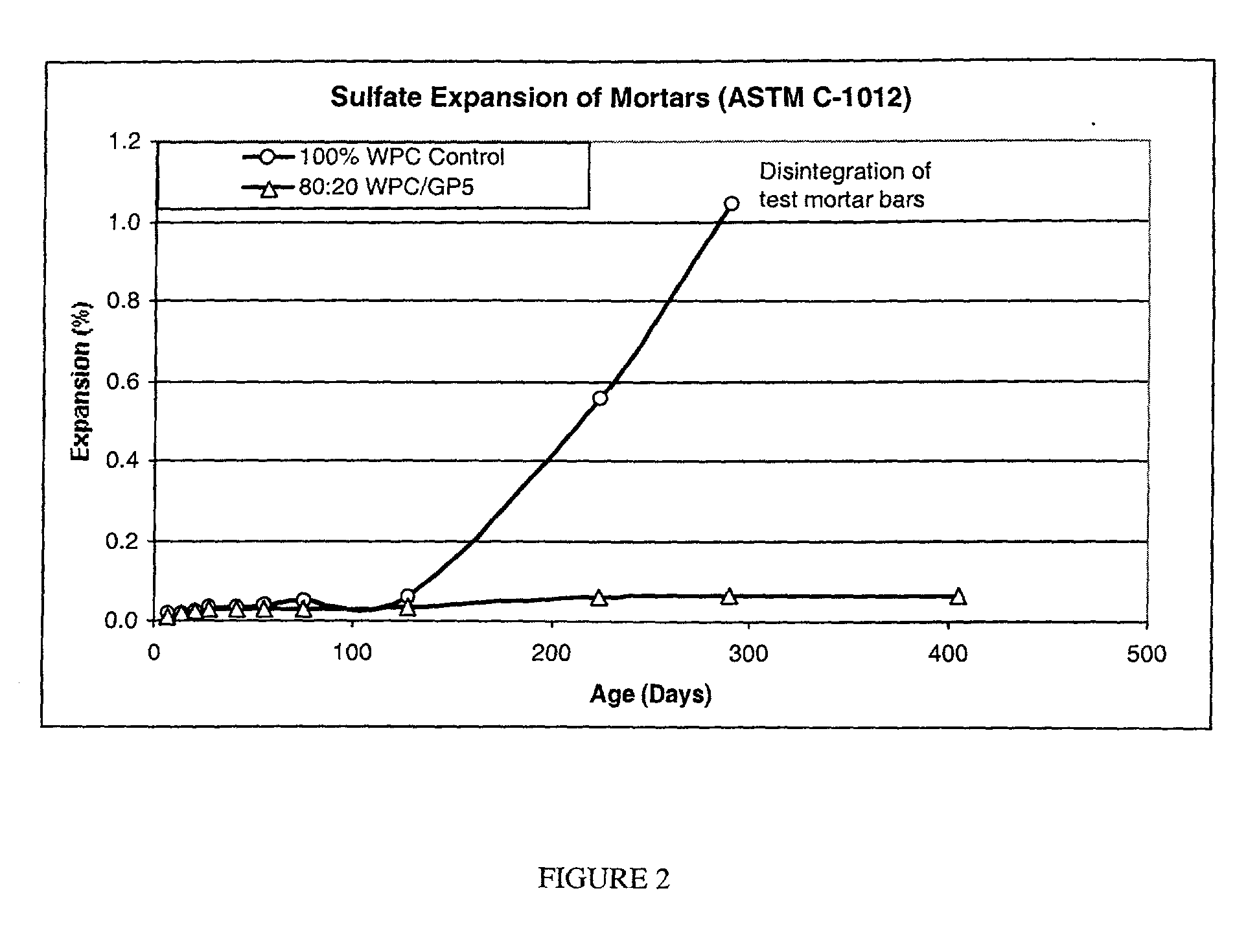

Process for producing a blended cement having enhanced cementitious properties capable of combination with class C fly ash

The present invention provides a method of producing a blended cement capable of meeting ASTM C-595 and C-1157 standards. The blended cement of the present invention contains portland cement clinker, calcium sulfate and volcanic ash. The volcanic ash utilized by the present invention has been subjected to heat in the range of between 800.degree. F. and 1300.degree. F. and contains between 40% and 45% hollow spheres unable to pass #325 sieve. The portland cement clinker, calcium sulfate and volcanic ash are interground to an ultimate blaine fineness of between 350 m.sup.2 / kg and 500 m.sup.2 / kg to produce a blended cement capable of subsequent admixing with class C fly ash to produce synergistic effects. Specifically, the addition of class C fly ash to the blended cement containing interground volcanic ash, portland cement clinker, and calcium sulfate is capable of producing an ultimate blended cement exhibiting improved sulfate resistance, improved workability, reduced permeability with regard to chlorides and sulfates, improved resistance to ASR and elimination of delayed ettringite formation.

Owner:CAPITOL AGGREGATES

Light aggregate foam concrete building blocks and method for manufacturing same

The invention discloses a lightweight aggregate cellular concrete block and a preparation method thereof. The lightweight aggregate cellular concrete block comprises cement, lightweight aggregate, water, a foaming agent and an additive. The lightweight aggregate is multihole lightweight aggregate with the stacking density of less than 1200kg / m3. The foaming agent is the substance, with which foam is formed in a material, thus forming a material in a closed pore or a connected pore structure. The additive is one, several or none of concrete common additives and mineral additives. In the preparation method, the cement, the additive, the chemical foaming agent (or not involved) and water are weighted and fed into an agitator, and beaten into a mixed cement paste; the mixed cement paste is manufactured into a foamed cement paste through a foaming device; after the lightweight aggregate is added to the foamed cement paste, the mixture is beaten and poured. Subsequently, the mixture is moulded at one step and cured. The manufacturing cost of the lightweight aggregate cellular concrete block is low; the manufacturing process is simple and easy to control; regions, which are able to invest on the production of the lightweight aggregate cellular concrete block, are wider.

Owner:王格

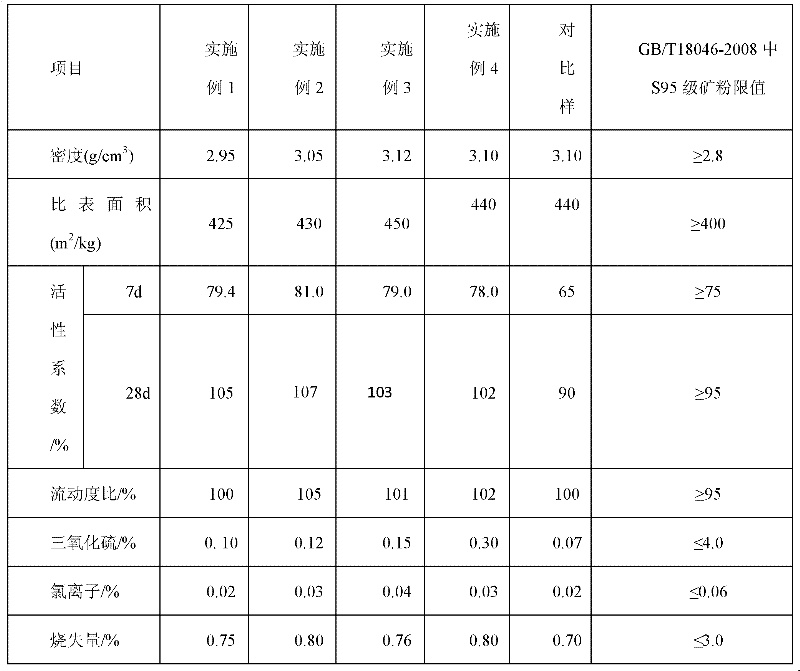

Modified steel slag composite admixture and preparation method thereof

InactiveCN102491664AOvercoming stability issuesImprove early activitySolid waste managementWork performanceSlag

The invention discloses a modified steel slag composite admixture and a preparation method thereof. The modified steel slag composite admixture comprises 55-75wt% of micro mineral slag powder, 20-40wt% of micro steel slag powder, and 1-5wt% of sintering desulphurization slag. Concrete prepared by mixing the modified steel slag composite admixture of the invention with cement has the following characteristics: the seven day active index is greater than 75%, the twenty-eight day active index is greater than 100%, the specific surface area is equal to or greater than 400m<2> / kg, the sulfur trioxide content is equal to or less than 4.0%, the chloride ion content is equal to or less than 0.06%, the ignition loss amount is equal to or less than 3.0%, and the autoclaving stability is qualified. The modified steel slag composite admixture which allows a low early strength disadvantage of steel slag composite admixtures to be overcome, working performances of concrete to be effectively improved, the strength and the endurance of concrete to be improved, and energy consumption required by slag grinding to be effectively reduced and is in favor of the low carbon economy realization, is a resource use type concrete admixture.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Composition and method for forming a sprayable materials cover

InactiveUS7284930B2Improve performanceImprove adhesionLandfill technologiesSolid waste disposalWater dispersibleSlurry

An alternative cover for landfill may be formed from a slurry mixture of water, cementitious binder, adhesion enhancing admixture and fiber. These constituents may be mixed and applied to cover landfilled wastes, granular material piles or for soil erosion control. The cover will harden to minimize water infiltration, wind blown dust, odor and affinity to birds, flies and other insects. The water may include tap water, landfill leachate and wastewater. The binder may include Portland cement, blended cement, cement kiln dust, class C fly ash, and / or calcium sulphate hemihydrate. The adhesion enhancing admixture includes water-dispersible polymers. The fibers may comprise shredded paper or wood or plastic fibers.

