Slow-setting type waterproof mortar having self-repairing function and secondary permeability resistance as well as preparation method thereof

A technology of secondary impermeability and waterproof mortar, applied in the field of building waterproof materials, can solve the problems of lack of self-healing function and secondary impermeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

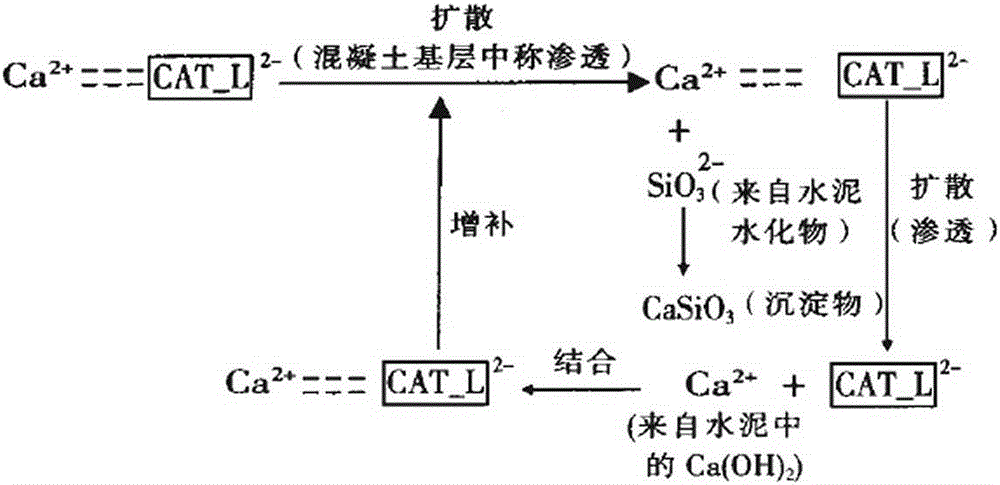

AI Technical Summary

Problems solved by technology

Method used

Image

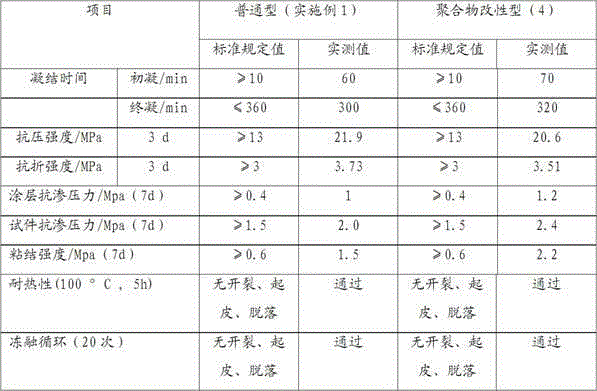

Examples

Embodiment 1

[0033] This example is an ordinary waterproof mortar: 52 kg of mixed cement, 36 kg of quartz sand, 2.2 kg of silica fume, 3 kg of heavy calcium, 5 kg of osmotic crystallization active masterbatch, 0.3 kg of defoamer, 1 kg of naphthalene-based water reducer, Lithium carbonate coagulant 0.4 kg, cellulose ether 0.1 kg. The weight ratio of ordinary Portland cement to quick-setting sulphoaluminate cement in the mixed cement is 8:1.

[0034] Its preparation method is as follows: Weigh all the components according to the formula amount, add them to the planetary mortar mixer and stir slowly for 23 seconds, then add the water required by the formula amount, then stir slowly for 37 seconds, then switch to fast stirring, and stop stirring after 30 seconds A retarded waterproof mortar can be prepared.

Embodiment 2

[0036] This example is ordinary waterproof mortar: 46 kg of mixed cement, 30 kg of quartz sand, 1.5 kg of silica fume, 5 kg of heavy calcium, 9 kg of osmotic crystal active masterbatch, 0.6 kg of defoamer, 1.5 kg of naphthalene-based water reducer, Lithium carbonate coagulant 0.2 kg, cellulose ether 0.05 kg. The weight ratio of ordinary Portland cement to quick-setting sulphoaluminate cement in the mixed cement is 8:1.

[0037] Its preparation method is as follows: Weigh all the components according to the formula amount, add them to the planetary mortar mixer and stir slowly for 23 seconds, then add the water required by the formula amount, then stir slowly for 37 seconds, then switch to fast stirring, and stop stirring after 30 seconds A retarded waterproof mortar can be prepared.

Embodiment 3

[0039] This example is an ordinary waterproof mortar: 48 kg of mixed cement, 32 kg of quartz sand, 1.8 kg of silica fume, 4 kg of heavy calcium, 8 kg of osmotic crystal active masterbatch, 0.5 kg of defoamer, 1.2 kg of naphthalene-based water reducer, Lithium carbonate coagulant 0.3 kilogram, cellulose ether 0.08 kilogram. The weight ratio of ordinary Portland cement to quick-setting sulphoaluminate cement in the mixed cement is 8:1.

[0040] Its preparation method is as follows: Weigh all the components according to the formula amount, add them to the planetary mortar mixer and stir slowly for 23 seconds, then add the water required by the formula amount, then stir slowly for 37 seconds, then switch to fast stirring, and stop stirring after 30 seconds A retarded waterproof mortar can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impermeability pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com