Owner:CJS TECH

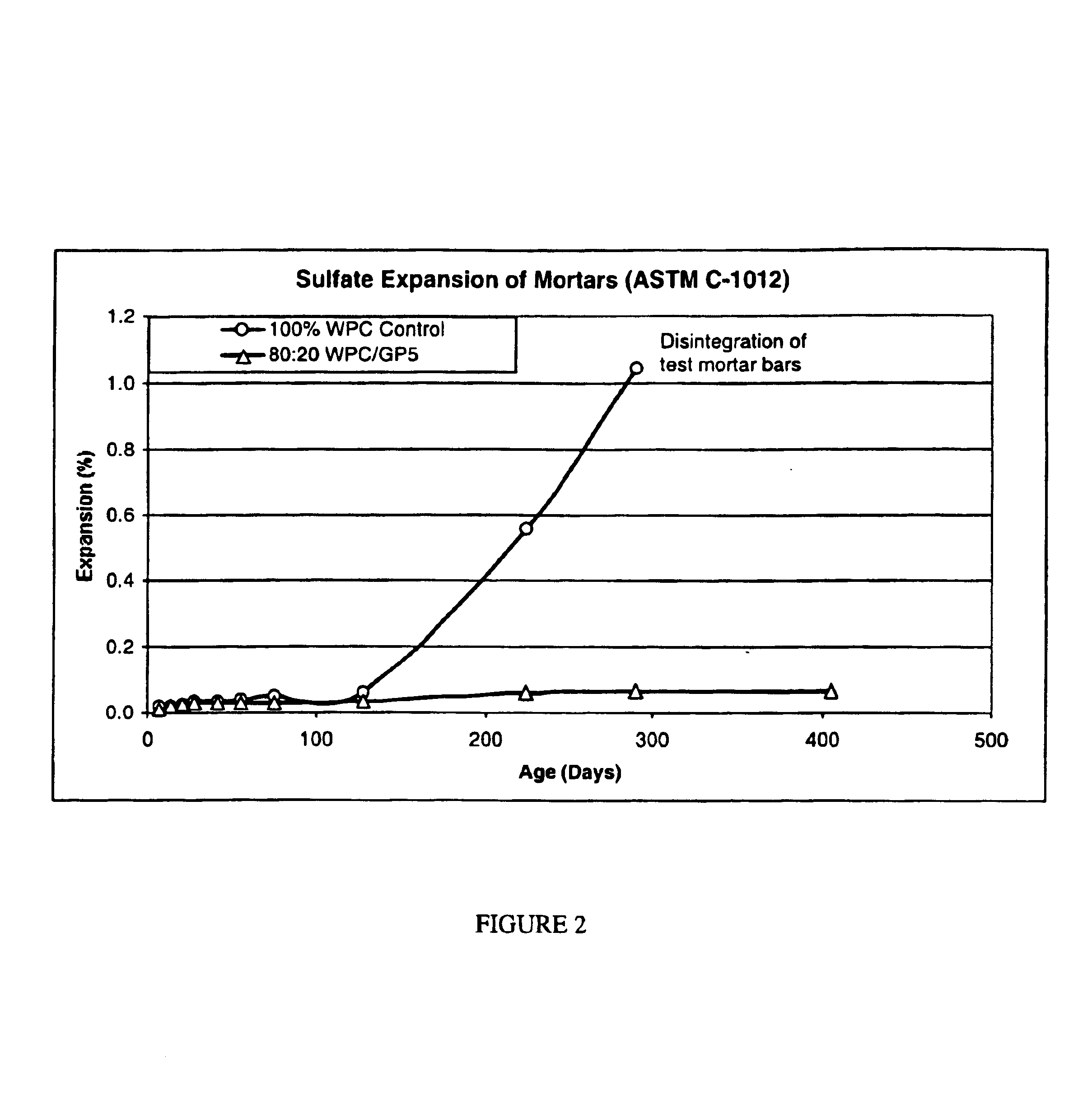

White pozzolan composition and blended cements containing same

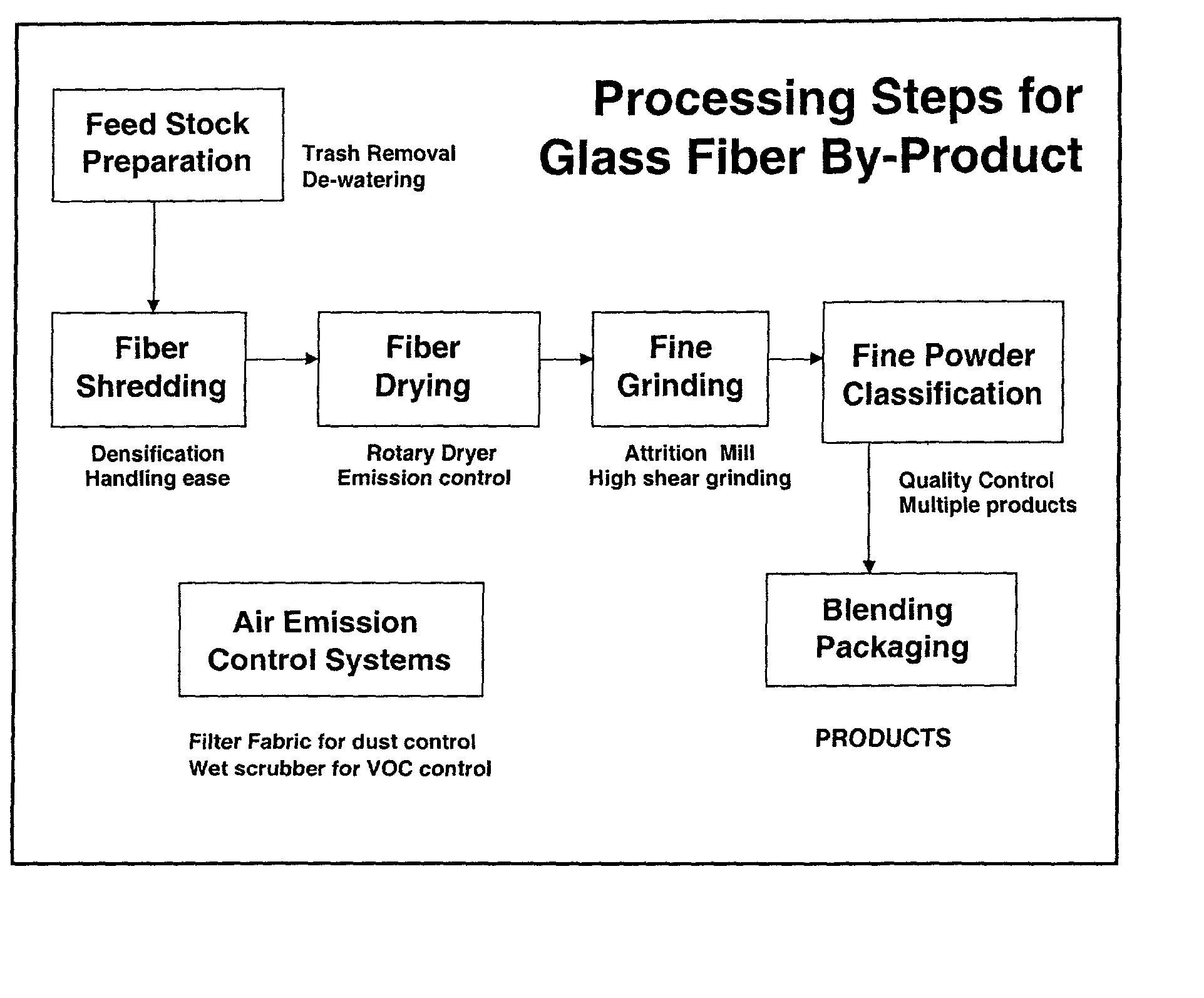

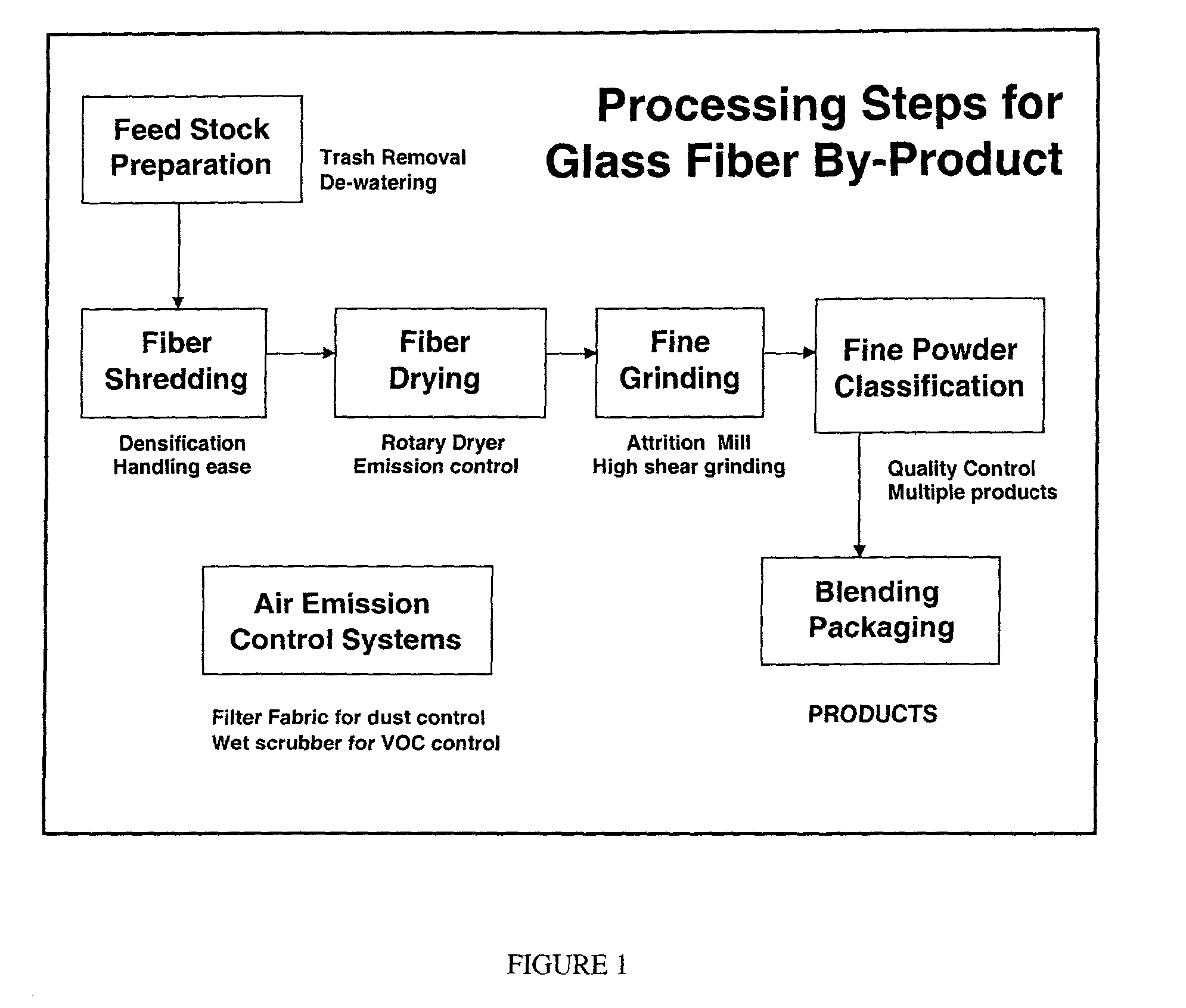

InactiveUS6776838B2Efficient workImprove compactionSynthetic resin layered productsCellulosic plastic layered productsGlass fiberPozzolan

A white pozzolan derived from by-products of manufacturing vitreous low alkali, low iron glass fibers, and to the method for producing the white pozzolan. The invention relates as well to cement compositions based on the white pozzolan, such as white and pigmented blended pozzolanic cements of high durability for use in applications such as white or colored architectural concrete, building materials, and manufactured cementitious products. The white pozzolan also functions as a high performance pozzolan with grey cement.

Owner:JOSEPH KEATING

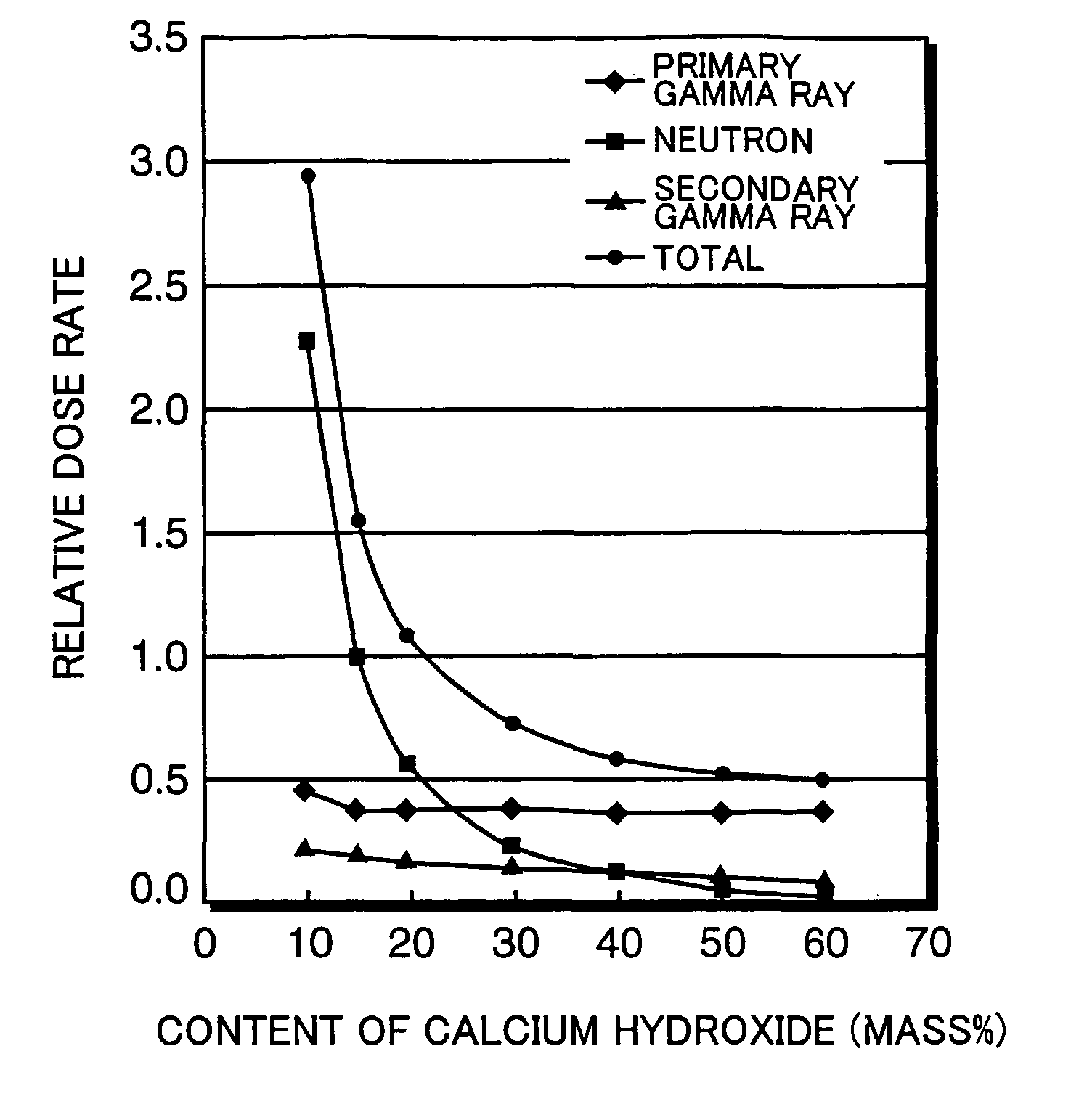

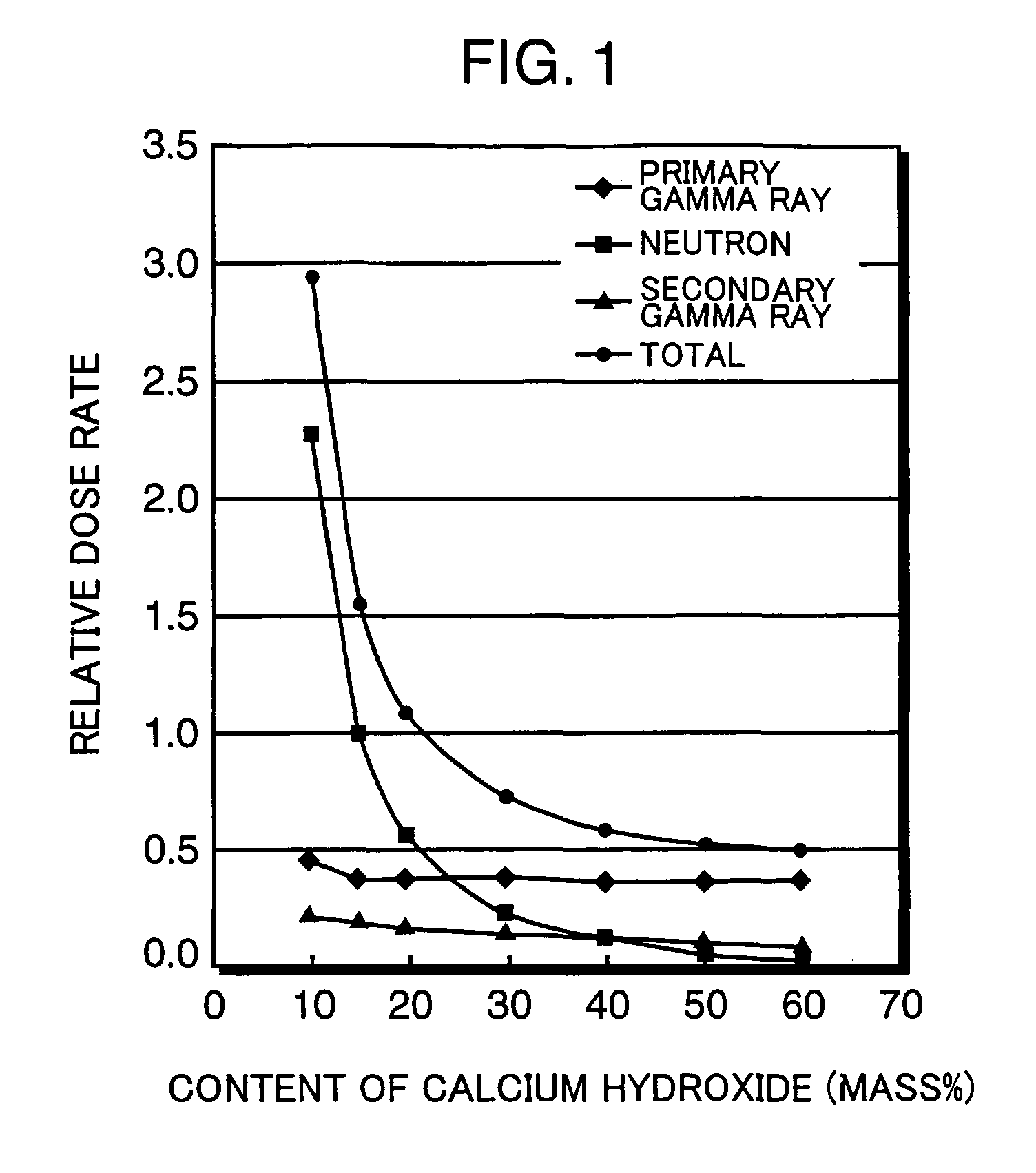

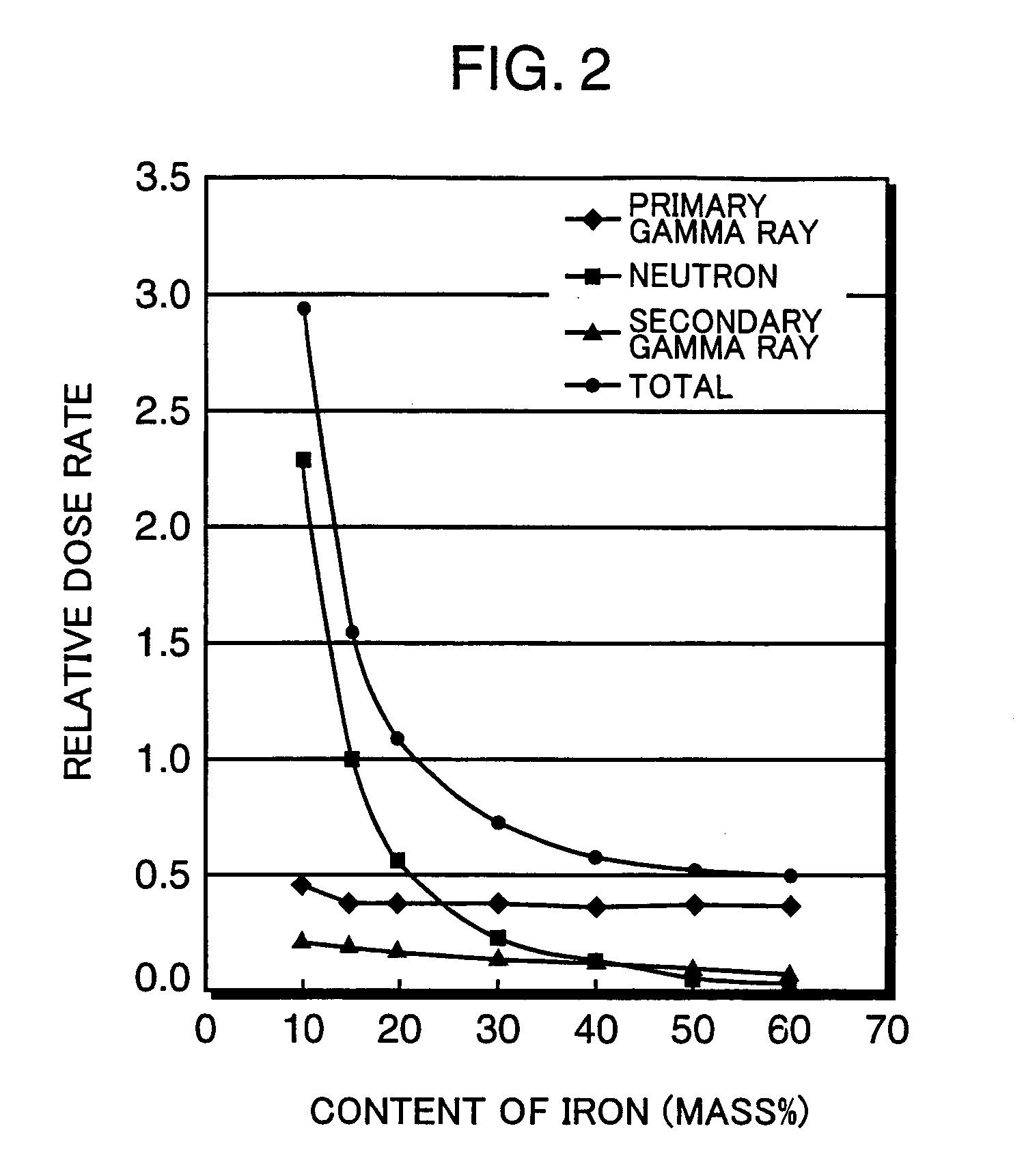

Cement composite, concrete, concrete cask and method of manufacturing concrete

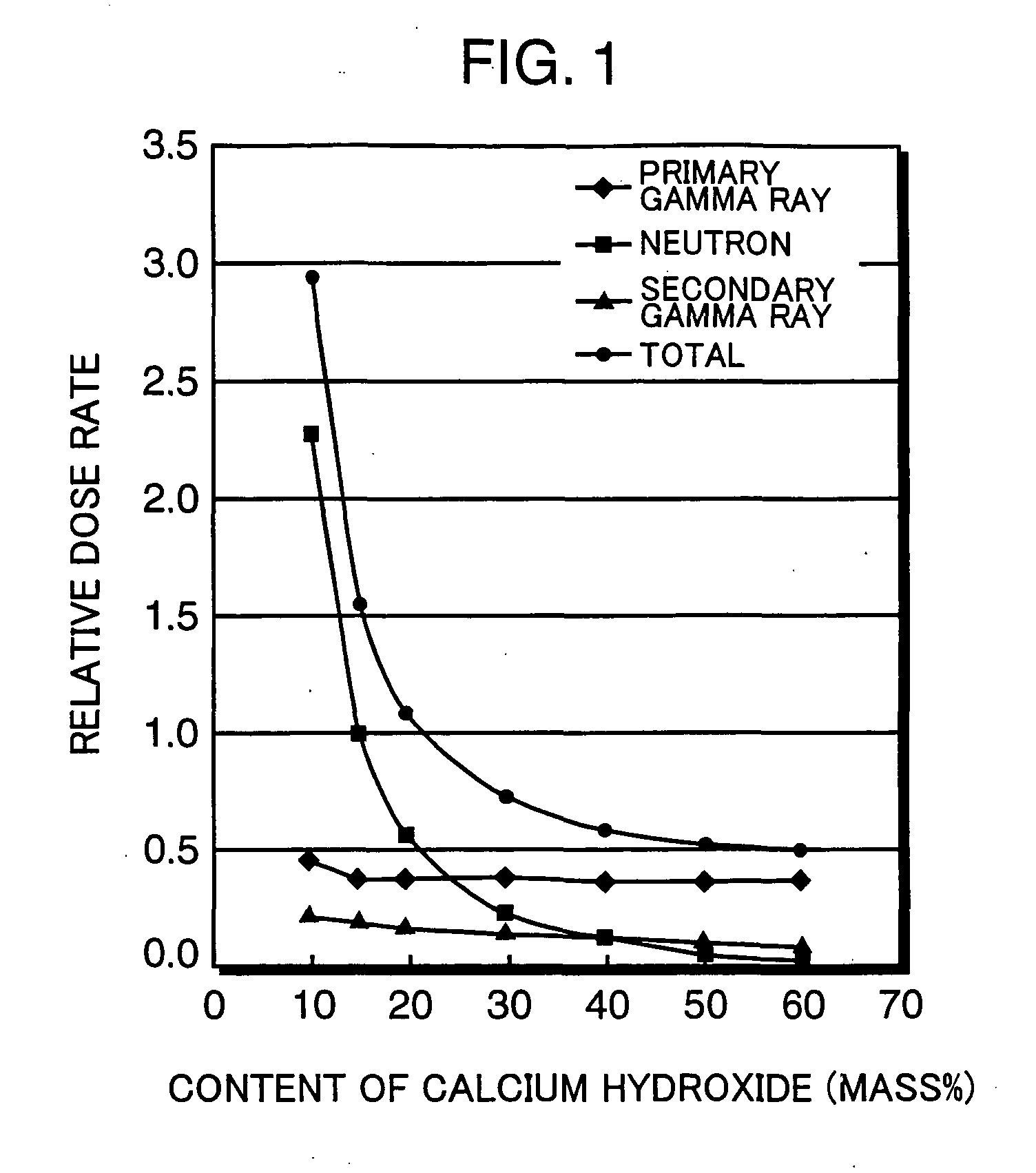

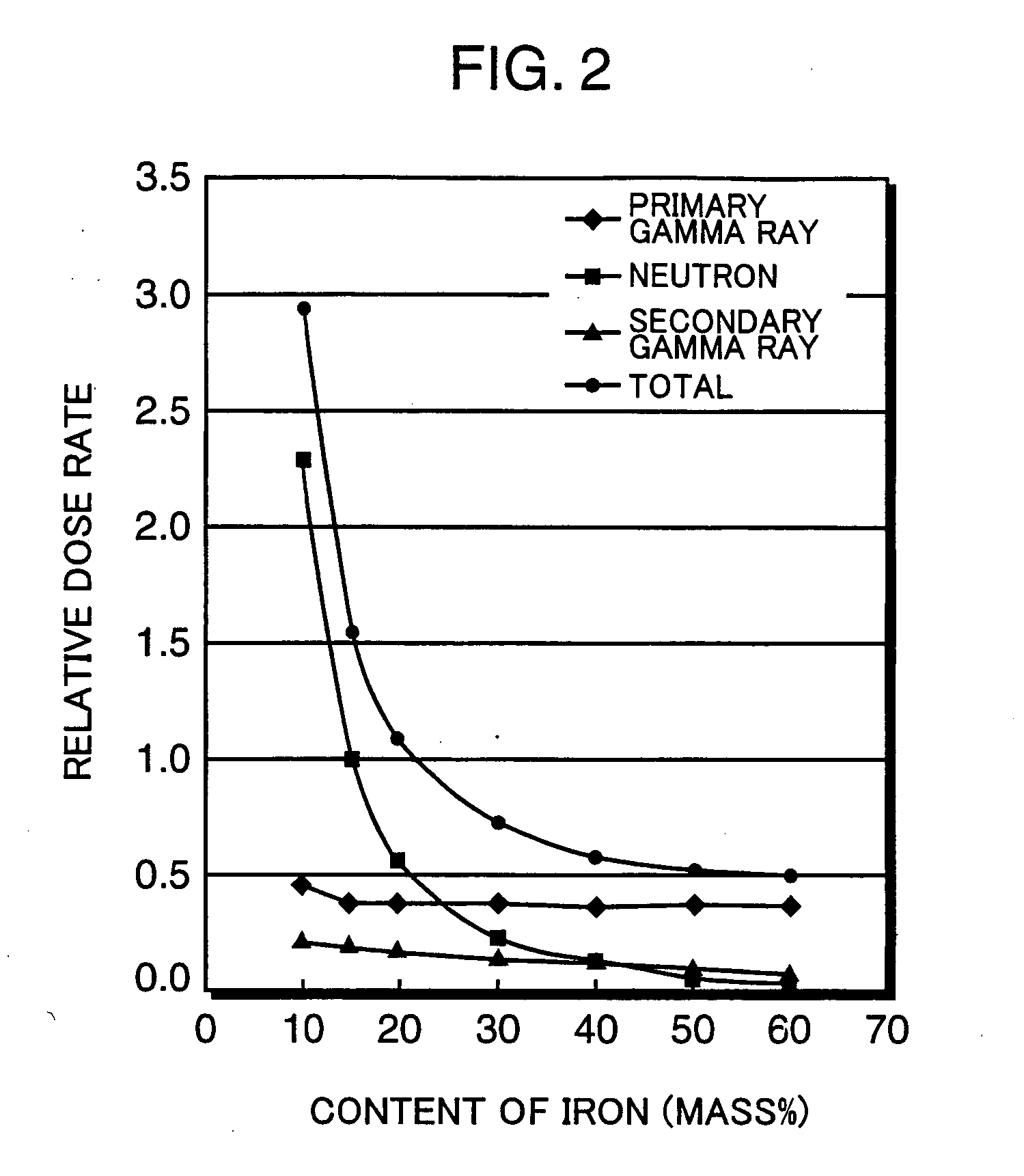

The invention provides a composite from which concrete featuring a sufficiently high heat resistance can be produced, as well as a high-safety sealed concrete cask having no opening (shielding defect) to offer high shielding performance that can prevent corrosion of an internal canister and release of radioactive material to the exterior. A concrete cask of the invention includes a cask body having a bottom but no lid in itself, and a lid which can open and close off a top opening of the cask body. Both the cask body and the lid are made of concrete manufactured by using a composite including Portland cement or blended cement containing Portland cement, which is mixed with water in such a manner that the content of calcium hydroxide falls in a range of 15% to 60% by mass after hardening through hydration reaction. Metallic heat-transfer fins are embedded in the cask body.

Owner:KOBE STEEL LTD +1

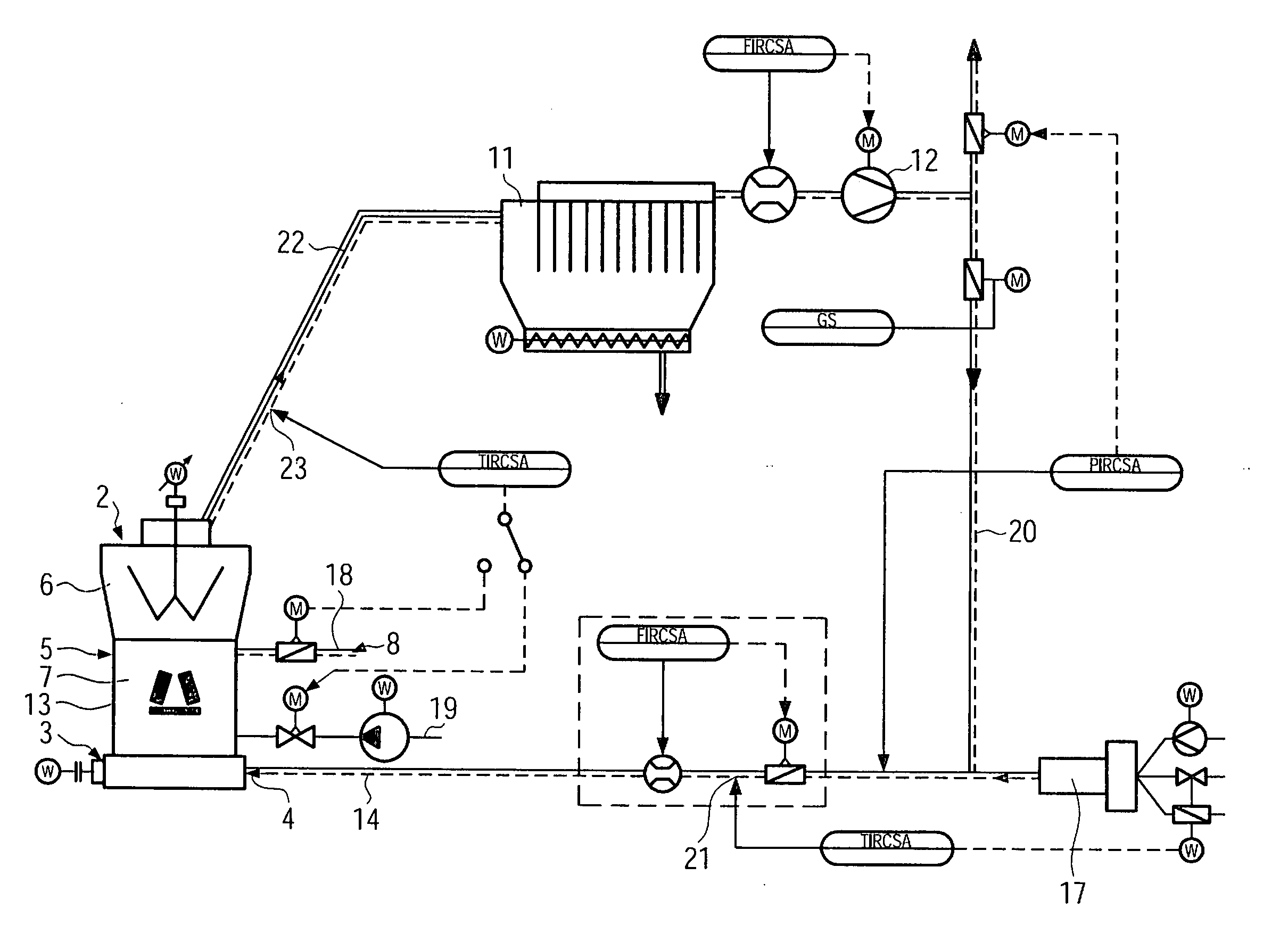

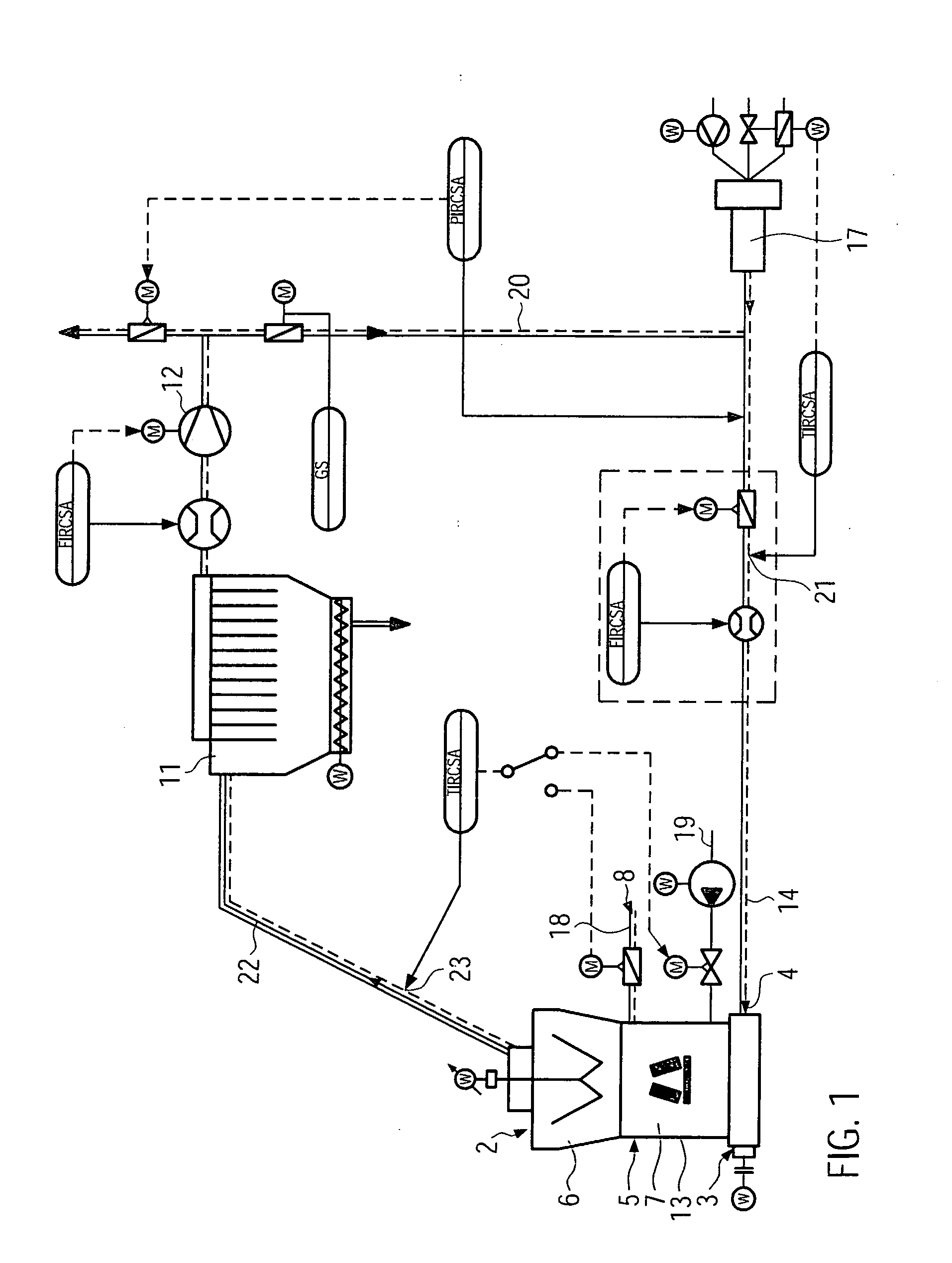

Method and Device for Grinding Hot, Wet Raw Material

The invention relates to a method and a device for grinding hot, wet raw material.The invention is particularly suitable for the cement industry and the grinding and simultaneous drying of cement clinker, slag and aggregates. In order to achieve a throughput increase and energy saving, as well as an improvement in the product quality, particularly with mixed cements, there is a simultaneous grinding and drying through a controlled supply of a cooling gas in the upper mill part with a relatively high hot gas inlet temperature in the lower mill part. The cooling gas supplies ensures a predetermined gas-product temperature downstream of the classifier and replaces or significantly reduces the disadvantageous cooling water injection.

Owner:LOESCHE GMBH

Cement composite, concrete, concrete cask and method of manufacturing concrete

InactiveUS7294375B2Improve heat resistanceImprove shielding effectLayered productsShieldingHydration reactionRadioactive agent

The invention provides a composite from which concrete featuring a sufficiently high heat resistance can be produced, as well as a high-safety sealed concrete cask having no opening (shielding defect) to offer high shielding performance that can prevent corrosion of an internal canister and release of radioactive material to the exterior. A concrete cask of the invention includes a cask body having a bottom but no lid in itself, and a lid which can open and close off a top opening of the cask body. Both the cask body and the lid are made of concrete manufactured by using a composite including Portland cement or blended cement containing Portland cement, which is mixed with water in such a manner that the content of calcium hydroxide falls in a range of 15% to 60% by mass after hardening through hydration reaction. Metallic heat-transfer fins are embedded in the cask body.

Owner:KOBE STEEL LTD +1

Substratum suitable for cultivation of northern crassostrea gigas and manufacturing method of substratum

InactiveCN106719186AEasy to stretchHigh strengthClimate change adaptationPisciculture and aquariaResistEpoxy

The invention provides a substratum used in an artificial breeding and production process of crassostrea gigas and a manufacturing method of the substratum, and provides a method for cultivating the crassostrea gigas by using the substratum. The manufacturing method of the substratum comprises the following steps: cutting and bundling polypropylene packing straps; then wrapping the outer surface of the polypropylene packing straps with mixed cement paste; and air-drying the polypropylene packing straps to obtain the substratum. The mixed cement paste comprises the following components in percentages by mass: 0.5-1% of epoxy resin, 10-15% of fine sand, 15-20% of shell powder and the balance of cement; and the total mass percentage is 100%. The substratum is made of materials obtained easily, is low in cost and high in strength, and resists stretching and seawater corrosion. By the manufactured substratum, seedlings are collected easily, and the seedling attachment effect is good. Compared with frequently used chlamys farreri, the substratum is better in effect.

Owner:OCEAN UNIV OF CHINA

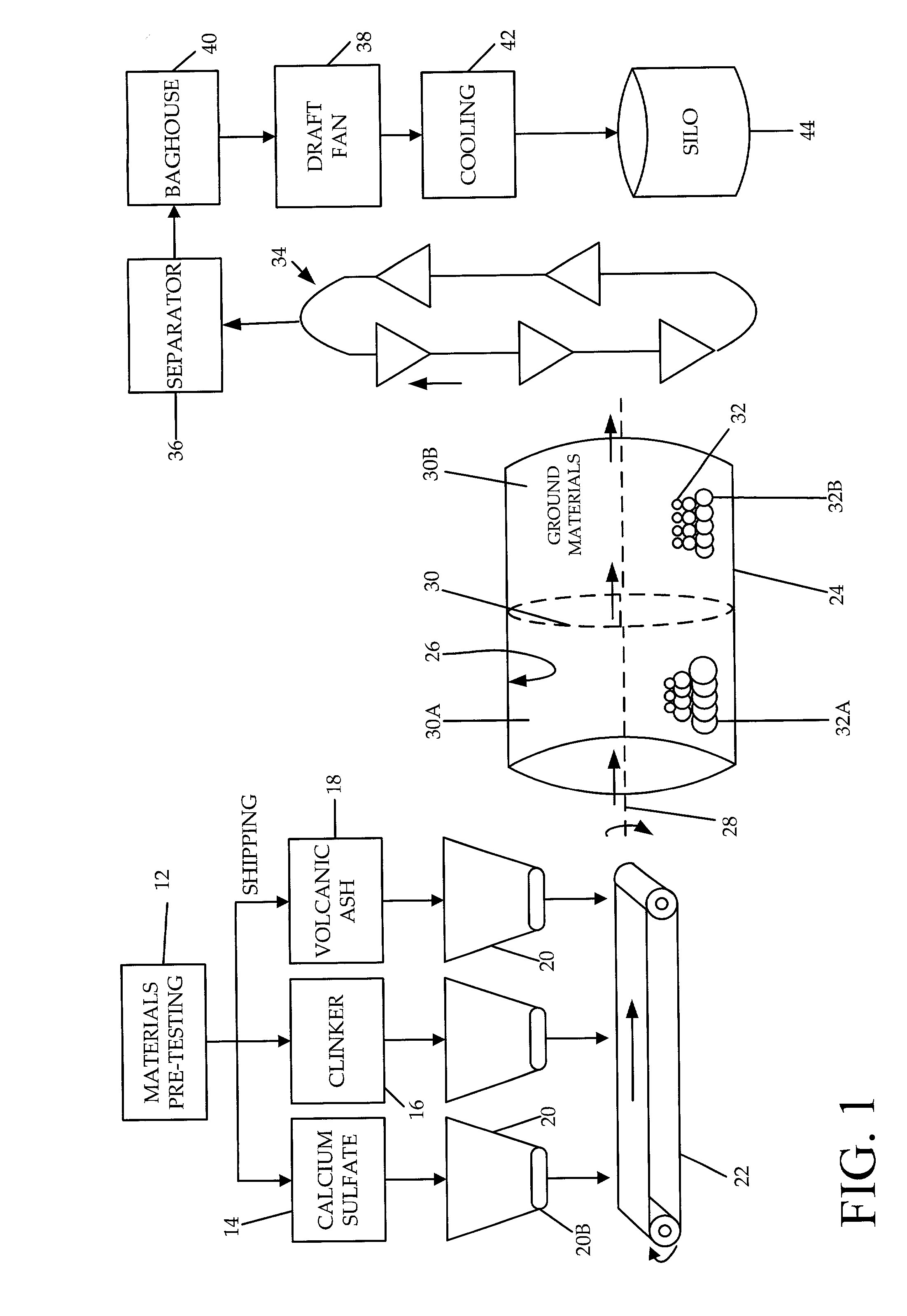

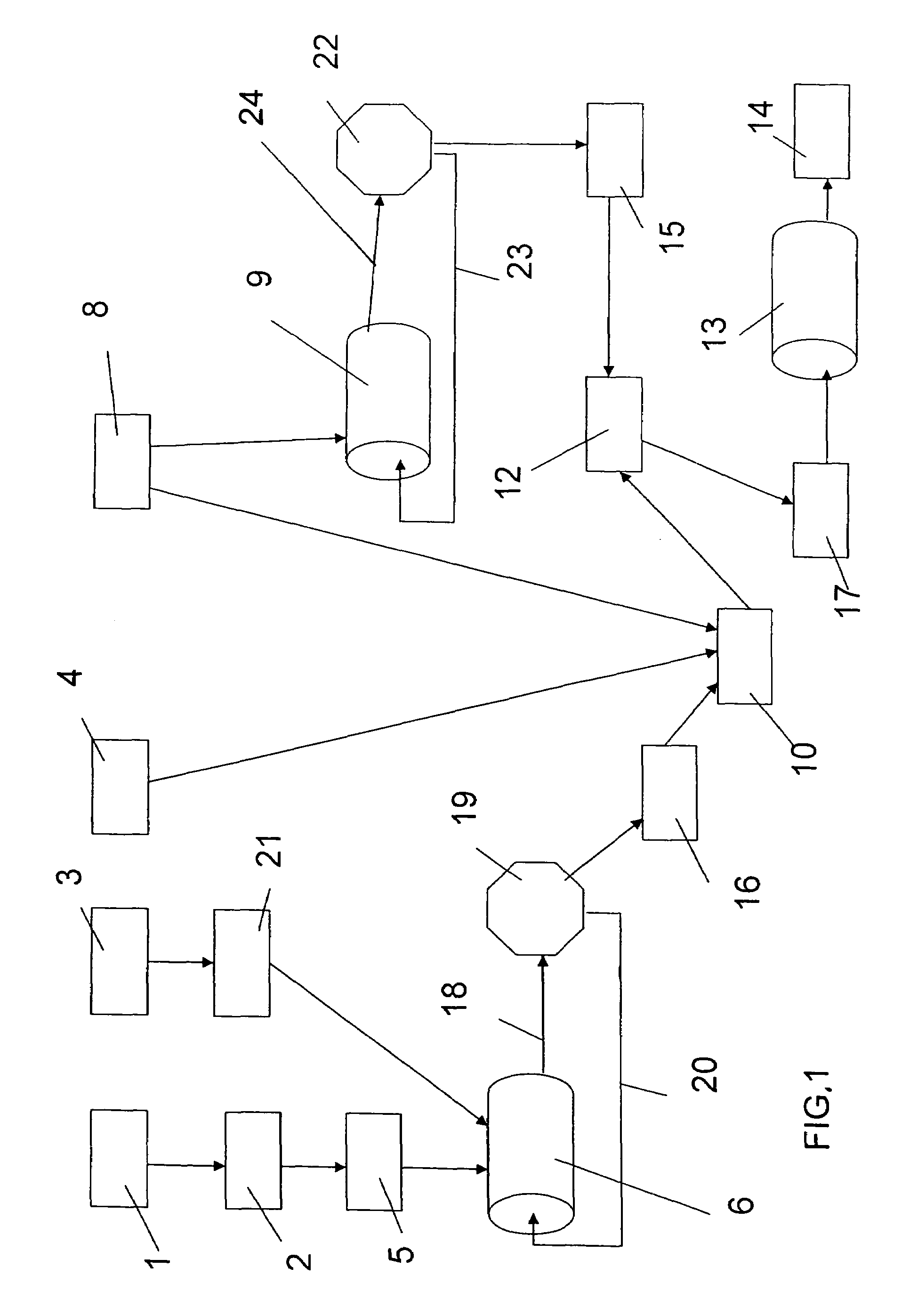

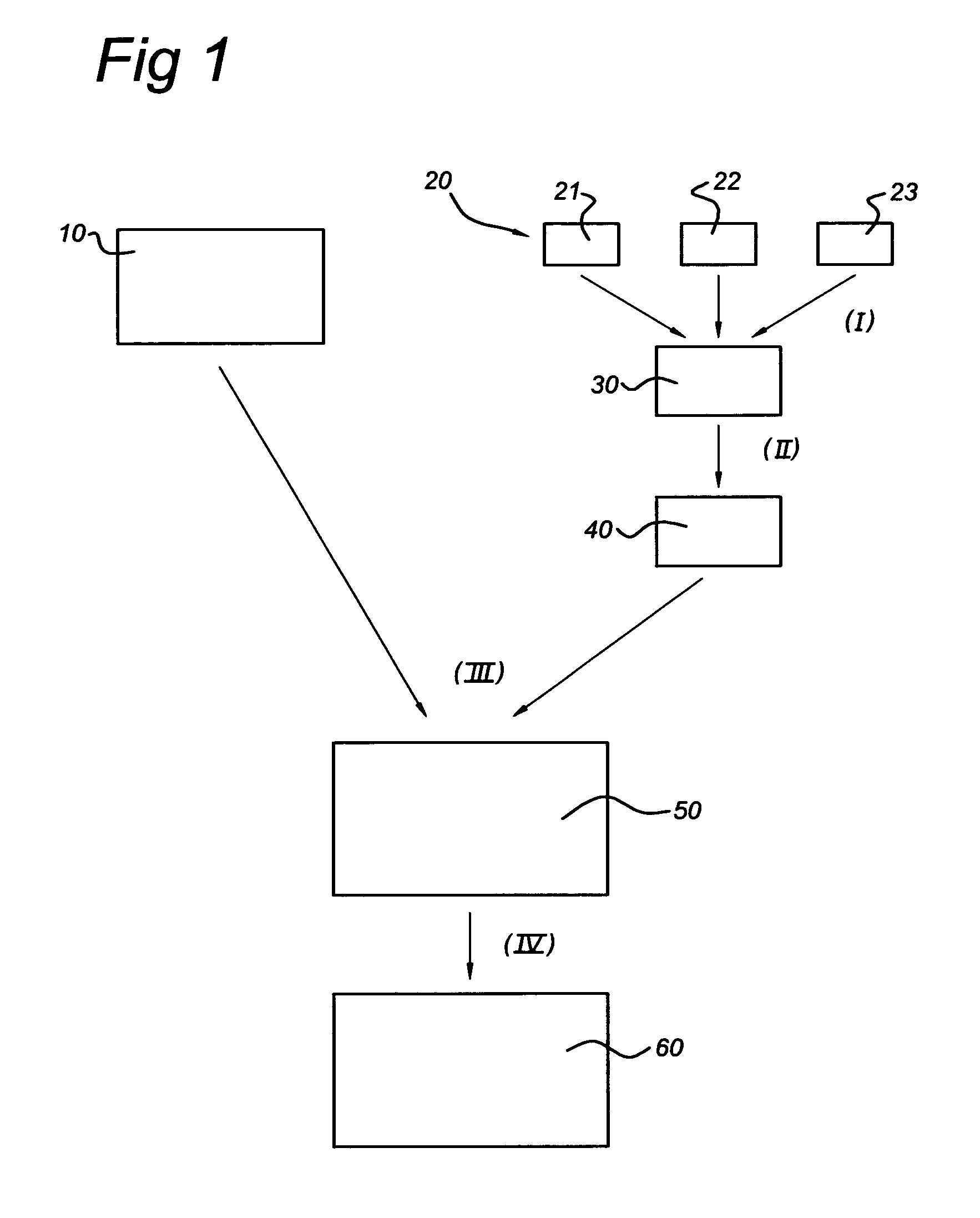

Processing system for manufacturing composite cementitious materials with reduced carbon dioxide emissions

A processing arrangement for manufacturing composite cementitious materials, such as hydraulic blended cements, with significantly reduced Portland clinker minerals content. The arrangement includes a milling unit for pregrinding supplementary cementitious materials and highly reactive pozzolans or mineral fillers, such as fly ash, blast furnace slag, fine quartz, granitic quarry fines, and the like, and a milling unit for pregrinding the Portland cement. The pregrinding units are followed by grinding unit for grinding the preground components. The pregrinding units are adapted to work as an open circuit or as a closed circuit for the material being ground.

Owner:PROCEDO ENTERPRISES ETAB

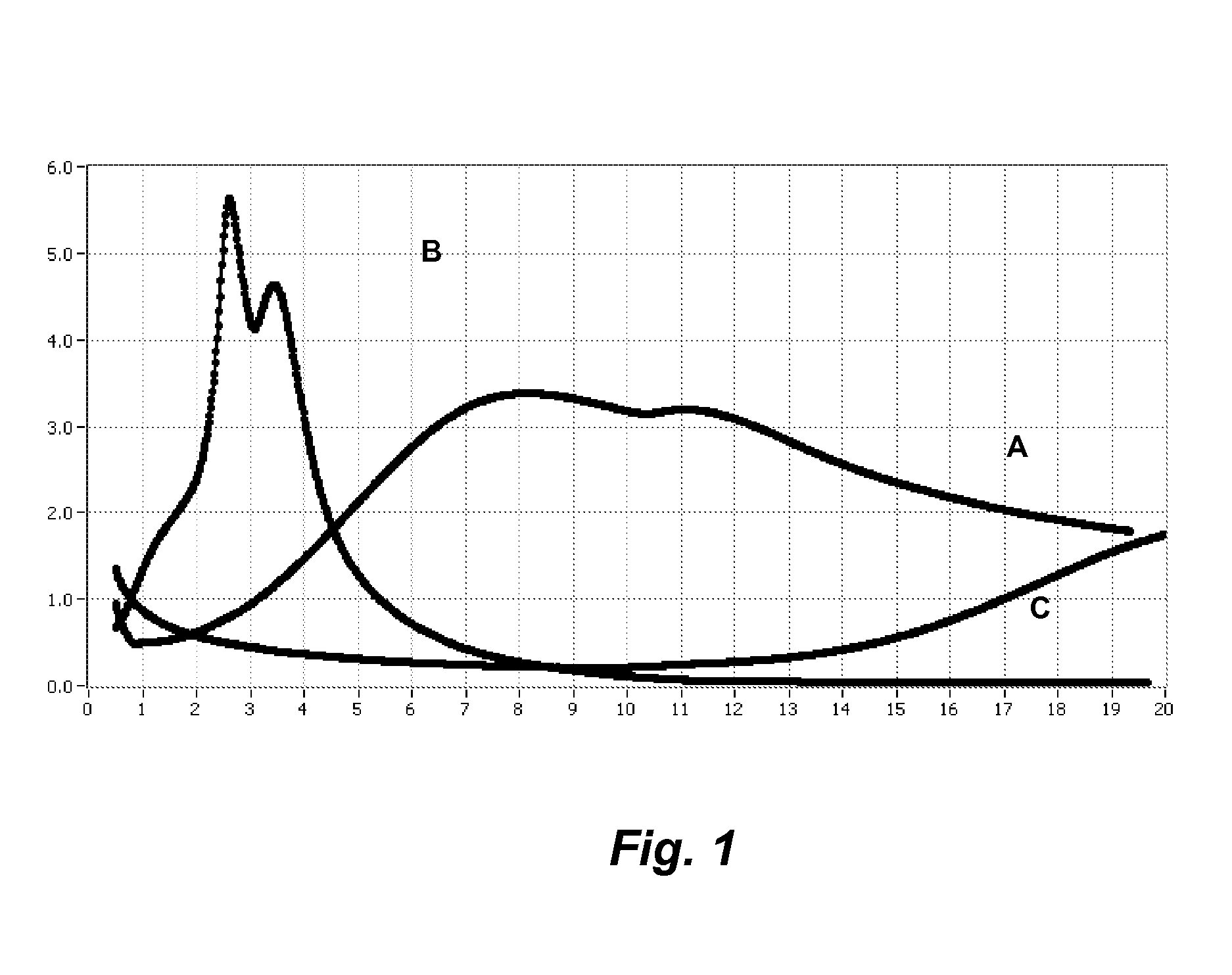

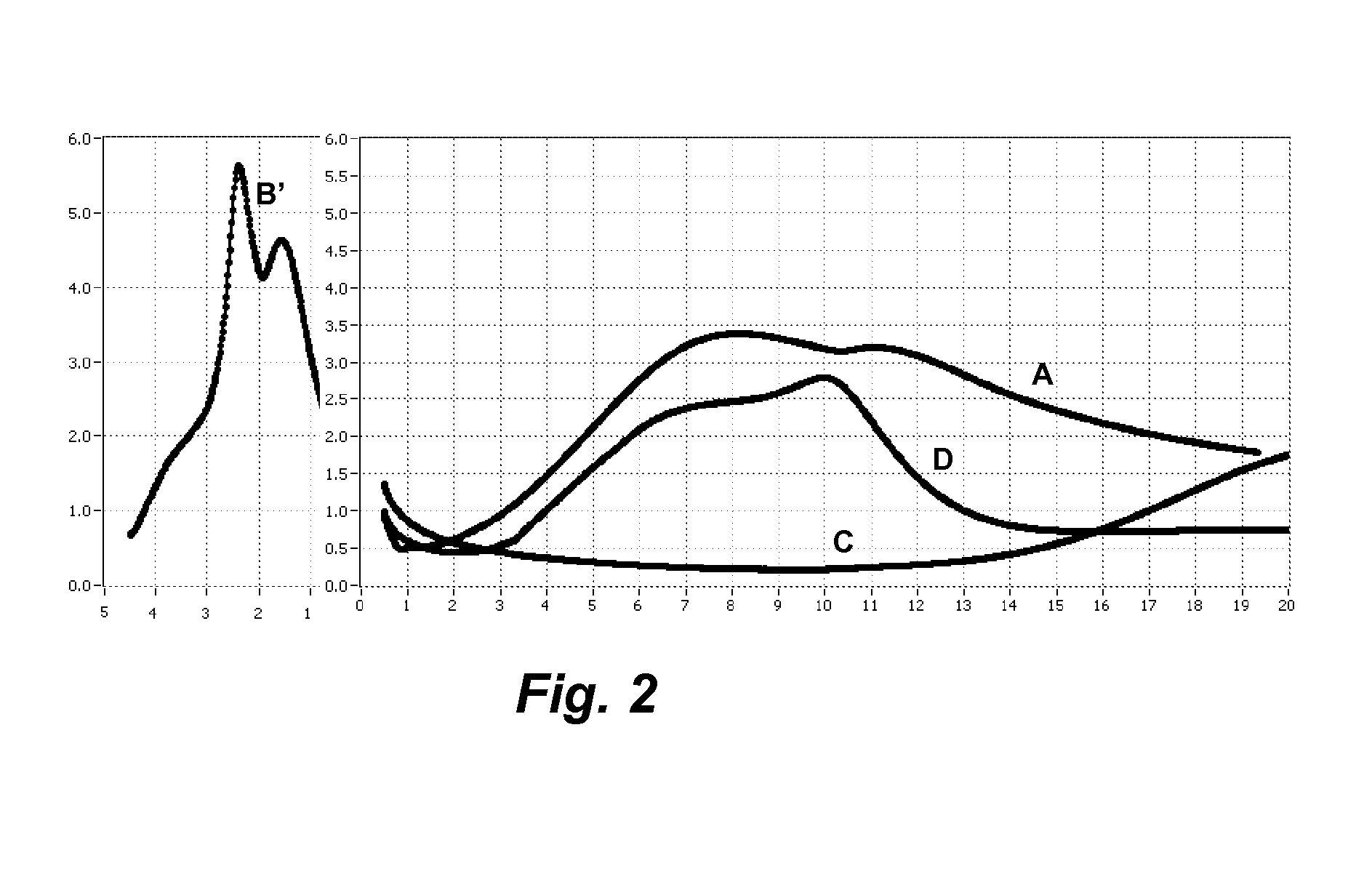

Suppression of antagonistic hydration reactions in blended cements

InactiveUS8518176B2Suppressing antagonistic hydration reactionAvoid interferenceSolid waste managementHydration reactionSlurry

Owner:GCP APPL TECH INC

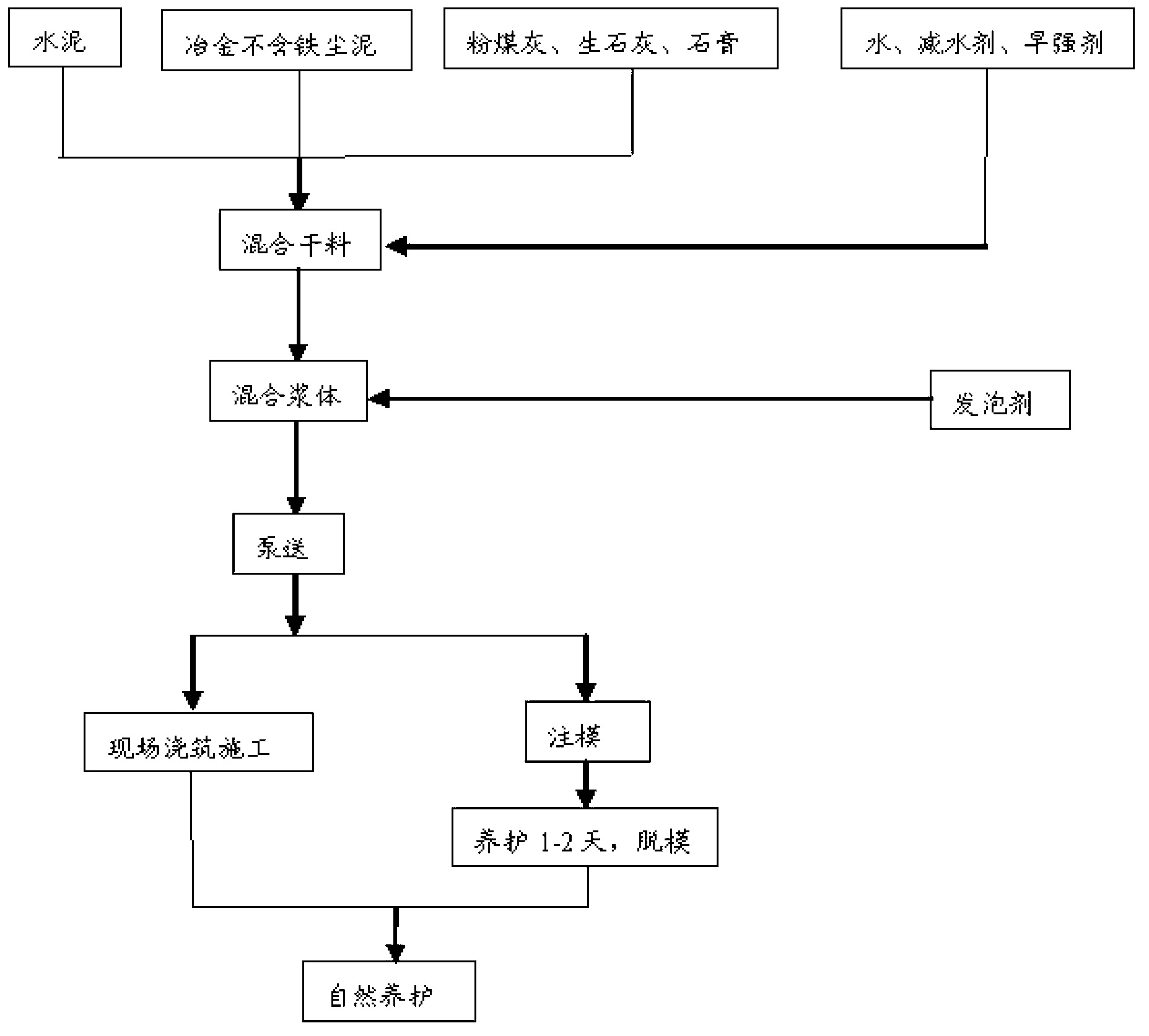

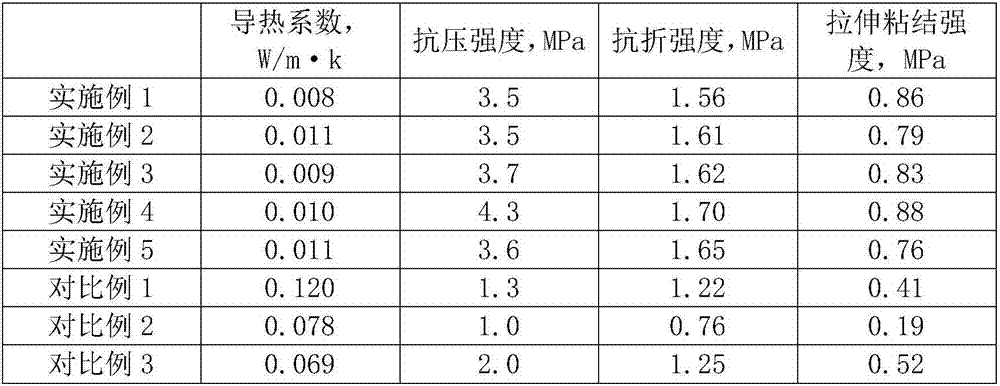

Waste-utilizing foam concrete and preparation process thereof

ActiveCN103011877AHigh compressive strengthImprove corrosion resistanceCeramicwareFoam concreteFoaming agent

The invention relates to the field of building materials, and in particular to waste-utilizing foam concrete and a preparation process thereof. The waste-utilizing foam concrete comprises dry materials, water and a foaming agent, wherein the dry materials comprise the following components in parts by weight: 21-50wt% of cement, 10-30wt% of metallurgical dust mud without iron, 20-30wt% of coal ash, 5-10wt% of quick lime, 2-5wt% of gypsum, 0.5-2.0wt% of water reducing agent, and 0.5-2.0wt% of early strength agent; the weight ratio of the dry materials to the water is 1:(0.38-0.50); and the weight ratio of the dry materials to the foaming agent is 1:(0.0008-0.006). According to the invention, by means of utilizing industrial solid wastes as raw materials, the industrial solid wastes are reutilized, so that wastes are turned into wealth. In addition, the amount of blended cement is further reduced, energy and sources which are in shortage day by day are saved, CO2 emission is reduced, and the ecological environment is protected.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

Method of making cement from tailings or rock fines containing silicate or siliceous compounds

InactiveUS20020033120A1Eliminate riskSolve the real problemSolid waste managementCompound aCrushed stone

A method of making cement from tailings or rock fines containing silicate or siliceous compounds includes grinding the tailings or rock fines to a size in the range of from about -250 to about 425 mesh to produce ground pozzolan. The ground pozzolan is mixed with Type 1 normal Portland cement or Type 3 high early strength Portland cement in a ratio of at least about 0.1:1 by weight to produce a blended cement.

Owner:FENICEM MINERALS

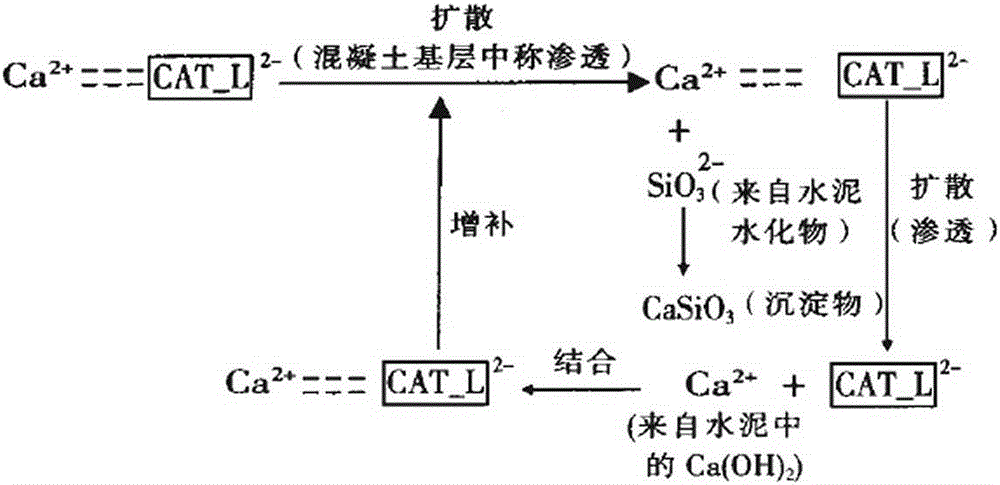

Slow-setting type waterproof mortar having self-repairing function and secondary permeability resistance as well as preparation method thereof

The invention discloses a slow-setting type waterproof mortar having self-repairing function and secondary permeability resistance as well as a preparation method thereof. The slow-setting type waterproof mortar having self-repairing function and secondary permeability resistance is prepared by using the following raw materials and water: a mixed cement, quartz sand, silica fume, heavy calcium, a capillary crystalline active master, a water reducer, an antifoaming agent, a coagulation accelerator and cellulose ether; and the mixed cement is composed of an ordinary portland cement and a quick-setting type sulphoaluminate cement. The slow-setting type waterproof mortar is used for repairing construction, if secondary leakage is happened, the capillary crystalline active master, the repairing mortar and a cement hydration product portlandite in concrete are continuously reacted for realizing self restoration, so that secondary anti-permeability effect can be reached, and secondary or multi-time restoration for regenerated cracks can be avoided.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

White pozzolan composition and blended cements containing same

InactiveUS20030047119A1Efficient workImprove compactionSynthetic resin layered productsCellulosic plastic layered productsGlass fiberMaterials science

A white pozzolan derived from by-products of manufacturing vitreous low alkali, low iron glass fibers, and to the method for producing the white pozzolan. The invention relates as well to cement compositions based on the white pozzolan, such as white and pigmented blended pozzolanic cements of high durability for use in applications such as white or colored architectural concrete, building materials, and manufactured cementitious products. The white pozzolan also functions as a high performance pozzolan with grey cement.

Owner:JOSEPH KEATING

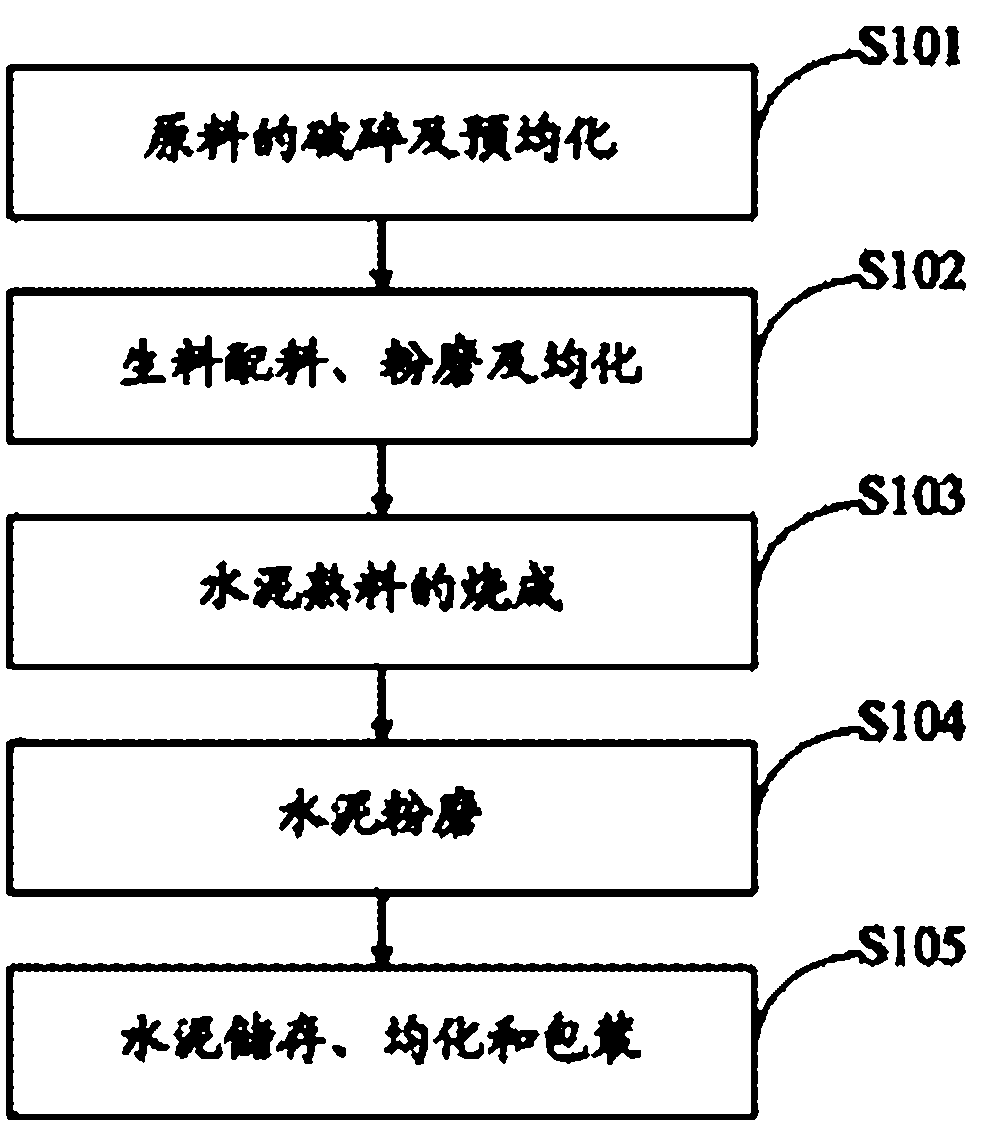

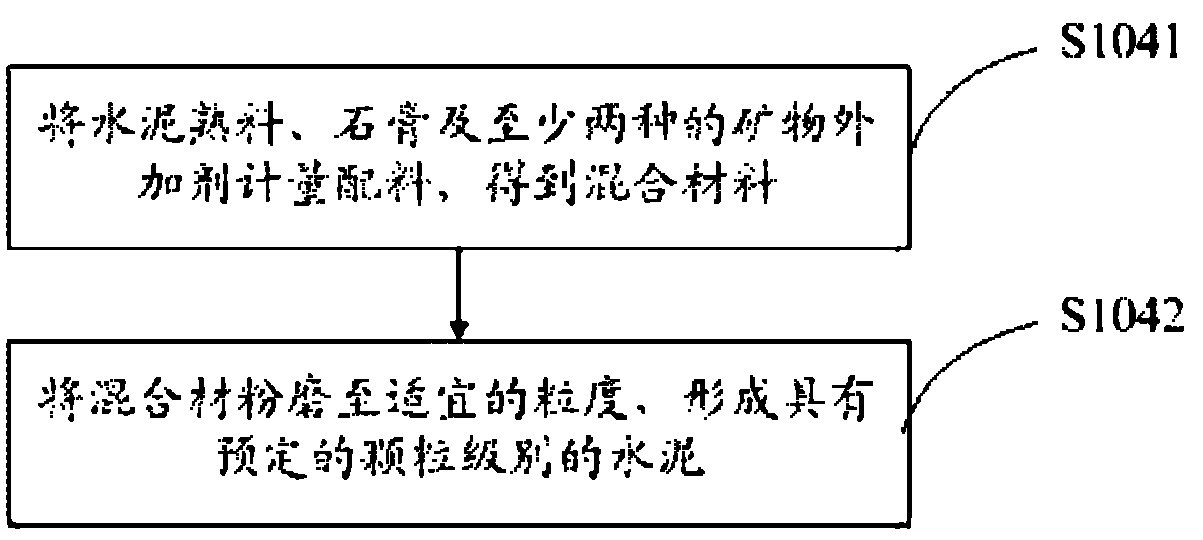

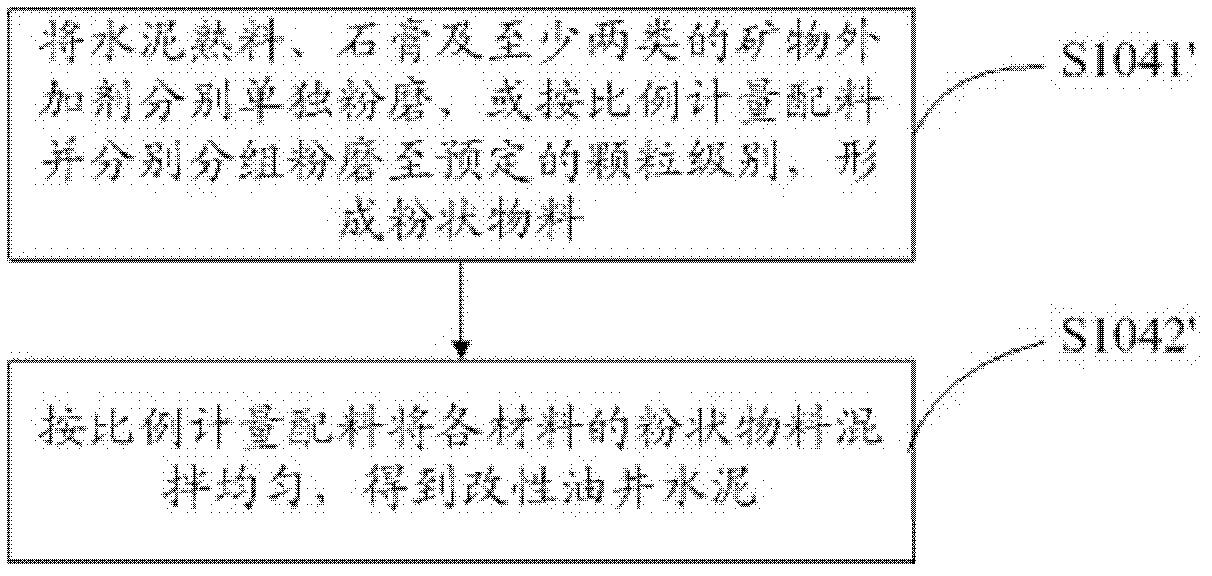

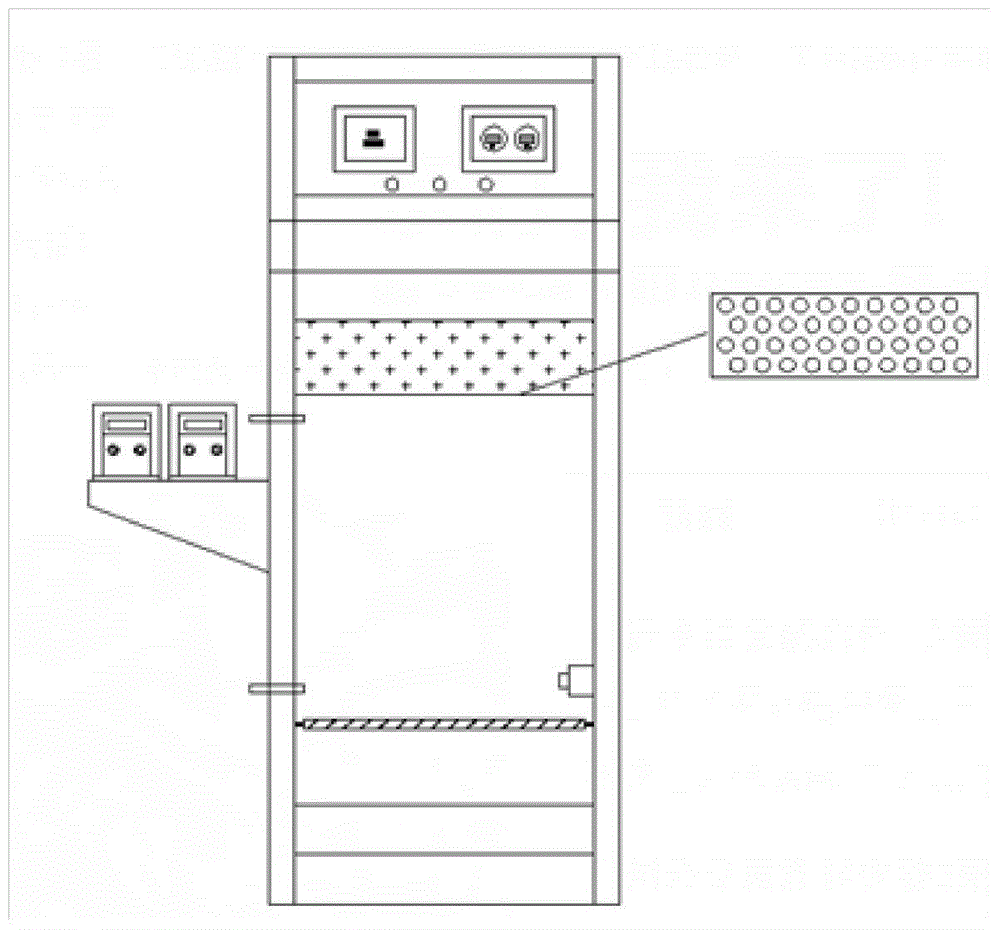

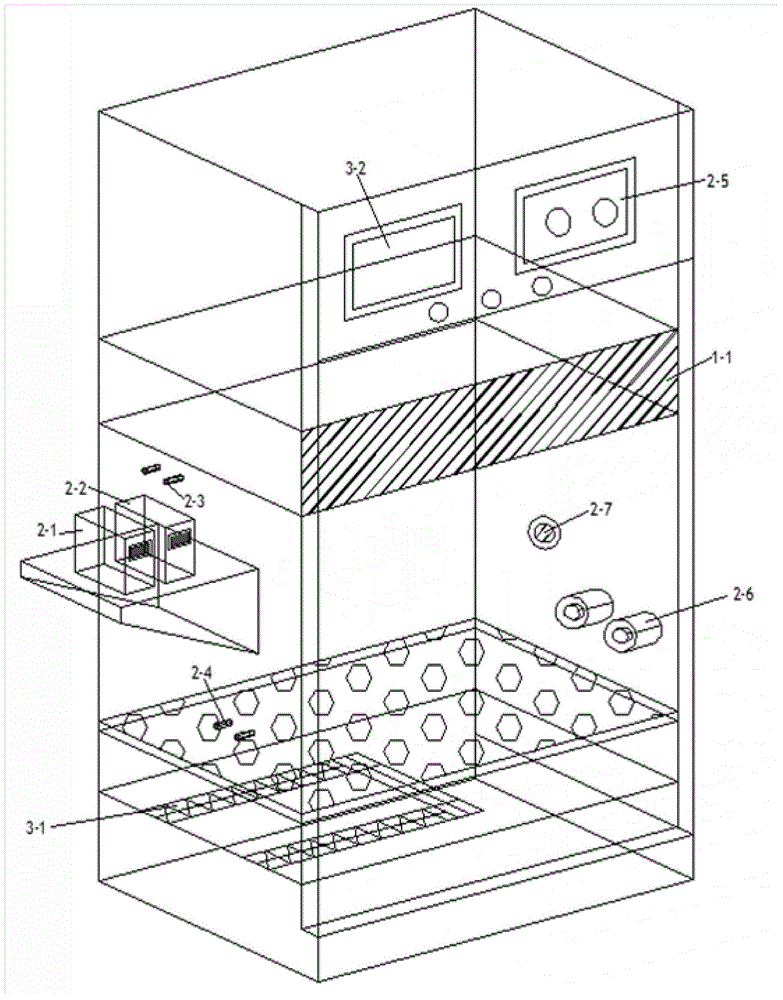

Modified oil-well cement, preparing method thereof and production line thereof

The invention discloses a kind of modified oil-well cement, a preparing method thereof and a production line thereof. The modified oil-well cement comprises components of cement clinker, gypsum and at least two mineral additives, and by mass ratio, the cement clinker occupies 20%-80%, the gypsum occupies 2%-10%, and all the mineral additives respectively occupy 0.1%-40%. The preparing method includes metering, dosing and grinding all components to form cement in a preset granular level, or independently grinding all components or metering and dosing all components in proportion and grinding all components in groups, and then metering and dosing all components in proportion and mixing all components evenly to obtain the cement. The production line comprises a metering and dosing system and a cement grinder, wherein the metering and dosing system meters, doses and mixes all components in proportion, and the cement grinder grinds mixed materials to cement in the preset granular level. Or the production line comprises a grinding system and a mixing stirrer, wherein the grinding system grinds all components independently or meters and doses all components in proportion and grinds all components in groups to be in the preset granular level, and the mixing stirrer evenly mixes powder materials of all components to be cement. The modified oil-well cement obtained through the preparing method and the production line properly reduces production cost on the basis of meeting the product performance index.

Owner:JIAHUA SPECIAL CEMENT

Healing agent for self-healing cementious material

ActiveUS8911549B2Good treatment effectImprove workabilityFatty acid chemical modificationNon-macromolecular adhesive additivesBiotechnologyMicrobiology

Owner:GREEN BASILISK BV

Preparation method of blended cement concrete capable of degrading NOx

The invention discloses a preparation method of blended cement concrete capable of degrading NOx. The preparation method comprises the following steps: (1) preparing lower-layer cement concrete; (2) preparing TiO2-blended polymer cement mortar, namely fully mixing titanium dioxide powder with active carbon to obtain a mixture of titanium dioxide powder and active carbon, uniformly mixing cement, the mixture of titanium dioxide powder and active carbon, an ethylene-vinyl acetate polymer and a dispersant, adding water and sand, and mixing to obtain the polymer cement mortar; (3) forming the blended cement concrete capable of degrading NOx. According to the preparation method, the newly stirred polymer cement mortar is spread on the surface layer of the lower-layer cement concrete prepared in the step (1) to form a cement-based photocatalytic mortar ultrathin surface layer, then a combined cement concrete surface layer is formed, and the curing operation is carried out to obtain the cement concrete; a test result shows that the decomposition rate of the blended cement concrete to NOx is more than 40%.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

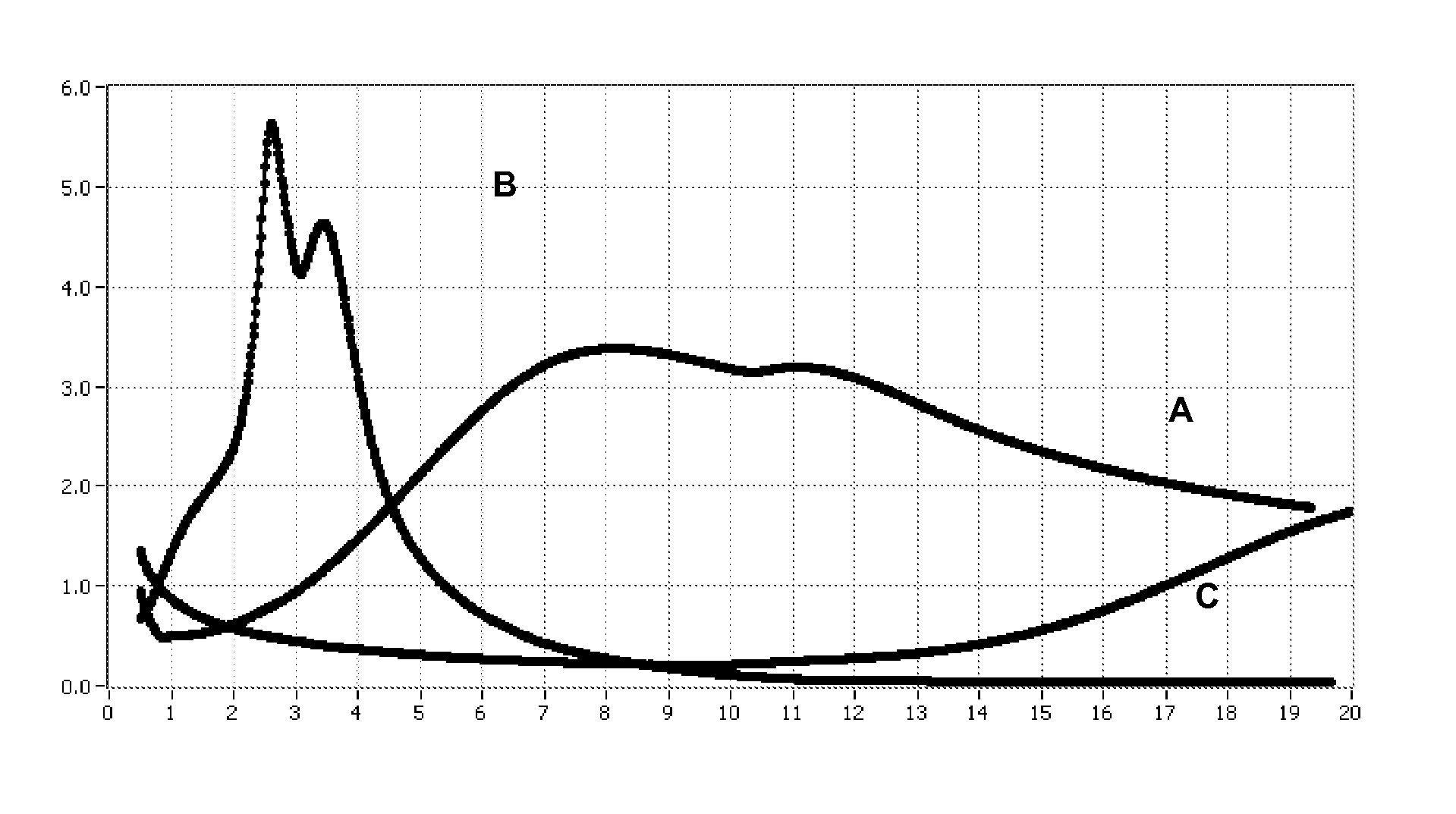

Suppression of antagonistic hydration reactions in blended cements

InactiveUS20120298011A1Suppressing antagonistic hydration reactionAvoid interferenceSolid waste managementHydration reactionSlurry

Method for suppressing antagonistic hydration reactions in Portland fly ash cement involves the use of unponded fly ash that is pre-hydrated, preferably as an aqueous slurry wherein fly ash, preferably having an alkaline earth metal oxide of at least 10% by weight, is soaked, whereby the hydration reaction of the resultant mixed fly ash and cement is accelerated when these components are mixed together with water to hydrate the cement. Blended Portland cement / fly ash compositions of the invention will also have higher early strength as well as shorter set time compared to untreated blends.

Owner:GCP APPL TECH INC

Fabrication method of novel lightweight mixed material wallboard

The invention relates to the technical field of fabrication methods of wall materials, in particular to a fabrication method of a novel lightweight mixed material wallboard. The fabrication method effectively employs industrial waste, sand and stone as substitutive raw materials, so that the use value of the industrial waste is increased; the production cost is lowered; the strength, toughness, sound insulation property, thermal insulation property, heat preservation effect, water resistance, moisture resistance and shock resistance of a finished product are good; and the weight of the wallboard is reduced. The fabrication method comprises the steps of 1), fabricating the industrial waste, the sand or the stone into pulp, wherein the industrial waste comprises coal cinder, grain slag, slag, phosphogypsum and fly ash; 2), mixing the pulp made from the industrial waste, sand or stone with cement, lime, gypsum and aluminum powder, stirring and casting, carrying out steam curing forming, and processing into particles with uneven sizes; 3), mixing the raw material particles processed in Step 2) with the cement and glass fiber yarn or polypropylene fiber yarn, stirring and casting into blocks; and 4), slotting and cutting the raw material blocks processed in Step 3) through slicing cutting equipment, and cutting the blocks into slices.

Owner:陈思源

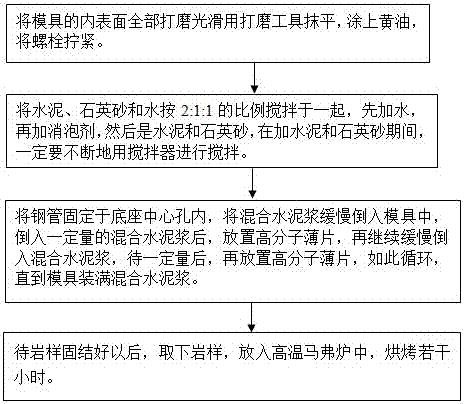

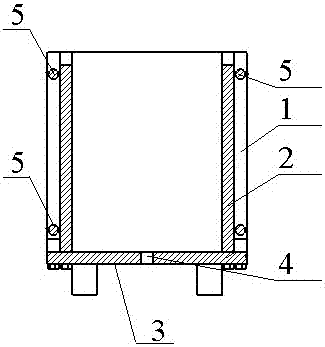

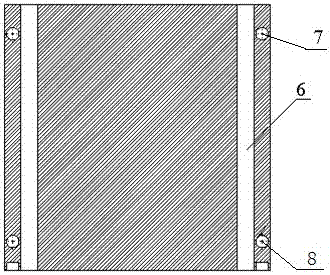

Preparation method of artificial core used for testing fracturing performance of rock containing controllable cracks

ActiveCN107884257AEasy to operateEasy to implementPreparing sample for investigationCement slurryRock sample

The invention relates to a preparation method of an artificial core used for testing the fracturing performance of rock containing controllable cracks. The preparation method of the artificial core used for testing the fracturing performance of the rock containing controllable cracks comprises the steps that mixed cement slurry is prepared; a mould is ground to be smooth and then coated with grease, a steel pipe is inserted into the mould through a central hole of a base, and the bottom of the steel pipe is exposed out of the mould; after a certain amount of mixed cement slurry is slowly poured into the mould, the surface of the mixed cement slurry is flatted, some high molecular slices are arranged on the surface of the mixed cement slurry, after the high molecular slices and the mixed cement slurry are stabilized, mixed cement slurry continues to be poured into the steel pipe, high molecular slices continue to be arranged, and the process is circulated in this way till the mould is filled with the mixed cement slurry; a rock sample obtained after the mixed cement slurry is solidified is formed through grinding, maintained and treated at a high temperature till the high molecularslices are heated to be decomposed into gas, the generated pores are real cracks, and then the artificial core used for testing the fracturing performance of the rock containing the controllable cracks is obtained. The rock sample formed by using the method can truly reflect the basic characteristics of the cracks.

Owner:NORTHEAST GASOLINEEUM UNIV

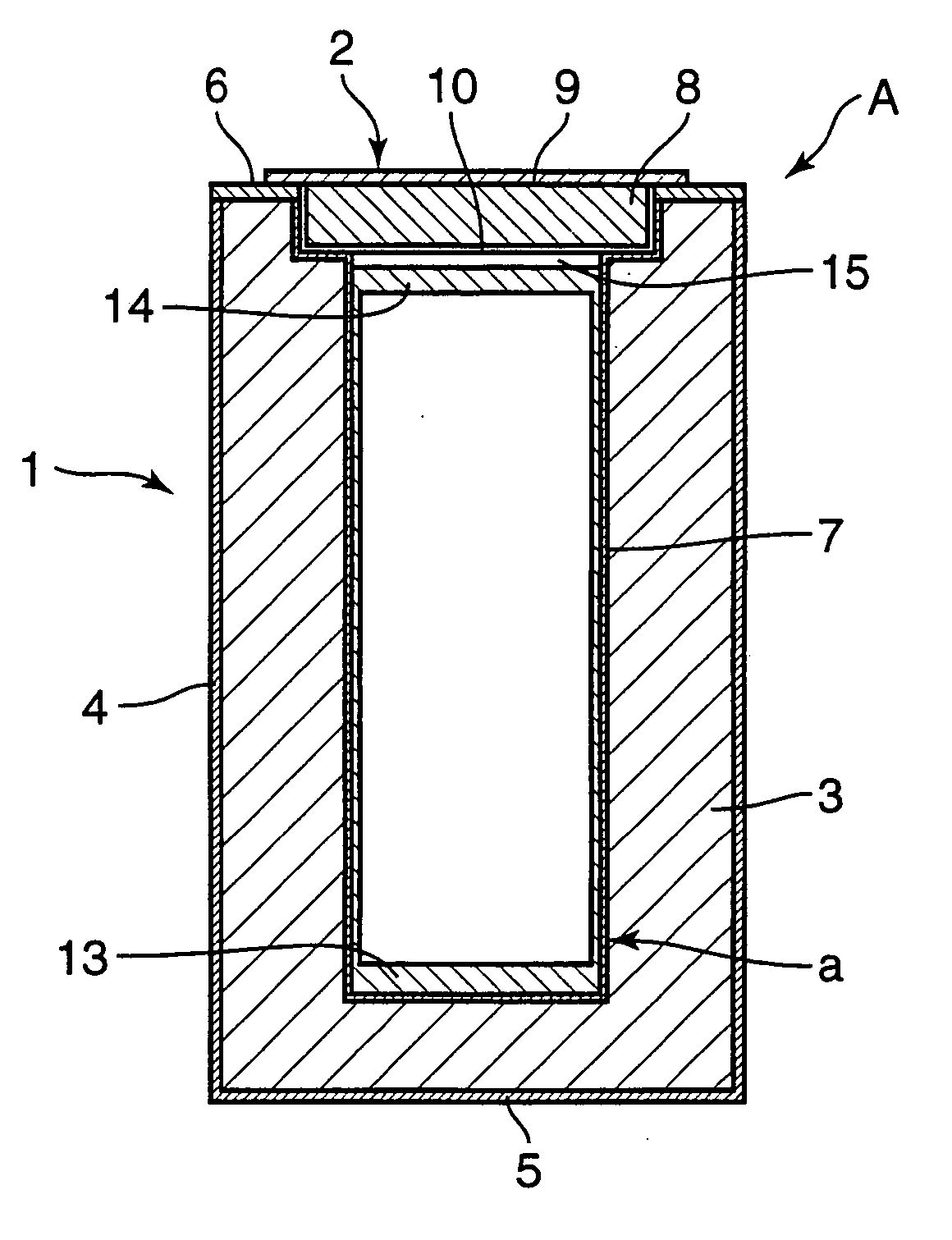

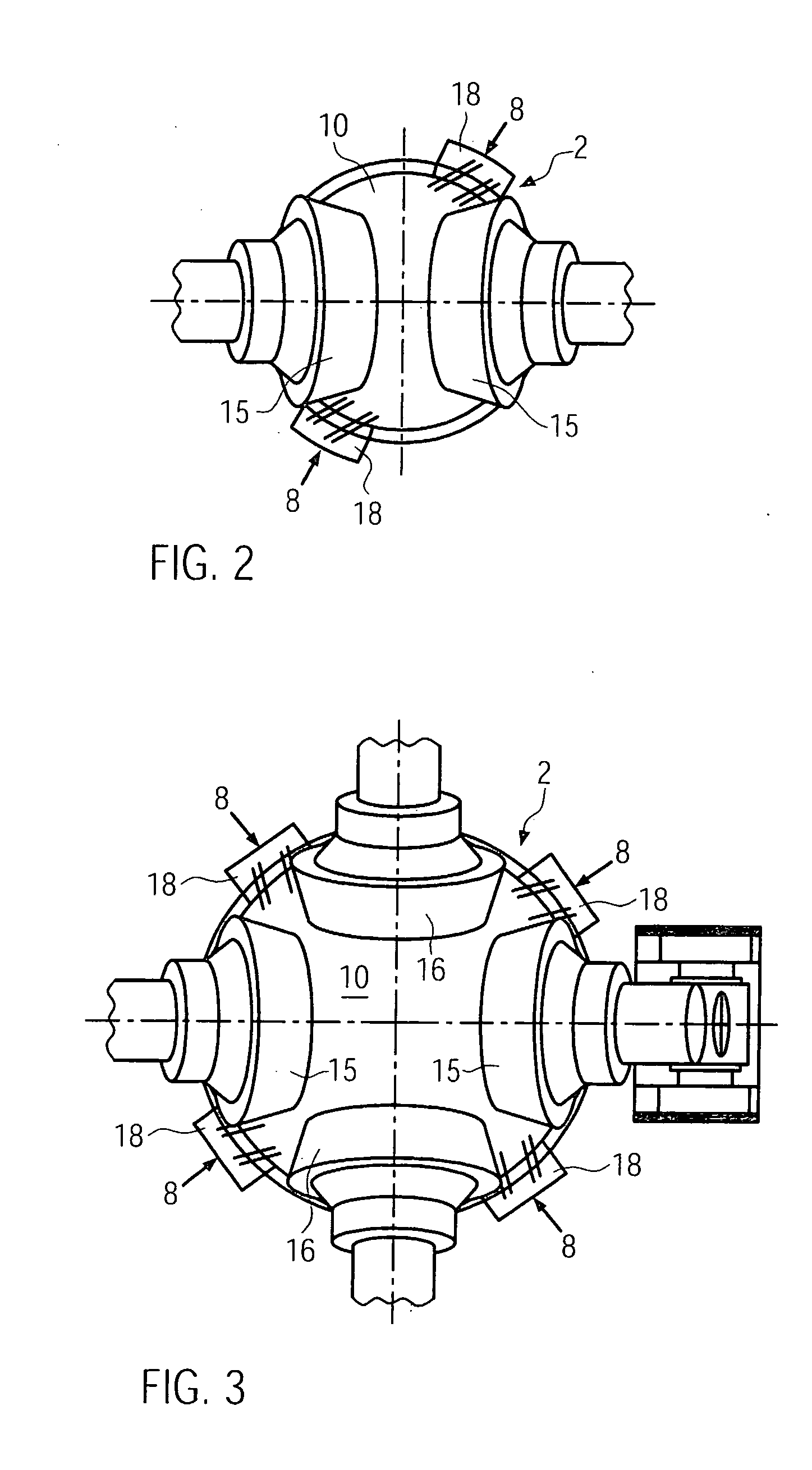

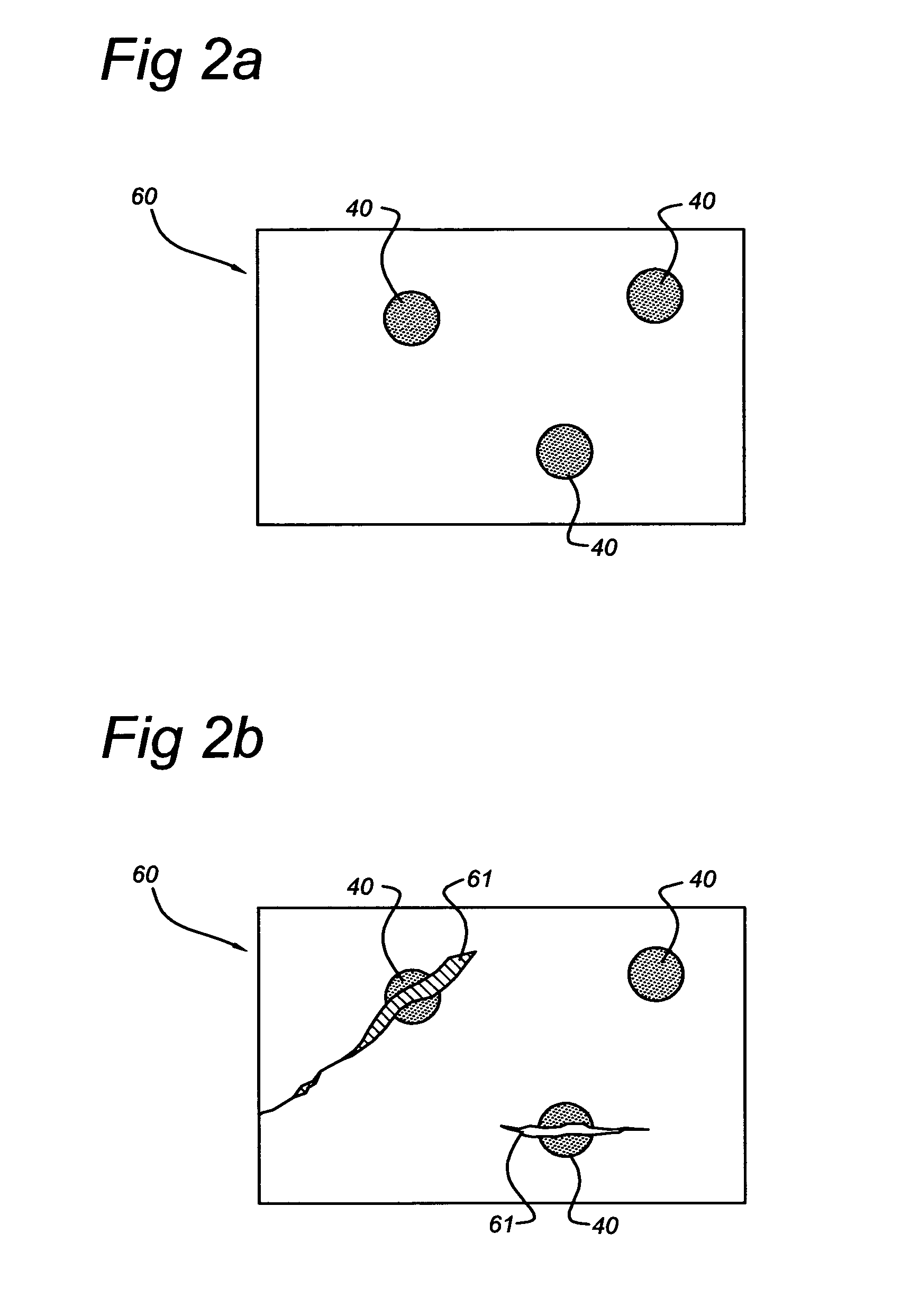

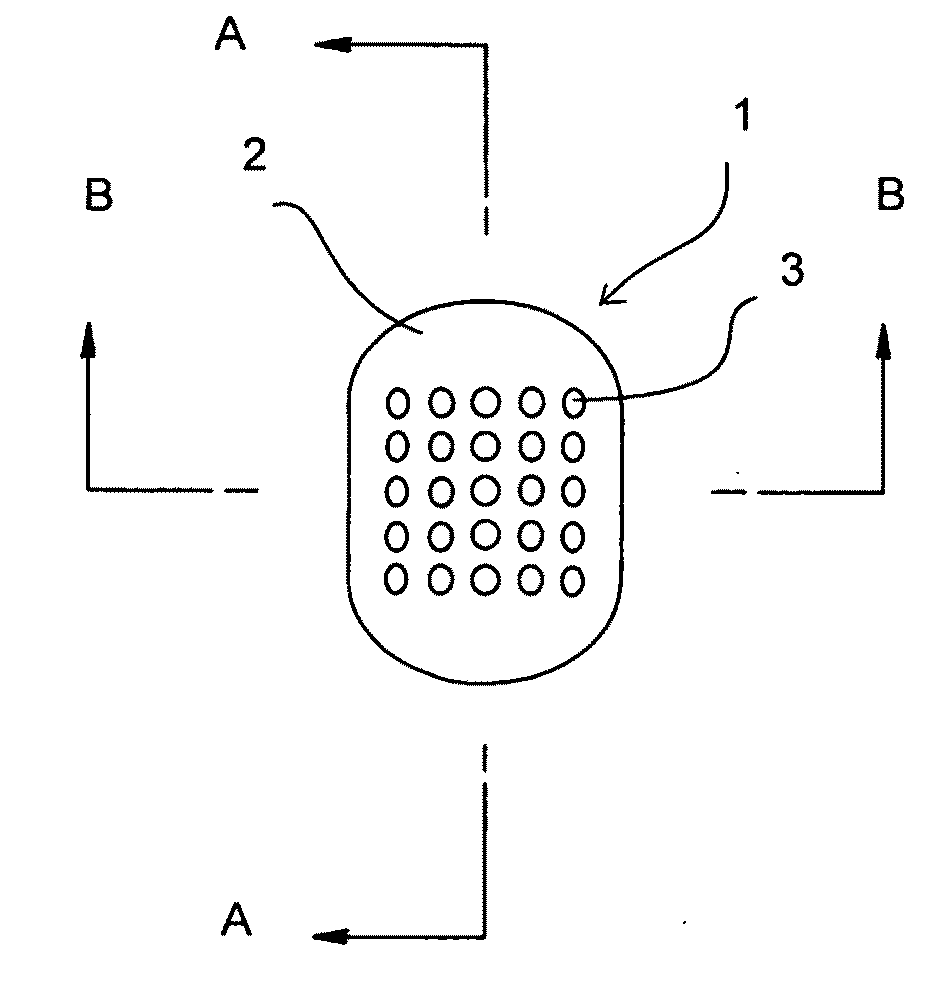

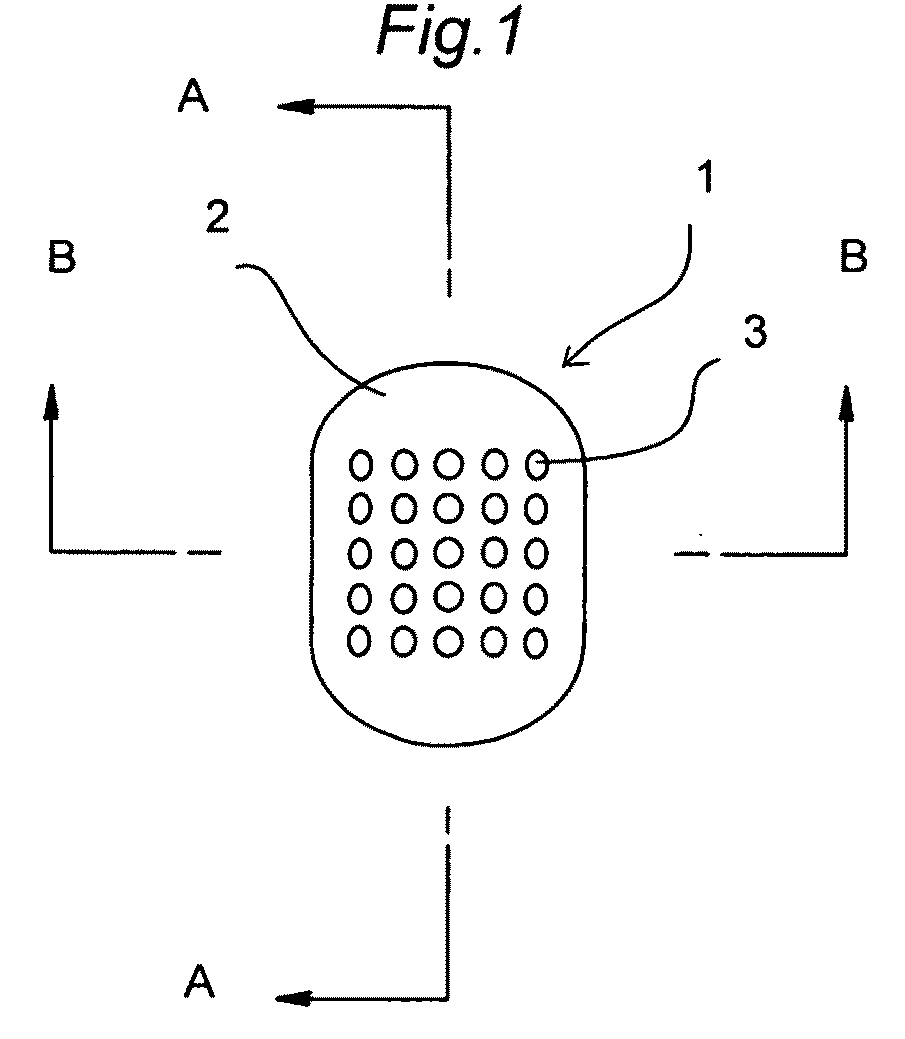

Wireless identification tag

InactiveUS20090289765A1Improve reliabilityImprove directionalityDigital data processing detailsCeramic shaping apparatusMaterials scienceCement

The present invention is aimed at providing a wireless identification tag which can save information with high reliability that is free from the possibility of being lost or falsified, is not broken or melt in the concrete, can expand directionality of an antenna, be distributed in a cement product to be in an appropriate condition for radio communication, and has good adhesion and affinity with cement or the like. A wireless identification tag 1 mixed in a cement product in the manufacturing procedure thereof in which cement, an aggregate, water, or the like are mixed including a protection body 2 incorporating the wireless identification tag 1 having an antenna portion which can write / read information by radio communication, wherein a concave portion 3 is provided on the surface of the protection body.

Owner:MITOMO

Preparation method of environment-friendly phase-changed insulated anti-cracking fast-setting spraying mortar

The invention discloses a preparation method of environment-friendly phase-changed insulated anti-cracking fast-setting spraying mortar. The preparation method comprises the following steps: mixing and stirring common silicate cement and sulfate aluminum cement into mixed cement; modifying expanded perlite by using polystyrene emulsion; adsorbing paraffin into a pore of the expanded perlite by using a reduced pressure adsorption method; coating by using cement; preparing silica-coated polyphenyl particles; preparing silica sol-modified aluminum oxide ceramic powder; uniformly mixing and stirring the prepared remaining blended cement, gypsum, aggregate coated with the blended cement, the silica-coated polyphenyl particles and the ceramic powder, continuously adding sepiolite fibers, polypropylene fibers and a thickening agent, and continuously performing uniform stirring and mixing to obtain the spraying mortar. The spraying mortar is good in thermal insulation, strong in adhesion strength and excellent in mechanical performance.

Owner:SHAOXING YISHENG MORTAR

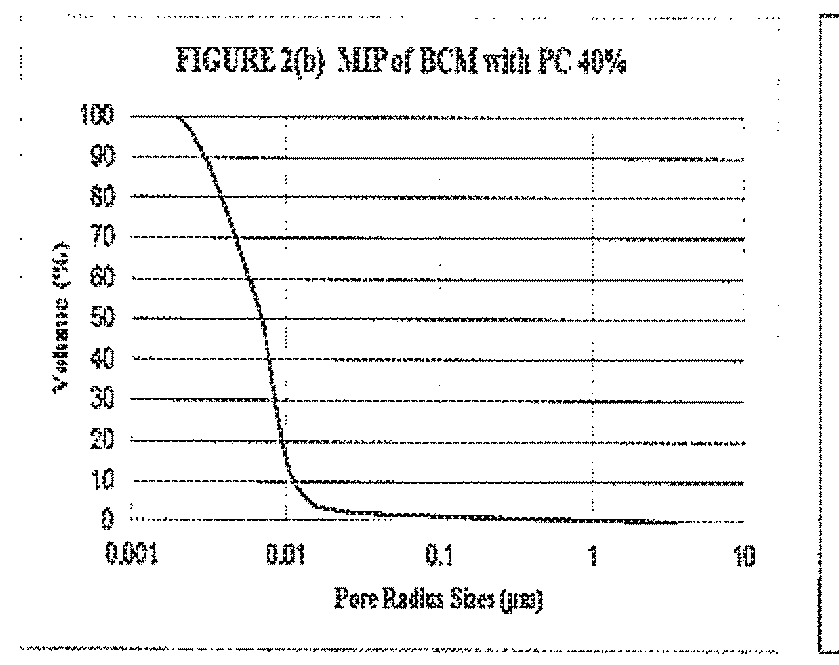

Blended cementitious mixtures

InactiveUS20180179111A1Enhance early-age strengthHigh day compressive strengthSolid waste managementCement productionChemical admixtureCarbonate

A blended cementitious mixture is disclosed, the blended cementitious mixture comprising: a cement included in an amount corresponding to greater than 3% and less than 40% by mass of powders in the cementitious mixture; supplemental cementitious materials included in an amount corresponding to greater than 50% and less than 90% by mass of powders in the cementitious mixture and a carbonate source included in an amount less than or equal to 20% by mass of powders in the cementitious mixture. The cementitious mixture can be mixed with concrete sand, water, chemical admixtures and coarse aggregates and cured to form concrete.

Owner:FANG PING +1

Process for producing blended cements with reduced carbon dioxide emissions

Owner:PROCEDO ENTERPRISES ETAB

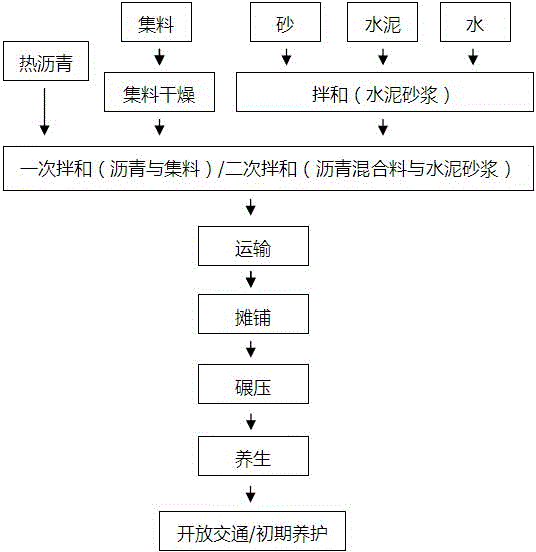

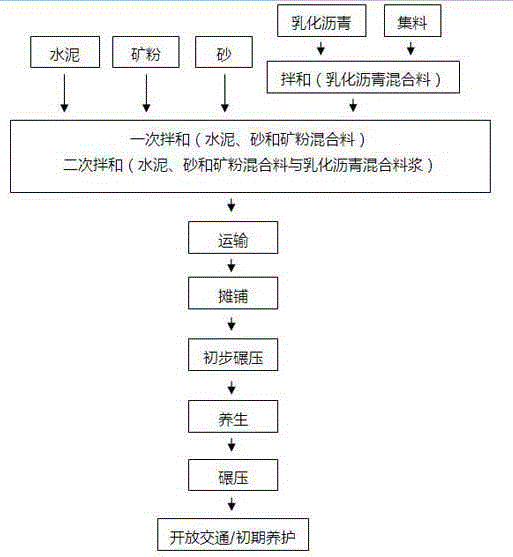

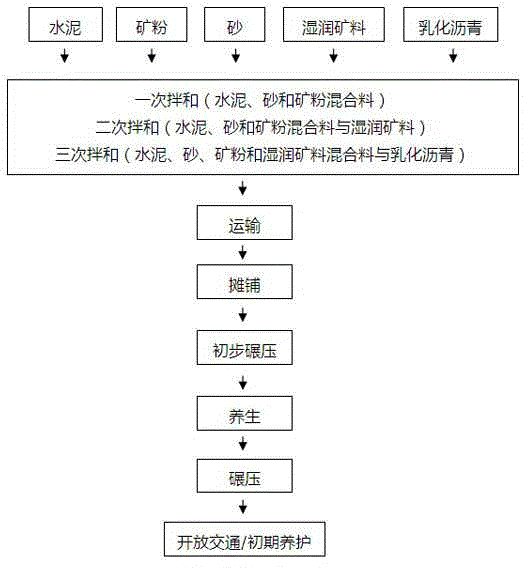

Construction method of cement-emulsified asphalt mortar injecting type semi-flexible pavement

ActiveCN106149500AImproves rutting resistanceSimple construction processIn situ pavingsBitumen emulsionStructural engineering

The invention relates to the technical field of road construction and maintenance, in particular to a construction method of a cement-emulsified asphalt mortar injecting type semi-flexible pavement. The construction method of the semi-flexible pavement comprises the steps that a lower bearing layer is paved with coarse aggregate macadam, well-blended cement-emulsified asphalt mortar is injected into gaps of the coarse aggregate macadam after leveling and pressure stabilizing are conducted, and the semi-flexible pavement is formed through the steps of maintaining, rolling forming and the like. According to the construction method of the cement-emulsified asphalt mortar injecting type semi-flexible pavement, the construction technology is simplified, miniaturization, simplification and minimization of matched construction machinery equipment are achieved, materials used in the method are common, the construction technology is simple and easy to master, application and popularization are convenient, construction can be conducted at room temperature, and wide application is achieved.

Owner:王海有

Cementitious compositions and methods of making cementitious compositions

Cementitious compositions having high compressive strength and high flexibility. An efficient method of making such strong cementitious compositions entails pre-mixing cement additives that can easily be added to a mixture of cement, silica, fibers and water. The cementitious compositions can be used to make strong, thin layers, such as tiles, that are relatively lightweight, as well as heavy structures, such as roads and bridges, without additional reinforcement.

Owner:THE SIERRA CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com